LT4 Head insert question

#1

Race Director

Thread Starter

For those of you that have removed the rocker arm studs from a LT4 head, I have a question. The studs screw into the head which has inserts threaded into the head. Looking into the hole with the inserts, the insert has a part that goes across the bottom of the hole. I looked at inserts at work and saw that the piece that goes across the bottom of the hole is used to screw the insert into place. These inserts have a small notch which appears to be there so you can break off this piece that goes across the insert for removal. This is hard to explain verbally so bear with me. The studs I bought from ARP bottom out before the shoulder of the stud rests on the head. Comparing the ARP stud and the OEM stud the OEM stud's threaded length is a little shorter and therefore, doesn't bottom out before the shoulder makes contact with the head. My question, is it common practice to remove that piece that goes across the bottom of the insert to make room for the ARP studs? Does the OEM insert have that notch?

You might ask why use the ARP studs? They are beefier and will allow for adjusting the rocker arms as I'm installing a GM Hot cam kit. As you know the OEM LT4 rocker arms are not adjustable.

Thanks for any insight to this topic.

You might ask why use the ARP studs? They are beefier and will allow for adjusting the rocker arms as I'm installing a GM Hot cam kit. As you know the OEM LT4 rocker arms are not adjustable.

Thanks for any insight to this topic.

#2

Drifting

Yes, you're supposed to remove that piece from the HeliCoil after installing it. . As you said, it's already scored. Just break it off and you'll be fine.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

Last edited by 1963SS; 10-01-2011 at 09:29 AM.

#3

Burning Brakes

Member Since: Nov 2006

Location: Portsmouth Virginia 396LT4 435RWHP/400RWTQ Best so far 11.26 @ 123mph

Posts: 1,102

Likes: 0

Received 1 Like

on

1 Post

A standard helicoil insert is normally designed to have the bottom tab removed after install. You should see a crimped area on the tab out near the helicoil I.D. which makes breaking off the tab easier after install.

Leaving the tab on in some cases can be nice if it's a thru hole and the tab doesn't block the stud thread engagement because you can still screw it out the bottom if it needs to be replaced for some reason in the future. With the LT4 heads having a blind hole though,the factory probably just left them alone since they're contained and the factory studs don't touch them. I would guess it's a manufacturing cost savings during the factory build to just leave them in place without removal.

Rick

Leaving the tab on in some cases can be nice if it's a thru hole and the tab doesn't block the stud thread engagement because you can still screw it out the bottom if it needs to be replaced for some reason in the future. With the LT4 heads having a blind hole though,the factory probably just left them alone since they're contained and the factory studs don't touch them. I would guess it's a manufacturing cost savings during the factory build to just leave them in place without removal.

Rick

#4

Race Director

Thread Starter

Yes, you're supposed to remove that piece from the HeliCoil after installing it. . As you said, it's already scored. Just break it off and you'll be fine.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

#5

Race Director

Thread Starter

A standard helicoil insert is normally designed to have the bottom tab removed after install. You should see a crimped area on the tab out near the helicoil I.D. which makes breaking off the tab easier after install.

Leaving the tab on in some cases can be nice if it's a thru hole and the tab doesn't block the stud thread engagement because you can still screw it out the bottom if it needs to be replaced for some reason in the future. With the LT4 heads having a blind hole though,the factory probably just left them alone since they're contained and the factory studs don't touch them. I would guess it's a manufacturing cost savings during the factory build to just leave them in place without removal.

Rick

Leaving the tab on in some cases can be nice if it's a thru hole and the tab doesn't block the stud thread engagement because you can still screw it out the bottom if it needs to be replaced for some reason in the future. With the LT4 heads having a blind hole though,the factory probably just left them alone since they're contained and the factory studs don't touch them. I would guess it's a manufacturing cost savings during the factory build to just leave them in place without removal.

Rick

Last edited by Strick; 10-01-2011 at 12:45 PM.

#6

Yes, you're supposed to remove that piece from the HeliCoil after installing it. . As you said, it's already scored. Just break it off and you'll be fine.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

When you're done it should look like this. Lt4 heads....check!, Helicoil for rocker......check!, 550# valve springs with Titanium retainer.......Uh, optional.

Titanium, Ti.

Just so pretty.

Light, very strong & extremely fucntional from 7,000 to 9,000 RPM's.

