'84 - '87 Headlight Gear Replacement

#1

Race Director

Thread Starter

I shut off my headlights and heard a really loud moaning noise that was coming from the driver's side headlight. Stripped gear (again...). If this happens to you, put the headlights in the up position and disconnect the gray connector. This will disable the motor and leave the headlight in the up position, but at least you will be able to use the headlight.

I've seen lots of threads on how to replace headlight motor bushings, but the older C4s don't have bushings. You have to replace the gear, so...

Remove the connectors for the headlight motor (gray) and headlight (black). It's easier to remove the bracket to get to the retainers for the connectors on the back. The bracket is attached to the body with 3 7mm screws:

Remove the 6 nuts/screws that hold the headlight frame to the hood. There are 2 nuts on the outside, 2 screws at the bottom and these 2 nuts on the inside. All are 10mm. The bracket that connects to the hood gas strut bracket must also be removed. 13mm nut. It's at the bottom in this pic:

Once the headlight mechanism is removed from the car, the headlight cover needs to come off. It is held on by 4 Torx screws. There are two T-20 screws, one on each side:

There are two T-15 screws in front. The large hex head screw in the middle is one of the stops that determine how far the headlight mechanism moves.

The cover must be removed to get access to the headlight-to-motor nut (15mm) and the three bolts (10mm) that mount the motor to the frame:

Take the motor apart by removing the Phillips head screws:

You will see a mess of old grease and silicone:

The large white gear is the one you will be replacing. There are four rubber shock absorbers in the gear, one of which appears to be very distorted in this picture:

New gear in position. These tangs must go between the rubber shock absorbers in the gear.

The most tedious part of this job is cleaning up the old silicone. The two halves of the motor housing need to be sealed with silicone because this area gets wet.

This is the polarity switch. The headlight mechanism slams up against the stops and the shaft of the motor moves back and forth, which changes the position of this switch. There are two grooves in the motor shaft that move the switch. There are two sets of contacts, one visible on the left and the other is sorta hidden on the right, held by the brass rivet.

This is why the headlight mechanism stops working. The plastic gear teeth get stripped and the worm gear can't turn it any more.

Attach the headlight motor to the headlight mechanism and turn the **** on the bottom of the motor until the mechanism is in the closed position. Reattach to the hood and you're done.

This is the third time I've done this on the driver's side. The passenger side is still working fine after 27 years of service. I couldn't find any obvious reason the driver's side failed. I've still got another spare gear, but I may go to a bronze one next time. I don't want to do this again.

I think it might be possible to remove just the motor from the headlight mechanism frame, leaving the rest of the mechanism attached to the hood, but I've always done it this way.

I've seen lots of threads on how to replace headlight motor bushings, but the older C4s don't have bushings. You have to replace the gear, so...

Remove the connectors for the headlight motor (gray) and headlight (black). It's easier to remove the bracket to get to the retainers for the connectors on the back. The bracket is attached to the body with 3 7mm screws:

Remove the 6 nuts/screws that hold the headlight frame to the hood. There are 2 nuts on the outside, 2 screws at the bottom and these 2 nuts on the inside. All are 10mm. The bracket that connects to the hood gas strut bracket must also be removed. 13mm nut. It's at the bottom in this pic:

Once the headlight mechanism is removed from the car, the headlight cover needs to come off. It is held on by 4 Torx screws. There are two T-20 screws, one on each side:

There are two T-15 screws in front. The large hex head screw in the middle is one of the stops that determine how far the headlight mechanism moves.

The cover must be removed to get access to the headlight-to-motor nut (15mm) and the three bolts (10mm) that mount the motor to the frame:

Take the motor apart by removing the Phillips head screws:

You will see a mess of old grease and silicone:

The large white gear is the one you will be replacing. There are four rubber shock absorbers in the gear, one of which appears to be very distorted in this picture:

New gear in position. These tangs must go between the rubber shock absorbers in the gear.

