Did basic tuning on new build and still running meh. Help with advanced tuning?

#21

Le Mans Master

Member Since: Aug 2017

Location: Cool Northern Michigan

Posts: 6,904

Received 2,127 Likes

on

1,634 Posts

One more thing then I give up. Take the dizzy cap off. Grab that rotor and turn it CCW then let go of it. Does it snap back or is it sluggish? Try it a few times to verify the springs are truely working and not stuck in either position of the rotor.

#22

Racer

Thread Starter

Yeah, it snaps back with ease

Last edited by Shdggsdv; 02-10-2018 at 09:16 PM.

#23

Pro

What transmission, stall converter (if automatic) and rear end ratio are you using?

Comp recommends a 2200+ stall with this cam (http://www.compcams.com/Company/CC/c...x?csid=87&sb=0). Using a stock converter will mean that it is sluggish up until 1800 RPMs (where Comp claims the power band starts). The stock converter catches around 1200 RPMs or so, so off the line performance will likely suffer as a result. A low-numbered rear is going to exacerbate that problem by not allowing the engine to rev up into its power band quickly.

In my 79 with a 4-speed, I used to have an Edelbrock Performer RPM camshaft. With a square-bore carb (and always cold-air coming into the inatke), the engine would buck and stumble until it finally crested 1500+ RPMs. With a smaller camshaft (Lunati Voodoo 268), that RPM decreased to 1200 RPMs. With a heated intake charge (working ThermAC system) and a Quadrajet, my car will not buck, even down to 800 RPMs in first gear.

The cam should really come alive above 4,000 RPMs, though. If the secondaries on your carb are opening late, you might not be getting all of the airflow that you should be getting at higher RPMs under load. For a short time, I used a Holley Ultra Street Avenger on my 79, and I could tell when the secondaries would open (I didn't use it long enough to get it really dialed in), and it was usually around 3500-4000RPMs.

Comp recommends a 2200+ stall with this cam (http://www.compcams.com/Company/CC/c...x?csid=87&sb=0). Using a stock converter will mean that it is sluggish up until 1800 RPMs (where Comp claims the power band starts). The stock converter catches around 1200 RPMs or so, so off the line performance will likely suffer as a result. A low-numbered rear is going to exacerbate that problem by not allowing the engine to rev up into its power band quickly.

In my 79 with a 4-speed, I used to have an Edelbrock Performer RPM camshaft. With a square-bore carb (and always cold-air coming into the inatke), the engine would buck and stumble until it finally crested 1500+ RPMs. With a smaller camshaft (Lunati Voodoo 268), that RPM decreased to 1200 RPMs. With a heated intake charge (working ThermAC system) and a Quadrajet, my car will not buck, even down to 800 RPMs in first gear.

The cam should really come alive above 4,000 RPMs, though. If the secondaries on your carb are opening late, you might not be getting all of the airflow that you should be getting at higher RPMs under load. For a short time, I used a Holley Ultra Street Avenger on my 79, and I could tell when the secondaries would open (I didn't use it long enough to get it really dialed in), and it was usually around 3500-4000RPMs.

Last edited by dmruschell; 02-11-2018 at 02:07 AM.

#24

Racer

Thread Starter

What transmission, stall converter (if automatic) and rear end ratio are you using?

Comp recommends a 2200+ stall with this cam (http://www.compcams.com/Company/CC/c...x?csid=87&sb=0). Using a stock converter will mean that it is sluggish up until 1800 RPMs (where Comp claims the power band starts). The stock converter catches around 1200 RPMs or so, so off the line performance will likely suffer as a result. A low-numbered rear is going to exacerbate that problem by not allowing the engine to rev up into its power band quickly.

In my 79 with a 4-speed, I used to have an Edelbrock Performer RPM camshaft. With a square-bore carb (and always cold-air coming into the inatke), the engine would buck and stumble until it finally crested 1500+ RPMs. With a smaller camshaft (Lunati Voodoo 268), that RPM decreased to 1200 RPMs. With a heated intake charge (working ThermAC system) and a Quadrajet, my car will not buck, even down to 800 RPMs in first gear.

The cam should really come alive above 4,000 RPMs, though. If the secondaries on your carb are opening late, you might not be getting all of the airflow that you should be getting at higher RPMs under load. For a short time, I used a Holley Ultra Street Avenger on my 79, and I could tell when the secondaries would open (I didn't use it long enough to get it really dialed in), and it was usually around 3500-4000RPMs.

