Poly front sway bar bushing problem

#1

Melting Slicks

Thread Starter

Ok I am thrilled with the VBP rear bar and bushings that made my rattle go away or bound up the car so it does not move enough to rattle..LOL But does drive well and does not feel bound and ride quality better not worse. I have the front bar here had it for a long time as well. I measured the bushings and steel insert in the bar and it adds up approximately .300" wider than the opening in the end link for the sway bar end. What gives? I have the instructions that came with the bar and they suggest jam it all in there, well it is not going to happen. Is this a cut to fit sort of operation? Possibly the poly bushing is a fits all sort of part or the steel sleeves pressed into the bar is different than stock or thhickness of the flat which is not flat I have to say the work done on the bar ends is shabby at best, not flat straight or square to anything in any plane.. sigh.. but on sale.. LOL..

I am up for hints of any sort but hoping to get them on today or tomorrow morning and cross this off my list before another week of too much work and not enough time.

Dave

I am up for hints of any sort but hoping to get them on today or tomorrow morning and cross this off my list before another week of too much work and not enough time.

Dave

#2

- 1986 Original Owner -

Ok I am thrilled with the VBP rear bar and bushings that made my rattle go away or bound up the car so it does not move enough to rattle..LOL But does drive well and does not feel bound and ride quality better not worse. I have the front bar here had it for a long time as well. I measured the bushings and steel insert in the bar and it adds up approximately .300" wider than the opening in the end link for the sway bar end. What gives? I have the instructions that came with the bar and they suggest jam it all in there, well it is not going to happen. Is this a cut to fit sort of operation? Possibly the poly bushing is a fits all sort of part or the steel sleeves pressed into the bar is different than stock or thhickness of the flat which is not flat I have to say the work done on the bar ends is shabby at best, not flat straight or square to anything in any plane.. sigh.. but on sale.. LOL..

I am up for hints of any sort but hoping to get them on today or tomorrow morning and cross this off my list before another week of too much work and not enough time.

Dave

I am up for hints of any sort but hoping to get them on today or tomorrow morning and cross this off my list before another week of too much work and not enough time.

Dave

#8

Le Mans Master

See about 3/4 into this post on how to deal with it.

See about 3/4 into this post on how to deal with it.I called Energy about that same issue last week after trying to use their set on my 26mm bar. The tech guy I spoke to had no idea it was an issue. I wonder what the best way is to cut down that bushing?

#9

Melting Slicks

Thread Starter

Did the install today with a friend we spent 2 1/2 hours at what looked like 45 minutes worth of work. The worst fitting POS I have ever dealt with. The bolts easily pushed out of the factory bar with minor effort and the bushings still in good shape. The ne bar has the ends bent too early so the frame bushings parially riding on a curved part. The end of the arms off angle in two different planes in all lacks the precision of a apprentice blacksmith. Supporting vendor or not it is about time they get called out for selling things that do not fit. There needs to be a pardigm shift that the vendor is not everything if they do not deliver if I get banned I do not care but telling the truth is more important than being a member of anything. The pressed in steel bushing carriers are cocked and not square. the ends too far apart and line up with nothing I might have been better trying a sway bar out of a truck than this thing. Sad at best and bound up to the point I gained 1 inch of ride height and hope i find a bumpy road to settle in the poorly made bar. funny thing is the rear fit quick and easy so suspect vendors different and endlessly changing good luck on this mod I am not impressed.

dave

dave

#10

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Did the install today with a friend we spent 2 1/2 hours at what looked like 45 minutes worth of work. The worst fitting POS I have ever dealt with. The bolts easily pushed out of the factory bar with minor effort and the bushings still in good shape. The ne bar has the ends bent too early so the frame bushings parially riding on a curved part. The end of the arms off angle in two different planes in all lacks the precision of a apprentice blacksmith. Supporting vendor or not it is about time they get called out for selling things that do not fit. There needs to be a pardigm shift that the vendor is not everything if they do not deliver if I get banned I do not care but telling the truth is more important than being a member of anything. The pressed in steel bushing carriers are cocked and not square. the ends too far apart and line up with nothing I might have been better trying a sway bar out of a truck than this thing. Sad at best and bound up to the point I gained 1 inch of ride height and hope i find a bumpy road to settle in the poorly made bar. funny thing is the rear fit quick and easy so suspect vendors different and endlessly changing good luck on this mod I am not impressed.

dave

dave

Something is bound to bend or break eventual.

