[Z06] Root Cause for Excessive Guide Wear Found

#701

Well since someone was there to tell us about it and you said the valves were cut apart "with very little heat" I was assuming the temperature was at least less than 206 degrees...so are you telling us that the valves which were inspected and you found "The sodium was already turned to a powder state inside." were inspected at a temperature above 206 degrees and that you consider 206 degrees "very little heat"

It's obvious that you and/or the reputable shop invloved thought there was something wrong with the "powdered state inside" the exhaust valve...my point is, that unless the inspection was being done at a temperature above 206 degrees (which seemed to NOT be the case given you comment about "with very little heat") someone doesn't have a clue about what's going on.

And now you have the audacity to ask me where it was you said the cutting apart happened at room temperature

Cheers, Paul.

It's obvious that you and/or the reputable shop invloved thought there was something wrong with the "powdered state inside" the exhaust valve...my point is, that unless the inspection was being done at a temperature above 206 degrees (which seemed to NOT be the case given you comment about "with very little heat") someone doesn't have a clue about what's going on.

And now you have the audacity to ask me where it was you said the cutting apart happened at room temperature

Cheers, Paul.

The sodium should not be powder at room tempurature, nor should it ever be powder in the stem. It is an alkali metal, it will have the consistency of a hard clay, and have a slight shimmer to it. Just figured i would clarify this. And i would venture a guess that there was moisture in the stem which reacted with and produced some sort of Na-X compound possible NaCl to make the crystalline powder he is describing.

#702

Burning Brakes

Thread Starter

I'm suggesting that a loose (I know that most wouldn't consider 0.0025" loose) fit let coking get started up in the guide. Coking eats guides like sandpaper would.

Your thoughts?

John

John

#703

You do realise you didn't actually check WIPE pattern, you took the easy route and merely checked a witness mark.

And why would my "heart hit the floor" when you finally got around to doing something I did years ago...in fact I am honoured that you 'the forum expert' has finally chosen to follow my lead even if you didn't really do the whole job

Cheers, Paul.

And why would my "heart hit the floor" when you finally got around to doing something I did years ago...in fact I am honoured that you 'the forum expert' has finally chosen to follow my lead even if you didn't really do the whole job

Cheers, Paul.

Is there anything else I need to do to indicate that I have done as much as is practical to remove myself from contention for the dropped valve club?

But seriously, is that all you got????

Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.

Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.

Very interesting...every valve has coking up inside the guide. Only two of mine did...the two really bad ones. It's the bottom of your guides that were all out. The tops of your guides were all in spec...although looser than the build I just did. All but one of mine are at 0.0015". The valve that was in 6 (worst guide by far) wound up at 0.3123" after I polished the crap out of it. I reamed to 0.314 so this one has clearance of 0.0017".

I'm suggesting that a loose (I know that most wouldn't consider 0.0025" loose) fit let coking get started up in the guide. Coking eats guides like sandpaper would.

Your thoughts?

John

John

I'm suggesting that a loose (I know that most wouldn't consider 0.0025" loose) fit let coking get started up in the guide. Coking eats guides like sandpaper would.

Your thoughts?

John

JohnBut I'm leaning towards them having been out of spec from the time they were built.

These came from off an '06. So if I'm right, then like some in here have speculated, then they were sending out heads with out of spec guides from way back.

I agree with you about the coking.

This particular case doesn't fit with some of what we have already discussed here.

I'm wondering how the guides got out of spec in these heads before I got them. And I'm thinking the guy whose car they were on, got a car with out of spec guides from the factory.

And now after I get them and they are installed in my car using my same pushrods and rockers, my geometry does not appear to be bad.

Last edited by '06 Quicksilver Z06; 12-19-2012 at 10:37 AM.

#704

Drifting

Member Since: Feb 2006

Location: Cocoa Florida

Posts: 1,890

Likes: 0

Received 0 Likes

on

0 Posts

if the bottoms were out and the tops were not, could be thermal expansion toward the bottom of the valve? once theres space for gunk to get in there its all she wrote.

my assumption though, im learning as you smarter folks post.

my assumption though, im learning as you smarter folks post.