The most tedious part of this job is cleaning up the old silicone. The two halves of the motor housing need to be sealed with silicone because this area gets wet.

This is the polarity switch. The headlight mechanism slams up against the stops and the shaft of the motor moves back and forth, which changes the position of this switch. There are two grooves in the motor shaft that move the switch. There are two sets of contacts, one visible on the left and the other is sorta hidden on the right, held by the brass rivet.

This is why the headlight mechanism stops working. The plastic gear teeth get stripped and the worm gear can't turn it any more.

Attach the headlight motor to the headlight mechanism and turn the **** on the bottom of the motor until the mechanism is in the closed position. Reattach to the hood and you're done.

This is the third time I've done this on the driver's side. The passenger side is still working fine after 27 years of service. I couldn't find any obvious reason the driver's side failed. I've still got another spare gear, but I may go to a bronze one next time. I don't want to do this again.

I think it might be possible to remove just the motor from the headlight mechanism frame, leaving the rest of the mechanism attached to the hood, but I've always done it this way.

The following users liked this post:

xrav22 (09-20-2017)

#2

Melting Slicks

Great write up with pics

Thanks for sharing, my 85 still has the original headlight motors and am waiting for them to fail. I hold my breath every time i use my headlights.

New project next time i have some spare time, that the little woman won't try to turn into a holiday away

Thanks for sharing, my 85 still has the original headlight motors and am waiting for them to fail. I hold my breath every time i use my headlights.

New project next time i have some spare time, that the little woman won't try to turn into a holiday away

#3

Great write up Cliff !

I'd like to add that anyone diving into the 87 and prior headlite drive should use caution to avoid that magnet case falling out of the case half. Do not disturb the aremature, breaker pts or the glass bulb (micro-switch). IF any of these parts fall out this WILL effect the assembled position of everything and might cause endless headaches with the stop/start end travel.

BE DAMN SURE to get that steel plate on the spring to drop in the CORRECT slot when you close the case halves.. Otherwise the shaft cannot torque in one direction and hit the limit swtiches...it won;t act right.

I'd like to add that anyone diving into the 87 and prior headlite drive should use caution to avoid that magnet case falling out of the case half. Do not disturb the aremature, breaker pts or the glass bulb (micro-switch). IF any of these parts fall out this WILL effect the assembled position of everything and might cause endless headaches with the stop/start end travel.

BE DAMN SURE to get that steel plate on the spring to drop in the CORRECT slot when you close the case halves.. Otherwise the shaft cannot torque in one direction and hit the limit swtiches...it won;t act right.

#4

Race Director

Thank you for the great write-up, this is one of my next projects as my passenger side motor has a mind of its own and only opens when it wants to..

The following users liked this post:

marines (06-24-2019)

#6

Race Director

While searching for this I found this old post by " onedef92..