Just about everything is made in china these days.

Even though it shines and sparkles, its still junk.

No blueprint tolerances adhered to.

No quality control.

No real world street and race testing.

Too bad VSE, Herb Adams suspension products are gone.

Were sold through MOROSO in CT where you are Dave.

Old Dick Moroso would roll over in his grave if he knew all the cheap china import crap sold today.

Including some forums.

Kick off one of the fathers & living legends behind the TT Callaway Corvette on CF C4( You Dave).

Wouldn't that be something else.

Just for telling the truth.

#11

Melting Slicks

Thread Starter

I knew Dick Moroso well a super guy and real hard core racer if there ever was one. He changed a lot when he lost his son Robbie in a car accident. The kid had a promising career as a race car driver, a real world statistic about partying on a Saturday night and being careless. I ran Dick's Winston cup engine shop in CT for a season when starting my own business around 20 years ago and have a ton of funny stories about it for another day. Ay 60 years old I know most of the old timers in the racing biz and plenty of the new ones as well. I build high quality parts for high end race cars and bikes and used to pride in high quality work being done. My client list reads like the who's who of professional racing, have been in a bunch of magizines , favorite being featured in 'Race Engine Technology' as a shop that can bring things from concept to real world race tracks. I am hoping the poly will distort a bit in 50 miles if not I have not thrown out the stock sway bar though it is too small to match up with the rear one. At the end of the day I need to find a proper bar or build some pillow blocks to move this one forward about an inch and run heim joint end links to pick up all the misaligned parts. That and find a new forum to hang out on no doubt. If I vanish from here everyone rock on and keep the shiney side up!

Dave

Dave

#12

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

I knew Dick Moroso well a super guy and real hard core racer if there ever was one. He changed a lot when he lost his son Robbie in a car accident. The kid had a promising career as a race car driver, a real world statistic about partying on a Saturday night and being careless. I ran Dick's Winston cup engine shop in CT for a season when starting my own business around 20 years ago and have a ton of funny stories about it for another day. Ay 60 years old I know most of the old timers in the racing biz and plenty of the new ones as well. I build high quality parts for high end race cars and bikes and used to pride in high quality work being done. My client list reads like the who's who of professional racing, have been in a bunch of magizines , favorite being featured in 'Race Engine Technology' as a shop that can bring things from concept to real world race tracks. I am hoping the poly will distort a bit in 50 miles if not I have not thrown out the stock sway bar though it is too small to match up with the rear one. At the end of the day I need to find a proper bar or build some pillow blocks to move this one forward about an inch and run heim joint end links to pick up all the misaligned parts. That and find a new forum to hang out on no doubt. If I vanish from here everyone rock on and keep the shiney side up!

Dave

Dave

East coast trip being planned for later this year.

In laws in Maryland to visit.

Your live along the way there.

Driving of course.

Digital Corvette Forum. Yellow Bullet. They are real rowdy on Y.B. at times so be prepared. They are real drag racers. Extreme hardcore.

9- second 1/4 mile cars are the norm & boring to them.

They like 8 second rides & faster. Can not blame them. Its 2012....

#13

Le Mans Master

Did the install today with a friend we spent 2 1/2 hours at what looked like 45 minutes worth of work. The worst fitting POS I have ever dealt with. The bolts easily pushed out of the factory bar with minor effort and the bushings still in good shape. The ne bar has the ends bent too early so the frame bushings parially riding on a curved part. The end of the arms off angle in two different planes in all lacks the precision of a apprentice blacksmith. Supporting vendor or not it is about time they get called out for selling things that do not fit. There needs to be a pardigm shift that the vendor is not everything if they do not deliver if I get banned I do not care but telling the truth is more important than being a member of anything. The pressed in steel bushing carriers are cocked and not square. the ends too far apart and line up with nothing I might have been better trying a sway bar out of a truck than this thing. Sad at best and bound up to the point I gained 1 inch of ride height and hope i find a bumpy road to settle in the poorly made bar. funny thing is the rear fit quick and easy so suspect vendors different and endlessly changing good luck on this mod I am not impressed.

dave

dave

#15

Melting Slicks

Thread Starter

I must have the car that nothing fits right or I expect the parts to fit better than they do.

First thing was the Magnaflow exhaust that did not clear the e-brake cable in the center of the car, sent it back as defective and told them what was wrong with the pipe after the cats missing a bend to clear the cable the factory pipe had. They sent another made exactly the same way wrong. Got a Borla cat back and the bend is right where it needs to be.

