ACA HID install prep - bulb jiggle "fix"

#1

Team Owner

Thread Starter

Thanks to jdmvette and Rupert for the posts detailing your fixes for ACA HID bulb jiggle. I took your suggestions to heart and opened mine up tonight before installing tomorrow and applied a similar fix.

Despite the high build quality of these lights, there seems to be an issue concerning bulb jiggle that plagues them. The jiggle appears to be due to the way the bulb socket is fitted into the housing.

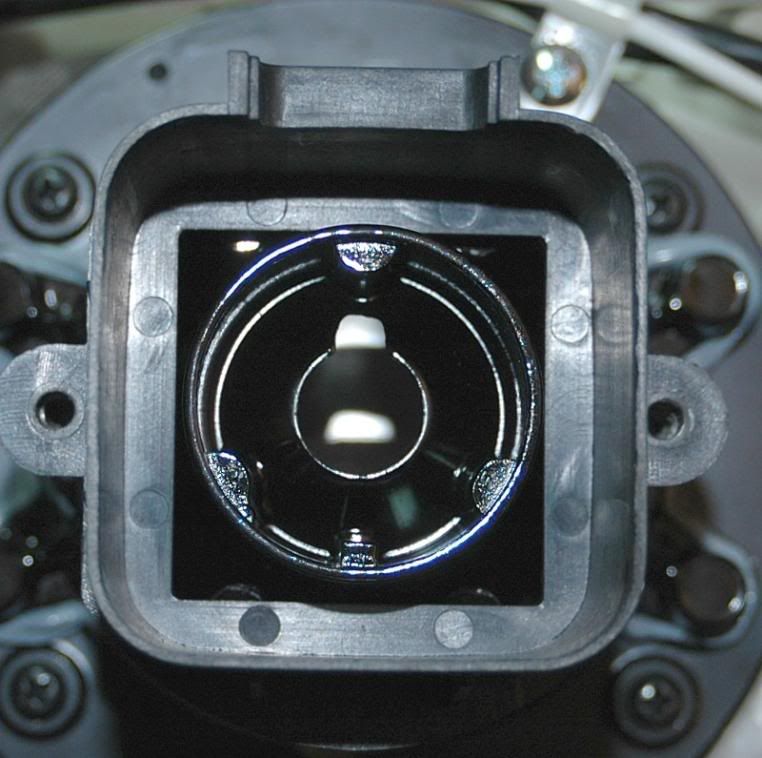

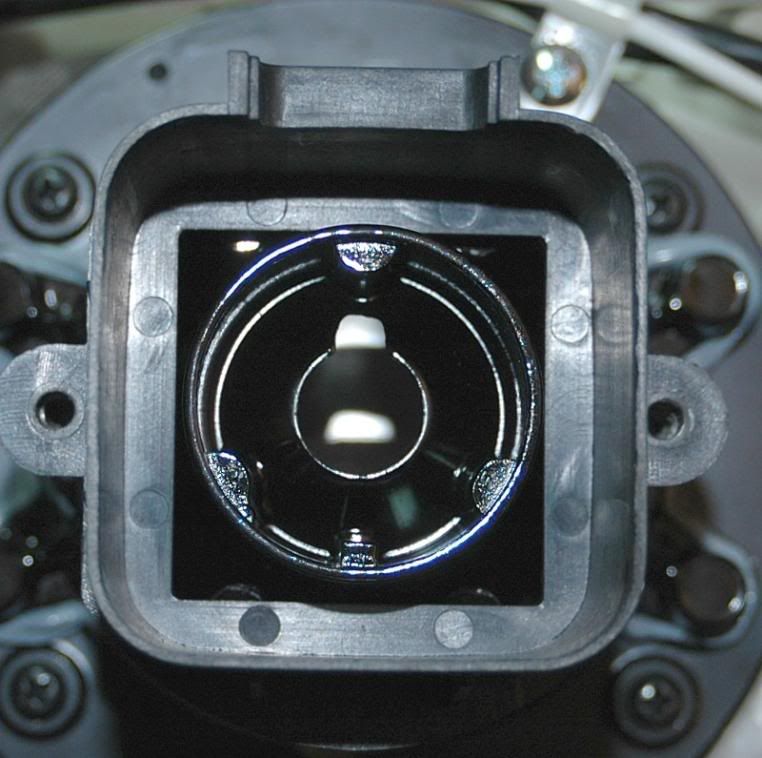

Here's a shot of the bulb as it sits in the housing. Notice the large gaps between the socket and housing. You can literally wobble the socket easily back and forth in the housing and it will fall out if you turn it upside-down.

The housing has a keyed recess that the socket simply slides into and sits there loose. There is no spring-loaded locking mechanism typical to headlight bulb mounts that hold them securely in place. The bulb stability depends on the axial squeeze placed on the back of the bulb socket, sandwiching it between the shoulder and the rear cap.

A pic of the housing without the bulb. The socket simply rests on the shoulder without being retained.

Here's the bulb and socket.

The cap has a thin piece of foam to act as a spacer and shock absorber to try and stabilize the bulb.