Comp recommends a 2200+ stall with this cam (http://www.compcams.com/Company/CC/c...x?csid=87&sb=0). Using a stock converter will mean that it is sluggish up until 1800 RPMs (where Comp claims the power band starts). The stock converter catches around 1200 RPMs or so, so off the line performance will likely suffer as a result. A low-numbered rear is going to exacerbate that problem by not allowing the engine to rev up into its power band quickly.

In my 79 with a 4-speed, I used to have an Edelbrock Performer RPM camshaft. With a square-bore carb (and always cold-air coming into the inatke), the engine would buck and stumble until it finally crested 1500+ RPMs. With a smaller camshaft (Lunati Voodoo 268), that RPM decreased to 1200 RPMs. With a heated intake charge (working ThermAC system) and a Quadrajet, my car will not buck, even down to 800 RPMs in first gear.

The cam should really come alive above 4,000 RPMs, though. If the secondaries on your carb are opening late, you might not be getting all of the airflow that you should be getting at higher RPMs under load. For a short time, I used a Holley Ultra Street Avenger on my 79, and I could tell when the secondaries would open (I didn't use it long enough to get it really dialed in), and it was usually around 3500-4000RPMs.

I can definitely tell when the secondaries open, but still has little power. It revs up really high and just moves accelerates slow like the stock engine. How do you tell if they're not allowing enough air flow at high RPMs?

#25

Pro

So my stall converter is stock and too low. I was planning to take it to a trans shop sometime next week to have that fixed, but even above that it's struggling like crazy. I believe my rear is 3:55 so shouldn't be giving me much issue

I can definitely tell when the secondaries open, but still has little power. It revs up really high and just moves accelerates slow like the stock engine. How do you tell if they're not allowing enough air flow at high RPMs?

I can definitely tell when the secondaries open, but still has little power. It revs up really high and just moves accelerates slow like the stock engine. How do you tell if they're not allowing enough air flow at high RPMs?