Second part the brake booster from Cardone with the wrong length pedal rod. A pre 90 car has a shorter pedal rod and it does not have a 1/4 spacer between the booster and firewall to hold the ECU bracket. Chatted with Cardone and they were unaware of the issue yet agreed when I gave them the dimensions. GM showed a different part number compared to a pre 90 as well so they knew.

Bought a set of Hooker headers that are supposed to fit a 84 to 96 corvette they don't as the flanges are drilled for ports on center when they are raised 0.250 above center for a Lt1 and LT4 port which is what the new fastburns have that I bought so sold both the heads and headers. GM said you had to have headers that fit a LT1 to fit correctly. I bought a set of gaskets for a LT1 port and they lined up perfectly so everyone knew but Hooker. The top of the port was blocked 1/4 and bottom had close to zero sealing surface.

This front bar is made wrong in my mind as it needs to move forward about 0.150 for the bolts to line up correctly. The factory bar fits perfectly with bushings that are no where distorted or worn out. If they put the 2 missing bends in the bar to help clear tie rods it would fit as it would shorten the arm length slightly and eliminate the need to move the bar forward.

The nothing fitting right more than half the time has pretty well discouraged me from modding this car or a C4 in general. The aftermarket parts for them is 99% junk and poorly made. I have been racing cars and bikes for 40 years and if I ever turned out things like these I would be out of business a very long time ago. It is just a complete lack of quality control or simple jigs and fixtures.

Rant over....

Dave

First thing was the Magnaflow exhaust that did not clear the e-brake cable in the center of the car, sent it back as defective and told them what was wrong with the pipe after the cats missing a bend to clear the cable the factory pipe had. They sent another made exactly the same way wrong. Got a Borla cat back and the bend is right where it needs to be.

Second part the brake booster from Cardone with the wrong length pedal rod. A pre 90 car has a shorter pedal rod and it does not have a 1/4 spacer between the booster and firewall to hold the ECU bracket. Chatted with Cardone and they were unaware of the issue yet agreed when I gave them the dimensions. GM showed a different part number compared to a pre 90 as well so they knew.

Bought a set of Hooker headers that are supposed to fit a 84 to 96 corvette they don't as the flanges are drilled for ports on center when they are raised 0.250 above center for a Lt1 and LT4 port which is what the new fastburns have that I bought so sold both the heads and headers. GM said you had to have headers that fit a LT1 to fit correctly. I bought a set of gaskets for a LT1 port and they lined up perfectly so everyone knew but Hooker. The top of the port was blocked 1/4 and bottom had close to zero sealing surface.

This front bar is made wrong in my mind as it needs to move forward about 0.150 for the bolts to line up correctly. The factory bar fits perfectly with bushings that are no where distorted or worn out. If they put the 2 missing bends in the bar to help clear tie rods it would fit as it would shorten the arm length slightly and eliminate the need to move the bar forward.

The nothing fitting right more than half the time has pretty well discouraged me from modding this car or a C4 in general. The aftermarket parts for them is 99% junk and poorly made. I have been racing cars and bikes for 40 years and if I ever turned out things like these I would be out of business a very long time ago. It is just a complete lack of quality control or simple jigs and fixtures.

Rant over....

Dave

#16

Safety Car

You need to talk to Danny Kellemyer at D.J Race. I use him for evereything these days. He's a retired GM engineer and ran a C4 team in both World Challenge and Corvette Challenge.

btw - You're right about the junk being sold today. I just went through a mess with bushings. The worst part was the suppliers really didn't care.

Richard Newton

btw - You're right about the junk being sold today. I just went through a mess with bushings. The worst part was the suppliers really didn't care.