#705

Melting Slicks

No I only checked the pattern on my rockers and checked a witness mark.

Is there anything else I need to do to indicate that I have done as much as is practical to remove myself from contention for the dropped valve club?

But seriously, is that all you got???? Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.

Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.

Is there anything else I need to do to indicate that I have done as much as is practical to remove myself from contention for the dropped valve club?

But seriously, is that all you got????

Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.

Trying to attack me because I didn't do my own heads and cam install???? Ask how many Katech customers did their own installs.Cheers, Paul.

Last edited by MTIRC6Z; 11-28-2012 at 12:23 PM.

#706

Safety Car

Sorry, by "whole job" I was only referring to the witness vs the wipe, not the head/cam install. I wouldn't "attack" anybody because they didn't do their own work...I just thought if you're actually in there doing the witness thing it really isn't much more effort to also do the wipe check (aka. the whole job). And it wasn't meant as an attack, I was just being very precise (you tend to force this) in that I wasn't technically a proponent of the witness thing, but I was (a LONG time ago) of the wipe test.

Cheers, Paul.

Cheers, Paul.

#707

Burning Brakes

Thread Starter

That's just it John, I don't know.

But I'm leaning towards them having been out of spec from the time they were built.

These came from off an '06. So if I'm right, then like some in here have speculated, then they were sending out heads with out of spec guides from way back.

I agree with you about the coking.

This particular case doesn't fit with some of what we have already discussed here.

I'm wondering how the guides got out of spec in these heads before I got them. And I'm thinking the guy whose car they were on, got a car with out of spec guides from the factory.

And now after I get them and they are installed in my car using my same pushrods and rockers, my geometry does not appear to be bad.

But I'm leaning towards them having been out of spec from the time they were built.

These came from off an '06. So if I'm right, then like some in here have speculated, then they were sending out heads with out of spec guides from way back.

I agree with you about the coking.

This particular case doesn't fit with some of what we have already discussed here.

I'm wondering how the guides got out of spec in these heads before I got them. And I'm thinking the guy whose car they were on, got a car with out of spec guides from the factory.

And now after I get them and they are installed in my car using my same pushrods and rockers, my geometry does not appear to be bad.

I see two paterns of wear emerging...X and Delta, if you will.

X is high wear at both ends of the guide but low in the middle.

Delta is little wear at the top, more in the middle and more again at the bottom.

I think I've seen more of the X type.

Bad geometry is going to cause the X type of wear.

Loose guides from the factory, allowing heat to go up the guides, will cause the delta type.

Not saying anything certain, just formulating possibilities.

John

John

#708

Melting Slicks

The sodium should not be powder at room tempurature, nor should it ever be powder in the stem. It is an alkali metal, it will have the consistency of a hard clay, and have a slight shimmer to it. Just figured i would clarify this. And i would venture a guess that there was moisture in the stem which reacted with and produced some sort of Na-X compound possible NaCl to make the crystalline powder he is describing.

And, at least if I'm wrong about this I will have learned something today thanks to both you and ramair

Cheers, Paul.

#709

Burning Brakes

Just for the record. All 3 sets that i purchased and had WCCH go through to change to the SS valves and new guides, every single one of the factory exhaust valves had severe coking of oil on each valve stem behind the valve. Also, one set that i did run before making the switch had oil burning issues due to bad guides and and every plug i pulled had oil on or around the thread. Upon teardown the valve seals were all intact. They had no more then 3,000 miles on them.

#710

Burning Brakes

Thread Starter

Just for the record. All 3 sets that i purchased and had WCCH go through to change to the SS valves and new guides, every single one of the factory exhaust valves had severe coking of oil on each valve stem behind the valve. Also, one set that i did run before making the switch had oil burning issues due to bad guides and and every plug i pulled had oil on or around the thread. Upon teardown the valve seals were all intact. They had no more then 3,000 miles on them.