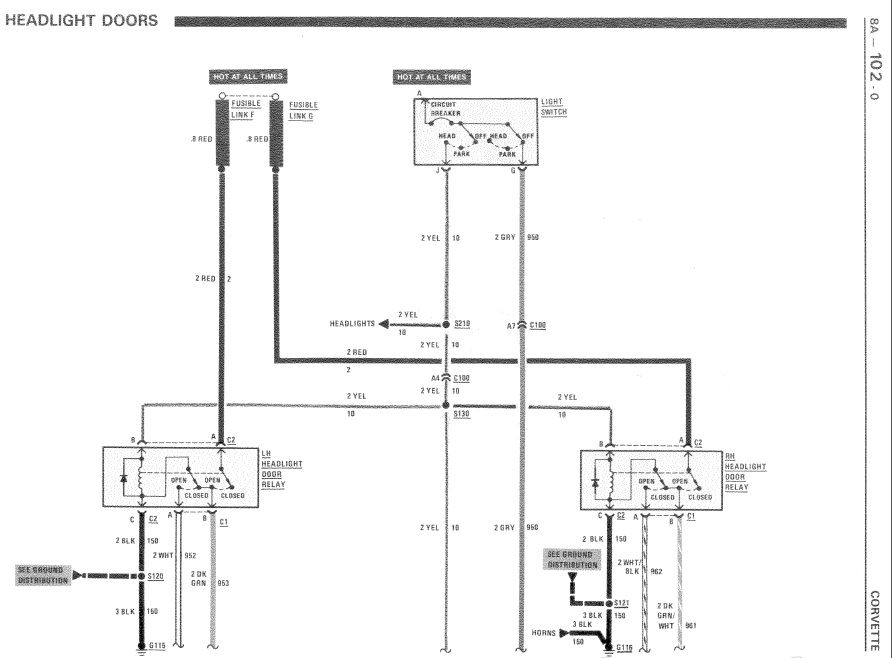

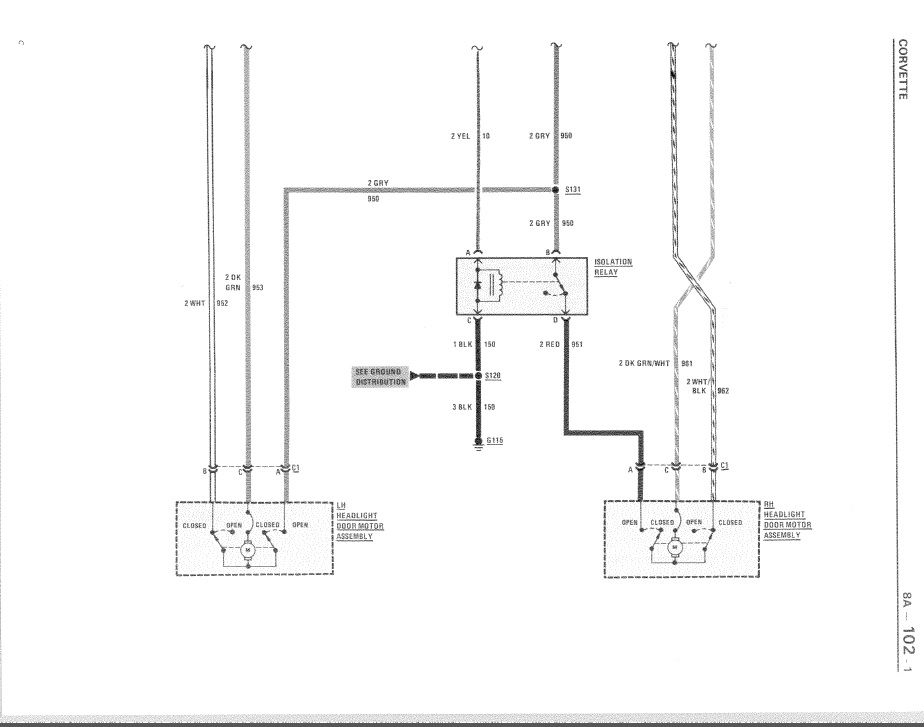

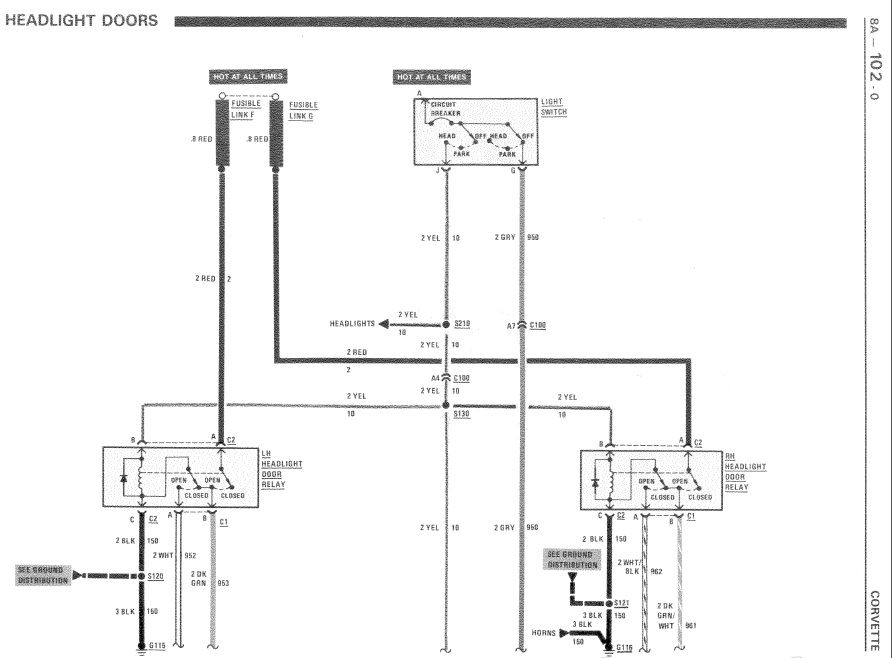

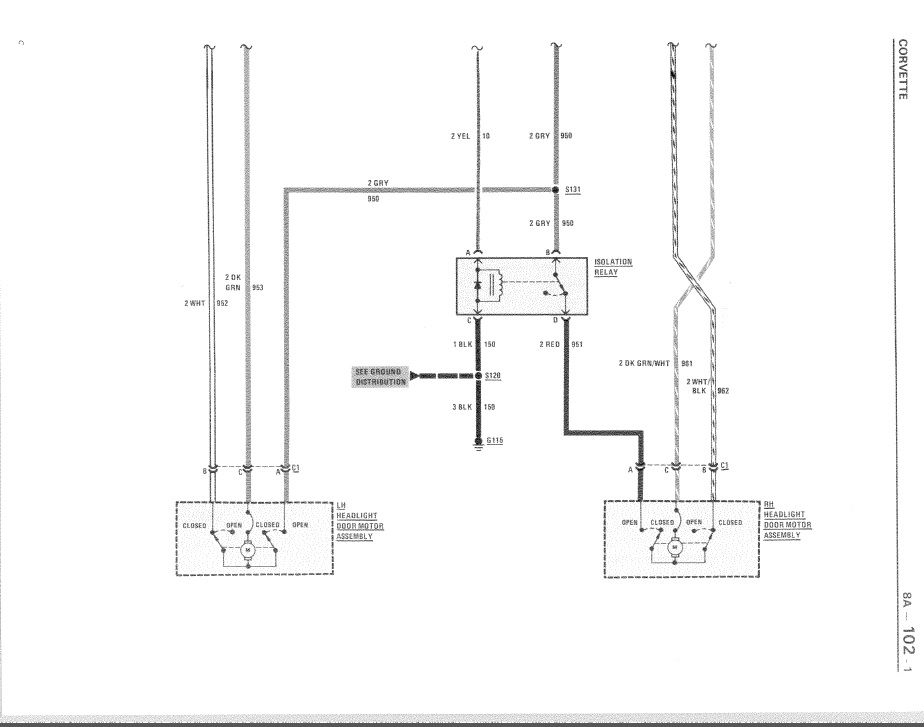

There are two motors, and three relays in the system. Here's how it works:

The headlight door motors reverse direction by reversing polarity. However, the automatic shut off (high torque switch, or HTS) makes that a rather more complex task than at first it might seem.

That's because when a motor reaches its limit, one of the 'wires' is disconnected from the motor by the HTS. Reversing the polarity at this point wouldn't do anything since the circuit is broken by the HTS.

Consequently, each motor has three wires for control. The combination of the blue wire, gray wire, and green wire provide polarity reversal to the motor (to make it able to run in both directions) and to run each motor from its resting state, after it has shut off.

There are of course two motors. They operate and are controlled identically.

Here's the matrix:

RIGHT HAND MOTOR

Blu Grn Gry

up: (+) (-)

dn: (+) (-)

That is, in order to run the motor up, the system connects the green wire to the hot side and the gray wire to ground. In order to run the motor down, the system connects the blue wire to the hot side, and the green wire to ground.