Super Late Model Cars can get 5 to 7 car lengths ahead on the back stretch of a hard dirt track clay 1/4 mile Oval with Ti connecting rods & Ti cascadium coated wrist pins.

Easy for me to spot who has & uses them.

SBC stroker engines wind out like a FAR series Snap On 3/8" air ratchet on 200 psi line pressure.

9K + RPM's instant.

LF wheel off the ground 2 feet high around the entire racetrack when on the gas too.

Look like CC Ti retainers or Trick Titanium on there from your pics.

Unique dish machined into them.

Brian

Last edited by 87 vette 81 big girl; 10-01-2011 at 12:57 PM.

#8

Drifting

Unique dish machined into them.

I had just got done checking those springs. Installed height was 1.985 (155#'s) and at .600 was 475#'s and at .700 was 550#'s. That should hold it down.

You are an RPM junkie aren't you??

Have you ever seen this RPM/throttle response video?

http://youtu.be/wbyJ7nsUJYM

#9

Hi Brian, yeah, sometimes a man's gotta do what a man's gotta do. Sometimes (depending on the rocker) when you go for higher lifts the tip of the rocker casting will hit the retainer instead of the roller hitting the valve. I also am running lash caps on this engine.

I had just got done checking those springs. Installed height was 1.985 (155#'s) and at .600 was 475#'s and at .700 was 550#'s. That should hold it down.

You are an RPM junkie aren't you??

Have you ever seen this RPM/throttle response video?

http://youtu.be/wbyJ7nsUJYM

I had just got done checking those springs. Installed height was 1.985 (155#'s) and at .600 was 475#'s and at .700 was 550#'s. That should hold it down.

You are an RPM junkie aren't you??

Have you ever seen this RPM/throttle response video?

http://youtu.be/wbyJ7nsUJYM

I watched your link, the Renault Indy Engine does wind up very fast.

Just missing the SBC or BBC exhaust roar.

The next video up was a Ferrari V12 in a Formula 1 car.

Much Kooler.

LOL

I want a Ferrari V12.

Just to have 1.

Mount it on a test stand & fire it up once in a while when I get bored.

And scare the neighbors at 3am.

My late bud Bill worked on Ferrari V12 engines sometimes back in the 1960's & 1970's.

The wealthy found him & needed the best mechanic around.

He told me they use NO Valve springs.

Unique Fork mechanism to open & close valves.

Miss racing each other at 3-4 AM on certain spots of IL roads.

Good old days.

Crazy too.

Brian

#11

Drifting

Man, I'm sorry Brian and I hijacked your thread. But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