John

John

#711

I'm surmising these would have passed the witness mark test.

I see two paterns of wear emerging...X and Delta, if you will.

X is high wear at both ends of the guide but low in the middle.

Delta is little wear at the top, more in the middle and more again at the bottom.

I think I've seen more of the X type.

Bad geometry is going to cause the X type of wear.

Loose guides from the factory, allowing heat to go up the guides, will cause the delta type.

Not saying anything certain, just formulating possibilities.

John

John

I see two paterns of wear emerging...X and Delta, if you will.

X is high wear at both ends of the guide but low in the middle.

Delta is little wear at the top, more in the middle and more again at the bottom.

I think I've seen more of the X type.

Bad geometry is going to cause the X type of wear.

Loose guides from the factory, allowing heat to go up the guides, will cause the delta type.

Not saying anything certain, just formulating possibilities.

John

JohnThink about it. What changed?

The guides.

Richard told me that the valve to stem tolerances on the heads they send out are at a range of .0012"-.0015" on the exhaust side. .0012"-.0015" on the intake side.

So when I got these heads back, that was the valve to stem clearance.

However who knows what the valve to stem clearance was when the original owner got them in his new car?

So I'm thinking the original guides started out bad, and ended up worse.

I don't think the pedestals were mismachined, or that there are any other errors in the bare heads.

Now that the heads have decent valve guides in them, the geometry checks out.

If there was a machining error in the castings, then where did it go?

I believe that the original powdered metal guides may have been bad in these heads from the start.

I think that what just might have happened here at this stage of the discussion, and with my doing your test and looking at the history and other specefics of my "new" heads, is possibly concrete proof that GM's statement about this being a 2008-2011 problem, is bogus.

There is apparently not a damn thing wrong with my castings. But yet the guides in this set of heads were smoked at 31K miles. And that didn't happen because the machining of the bare heads was bad.

The only path for oil getting in the guides and down the valve stems is by going past the seals. The seals must have started leaking early on...I had this same thought regarding quick's heads. What can cause seals to fail so early on? I think it has to be in your case and quick's case, bad surface finish on the stems is very likely.

John

John

John

JohnLast edited by '06 Quicksilver Z06; 12-19-2012 at 10:39 AM.

#712

Burning Brakes

Well since someone was there to tell us about it and you said the valves were cut apart "with very little heat" I was assuming the temperature was at least less than 206 degrees...so are you telling us that the valves which were inspected and you found "The sodium was already turned to a powder state inside." were inspected at a temperature above 206 degrees and that you consider 206 degrees "very little heat"

It's obvious that you and/or the reputable shop invloved thought there was something wrong with the "powdered state inside" the exhaust valve...my point is, that unless the inspection was being done at a temperature above 206 degrees (which seemed to NOT be the case given you comment about "with very little heat") someone doesn't have a clue about what's going on.

And now you have the audacity to ask me where it was you said the cutting apart happened at room temperature

Cheers, Paul.

It's obvious that you and/or the reputable shop invloved thought there was something wrong with the "powdered state inside" the exhaust valve...my point is, that unless the inspection was being done at a temperature above 206 degrees (which seemed to NOT be the case given you comment about "with very little heat") someone doesn't have a clue about what's going on.

And now you have the audacity to ask me where it was you said the cutting apart happened at room temperature

Cheers, Paul.

#713

Burning Brakes

The only path for oil getting in the guides and down the valve stems is by going past the seals. The seals must have started leaking early on...I had this same thought regarding quick's heads. What can cause seals to fail so early on? I think it has to be in your case and quick's case, bad surface finish on the stems is very likely.

John

John

John

John

#714

Burning Brakes

Thread Starter

1. Seals were bad from day 1.

2. Geometry may have been fine, but bad surface finish caused early seal failure.

3. During assembly, intake seals (not good with heat) were installed on the exhaust valves...hardened from heat and wore out quickly.

