how do u inspect and or test the flat tappet cam while on the car

#1

Oil Producer

Thread Starter

iron head 86.

over in my 4+3 refurb thread here, it has been suggested that while im cleaning the engine up with intake manifold off, i should inspect the flat tappet cam for wear.

While on the car how would i do that? i was thinking i could measure deflection of the lifter as i rotate the engine by hand? i have a caliper and i have a runout dial gauge.

This is beyond my current level of wrenching apptitude but if there were a few c4 friends able to guide me i would carry out this test with enthusiasm!

over in my 4+3 refurb thread here, it has been suggested that while im cleaning the engine up with intake manifold off, i should inspect the flat tappet cam for wear.

While on the car how would i do that? i was thinking i could measure deflection of the lifter as i rotate the engine by hand? i have a caliper and i have a runout dial gauge.

This is beyond my current level of wrenching apptitude but if there were a few c4 friends able to guide me i would carry out this test with enthusiasm!

#2

Le Mans Master

measuring rocker lift, or if its really bad,, just looking at them while engine is running, will work . They should be all just about the same. However, it could be a poor/bad lifter that will cause low rocker arm lift Don't forget to look for a rocker arm stud that pulling out of the head.

Last edited by ghoastrider1; 02-01-2018 at 11:12 AM.

#3

Race Director

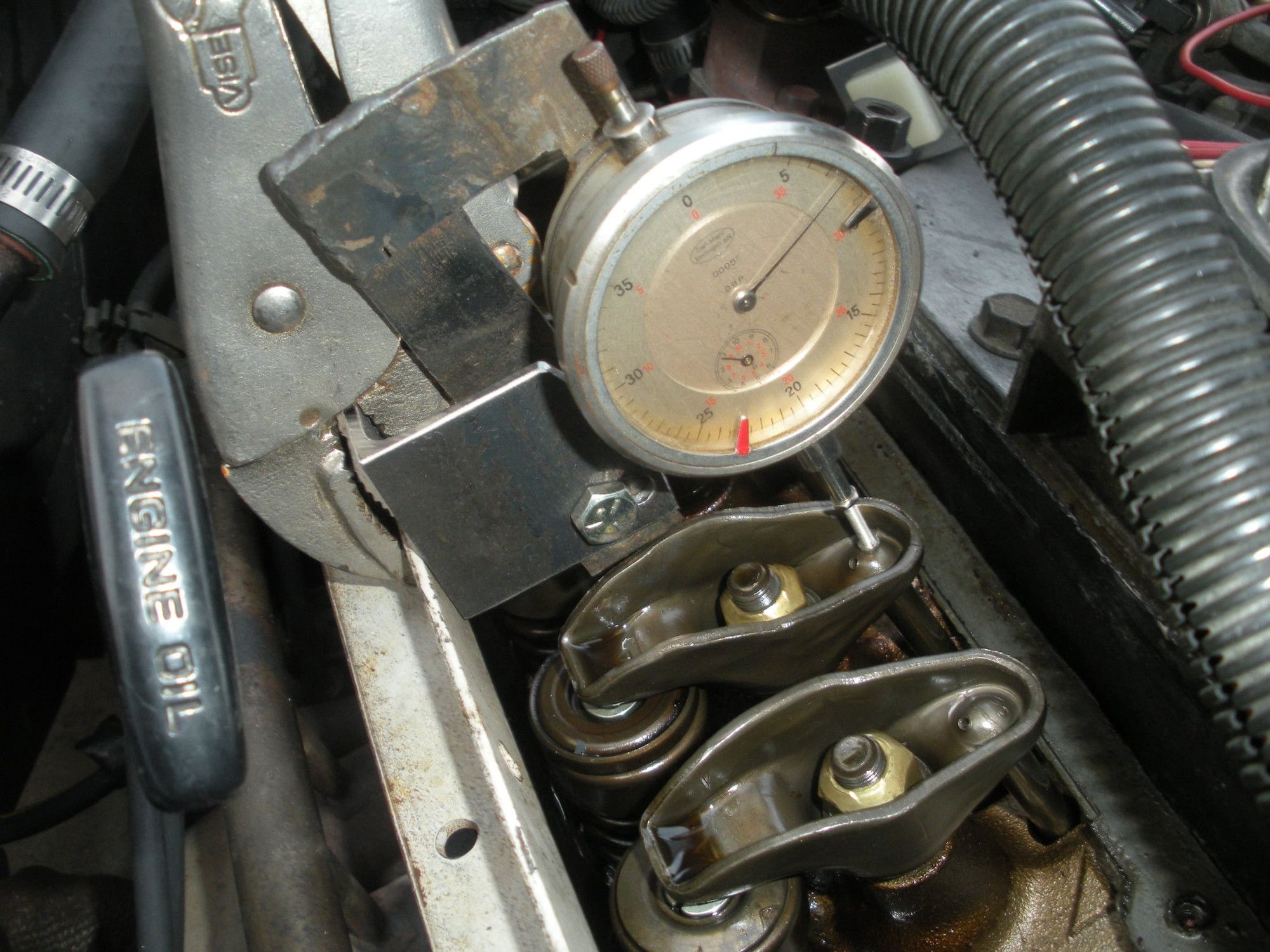

Place the dial indicator on the edge of the lifter and measure the lift of each as you rotate the motor. Compare with specs

#4

Oil Producer

Thread Starter

I do not think that I will be able to fit the dial gauge to each lifter or rocker arm stud in a repeatable way. there are rocker stud mounting arms but meh, i think i will use a ruler or my caliper. i should be able to get the same measurement.

Also, im not expecting any problems but i think this is a good suggestion and im going to give it a check. I've listed to what a wiped cam sounds like and i sure don't have any indications of that.

Here is a clip i found from a website: https://itstillruns.com/tell-bad-lob...t-6293277.html