#26

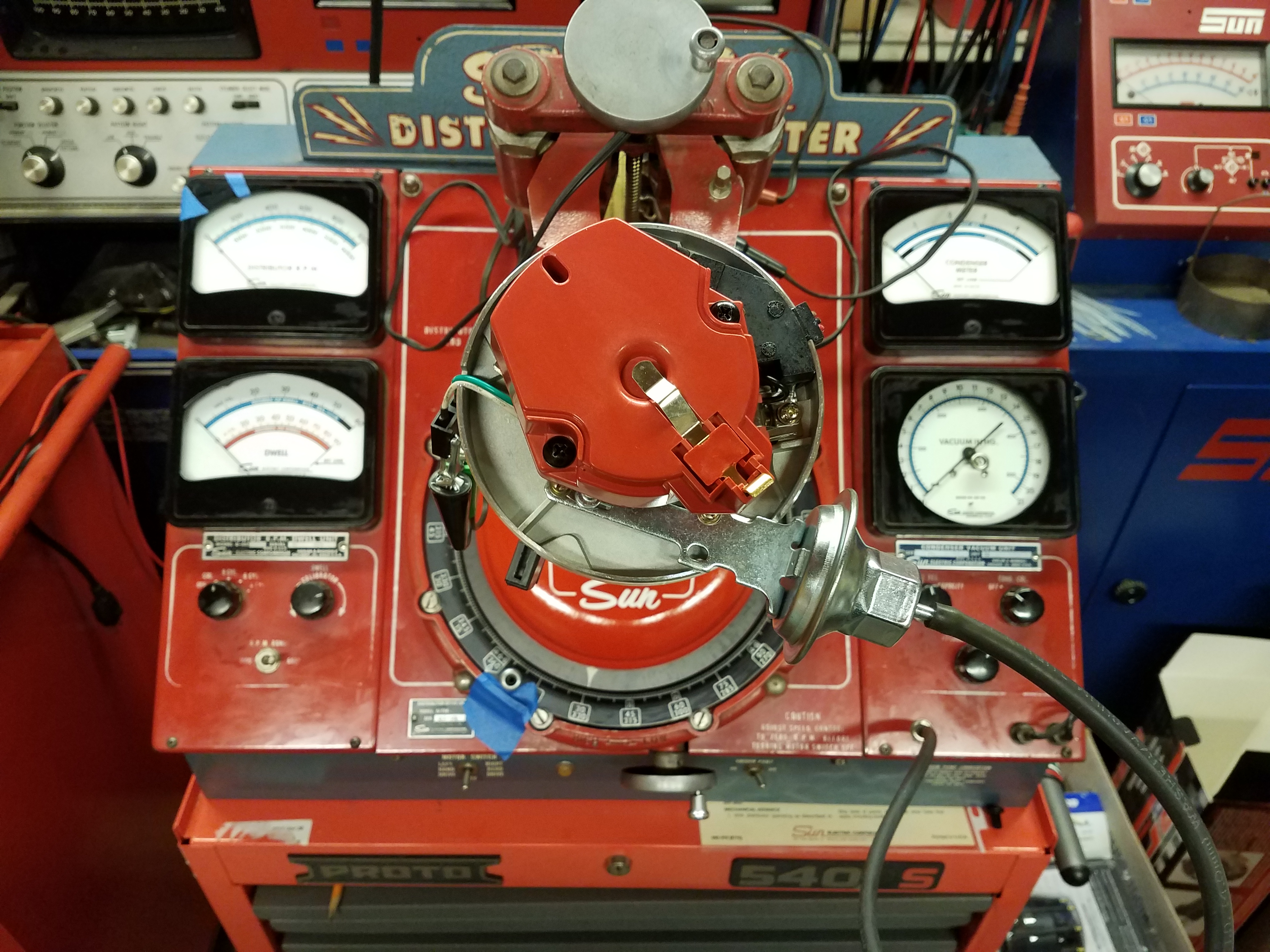

I have a brand new 8362 here. I just took it out of the box, chucked it up in my Sun506, and tested it.