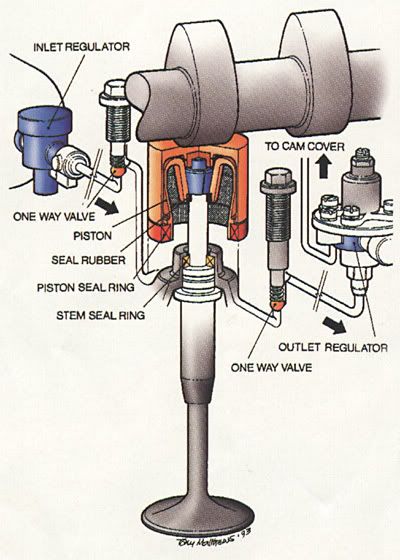

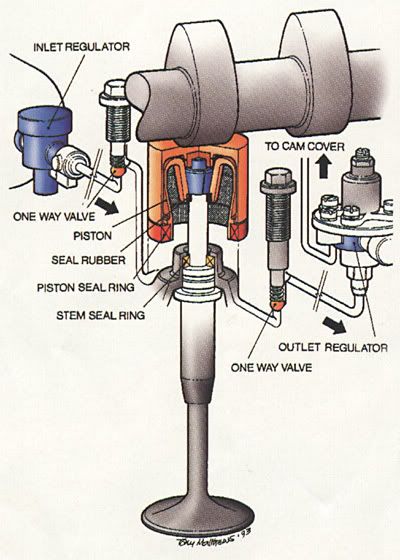

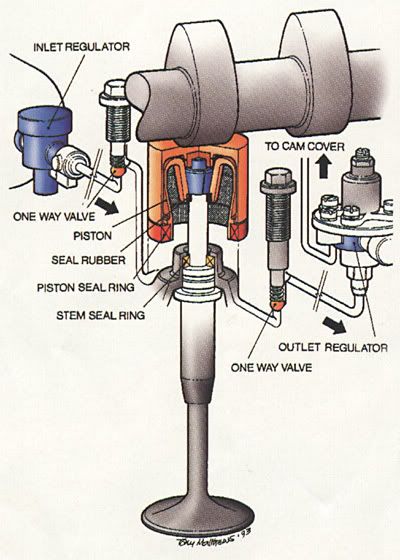

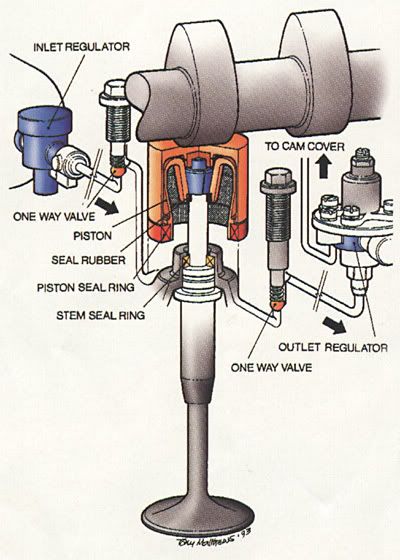

Well, not the electric that they wanted. They've been using air operated valves for some time now. Kinda like this.

I just love the technology that's going on in F1. Here's a vid of a V8 turning 18000 RPM's. The max allowed. They are making close to a thousand horsepower from those little 2.4 liter 200 pound engines with no power adders like turbo's or anything. Just sucking in air. Also, the engine is a stressed member of the suspension. The suspension bolts to those little 200 pound things. The engine blocks are even forged.

http://youtu.be/Eo-9Io41bt8

One of our 350 cu in engines would have to make 2375 horsepower to be as efficient as a F1 engine......no NOX or blowers allowed. Just sucking air. Those little pistons are flying up and down 300 times every second and the valves are doing their thing 150 times a second. Now that's just plain nuts. And each engine has to last 2 races.

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

Speaking of F1, did they ever figure out how to use solenoid operating valves? The main problem seemed to be heat removal.

I just love the technology that's going on in F1. Here's a vid of a V8 turning 18000 RPM's. The max allowed. They are making close to a thousand horsepower from those little 2.4 liter 200 pound engines with no power adders like turbo's or anything. Just sucking in air. Also, the engine is a stressed member of the suspension. The suspension bolts to those little 200 pound things. The engine blocks are even forged.

http://youtu.be/Eo-9Io41bt8

One of our 350 cu in engines would have to make 2375 horsepower to be as efficient as a F1 engine......no NOX or blowers allowed. Just sucking air. Those little pistons are flying up and down 300 times every second and the valves are doing their thing 150 times a second. Now that's just plain nuts. And each engine has to last 2 races.

#12

Race Director

Thread Starter

All is good. Problem solved. And I think F1 is the last of real racing. The drags shortened the distance because they went too fast, NASCAR keeps slowing them down because someone might get hurt, and Indy, too has too many restrictions. You want to see excitment? F1 or go to I95 during rush hour.

#13

Man, I'm sorry Brian and I hijacked your thread. But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

Well, not the electric that they wanted. They've been using air operated valves for some time now. Kinda like this.

I just love the technology that's going on in F1. Here's a vid of a V8 turning 18000 RPM's. The max allowed. They are making close to a thousand horsepower from those little 2.4 liter 200 pound engines with no power adders like turbo's or anything. Just sucking in air. Also, the engine is a stressed member of the suspension. The suspension bolts to those little 200 pound things. The engine blocks are even forged.

http://youtu.be/Eo-9Io41bt8

One of our 350 cu in engines would have to make 2375 horsepower to be as efficient as a F1 engine......no NOX or blowers allowed. Just sucking air. Those little pistons are flying up and down 300 times every second and the valves are doing their thing 150 times a second. Now that's just plain nuts. And each engine has to last 2 races.

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?

But since you are the original poster and asked a question here ya' go. Thanks for not getting mad. We did come through and answer your question....right?Well, not the electric that they wanted. They've been using air operated valves for some time now. Kinda like this.