The left hand motor operates the same, except for its blue wire is actually blue with white stripes.

There is an actuator relay for each light mounted on the body of the light housing. There is also an isolator relay, mounted on the fender wall on the driver's side. When operating properly, the two actuator relays act identically.

The actuator relays get their instructions from the isolation relay. When the motors need to run down, the isolation relay is not energized, the blue (and blue/white) wires make with the hot side through the closed contacts of the isolation relay (which is not energized), and the ground is furnished to the motor through the closed contacts of the actuator relay until the circuit is broken by the HTS. When operating properly, neither the motors nor the relays draw any current in the full down position.

When it's time to go up, the actuator relays are energized when the pink wires coming from the isolation relay are connected to the hot side through the newly closed contacts of the isolation relay, the isolation relay is energized because the yellow wire coming from the head light switch is now hot.

When the actuator relays are energized, they furnish 12v from the always hot red wires, through their newly closed contacts, to the green wire. The motor is grounded through the newly closed contacts of the actuator relays. The motors will run up until the circuit is broken by the HTS. When operating properly, with the light doors in the full up position, all relays are energized and draw current, but the motors do not.

There are very counterintuitive things about this circuitry: When the motors are running UP, both the hot side and the ground are furnished by and through the actuator relay. However, when the motors are running DOWN, only the ground is furnished by the actuator relay because the blue and blue/white wires do not run to or through the actuator relay.

Similarly counterintuitive, when the motors are running down, the hot side is supplied by and through the isolation relay, but when they are running up, the hot side is supplied not by and through the isolation relay, but through the always hot fusible link.

That's how the headlamp door relays and motors work. The relays are not cheap but not terribly expensive, either: $17 ea for the actuator relays and $25 for the isolation relay. Proper trouble shooting can save a buck or two.

It is fairly easy to swap the actuator relays from side to side. If the symptoms change with them, then its probably the relays.

Although the actuator relays look similar to the isolation relay, they are very different, they cannot be swapped. Please note that the system is very interdependent, and it's easy to see why Chevrolet changed to electronic (as opposed to electro-mechanical) controls.

Hope this helps..

There are two motors, and three relays in the system. Here's how it works:

The headlight door motors reverse direction by reversing polarity. However, the automatic shut off (high torque switch, or HTS) makes that a rather more complex task than at first it might seem.

That's because when a motor reaches its limit, one of the 'wires' is disconnected from the motor by the HTS. Reversing the polarity at this point wouldn't do anything since the circuit is broken by the HTS.

Consequently, each motor has three wires for control. The combination of the blue wire, gray wire, and green wire provide polarity reversal to the motor (to make it able to run in both directions) and to run each motor from its resting state, after it has shut off.

There are of course two motors. They operate and are controlled identically.

Here's the matrix:

RIGHT HAND MOTOR

Blu Grn Gry

up: (+) (-)

dn: (+) (-)

That is, in order to run the motor up, the system connects the green wire to the hot side and the gray wire to ground. In order to run the motor down, the system connects the blue wire to the hot side, and the green wire to ground.

The left hand motor operates the same, except for its blue wire is actually blue with white stripes.

There is an actuator relay for each light mounted on the body of the light housing. There is also an isolator relay, mounted on the fender wall on the driver's side. When operating properly, the two actuator relays act identically.

The actuator relays get their instructions from the isolation relay. When the motors need to run down, the isolation relay is not energized, the blue (and blue/white) wires make with the hot side through the closed contacts of the isolation relay (which is not energized), and the ground is furnished to the motor through the closed contacts of the actuator relay until the circuit is broken by the HTS. When operating properly, neither the motors nor the relays draw any current in the full down position.

When it's time to go up, the actuator relays are energized when the pink wires coming from the isolation relay are connected to the hot side through the newly closed contacts of the isolation relay, the isolation relay is energized because the yellow wire coming from the head light switch is now hot.