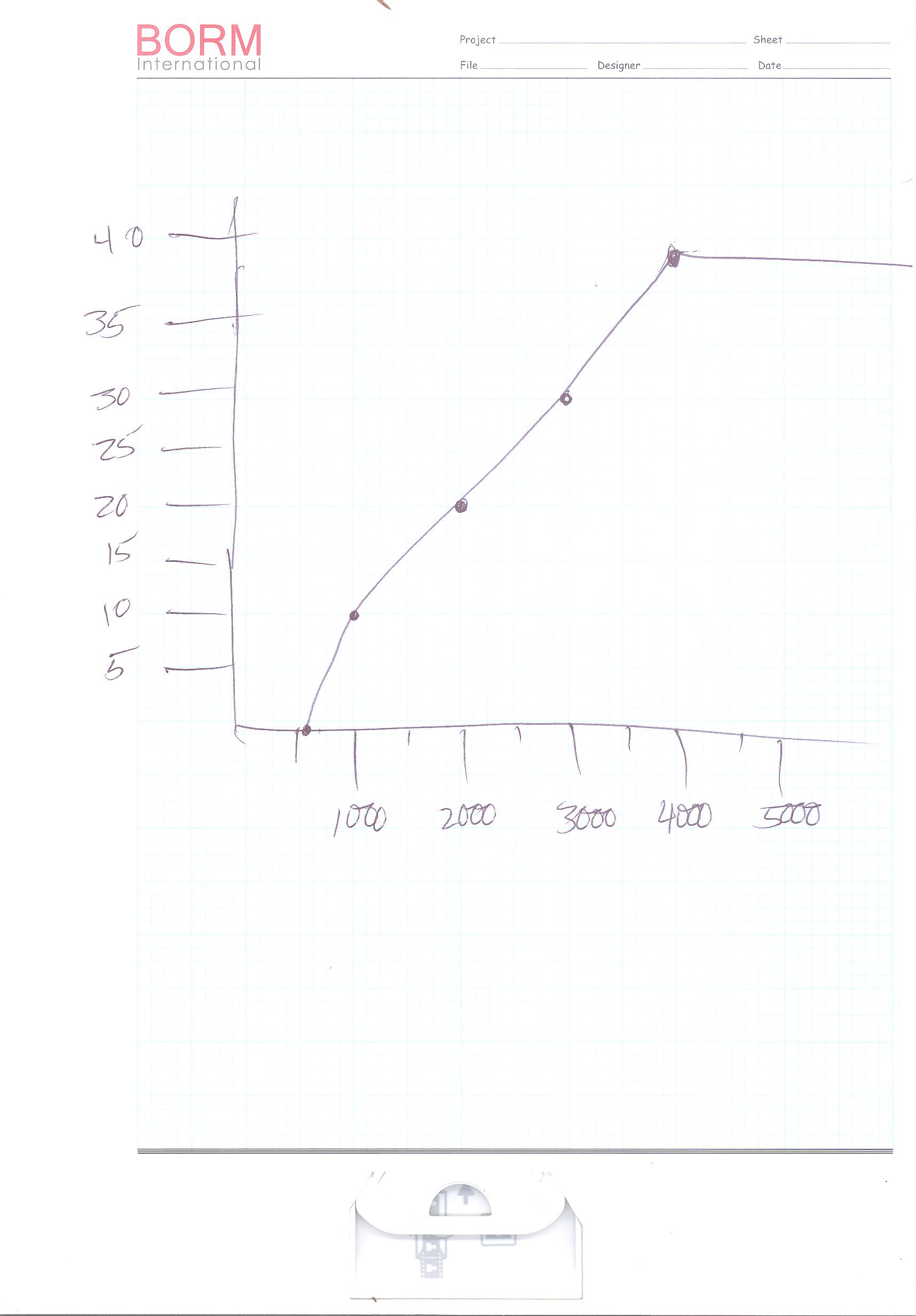

It is the worst POS curve I have ever seen:

Excuse the rough graph, but its stupid and worthless. I didn't bother with vacuum yet. Yes. 40* advance at 4K RPM. No, not 20*, 40*

#27

Racer

Thread Starter

So I ended up trying something different for my curve. I swapped out my springs for some ones in an old HEI of mine. They felt light and figured why not. I'm getting something like 16 degrees of advance at about 2800 RPM. Then I did the Lars method where I set my dialback light to 34 degrees, set my idle to 3k, and just turned the distributor till the mark went to 0 (Setting my all-in at 34)

But, my timing mark seems to wobble around about a degree. I hadn't noticed it before. Could there be some issue with the distributor?

But, my timing mark seems to wobble around about a degree. I hadn't noticed it before. Could there be some issue with the distributor?

#28

So I ended up trying something different for my curve. I swapped out my springs for some ones in an old HEI of mine. They felt light and figured why not. I'm getting something like 16 degrees of advance at about 2800 RPM. Then I did the Lars method where I set my dialback light to 34 degrees, set my idle to 3k, and just turned the distributor till the mark went to 0 (Setting my all-in at 34)

But, my timing mark seems to wobble around about a degree. I hadn't noticed it before. Could there be some issue with the distributor?

But, my timing mark seems to wobble around about a degree. I hadn't noticed it before. Could there be some issue with the distributor?

The EXACT same unit here has 20* of distributor degree advance. That's 40* of engine advance. With 9* distributor degrees of vacuum advance, that's a total range of 58* from idle to full advance.(Dizzys turn 1/2 speed of the crank). Even if you set idle to 0*, the total advance would make the engine go nutz.

Setting it at 16* at idle would give you 56* total without vacuum advance.

It's NOT the carb. It's the dizzy.

#29

When I have time today, I'll take it apart and figure out the cure. I have to check the slot. A bushing would have to center in the range, but if the slot is wrong, the rotor phasing would be off as well.

The advance chart with the dizzy is close, but in DISTRIBUTOR degrees.

The advance chart with the dizzy is close, but in DISTRIBUTOR degrees.