I just love the technology that's going on in F1. Here's a vid of a V8 turning 18000 RPM's. The max allowed. They are making close to a thousand horsepower from those little 2.4 liter 200 pound engines with no power adders like turbo's or anything. Just sucking in air. Also, the engine is a stressed member of the suspension. The suspension bolts to those little 200 pound things. The engine blocks are even forged.

http://youtu.be/Eo-9Io41bt8

One of our 350 cu in engines would have to make 2375 horsepower to be as efficient as a F1 engine......no NOX or blowers allowed. Just sucking air. Those little pistons are flying up and down 300 times every second and the valves are doing their thing 150 times a second. Now that's just plain nuts. And each engine has to last 2 races.

Very Cool Video.

Such Pretty Blue Methanol Alcohol Exhaust flames present when throttle is gunned hard WOT.

I noted the Coffin style Airbox.

8 short stacked Tuned IR induction system hidden down below.

Very Cool.

Brian

#14

Safety Car

I keep hearing GM wanting to go that way with the Corvette motor..Small Cu and big RPM.One of my cars is an AUDI small motor big turbo and lots RPM and will haul butt. Low end not much.. Get the little thing going and it will pull you back in the seat.. It's funny you can go 2 1/2 times the speed limit and then open the hood and this little bity motor looking at you . I think it's comeing.. My LT-4 @7,000rpm cool also...Thanks for knowing stuff...

#15

Drifting

Such Pretty Blue Methanol Alcohol Exhaust flames present when throttle is gunned hard WOT.

I keep hearing GM wanting to go that way with the Corvette motor

#16

Race Director

Thread Starter

I'd love to see Corvette go this route. It has to be out there on the leading edge. Push rods are old school, but they do sound cool. And low end torque is where most of us play. But let's be serious here, where could you drive at 10 to 15000 rpm?

#17

Drifting

Well, with an 8.56 rear you could drive about anywhere. 70 MPH would probably be around 6000 RPM's but boy it would sound cool......If you think the sound of an angry honey bee is cool.

Well, with an 8.56 rear you could drive about anywhere. 70 MPH would probably be around 6000 RPM's but boy it would sound cool......If you think the sound of an angry honey bee is cool. With only 200 ft/lbs of torque you'd have to rev it to the moon just to get off the line.

With only 200 ft/lbs of torque you'd have to rev it to the moon just to get off the line.

Last edited by 1963SS; 10-02-2011 at 10:39 AM.

#18

Well, with an 8.56 rear you could drive about anywhere. 70 MPH would probably be around 6000 RPM's but boy it would sound cool......If you think the sound of an angry honey bee is cool.

Well, with an 8.56 rear you could drive about anywhere. 70 MPH would probably be around 6000 RPM's but boy it would sound cool......If you think the sound of an angry honey bee is cool. With only 200 ft/lbs of torque you'd have to rev it to the moon just to get off the line.

With only 200 ft/lbs of torque you'd have to rev it to the moon just to get off the line.How about at least 632 cubic inches of BBC power.

Roots supercharger, 11-32 Dyers, water inter cooler on top like the current ZR1 LS has.

Give the engine 40 psi of boost on 120 + motor octane fuel or Methanol alcohol.

Power starts as low as 700 RPM's and revs to 8,200 RPM's.

Give it Crower Long Rod Titanium 6A4LV connecting rods,

Brooks Billet steel crankshaft.

Pontiac Big Chief Brodix Pro Stock Cylinder heads.

Real headers.

Not sissy pushrod C4 sbc stuff we have now.

2-5/8 " primary tubes with 5 " inch collectors.

Run it with open headers on the street with just 5" inch turn downs.

Gear the Corvette with 4.10's.

Lenco trans with Trick titanium blowproof bellhousing.

Crower glide clutch.

NHRA certified 14- point roll cage good for 6.0's 1/4 mile time.

Real racing seats with 5- point RJS seatbelts stock.

Too old & too fat........Too bad.....

Widest Mickey Thompson Drag radials on the rear 14 inch wide wheels.

Skinny Pro stock wheels up front.

MOROSO brand skinnys for excellent rollout and track ability on launch.

Must have 3,000 HP to the ground.

Independent rear ?

Thats goes in the garbage can.

Strange Engineering 10.5" inch unit out back.

They New Chevy Corvette....................2012.

The way it should be built I think.

Brian R.

#20

Drifting

I've got a small pair of needle nose pliers that I use for electrical work. They snuck right down in the hole and twisted it back and forth about twice and it was done. Hope yours is that easy but it's not usually an issue. Good luck with the rest of the job.

[/IMG]

[/IMG]