When the actuator relays are energized, they furnish 12v from the always hot red wires, through their newly closed contacts, to the green wire. The motor is grounded through the newly closed contacts of the actuator relays. The motors will run up until the circuit is broken by the HTS. When operating properly, with the light doors in the full up position, all relays are energized and draw current, but the motors do not.

There are very counterintuitive things about this circuitry: When the motors are running UP, both the hot side and the ground are furnished by and through the actuator relay. However, when the motors are running DOWN, only the ground is furnished by the actuator relay because the blue and blue/white wires do not run to or through the actuator relay.

Similarly counterintuitive, when the motors are running down, the hot side is supplied by and through the isolation relay, but when they are running up, the hot side is supplied not by and through the isolation relay, but through the always hot fusible link.

That's how the headlamp door relays and motors work. The relays are not cheap but not terribly expensive, either: $17 ea for the actuator relays and $25 for the isolation relay. Proper trouble shooting can save a buck or two.

It is fairly easy to swap the actuator relays from side to side. If the symptoms change with them, then its probably the relays.

Although the actuator relays look similar to the isolation relay, they are very different, they cannot be swapped. Please note that the system is very interdependent, and it's easy to see why Chevrolet changed to electronic (as opposed to electro-mechanical) controls.

Hope this helps..

The following users liked this post:

ottowaluver (06-27-2020)

#8

Inspired by Cliff’s awesome step-by-step write up (thanks Cliff!), I just posted similar instructions at...

http://forums.corvetteforum.com/c4-g...tructions.html

... for the same kind of repair I just did on my 84's passenger-side headlight (aka headlamp). There are many differences along the way, but the root cause for me was also different: the smaller black gear in my motor had missing teeth, whereas the much more typical cause is stripped teeth in the larger white gear.

http://forums.corvetteforum.com/c4-g...tructions.html

... for the same kind of repair I just did on my 84's passenger-side headlight (aka headlamp). There are many differences along the way, but the root cause for me was also different: the smaller black gear in my motor had missing teeth, whereas the much more typical cause is stripped teeth in the larger white gear.

#9

Burning Brakes

I have one question....Does it mean that the gears need to be changed even if the headlight lights? I don't hear anything coming from my headlight motor. I did change one gear assembly when I first got the car but; that motor wouldn't turn off unless I pulled the plug. This makes no noise at all and it happened all of a sudden. This is the other side that has stopped working. Could it be the headlight motor??

thanks....

thanks....

#10

Race Director

Thread Starter

If the headlight is not moving or hesitates then the gears are probably bad.

The second time mine failed the headlight worked OK with the hood in the normal position but wouldn't turn if the hood was up.

I think there is a problem with the way the gears mesh in my driver's side headlight mechanism. It has stripped the white gear twice. The passenger side has been fine for 27 years. I couldn't figure out a way to adjust this, so ???

The second time mine failed the headlight worked OK with the hood in the normal position but wouldn't turn if the hood was up.

I think there is a problem with the way the gears mesh in my driver's side headlight mechanism. It has stripped the white gear twice. The passenger side has been fine for 27 years. I couldn't figure out a way to adjust this, so ???

#11

Race Director

If you unplug the motor you can check for power on the plug, 12v on the grey wire if drivers side and ground on the dark green. You could also manually open the door part way, plug it back in, and see if it closes.. If it closes but wont open I would suspect the relay or the fusible link that feeds the relay.

#12

Race Director

Cliff if you are getting excessive worm gear wear, I would suggest next time you have it open to check the amount of travel of the nylon block on the shaft needs to open the contacts..

Last edited by ccrazor; 05-28-2013 at 02:43 AM.

#14

Burning Brakes

If you unplug the motor you can check for power on the plug, 12v on the grey wire if drivers side and ground on the dark green. You could also manually open the door part way, plug it back in, and see if it closes.. If it closes but wont open I would suspect the relay or the fusible link that feeds the relay.

