1985 coolant sensor issue

#1

Intermediate

Thread Starter

Member Since: Jul 2010

Location: Norfolk Virginia

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Ok following the manual to the best of my abilities this is where I am at but it isn't quite jiving to me.

This is the sensor I was givin at car quest with a double ended pigtail to connect it up.

But I have found these two connectors coming out of the loom for the starter wires. The male connector is solid green white and the female connector is green.

Then at one point some one must of tried over riding the relay and the connector just dead ends over here.

So I have this sensor going into the left passenger side because I found a dead green wire coming out of the starter loom. Which I imagined is for the coolant fan switch.

Ive read enough to know if I get them wrong I will get false temperature indications and my fans might not even work.

Oh on a side note I didn't know if there is something that is suppost to be in these two holes around the oil filter.

This is the sensor I was givin at car quest with a double ended pigtail to connect it up.

But I have found these two connectors coming out of the loom for the starter wires. The male connector is solid green white and the female connector is green.

Then at one point some one must of tried over riding the relay and the connector just dead ends over here.

So I have this sensor going into the left passenger side because I found a dead green wire coming out of the starter loom. Which I imagined is for the coolant fan switch.

Ive read enough to know if I get them wrong I will get false temperature indications and my fans might not even work.

Oh on a side note I didn't know if there is something that is suppost to be in these two holes around the oil filter.

#2

Melting Slicks

The sensor between #1 and #3 cylinders is for the dash gauge. It has a single wire blade connector. The coolant sensor for the ECM is located on the front of the intake manifold. It has a 2 wire connector. The sensor located between #6 and #8 cylinders is the fan switch. It is a single round pin. It looks like yours might have been modified to turn on both fans. That's a common change.

#3

Intermediate

Thread Starter

Member Since: Jul 2010

Location: Norfolk Virginia

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

ok so the single blade sensor goes on the driver side and one of the two green wires should go to it. Then On the passenger side between 8 and 6 I am looking for the sensor that has a connector like the knock sensor. So probably what I have right now in cylinder 1 and 3 is the ecm sensor.

#4

Melting Slicks

ok so the single blade sensor goes on the driver side and one of the two green wires should go to it. Then On the passenger side between 8 and 6 I am looking for the sensor that has a connector like the knock sensor. So probably what I have right now in cylinder 1 and 3 is the ecm sensor.