Richard Newton

#18

Race Director

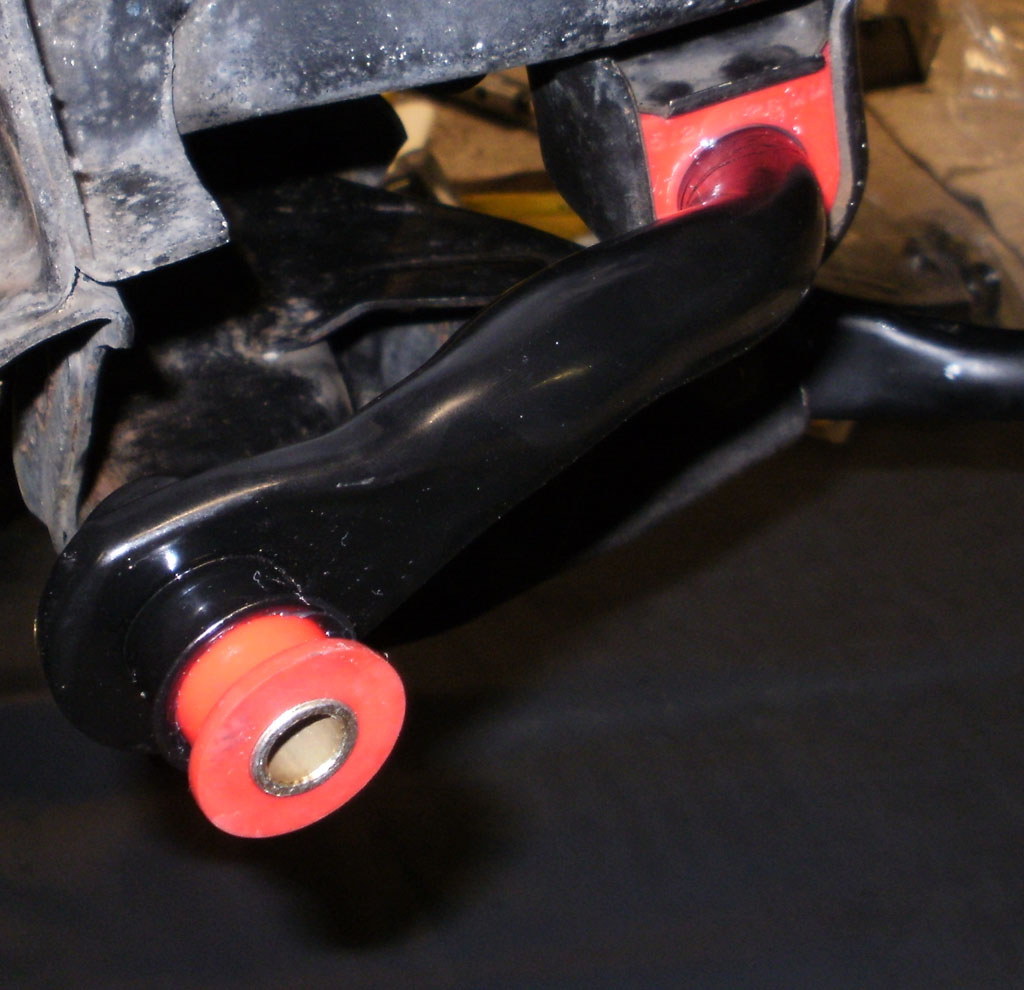

Re: front sway bar fitment. Do you have offset bushings? Can't tell from the pix. There are some made with the hole not in the center. You can put the thin side forward or back to adjust the bar.

#19

Melting Slicks

Thread Starter

Dave

#20

Melting Slicks

Thread Starter

The on going sway bar saga continues if the rest of the parts get here. I decided to pt the stock front bar back on for a little bit until I sort out things and what I really want to do instead of what every tells me I should they might be right but the more I think about it I am not a believer that a 32 mm bar is the one for me. SoIordered some 26mm poly bushings for the stock bar, opened the package and of course they did not send a complete kit missing the lube and steel sleeves for the sway bar, with luck they will show up today as express mail. Got them from VB&P as no one could get them to me for weekend installation. Just for kicks I measured what they did send and the new ones are offset bored by about 4mm but the stock bushings do not have any offset bored on center. What gives here I don't get it. I have no idea if they will fit until the rest of the parts get here and with luck try putting it back on Sunday.

So my real question before i jack the car up and pull everything apart is does everyone else have offset bushings on a stock 26mm front sway bar?

Dave

Just got the missing parts and loads of extra grease from VB&P they paid shipping next day to try and make things happen a big thumbs up to them for doing what they said they would do and getting it done no matter what it took all no charge!!!!

So my real question before i jack the car up and pull everything apart is does everyone else have offset bushings on a stock 26mm front sway bar?

Dave

Just got the missing parts and loads of extra grease from VB&P they paid shipping next day to try and make things happen a big thumbs up to them for doing what they said they would do and getting it done no matter what it took all no charge!!!!

Last edited by ddahlgren; 03-24-2012 at 12:03 PM.