Thanks again for the info. Today I wanted to check to see if I am getting power to headlight motor. I know the headlight is working. I unplugged the motor and checked the volts. Yes everything is fine. I then decided to clean the contacts and give them a little electrical grease. When I plugged everything back in the headlight works fine now. I still ordered the gears it can't hurt to have them. I did the job once and I know its not that hard.

#16

While searching for this I found this old post by " onedef92..

There are two motors, and three relays in the system. Here's how it works:

The headlight door motors reverse direction by reversing polarity. However, the automatic shut off (high torque switch, or HTS) makes that a rather more complex task than at first it might seem.

I

That's because when a motor reaches its limit, one of the 'wires' is disconnected from the motor by the HTS. Reversing the polarity at this point wouldn't do anything since the circuit is broken by the HTS.

Consequently, each motor has three wires for control. The combination of the blue wire, gray wire, and green wire provide polarity reversal to the motor (to make it able to run in both directions) and to run each motor from its resting state, after it has shut off.

There are of course two motors. They operate and are controlled identically.

Here's the matrix:

RIGHT HAND MOTOR

Blu Grn Gry

up: (+) (-)

dn: (+) (-)

That is, in order to run the motor up, the system connects the green wire to the hot side and the gray wire to ground. In order to run the motor down, the system connects the blue wire to the hot side, and the green wire to ground.

The left hand motor operates the same, except for its blue wire is actually blue with white stripes.

There is an actuator relay for each light mounted on the body of the light housing. There is also an isolator relay, mounted on the fender wall on the driver's side. When operating properly, the two actuator relays act identically.

The actuator relays get their instructions from the isolation relay. When the motors need to run down, the isolation relay is not energized, the blue (and blue/white) wires make with the hot side through the closed contacts of the isolation relay (which is not energized), and the ground is furnished to the motor through the closed contacts of the actuator relay until the circuit is broken by the HTS. When operating properly, neither the motors nor the relays draw any current in the full down position.

When it's time to go up, the actuator relays are energized when the pink wires coming from the isolation relay are connected to the hot side through the newly closed contacts of the isolation relay, the isolation relay is energized because the yellow wire coming from the head light switch is now hot.

When the actuator relays are energized, they furnish 12v from the always hot red wires, through their newly closed contacts, to the green wire. The motor is grounded through the newly closed contacts of the actuator relays. The motors will run up until the circuit is broken by the HTS. When operating properly, with the light doors in the full up position, all relays are energized and draw current, but the motors do not.

There are very counterintuitive things about this circuitry: When the motors are running UP, both the hot side and the ground are furnished by and through the actuator relay. However, when the motors are running DOWN, only the ground is furnished by the actuator relay because the blue and blue/white wires do not run to or through the actuator relay.

Similarly counterintuitive, when the motors are running down, the hot side is supplied by and through the isolation relay, but when they are running up, the hot side is supplied not by and through the isolation relay, but through the always hot fusible link.

That's how the headlamp door relays and motors work. The relays are not cheap but not terribly expensive, either: $17 ea for the actuator relays and $25 for the isolation relay. Proper trouble shooting can save a buck or two.

It is fairly easy to swap the actuator relays from side to side. If the symptoms change with them, then its probably the relays.

Although the actuator relays look similar to the isolation relay, they are very different, they cannot be swapped. Please note that the system is very interdependent, and it's easy to see why Chevrolet changed to electronic (as opposed to electro-mechanical) controls.

Hope this helps..

There are two motors, and three relays in the system. Here's how it works:

The headlight door motors reverse direction by reversing polarity. However, the automatic shut off (high torque switch, or HTS) makes that a rather more complex task than at first it might seem.

I

That's because when a motor reaches its limit, one of the 'wires' is disconnected from the motor by the HTS. Reversing the polarity at this point wouldn't do anything since the circuit is broken by the HTS.

Consequently, each motor has three wires for control. The combination of the blue wire, gray wire, and green wire provide polarity reversal to the motor (to make it able to run in both directions) and to run each motor from its resting state, after it has shut off.