"All of the above are signs, but the definitive test is measuring valve lift at the spring with a dial indicator. You'll need to take the valve cover off, and install the dial indicator on the rocker studs one at a time. Position it to measure the rise of the valve spring at the retainer, or the top of the rocker arm, depending on your engine design. Be consistent with the placement from valve to valve. Turn the engine over by hand with a wrench on the crank center-bolt, with the spark plugs removed. Record the reading for each cylinder; they should be near-identical -- within 0.01-inch or so -- for each of the intake or exhaust valves relative to the rest. If you get a much lower reading for one intake valve compared to the other intakes, you've found your bad lobe. The same goes for the exhaust lobes and valves. Remember, only compare intake to intake, and exhaust to exhaust; many engines have "split-pattern" cams with different specs for the intake and exhaust lobes."

Last edited by VikingTrad3r; 01-31-2018 at 04:47 PM.

The following users liked this post:

yakmastermax (03-07-2024)

#5

Burning Brakes

When I checked on my 86, I found it easiest to remove the rocker arms and use my calipers to measure the lift at the pushrod. It was just easier than getting down into the lifter valley (and I did it with the lower intake on the motor as well.

Once you remove the rocker arms that will relieve any pressure on the lifters so it should give you a pretty good reading.

Good Luck, I hope you have better results than I did. I ended up with three bad lobes and two more degraded. And that was on an engine that had been rebuilt sometime prior to me owning the car. I am very happy I rebuilt the motor though, did it with my teenage son and we had a good time.

By the way, if it is wiped, the Melling CCS-37 has the same grind as the factory cam.

Once you remove the rocker arms that will relieve any pressure on the lifters so it should give you a pretty good reading.

Good Luck, I hope you have better results than I did. I ended up with three bad lobes and two more degraded. And that was on an engine that had been rebuilt sometime prior to me owning the car. I am very happy I rebuilt the motor though, did it with my teenage son and we had a good time.

By the way, if it is wiped, the Melling CCS-37 has the same grind as the factory cam.

#6

Race Director

Thanks guys the intake is off so i'll do both. one will tell us about a collapsed lifter and the other will tell us about a wiped lobe.

I do not think that I will be able to fit the dial gauge to each lifter or rocker arm stud in a repeatable way. there are rocker stud mounting arms but meh, i think i will use a ruler or my caliper. i should be able to get the same measurement.

I do not think that I will be able to fit the dial gauge to each lifter or rocker arm stud in a repeatable way. there are rocker stud mounting arms but meh, i think i will use a ruler or my caliper. i should be able to get the same measurement.

Last edited by 383vett; 01-31-2018 at 01:37 PM.

#7

Safety Car

#8

Oil Producer

Thread Starter

Hey HRR, would the same apply for the rim of the lifter in the valley?

#9

Le Mans Master

..... Trying to set up a dial indicator in 16 locations in the valley of the engine will test your patience . If you can , just pull each lifter out and look at its base where it contacts the cam . You will know very quickly if you HAVE a problem or NOT ... the lobe is not likely to wear without wearing the lifter and vice versa ... while the lifter is out , you will be able to see and visually inspect the cam lobe as well ... make sure you do one lifter at a time or organize them in such a way that they will go back in the exact same place .....

The following users liked this post:

rocco16 (01-31-2018)

#10

Oil Producer

Thread Starter

..... Trying to set up a dial indicator in 16 locations in the valley of the engine will test your patience . If you can , just pull each lifter out and look at its base where it contacts the cam . You will know very quickly if you HAVE a problem or NOT ... the lobe is not likely to wear without wearing the lifter and vice versa ... while the lifter is out , you will be able to see and visually inspect the cam lobe as well ... make sure you do one lifter at a time or organize them in such a way that they will go back in the exact same place .....

the issue is that there is no way to get it exactly the same every time with all these articulating parts on this magnetic base and arm system.

the other thing is that at least on the 86e, you cannot do this on the rocker arm. ive never seen a lifter or how it works but it sags.

the outside cylinder does not seem to sag, only the center part where the pushrod is seated.

i really didn't want to re-adjust valve lash. i'll see if i can use a simple ruler to see any big differences in the max height of the outer cylinder shell of the each lifter.

i can't get my dial gauge on that outer rim.

#11

Oil Producer

Thread Starter

reason i don't want to pull the rockers is because i don't have much time.

i used a method to get a ballpark (mostly to see if i have any huge issues) and no i don't.

intakes, in millimeters

8.22, 8.05, 8.29, 8.10 -- passenger 2,4,6,8

8.13, 7.9, 7.95, 8.00 -- driver 1,3,5,7

exhausts, in millimeters

8.81, 8.1, 8.39, 8.54 -- passenger, 2,4,6,8

8.17, 7.15. 7.7, 7.98 -- driver, 1,3,5,7

So they are all very close and remember all i did was use my digital caliper in as close to the same way for every lifter. this shouldn't reflect whatever the actual lift is. simply getting an idea how close they are all to each other. given the fluctuations in my measuring techniques, they are all quite close.

1 millimeter = .039 inches

i used a method to get a ballpark (mostly to see if i have any huge issues) and no i don't.

intakes, in millimeters

8.22, 8.05, 8.29, 8.10 -- passenger 2,4,6,8

8.13, 7.9, 7.95, 8.00 -- driver 1,3,5,7

exhausts, in millimeters

8.81, 8.1, 8.39, 8.54 -- passenger, 2,4,6,8

8.17, 7.15. 7.7, 7.98 -- driver, 1,3,5,7

So they are all very close and remember all i did was use my digital caliper in as close to the same way for every lifter. this shouldn't reflect whatever the actual lift is. simply getting an idea how close they are all to each other. given the fluctuations in my measuring techniques, they are all quite close.

1 millimeter = .039 inches

#13

Oil Producer

Thread Starter

intakes, in millimeters

8.22, 8.05, 8.29, 8.10 -- passenger 2,4,6,8

8.13, 7.9, 7.95, 8.00 -- driver 1,3,5,7

exhausts, in millimeters

8.71, 8.1, 8.39, 8.54 -- passenger, 2,4,6,8

8.17, 7.81. 7.7, 7.98 -- driver, 1,3,5,7

much closer now. its tough because the way i did the measurements allowed for slight changes. like the angle of the caliper which i tried to keep as close to the same as possible.

no BIG differences = good to go IMO.

#14

Le Mans Master

Since intake is off i would look at bottom of lifters with 7.xx the hardened surfaces of cam and lifters is in the thousandths. If there is no pitting and lifter is not concave it's probably ok. Once the hardened surface is worn through, the softer iron will wear rapidly. I would shop a cam change and timing chain set. Unless you know timing set has already been changed.