Deburring and Polishing Engine Parts

#121

Racer

Curious as to why you did the intercooler in white.

In my mind, white reflects more thermal energy than black which absorbs it.

If this portion of the intercooler is intended to remove heat from your air charge, wouldn't it make sense for it to be black so that it absorbs more heat rather than white which would reflect that heat? (In theory...)

In my mind, white reflects more thermal energy than black which absorbs it.

If this portion of the intercooler is intended to remove heat from your air charge, wouldn't it make sense for it to be black so that it absorbs more heat rather than white which would reflect that heat? (In theory...)

#122

You are correct about colors and radiate heat. But colors are only something our minds create because the object is reflecting whatever wavelength weíre seeing.. anywho so since itís boron nitride itís physical properties are what give it itís high thermal conductivity and not itís color but yes a black tinted boron nitride would in theory work better. My intent is to reduce radiant heat as much as possible with heat resistant coatings (exterior/interior) and heat barriers. But yes you are correct that technically black is a better absorber of thermal energy than white but I am not tryin to absorb I am radiating like a ice bong does....By reducing all that radiant heat my high velocity cold air (convection does a really good job of picking up heat) wonít be superheated. Remember air is a horrible conductor of energy but hot metal and fast moving air does a good job of transferring that heat. Remember the ice bong? That air grabs a lot of cold in those few inches so think about how much heat it grabs in a typical 6Ē long intake port thatís surrounded by 220*F + coolant and oil ....Iím just viewing it differently than most for the most part kinda thing...radiating cold air vs absorbing hot air since itís really isochoric. The colder I make the air the closer the molecules are together which increases thermal conductivity along with the water/meth injection removing heat by latent heat of vaporization and by increasing density. I asked for a pro FLIR camera for Christmas so weíll see what the story tells.

Last edited by Petraszewsky; 12-20-2018 at 02:42 PM. Reason: sorry that kinda turned into me blabbing a bit