There are of course two motors. They operate and are controlled identically.

Here's the matrix:

RIGHT HAND MOTOR

Blu Grn Gry

up: (+) (-)

dn: (+) (-)

That is, in order to run the motor up, the system connects the green wire to the hot side and the gray wire to ground. In order to run the motor down, the system connects the blue wire to the hot side, and the green wire to ground.

The left hand motor operates the same, except for its blue wire is actually blue with white stripes.

There is an actuator relay for each light mounted on the body of the light housing. There is also an isolator relay, mounted on the fender wall on the driver's side. When operating properly, the two actuator relays act identically.

The actuator relays get their instructions from the isolation relay. When the motors need to run down, the isolation relay is not energized, the blue (and blue/white) wires make with the hot side through the closed contacts of the isolation relay (which is not energized), and the ground is furnished to the motor through the closed contacts of the actuator relay until the circuit is broken by the HTS. When operating properly, neither the motors nor the relays draw any current in the full down position.

When it's time to go up, the actuator relays are energized when the pink wires coming from the isolation relay are connected to the hot side through the newly closed contacts of the isolation relay, the isolation relay is energized because the yellow wire coming from the head light switch is now hot.

When the actuator relays are energized, they furnish 12v from the always hot red wires, through their newly closed contacts, to the green wire. The motor is grounded through the newly closed contacts of the actuator relays. The motors will run up until the circuit is broken by the HTS. When operating properly, with the light doors in the full up position, all relays are energized and draw current, but the motors do not.

There are very counterintuitive things about this circuitry: When the motors are running UP, both the hot side and the ground are furnished by and through the actuator relay. However, when the motors are running DOWN, only the ground is furnished by the actuator relay because the blue and blue/white wires do not run to or through the actuator relay.

Similarly counterintuitive, when the motors are running down, the hot side is supplied by and through the isolation relay, but when they are running up, the hot side is supplied not by and through the isolation relay, but through the always hot fusible link.

That's how the headlamp door relays and motors work. The relays are not cheap but not terribly expensive, either: $17 ea for the actuator relays and $25 for the isolation relay. Proper trouble shooting can save a buck or two.

It is fairly easy to swap the actuator relays from side to side. If the symptoms change with them, then its probably the relays.

Although the actuator relays look similar to the isolation relay, they are very different, they cannot be swapped. Please note that the system is very interdependent, and it's easy to see why Chevrolet changed to electronic (as opposed to electro-mechanical) controls.

Hope this helps..

#18

Melting Slicks

Way to go Cliff. Glad I have a 88 with the 3 replacement bushings I installed in 2001. That was my first post "problem". When I researched buying a C4 back in the mid 90's I learned that a 88 and up had aluminum heads, real power windows with no plastic ribbons, and the updated 700R4. I made a wise choice. Glad you got your headlights working again.

Last edited by HAD2HAV2; 08-07-2015 at 10:45 PM.

#19

Advanced

If the headlight is not moving or hesitates then the gears are probably bad.

The second time mine failed the headlight worked OK with the hood in the normal position but wouldn't turn if the hood was up.

I think there is a problem with the way the gears mesh in my driver's side headlight mechanism. It has stripped the white gear twice. The passenger side has been fine for 27 years. I couldn't figure out a way to adjust this, so ???

The second time mine failed the headlight worked OK with the hood in the normal position but wouldn't turn if the hood was up.

I think there is a problem with the way the gears mesh in my driver's side headlight mechanism. It has stripped the white gear twice. The passenger side has been fine for 27 years. I couldn't figure out a way to adjust this, so ???

#20

Le Mans Master

Thanks for bringing this up, this is something i still have to do wow !

86project, if i were you, i would change both sides and both gears

so you'll have peace of mind that you have the complete system brand new.

86project, if i were you, i would change both sides and both gears

so you'll have peace of mind that you have the complete system brand new.