#30

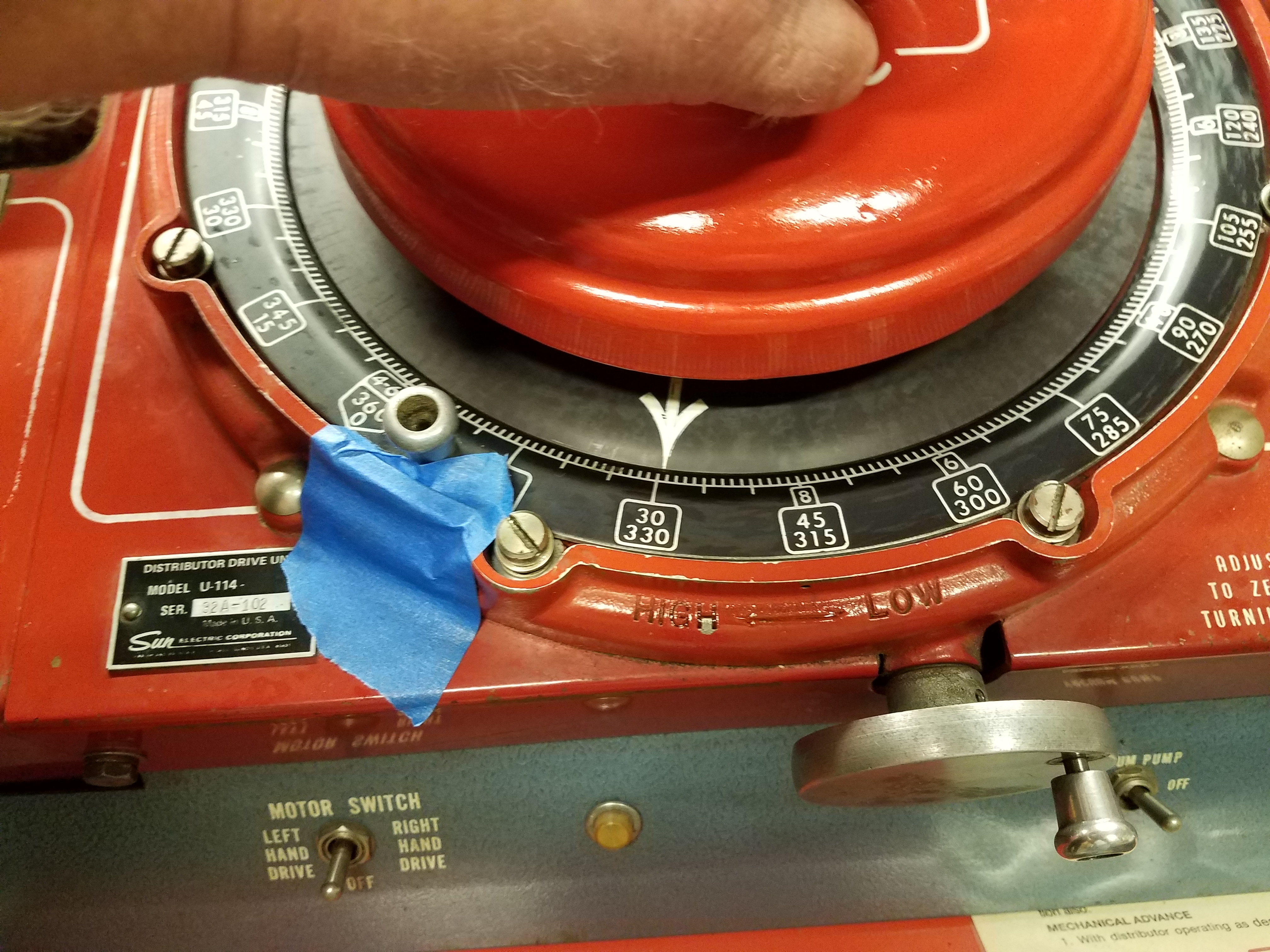

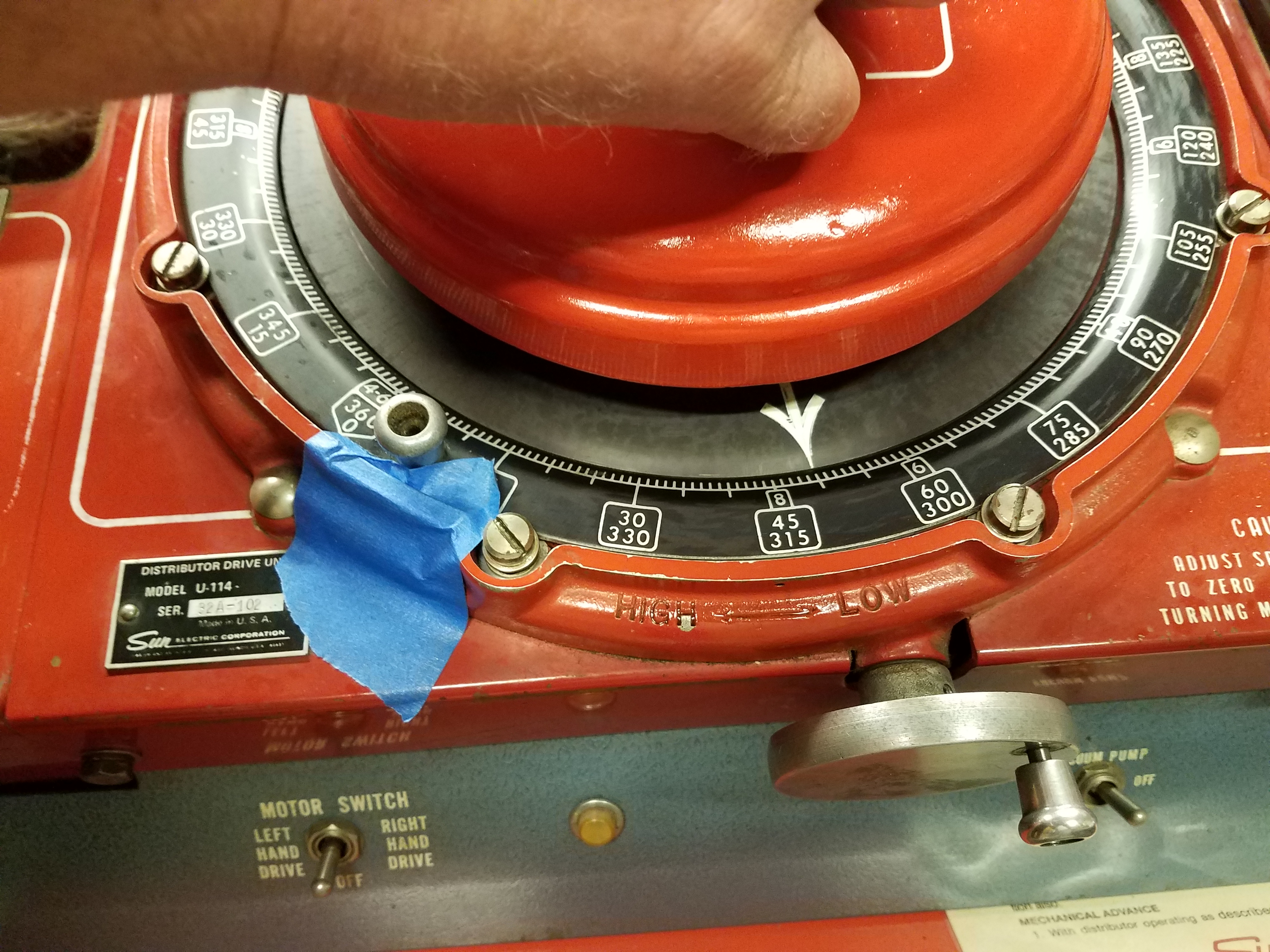

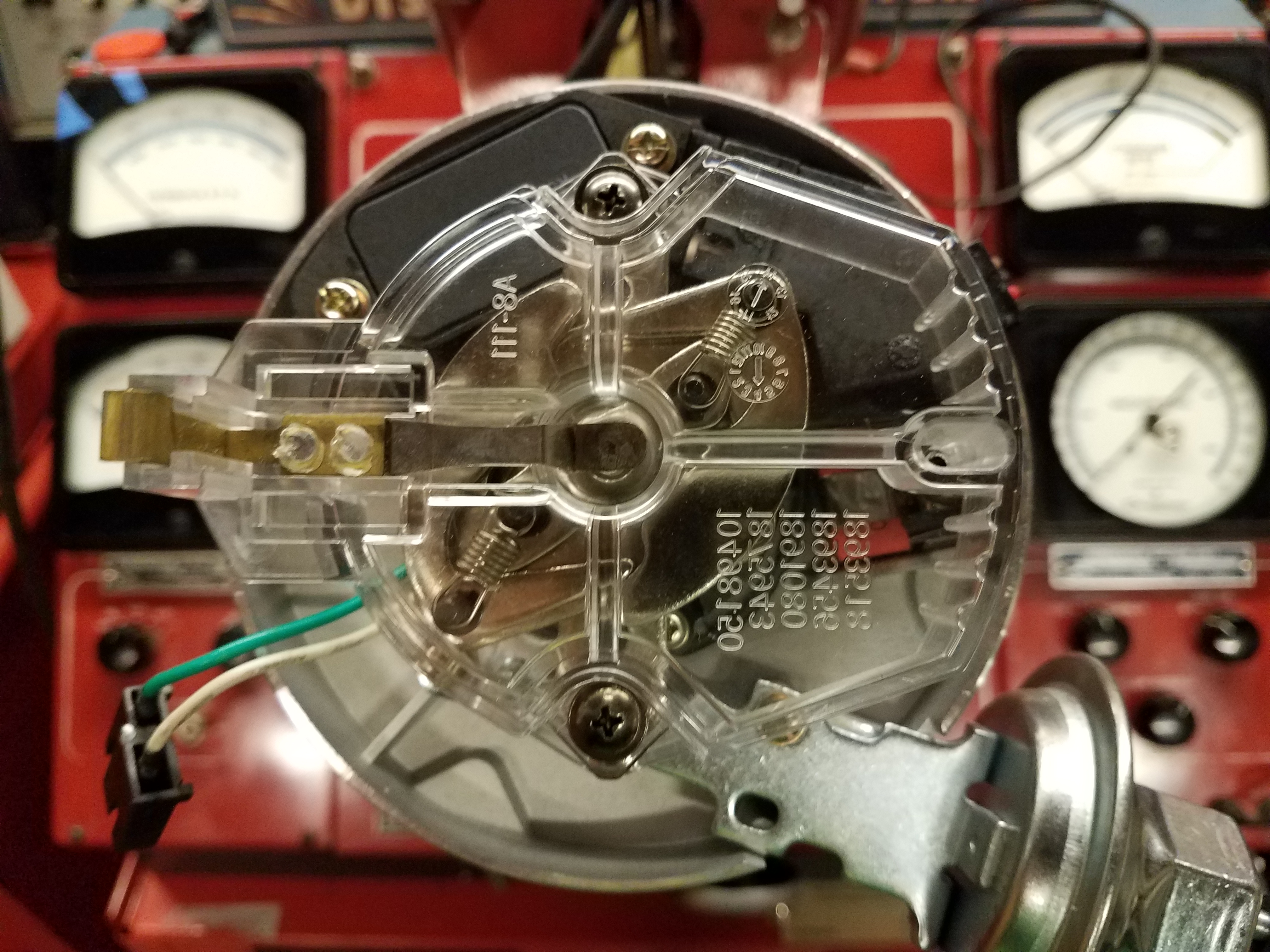

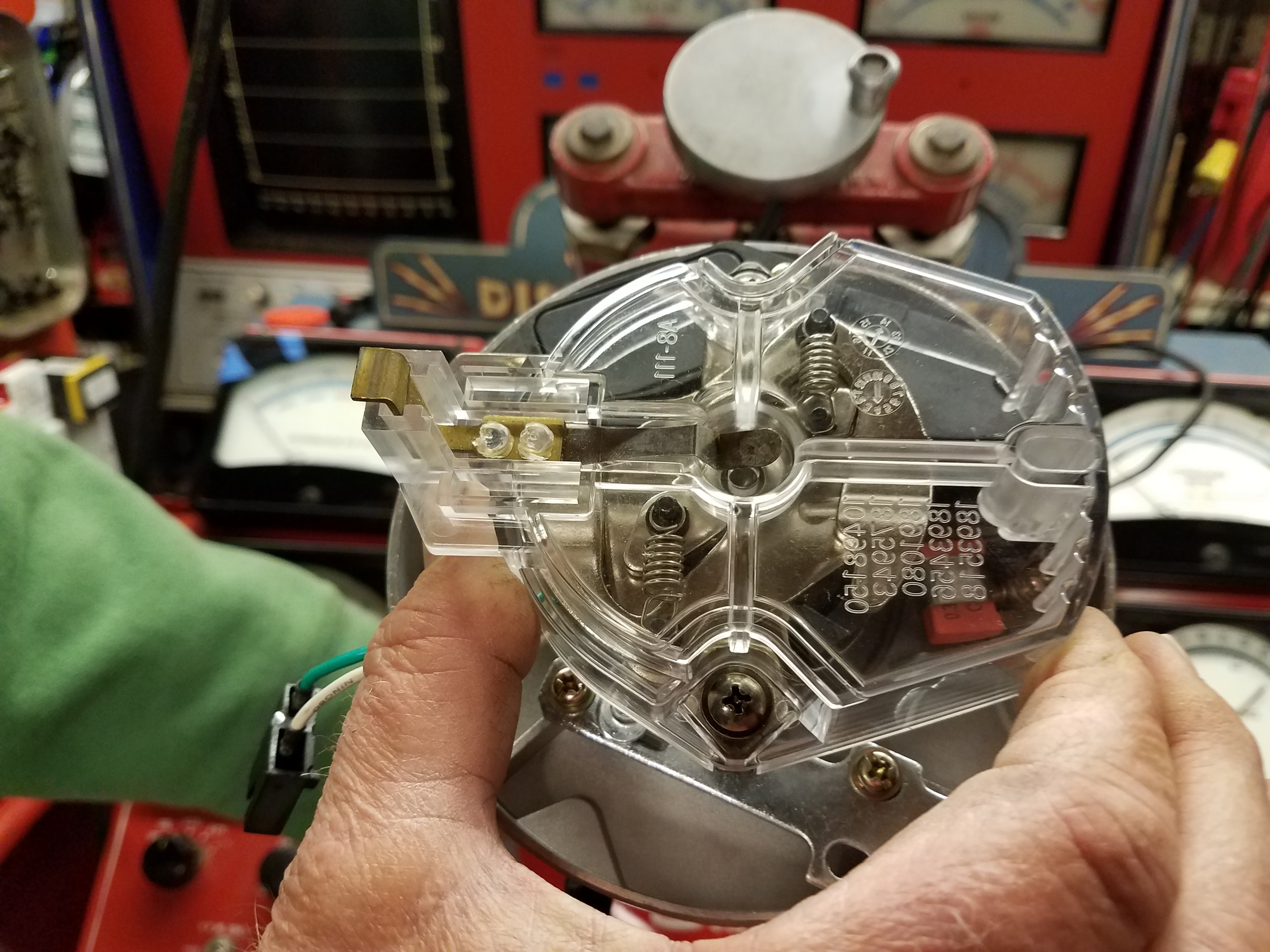

To verify , I locked the rotor with my hand.

One picture shows at rest, the next is the total mechanical advance range.

20* distributor degrees. That is TWICE what you need.

#32

I can't tune like Lars. He has more toys, but I think he would agree, Dyno testing of carbs and dizzys is important. They proof guns, right?

#34

Drifting

I am just throwing this out there because I am in the process of building my motor and learning a lot of things I never gave thought to. One