I took a cue from the other guys and found a sheet of high-durometer EPDM I had laying around to use to stabilize the socket. I cut some pieces to fit very snugly into the gaps and pushed them securely in place.

My HID bulb sockets are now rock-solid. There is absolutely no play left and the EPDM should remain stable over a long period of time. The pieces I cut are full-depth so they can't loosen and slip down into the housing. They'll never move out of place.

I had some thinner rubber sheet I cut to shape to put in the cap behind the socket to try and create more compression force but the assembly was already so tight and solid that I was afraid I'd strip the screw holes in the housing and that the cap gaskets wouldn't seal so I left them off. The caps went back on very tightly as it was.

Also, I think that eliminating the wobble the socket has side-to-side is a more effective approach as you can only put so much axial load on the screws before they strip the threads, Without the caps on, my bulbs are quite stable so the rear loading from the cap is less critical and I shouldn't have to worry about overtightening or, hopefully, having to go back in to retighten anytime soon.

Despite the high build quality of these lights, there seems to be an issue concerning bulb jiggle that plagues them. The jiggle appears to be due to the way the bulb socket is fitted into the housing.

Here's a shot of the bulb as it sits in the housing. Notice the large gaps between the socket and housing. You can literally wobble the socket easily back and forth in the housing and it will fall out if you turn it upside-down.

The housing has a keyed recess that the socket simply slides into and sits there loose. There is no spring-loaded locking mechanism typical to headlight bulb mounts that hold them securely in place. The bulb stability depends on the axial squeeze placed on the back of the bulb socket, sandwiching it between the shoulder and the rear cap.

A pic of the housing without the bulb. The socket simply rests on the shoulder without being retained.

Here's the bulb and socket.

The cap has a thin piece of foam to act as a spacer and shock absorber to try and stabilize the bulb.

I took a cue from the other guys and found a sheet of high-durometer EPDM I had laying around to use to stabilize the socket. I cut some pieces to fit very snugly into the gaps and pushed them securely in place.

My HID bulb sockets are now rock-solid. There is absolutely no play left and the EPDM should remain stable over a long period of time. The pieces I cut are full-depth so they can't loosen and slip down into the housing. They'll never move out of place.

I had some thinner rubber sheet I cut to shape to put in the cap behind the socket to try and create more compression force but the assembly was already so tight and solid that I was afraid I'd strip the screw holes in the housing and that the cap gaskets wouldn't seal so I left them off. The caps went back on very tightly as it was.

Also, I think that eliminating the wobble the socket has side-to-side is a more effective approach as you can only put so much axial load on the screws before they strip the threads, Without the caps on, my bulbs are quite stable so the rear loading from the cap is less critical and I shouldn't have to worry about overtightening or, hopefully, having to go back in to retighten anytime soon.

The following users liked this post:

HotRod Junkie (11-16-2020)

#3

Team Owner

Thread Starter

The ideal mount for these would be something like a quarter-turn locking interface between the socket base and mating housing that eliminates all the wobble and doesn't depend on end-loading the bulb to keep it in place. Look at the high beam bulb right next to it - the HID should mount smilarly.

I couldn't see a way to easily modify the housing to accomplish that without risking the housing integrity. Definitely a reason to continue looking for ways to improve upon this solution. In the meantime, Mrs. Patches needs to see at night.

I couldn't see a way to easily modify the housing to accomplish that without risking the housing integrity. Definitely a reason to continue looking for ways to improve upon this solution. In the meantime, Mrs. Patches needs to see at night.

#5

Team Owner

Thread Starter

Totally agree. It appears they may not have done any dynamic testing to check for stability.

On the bright side, I am already halfway through the install with no issues so far and am ready to put these puppies in the car. I will be posting the results after I've had a chance to finish up and create an installation thread.

On the bright side, I am already halfway through the install with no issues so far and am ready to put these puppies in the car. I will be posting the results after I've had a chance to finish up and create an installation thread.

#6

Le Mans Master

#7

Night Owl for life

Member Since: Nov 2003

Location: Bugs Bunny should'a made a left turn here

Posts: 23,194

Received 3,241 Likes

on

1,664 Posts

#8

Team Owner

Thread Starter

I just finished the install and all is well so I'm going to clean everything up and start uploading my pics to my desktop.

Thanks again, jdmvette.

#9

Le Mans Master

I have tried, all links come back as dead and phone numbers as disconnected.

Pretty sure jdmvette has tried as well.

#11

Le Mans Master

it should take about 2hrs for someone that has never done one before.

as long as you're mechanically inclined to begin with.

you need to remove your old headlight housings, run the new wiring harnesses, and mount the HID ballasts.

plus there's a little "modification" that needs to be done to the headlight doors to gain a little more adjustment room for the new housings.

then, of course, you will need to re-aim your new headlights.

#12

Le Mans Master

Not really any harder than installing the bulb/ballast/harness kit....depending on how you do it. The only real difference is removing the OEM headlight assembly.

I would say three hours depending on how many beers are involved

#13

Tech Contributor

Member Since: Aug 1999

Location: Should this thoughtful, valuable contribution meet with no acknowledgement or 'thanks' this post----

Posts: 16,382

Received 399 Likes

on

257 Posts

Patches, I'm looking forward to your color pics. The instructions I have are all black and white photos which makes it difficult to make out the details.