John

John

#715

Burning Brakes

The only path for oil getting in the guides and down the valve stems is by going past the seals. The seals must have started leaking early on...I had this same thought regarding quick's heads. What can cause seals to fail so early on? I think it has to be in your case and quick's case, bad surface finish on the stems is very likely.

John

John

John

John

#716

X amount of heat is generated in the combustion chamber; it's transferred to the various parts with which it comes into contact - the head, the piston, the exhaust system, and the valves.

Since the LS7 exhaust valve is bigger than any other LS engine, it's gonna absorb more heat. But it's got the same size stem and guide, so it's trying to pass more heat into the same size 'sink'.

I'll posit that, at similar conditions (throttle position, engine speed, etc.) the combustion temps in the LS7 are higher than the other LS engines, since the static CR is higher. I'm talking partial-throttle here, I presume the boosted engines get hotter at WOT. Note that there is some indication that exhaust valve guides might be an issue in the LS9, although not nearly to the degree seen here.

The LS7 also revs higher, potentially creating more combustion events per unit time - ergo, more heat to dissipate.

I'd feel a lot better if the LS7 had piston oil squirters and thermal barrier-coated exhaust valves.

#717

Burning Brakes

Thread Starter

I had two plugs with dripping wet oil. When I tore down, the seals looked fine to the naked eye...but it's crystal clear that oil was going past them.

John

John

#718

Burning Brakes

Thread Starter

I will have to agree that the surface finish on the exhaust valve could have been unexceptable and in turn wore out the guide. But i do also think like some of the others here that the guides were bad to begin with. Not quite out of spec new, but so close to the spec that any other little contributing factor pushed over the edge fast!

John

John

#719

#720

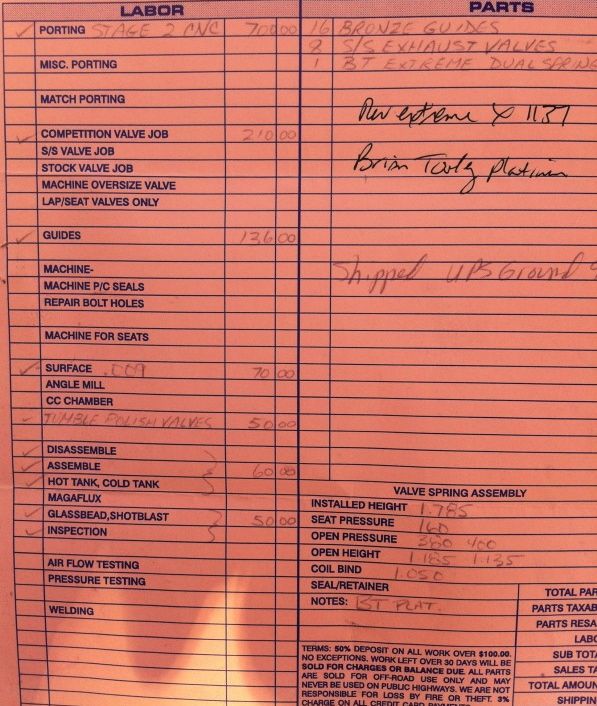

Lot's of good info here from numerous people. For what its worth, here are what my exhaust valves looked like after ~20k miles when I had WCCH rebuild my heads, and this is on a car that had guides perfectly in spec at that point. They don't look nearly as coked up as others posting theirs, and I don't think WCCH did anything to clean them, but maybe they did. Also, I did not have any oil on my plugs when I pulled them, so that test may have some merit.

I'm with those that feel many are leaving the factory at the limit or even slightly beyond, but then I still wonder why the exhaust side is consistently worse than the intake if thats the case. Aren't the guides all the same?

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

I'm with those that feel many are leaving the factory at the limit or even slightly beyond, but then I still wonder why the exhaust side is consistently worse than the intake if thats the case. Aren't the guides all the same?

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]