is degree-ing the cam. The OP stated he installed a cam. Through all my conversations and readings, it is clear that a cam MUST be degree'd or you will chase your tail. Just a thought. I saw no mention of this.

#35

So I checked rotor phasing. The start is at ignition point at zero advance to start. Top to bottom. Zero, 10*, 20*.

Clearly the rotor and cap can handle 10* distributor degrees max advance.

At 20* (40*engine), it's gonna misfire all over the place.

#36

So , two more quick pictures. First is the advance at rest. The second is full advance.

The internal dimensions of the rotor is the only stop on this dizzy. In the second picture, the weights are up against the inside of the rotor, and the "stop" pin is still not engaged.

Today I'll pull it apart, and find the cure.

#37

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,363

Received 771 Likes

on

553 Posts

I need you to post the "specs" you used, exactly, and I will test it here.

I have a brand new 8362 here. I just took it out of the box, chucked it up in my Sun506, and tested it.

It is the worst POS curve I have ever seen:Attachment 48253904

Excuse the rough graph, but its stupid and worthless. I didn't bother with vacuum yet. Yes. 40* advance at 4K RPM. No, not 20*, 40*

I have a brand new 8362 here. I just took it out of the box, chucked it up in my Sun506, and tested it.

It is the worst POS curve I have ever seen:Attachment 48253904

Excuse the rough graph, but its stupid and worthless. I didn't bother with vacuum yet. Yes. 40* advance at 4K RPM. No, not 20*, 40*

#38

What printer Mike? Or do you mean the same results?

I jambed in the largest bushing I had and clearanced the slots. Still way too much. Going to weld a slot shut and drill my own hole.

I jambed in the largest bushing I had and clearanced the slots. Still way too much. Going to weld a slot shut and drill my own hole.

Last edited by Big2Bird; 02-13-2018 at 07:04 PM.

#40