#5

Hi Booncky,at the end you have a shop manual...good

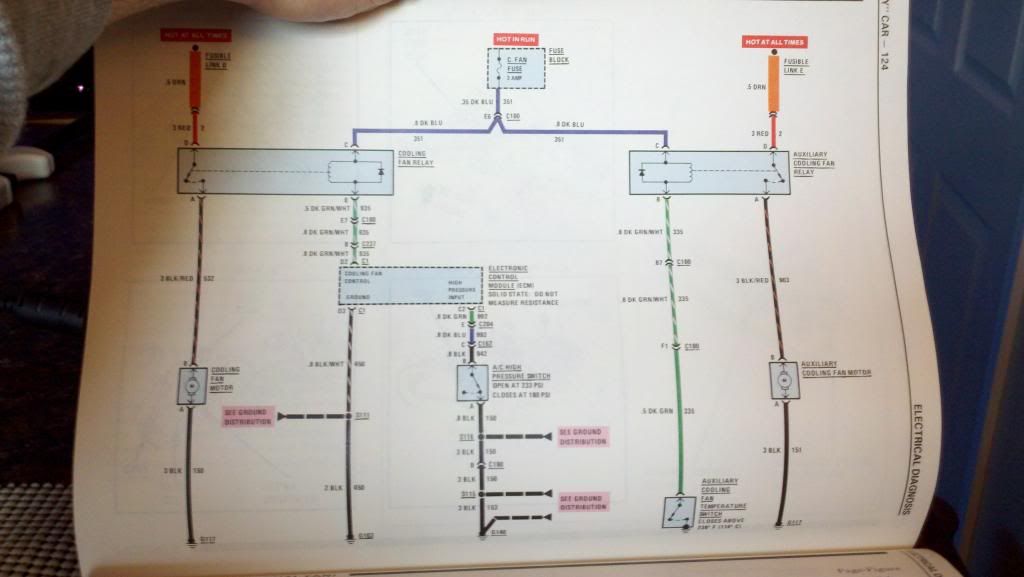

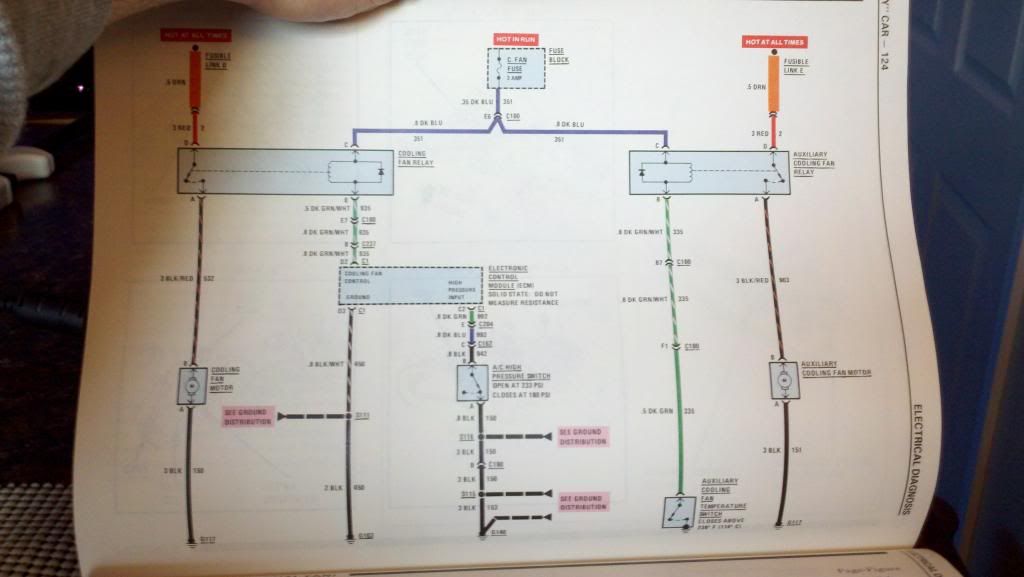

the dark blu wire and the green white are a 12 v and ground to energize relais and close the 12v supply to the fan motors as you can see from the schematics.This is the dual fan schematic.

the main fan is operated via ECM,in the tune there is a scalar for fan enamble temperature,the ECM uses the coolant sensor on the front of intake manifold to "read" the temperature,when it reaches the temp in the tune the driver inside the ECM feed the ground using the green white wire,this energizes the cooling fan relay ,it closes giving 12 v to the main fan motor( left part in your schematic).

Auxiliary fan motor is operated by auxliary fan relay ,but here the ground is feed to relay from the auxiliary temperature switch,again it energizes the relay,it gives 12 v to auxiliary fan motor,and it starts

quote "It looks like yours might have been modified to turn on both fans. That's a common change."

yep,they are using main relay to run both fans,the main and auxiliary...

fan switch

connector to fan switch (aftermarket)

the dark blu wire and the green white are a 12 v and ground to energize relais and close the 12v supply to the fan motors as you can see from the schematics.This is the dual fan schematic.

the main fan is operated via ECM,in the tune there is a scalar for fan enamble temperature,the ECM uses the coolant sensor on the front of intake manifold to "read" the temperature,when it reaches the temp in the tune the driver inside the ECM feed the ground using the green white wire,this energizes the cooling fan relay ,it closes giving 12 v to the main fan motor( left part in your schematic).

Auxiliary fan motor is operated by auxliary fan relay ,but here the ground is feed to relay from the auxiliary temperature switch,again it energizes the relay,it gives 12 v to auxiliary fan motor,and it starts

quote "It looks like yours might have been modified to turn on both fans. That's a common change."

yep,they are using main relay to run both fans,the main and auxiliary...

fan switch

connector to fan switch (aftermarket)

Last edited by tunedport85inject; 05-06-2013 at 02:16 AM.

#6

Melting Slicks

#7

Melting Slicks

Yes the 4 bolt block i that my 383 was built in had a dipstick hole between cyl 5 and 7. I plugged that up and used the std vette dipstick on the other side after i drilled the casting.

#8

Intermediate

Thread Starter

Member Since: Jul 2010

Location: Norfolk Virginia

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Hi Booncky,at the end you have a shop manual...good

the dark blu wire and the green white are a 12 v and ground to energize relais and close the 12v supply to the fan motors as you can see from the schematics.This is the dual fan schematic.

the main fan is operated via ECM,in the tune there is a scalar for fan enamble temperature,the ECM uses the coolant sensor on the front of intake manifold to "read" the temperature,when it reaches the temp in the tune the driver inside the ECM feed the ground using the green white wire,this energizes the cooling fan relay ,it closes giving 12 v to the main fan motor( left part in your schematic).

Auxiliary fan motor is operated by auxliary fan relay ,but here the ground is feed to relay from the auxiliary temperature switch,again it energizes the relay,it gives 12 v to auxiliary fan motor,and it starts

quote "It looks like yours might have been modified to turn on both fans. That's a common change."

yep,they are using main relay to run both fans,the main and auxiliary...

fan switch

connector to fan switch (aftermarket)

the dark blu wire and the green white are a 12 v and ground to energize relais and close the 12v supply to the fan motors as you can see from the schematics.This is the dual fan schematic.

the main fan is operated via ECM,in the tune there is a scalar for fan enamble temperature,the ECM uses the coolant sensor on the front of intake manifold to "read" the temperature,when it reaches the temp in the tune the driver inside the ECM feed the ground using the green white wire,this energizes the cooling fan relay ,it closes giving 12 v to the main fan motor( left part in your schematic).

Auxiliary fan motor is operated by auxliary fan relay ,but here the ground is feed to relay from the auxiliary temperature switch,again it energizes the relay,it gives 12 v to auxiliary fan motor,and it starts

quote "It looks like yours might have been modified to turn on both fans. That's a common change."

yep,they are using main relay to run both fans,the main and auxiliary...

fan switch

connector to fan switch (aftermarket)

#9

Intermediate

Thread Starter

Member Since: Jul 2010

Location: Norfolk Virginia

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts