Adventures in Clutchland - Detail 101

#1

Melting Slicks

Thread Starter

I'll be the 1st to admit that for the last 8 to 10 years, I've never taken any measurements during a clutch install. However, I think possibly for the last year, I've been having an issue with this RXT 1200. It may have cost one trans, it's definitely cost a few races, and is killing the ET potential via missed gears and slower than acceptable shifting.

This thread is meant to go through the discovery phase of what is found to be the issue. For anyone that is in the same situation or wondering how to get the best results follow along. There may be some out there who have already been through this and learned the ins and outs, feel free to provide input.

Current Hardware

McLeod RXT 1000 that was rebuilt and upgraded to McLeod RXT 1200

SPEC aluminum flywheel with replaceable friction insert

Tick master cylinder

LS6 slave cylinder

Remote bleeder

Motul 600 fluid

Line from master to slave is covered with a thermal protective sleeve

Current Symptoms

After 2 passes at the track, the trans wouldn't hit 2nd gear when trying to shift quickly. Over the next 4 passes it became hard to shift any gear quickly. After the 6th pass, the trans wouldn't shift into any gear with the car stationary and the clutch pedal depressed. You could feel the car trying to creep forward but the gear wouldn't engage. I shut the car off, re-cranked it in gear and limped it back to the house. With the rear tires off the ground, trans in 1st gear, and clutch pedal depressed, it was very hard to turn the rear wheel. You could hear the clutch disk dragging.

A Tale of Two Clutch Orders

McLeod Timeline

4/17/17---Day 0 - Clutch received at McLeod

4/24/17---Day 5 - Clutch on rebuild stand; McLeod waiting on floaters; ETA 4/25/17

4/25/17---Day 6 - 50 floater plates arrived and were installed on new units; I was told still waiting on floaters

4/28/17---Day 9 - No floaters, we will call you next week

5/1/17----Day 10 - No call, so I called, still waiting on floaters; this is when I learned they received 50 items the week before

SPEC and Maryland Speed Timeline

4/22/17---Day 0 – Placed order with Maryland Speed on a Saturday

4/24/17---Day 1 – Contacted SPEC to confirm order; notified me of possible parts shortage

4/28/17---Day 5 – Clutch drop shipped from SPEC

5/1/17----Day 6 – Clutch is out for delivery

This thread is meant to go through the discovery phase of what is found to be the issue. For anyone that is in the same situation or wondering how to get the best results follow along. There may be some out there who have already been through this and learned the ins and outs, feel free to provide input.

Current Hardware

McLeod RXT 1000 that was rebuilt and upgraded to McLeod RXT 1200

SPEC aluminum flywheel with replaceable friction insert

Tick master cylinder

LS6 slave cylinder

Remote bleeder

Motul 600 fluid

Line from master to slave is covered with a thermal protective sleeve

Current Symptoms

After 2 passes at the track, the trans wouldn't hit 2nd gear when trying to shift quickly. Over the next 4 passes it became hard to shift any gear quickly. After the 6th pass, the trans wouldn't shift into any gear with the car stationary and the clutch pedal depressed. You could feel the car trying to creep forward but the gear wouldn't engage. I shut the car off, re-cranked it in gear and limped it back to the house. With the rear tires off the ground, trans in 1st gear, and clutch pedal depressed, it was very hard to turn the rear wheel. You could hear the clutch disk dragging.

A Tale of Two Clutch Orders

McLeod Timeline

4/17/17---Day 0 - Clutch received at McLeod

4/24/17---Day 5 - Clutch on rebuild stand; McLeod waiting on floaters; ETA 4/25/17

4/25/17---Day 6 - 50 floater plates arrived and were installed on new units; I was told still waiting on floaters

4/28/17---Day 9 - No floaters, we will call you next week

5/1/17----Day 10 - No call, so I called, still waiting on floaters; this is when I learned they received 50 items the week before

SPEC and Maryland Speed Timeline

4/22/17---Day 0 – Placed order with Maryland Speed on a Saturday

4/24/17---Day 1 – Contacted SPEC to confirm order; notified me of possible parts shortage

4/28/17---Day 5 – Clutch drop shipped from SPEC

5/1/17----Day 6 – Clutch is out for delivery

Last edited by Turbo-Geist; 05-01-2017 at 06:58 PM.

#2

Melting Slicks

Thread Starter

Troubleshooting

Last weekend I bled the clutch system and made sure there wasn't any air. A mity vac was used to pull a vacuum and cause any bubbles to rise to the surface. Next, the remote bleed line was opened and submerged in a bottle of brake fluid. Vacuum was re-established drawing fresh fluid through the slave, master, and reservoir. Finally, the remote bleeder was used via the clutch pedal to push fluid from the master cylinder to the slave and out to a bottle of brake fluid. No bubbles were observed during this final step.

With the wheels off the ground, the trans in 1st gear, and clutch pedal depressed, the results were the same. The rear wheels were still very hard to turn.

Tonight I pulled the driver side downpipe and inspection cover and found the slave cylinder bottomed out against the aluminum base.

Here’s a video from tonight showing the slave cylinder is functioning but it can’t extend far enough to fully release the clutch.

Here’s a new stock slave cylinder showing approximately how much travel is available.

Last weekend I bled the clutch system and made sure there wasn't any air. A mity vac was used to pull a vacuum and cause any bubbles to rise to the surface. Next, the remote bleed line was opened and submerged in a bottle of brake fluid. Vacuum was re-established drawing fresh fluid through the slave, master, and reservoir. Finally, the remote bleeder was used via the clutch pedal to push fluid from the master cylinder to the slave and out to a bottle of brake fluid. No bubbles were observed during this final step.

With the wheels off the ground, the trans in 1st gear, and clutch pedal depressed, the results were the same. The rear wheels were still very hard to turn.

Tonight I pulled the driver side downpipe and inspection cover and found the slave cylinder bottomed out against the aluminum base.

Here’s a video from tonight showing the slave cylinder is functioning but it can’t extend far enough to fully release the clutch.

Here’s a new stock slave cylinder showing approximately how much travel is available.

Last edited by Turbo-Geist; 04-19-2017 at 01:14 AM.

#3

Melting Slicks

Interesting, I just recently installed an RXT in my car and now I'm wondering if I will have similar issues.

#4

Melting Slicks

Thread Starter

#5

Melting Slicks

I did not take any. I figured that since I was running a brand new flywheel, clutch and OEM slave I should be ok. I may pull my inspection cover off tonight and take a peek.

#6

Melting Slicks

Thread Starter

You should be able to compress the slave by hand against the spring. I'm not sure yet how much free travel is ideal. I'm trying to figure it out. In my case, there isn't any free travel because the slave is bottomed out. Mcleod says the throw out bearing travel should be 0.440 to 0.445" Is that how far it can extend?

#7

Drifting

I believe that is the distance for the plate to fully disengage. As things wear the fingers will move out or towards the bell, but distance for release should remain about the same, but have different start and end points as the assembly moves position slightly due to spring curve, etc.

#8

Melting Slicks

Thread Starter

Ok, makes sense. I'm between a rock and a hard place so to speak. Slave is bottomed out but touching the pressure plate fingers. Adding a shim would give more travel, but make it like you are riding the clutch.

I'll try to measure tonight and see if the bearing is moving within the 0.440" to 0.445" range. I don't think an over-extension has occurred. The fingers would be bent downward and not touching the bearing plus the slave would have over-extended and blown out the seals.

Either way, the driveline is coming out this week. Pump Gas Invitational is May 13, 2017. I sent the spare RXT 1000 back to McLeod to be upgraded to the 1200. I'm wondering if I should go with something that has more capacity since the car is getting bigger turbos later this year.

I'll try to measure tonight and see if the bearing is moving within the 0.440" to 0.445" range. I don't think an over-extension has occurred. The fingers would be bent downward and not touching the bearing plus the slave would have over-extended and blown out the seals.

Either way, the driveline is coming out this week. Pump Gas Invitational is May 13, 2017. I sent the spare RXT 1000 back to McLeod to be upgraded to the 1200. I'm wondering if I should go with something that has more capacity since the car is getting bigger turbos later this year.

#9

Melting Slicks

Thread Starter

Here's one of the tech tips from McLeod:

Throw Out Bearing Travel Tech Tip

This McLeod multi disc clutch assembly (RST, RXT or Street Twin) is designed to operate with the stock factory clutch linkage, regardless if it is mechanical or hydraulic. The amount of throw-out bearing travel is critical for proper clutch release and apply. Many later model vehicles are equipped with a hydraulic throw-out bearing and master cylinder assembly. Typically with OEM applications the throw-out bearing travel is .440” - .445”. This clutch is designed to operate within these factory tolerances!

When installing an aftermarket conversion kit (mechanical linkage to hydraulic system) or replacing a factory clutch master cylinder you must be certain the amount of throw out bearing travel remains correct for your application. Bore size on the clutch master cylinder is extremely important!! Most factory hydraulic master cylinders are ¾” bore. Aftermarket conversion kits may be equipped with ¾”, 13/16” or 7/8” diameter bores. While this does not seem to be a big difference it may cause clutch malfunction, inadequate release or too much release, increasing pedal effort as well as other problems. Keep in mind bigger is not always better. If your stock clutch master cylinder was ¾” and you change to a 7/8” clutch master cylinder you will end up with too much throw out bearing travel with the same pedal stroke. This will cause the throw out bearing to push the clutch fingers (or diaphragm) too far into the pressure plate assembly and damage the pressure plate components.

If mixing and matching aftermarket hydraulic throw out bearing components; be sure to check with the aftermarket manufacturer to be certain the components are compatible!

Throw Out Bearing Travel Tech Tip

This McLeod multi disc clutch assembly (RST, RXT or Street Twin) is designed to operate with the stock factory clutch linkage, regardless if it is mechanical or hydraulic. The amount of throw-out bearing travel is critical for proper clutch release and apply. Many later model vehicles are equipped with a hydraulic throw-out bearing and master cylinder assembly. Typically with OEM applications the throw-out bearing travel is .440” - .445”. This clutch is designed to operate within these factory tolerances!

When installing an aftermarket conversion kit (mechanical linkage to hydraulic system) or replacing a factory clutch master cylinder you must be certain the amount of throw out bearing travel remains correct for your application. Bore size on the clutch master cylinder is extremely important!! Most factory hydraulic master cylinders are ¾” bore. Aftermarket conversion kits may be equipped with ¾”, 13/16” or 7/8” diameter bores. While this does not seem to be a big difference it may cause clutch malfunction, inadequate release or too much release, increasing pedal effort as well as other problems. Keep in mind bigger is not always better. If your stock clutch master cylinder was ¾” and you change to a 7/8” clutch master cylinder you will end up with too much throw out bearing travel with the same pedal stroke. This will cause the throw out bearing to push the clutch fingers (or diaphragm) too far into the pressure plate assembly and damage the pressure plate components.

If mixing and matching aftermarket hydraulic throw out bearing components; be sure to check with the aftermarket manufacturer to be certain the components are compatible!

#10

Former Vendor

Ok, makes sense. I'm between a rock and a hard place so to speak. Slave is bottomed out but touching the pressure plate fingers. Adding a shim would give more travel, but make it like you are riding the clutch.

I'll try to measure tonight and see if the bearing is moving within the 0.440" to 0.445" range. I don't think an over-extension has occurred. The fingers would be bent downward and not touching the bearing plus the slave would have over-extended and blown out the seals.

Either way, the driveline is coming out this week. Pump Gas Invitational is May 13, 2017. I sent the spare RXT 1000 back to McLeod to be upgraded to the 1200. I'm wondering if I should go with something that has more capacity since the car is getting bigger turbos later this year.

I'll try to measure tonight and see if the bearing is moving within the 0.440" to 0.445" range. I don't think an over-extension has occurred. The fingers would be bent downward and not touching the bearing plus the slave would have over-extended and blown out the seals.

Either way, the driveline is coming out this week. Pump Gas Invitational is May 13, 2017. I sent the spare RXT 1000 back to McLeod to be upgraded to the 1200. I'm wondering if I should go with something that has more capacity since the car is getting bigger turbos later this year.

#11

Melting Slicks

Thread Starter

A couple of more tips:

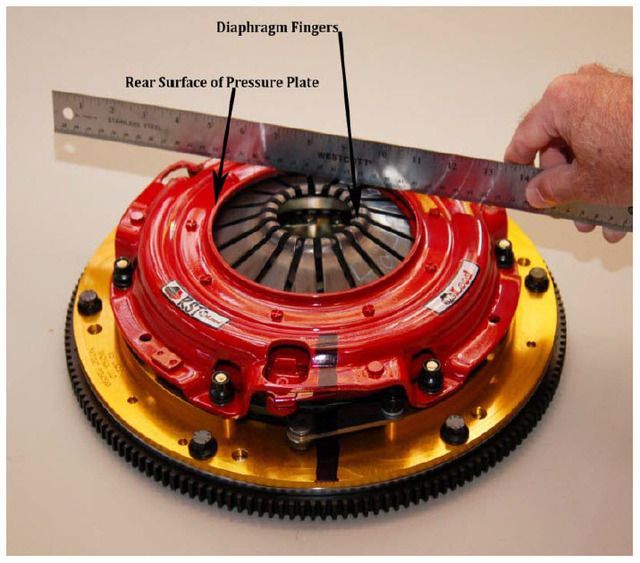

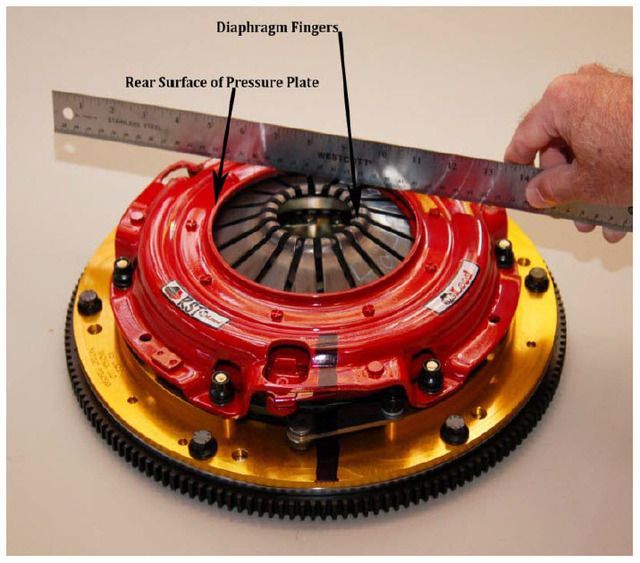

12) Check diaphragm finger height at this time by placing a straight edge onto the pressure plate across the finger opening. All of the fingers should be below the rear surface of the pressure plate. Figure 7.

Figure 7

13) Continue with the bell-housing, throw-out bearing and transmission installation.

14) Clutch release clearance can be checked at this point, you should have .020” - .025” clearance between each disc at full clutch release.

12) Check diaphragm finger height at this time by placing a straight edge onto the pressure plate across the finger opening. All of the fingers should be below the rear surface of the pressure plate. Figure 7.

Figure 7

13) Continue with the bell-housing, throw-out bearing and transmission installation.

14) Clutch release clearance can be checked at this point, you should have .020” - .025” clearance between each disc at full clutch release.

#12

Melting Slicks

Thread Starter

What type of multi-disc clutches do you have available that fit in a C5 bellhousing and can handle > 1200 ft-lbs? I'm also looking for something that is drag-strip friendly. This clutch didn't engage too harshly on the launch. It was a good blend of slip and grip.

#13

Melting Slicks

Here's one of the tech tips from McLeod:

Throw Out Bearing Travel Tech Tip

This McLeod multi disc clutch assembly (RST, RXT or Street Twin) is designed to operate with the stock factory clutch linkage, regardless if it is mechanical or hydraulic. The amount of throw-out bearing travel is critical for proper clutch release and apply. Many later model vehicles are equipped with a hydraulic throw-out bearing and master cylinder assembly. Typically with OEM applications the throw-out bearing travel is .440” - .445”. This clutch is designed to operate within these factory tolerances!

When installing an aftermarket conversion kit (mechanical linkage to hydraulic system) or replacing a factory clutch master cylinder you must be certain the amount of throw out bearing travel remains correct for your application. Bore size on the clutch master cylinder is extremely important!! Most factory hydraulic master cylinders are ¾” bore. Aftermarket conversion kits may be equipped with ¾”, 13/16” or 7/8” diameter bores. While this does not seem to be a big difference it may cause clutch malfunction, inadequate release or too much release, increasing pedal effort as well as other problems. Keep in mind bigger is not always better. If your stock clutch master cylinder was ¾” and you change to a 7/8” clutch master cylinder you will end up with too much throw out bearing travel with the same pedal stroke. This will cause the throw out bearing to push the clutch fingers (or diaphragm) too far into the pressure plate assembly and damage the pressure plate components.

If mixing and matching aftermarket hydraulic throw out bearing components; be sure to check with the aftermarket manufacturer to be certain the components are compatible!

Throw Out Bearing Travel Tech Tip

This McLeod multi disc clutch assembly (RST, RXT or Street Twin) is designed to operate with the stock factory clutch linkage, regardless if it is mechanical or hydraulic. The amount of throw-out bearing travel is critical for proper clutch release and apply. Many later model vehicles are equipped with a hydraulic throw-out bearing and master cylinder assembly. Typically with OEM applications the throw-out bearing travel is .440” - .445”. This clutch is designed to operate within these factory tolerances!

When installing an aftermarket conversion kit (mechanical linkage to hydraulic system) or replacing a factory clutch master cylinder you must be certain the amount of throw out bearing travel remains correct for your application. Bore size on the clutch master cylinder is extremely important!! Most factory hydraulic master cylinders are ¾” bore. Aftermarket conversion kits may be equipped with ¾”, 13/16” or 7/8” diameter bores. While this does not seem to be a big difference it may cause clutch malfunction, inadequate release or too much release, increasing pedal effort as well as other problems. Keep in mind bigger is not always better. If your stock clutch master cylinder was ¾” and you change to a 7/8” clutch master cylinder you will end up with too much throw out bearing travel with the same pedal stroke. This will cause the throw out bearing to push the clutch fingers (or diaphragm) too far into the pressure plate assembly and damage the pressure plate components.

If mixing and matching aftermarket hydraulic throw out bearing components; be sure to check with the aftermarket manufacturer to be certain the components are compatible!

#14

Safety Car

Troubleshooting

Last weekend I bled the clutch system and made sure there wasn't any air. A mity vac was used to pull a vacuum and cause any bubbles to rise to the surface. Next, the remote bleed line was opened and submerged in a bottle of brake fluid. Vacuum was re-established drawing fresh fluid through the slave, master, and reservoir. Finally, the remote bleeder was used via the clutch pedal to push fluid from the master cylinder to the slave and out to a bottle of brake fluid. No bubbles were observed during this final step.

With the wheels off the ground, the trans in 1st gear, and clutch pedal depressed, the results were the same. The rear wheels were still very hard to turn.

Tonight I pulled the driver side downpipe and inspection cover and found the slave cylinder bottomed out against the aluminum base.

Here’s a video from tonight showing the slave cylinder is functioning but it can’t extend far enough to fully release the clutch.

Here’s a new stock slave cylinder showing approximately how much travel is available.

Last weekend I bled the clutch system and made sure there wasn't any air. A mity vac was used to pull a vacuum and cause any bubbles to rise to the surface. Next, the remote bleed line was opened and submerged in a bottle of brake fluid. Vacuum was re-established drawing fresh fluid through the slave, master, and reservoir. Finally, the remote bleeder was used via the clutch pedal to push fluid from the master cylinder to the slave and out to a bottle of brake fluid. No bubbles were observed during this final step.

With the wheels off the ground, the trans in 1st gear, and clutch pedal depressed, the results were the same. The rear wheels were still very hard to turn.

Tonight I pulled the driver side downpipe and inspection cover and found the slave cylinder bottomed out against the aluminum base.

Here’s a video from tonight showing the slave cylinder is functioning but it can’t extend far enough to fully release the clutch.

Here’s a new stock slave cylinder showing approximately how much travel is available.

#15

Safety Car

I wonder if a shim behind the slave would help, but since it gets worse with heat it might not be enough. This is what led me down the path to auto swap, but I know you'd rather buy a minivan than do that lol.

#16

I had issues with my RST. I put the tick master in thinking i wasn't getting full engagement. Ended up putting a shim behind the slave this time and backing down the master cylinders throw so i wouldn't over extend the slave.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

#17

Safety Car

I had issues with my RST. I put the tick master in thinking i wasn't getting full engagement. Ended up putting a shim behind the slave this time and backing down the master cylinders throw so i wouldn't over extend the slave.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

#18

Melting Slicks

Thread Starter

In regards to the auto, I wouldn't buy a mini-van with the money required for an auto swap, but I could buy a dedicated quarter mile car that is much easier to work on and would be way faster.

I'll keep hashing out these details. I know the car is at a handicap with the 6 speed for the quarter but it has held it's own against some fast autos and won 3rd a few years ago in a True Street event. It will go faster once I sort out this clutch system/shifting issue. I've never measured anything. If the manufacturer recommends 0.025" clearance then that's where it's headed.

#19

Melting Slicks

Thread Starter

I'm having the same issue. When i try to put into gear the car started to move forward with pedal pressed down to the floor. Reverse is even worst. Sometimes i have to shut the car off put it in reverse to work. When i installed this clutch (RXT twin) i did not know about this measuring BS. When i jack up the rear and put it into gear the tires turn pretty fast while the clutch is pushed in. I'm going to try the mantic twin when this clutch is smoked. I've been living with this situation for awhile now, just don't feel like changing the clutch again. I learned how to get it into gear. My neighbor tried to drive my car and had the hardest problem driving it this way, but like i said i figured out ways to make it useable until i change it out. I heard it's a hit or miss with these clutches. And the chatter is getting worst.

I had issues with my RST. I put the tick master in thinking i wasn't getting full engagement. Ended up putting a shim behind the slave this time and backing down the master cylinders throw so i wouldn't over extend the slave.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

I still have some shifting issues, but once it gets warmed up it seems to be better. I'm interested to see how this thread goes because i didn't measure anything either. Just send it and see what happens lol.

#20

Melting Slicks

Thread Starter