#14

Drifting

Member Since: Jun 2001

Location: Milwaukee WI

Posts: 1,279

Likes: 0

Received 0 Likes

on

0 Posts

Excellent tip for an amazing write-up!

Did you ever measure the thickness of the EPDM that you used? Where can I buy some of that if I don't happen to have it laying around?

It seems like Patches always has whatever he needs just laying around. I wish my garage worked liked that!

Did you ever measure the thickness of the EPDM that you used? Where can I buy some of that if I don't happen to have it laying around?

It seems like Patches always has whatever he needs just laying around. I wish my garage worked liked that!

#15

Team Owner

Thread Starter

1/8" thick high-durometer EPDM. I believe I got mine from mcmaster.com some time ago.

Since doing this, I've realized the entire headlight assembly needs to be made more rigid to eliminate the rest of the shaking. With the sharp cutoff the HIDs have, the jiggling inherent to this pop-up headlight design is magnified. You normally don't see this effect with the stock headlights because the edges of the light are so diffuse. I'll post what I do when I have that finished. I think a couple of others have already shored their's up.

Since doing this, I've realized the entire headlight assembly needs to be made more rigid to eliminate the rest of the shaking. With the sharp cutoff the HIDs have, the jiggling inherent to this pop-up headlight design is magnified. You normally don't see this effect with the stock headlights because the edges of the light are so diffuse. I'll post what I do when I have that finished. I think a couple of others have already shored their's up.

Last edited by Patches; 09-07-2009 at 04:09 PM.

#16

Instructor

Member Since: Jul 2004

Location: Rancho Bernardo CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

1/8" thick high-durometer EPDM. I believe I got mine from mcmaster.com some time ago.

Since doing this, I've realized the entire headlight assembly needs to be made more rigid to eliminate the rest of the shaking. With the sharp cutoff the HIDs have, the jiggling inherent to this pop-up headlight design is magnified. You normally don't see this effect with the stock headlights because the edges of the light are so diffuse. I'll post what I do when I have that finished. I think a couple of others have already shored their's up.

Since doing this, I've realized the entire headlight assembly needs to be made more rigid to eliminate the rest of the shaking. With the sharp cutoff the HIDs have, the jiggling inherent to this pop-up headlight design is magnified. You normally don't see this effect with the stock headlights because the edges of the light are so diffuse. I'll post what I do when I have that finished. I think a couple of others have already shored their's up.

Patches, first of all, thank you for creating such a great set of install instructions.

I have installed the ACA's, and am having the jitter problem that seems to be based on the entire headlight assembly jitter, rather than the housing. Please let me know if you find a major fix for this.

#19

Team Owner

Thread Starter

Let me add one more critical update here before this one gets locked down for having cobwebs hangin' all over it.

The bulb jiggle fix did help the issue somewhat but the primary issue here stems from the fact that the C5 headlight linkage and support structure was originally designed for halogen lamps and so did not require the rock-solid mount that HID's do due to their discreet cutoff and precise beam spread. This is why the C6 has fixed, exposed mounts for its HID's and so do, for that matter most modern cars with HID/Xenon lighting systems such as my dd Mini Cooper S with Bi-Xenons.

In subsequent forays into aftermarket HID setups for the C5, I received one of the first prototype sets of the low-opening JWM HID's and, in the process of installing those, fortified the stability of the headlight bracket/pivot system by reducing the slop as much as possible and also by installing the stabilizing spacer at the back of the headlight the designer so cleverly built into the system. So far, that seems to be the best combination of jiggle-mitigation I have seen short of going to a fixed-headlight mounting system.

So, although the fix above does help, approaching the problem from the stabilization/fortification of the housing pivot and support structure should produce the most significant results for those wnating to reduce the annoying jiggle in an HID setup installed in a set of retractable C5 headlights.

The bulb jiggle fix did help the issue somewhat but the primary issue here stems from the fact that the C5 headlight linkage and support structure was originally designed for halogen lamps and so did not require the rock-solid mount that HID's do due to their discreet cutoff and precise beam spread. This is why the C6 has fixed, exposed mounts for its HID's and so do, for that matter most modern cars with HID/Xenon lighting systems such as my dd Mini Cooper S with Bi-Xenons.

In subsequent forays into aftermarket HID setups for the C5, I received one of the first prototype sets of the low-opening JWM HID's and, in the process of installing those, fortified the stability of the headlight bracket/pivot system by reducing the slop as much as possible and also by installing the stabilizing spacer at the back of the headlight the designer so cleverly built into the system. So far, that seems to be the best combination of jiggle-mitigation I have seen short of going to a fixed-headlight mounting system.

So, although the fix above does help, approaching the problem from the stabilization/fortification of the housing pivot and support structure should produce the most significant results for those wnating to reduce the annoying jiggle in an HID setup installed in a set of retractable C5 headlights.

although in the meantime, that's a great solution Patches. I suppose the key is in the thickness of the epdm, correct?

although in the meantime, that's a great solution Patches. I suppose the key is in the thickness of the epdm, correct?