#123

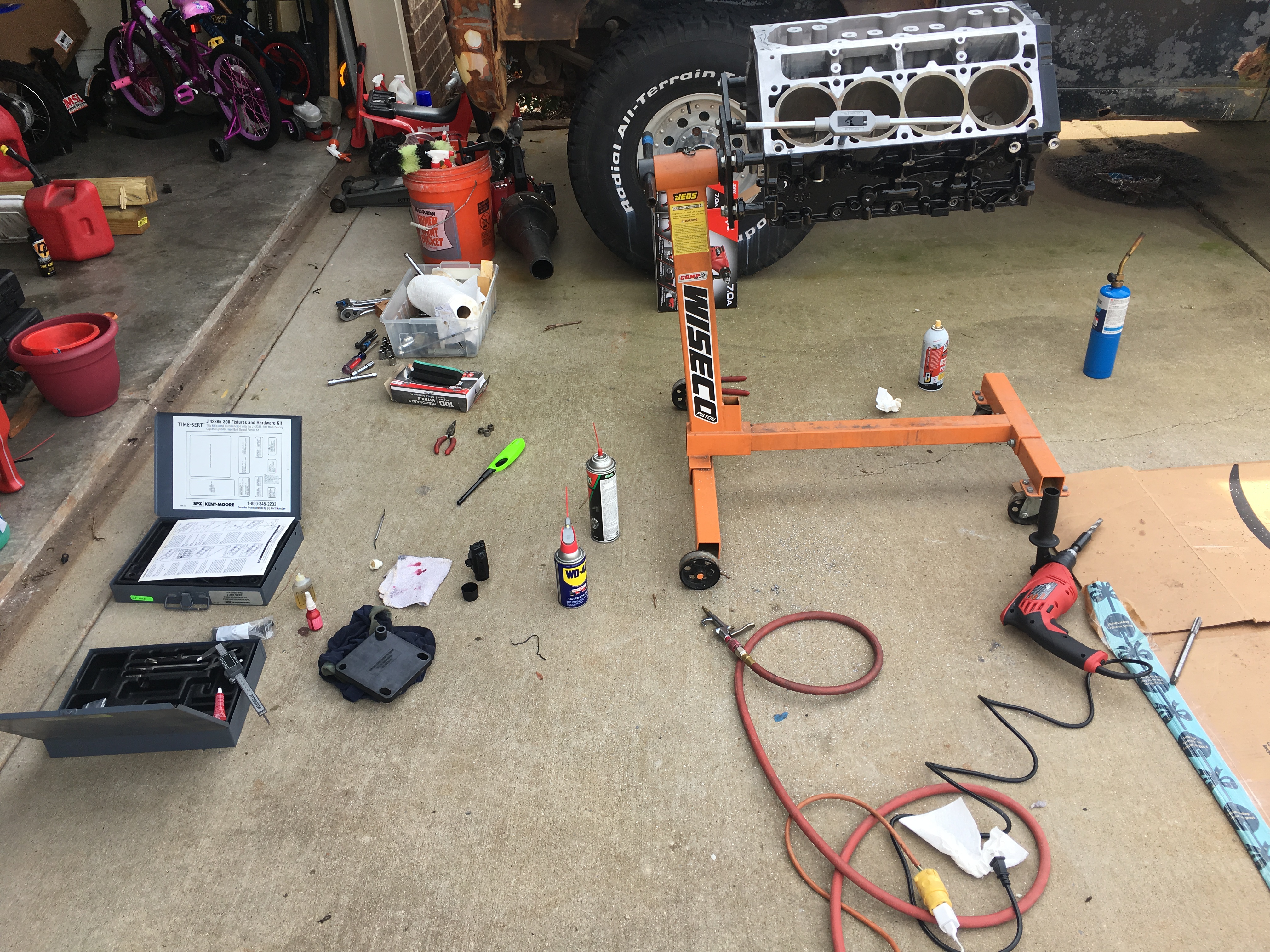

Iíll put together a list but itís truthfully mostly harbor freight stuff, labor, and patience. My 19x20 garage canít be walked or worked in from clutter so itís 99% driveway.

#125

That was the intercooler for the supercharger but I will be doing the radiator and oil coolers in the future as well

The boron nitride has a very high thermal conductivity which will allow more heat energy to be absorbed more readily. Like copper vs aluminum.....copper (400 W/m-K) does a better job of conducting thermal energy than aluminum (200 W/m-K) but that doesn’t mean you can’t improve the ability or capacity to conduct thermal energy which led to the boron nitride (hexagonal boron nitride hBN specifically) because of its superior thermal conductivity.....up to 400 W/m-K at room temperature. Anywho so the reason I coated the intercooler with hBN was to increase its thermal conductivity so that it may cool the air much lower and at a faster rate (time based) by absorbing more of that heat energy from the compressed air and more easily pass it into the coolant that fills the intercooler. I’m also coating the coils on my condensor for my house with it to lower my summer cooling bills. Thankfully boron nitride along with the tungsten and moly have come down in price over the years so we peasants may acquire it.

The boron nitride has a very high thermal conductivity which will allow more heat energy to be absorbed more readily. Like copper vs aluminum.....copper (400 W/m-K) does a better job of conducting thermal energy than aluminum (200 W/m-K) but that doesn’t mean you can’t improve the ability or capacity to conduct thermal energy which led to the boron nitride (hexagonal boron nitride hBN specifically) because of its superior thermal conductivity.....up to 400 W/m-K at room temperature. Anywho so the reason I coated the intercooler with hBN was to increase its thermal conductivity so that it may cool the air much lower and at a faster rate (time based) by absorbing more of that heat energy from the compressed air and more easily pass it into the coolant that fills the intercooler. I’m also coating the coils on my condensor for my house with it to lower my summer cooling bills. Thankfully boron nitride along with the tungsten and moly have come down in price over the years so we peasants may acquire it.

Last edited by Petraszewsky; 12-22-2018 at 12:54 PM.

#127

I’ve had some people ask about what products I’ve used to do this stuff so I made this list

I personally learned about polishing and buffing metal from reading, watching YouTube, and doing it. Patience!!!!

Chicago electric 6” bench top buffer (eye protection and respirator are a MUST!!!)

https://www.google.com/shopping/product/1?lsf=seller:8049,store:3588810996349851 405&prds=pid:10496129544473542068,oid:34 75870454359161297&q=hrbor+freight+biuffe r&hl=en&ei=FaoeXMzzO8O9ggfJ6JuYBg&lsft=g clid:EAIaIQobChMI44i9tq603wIVAsDICh1jXQP FEAQYASABEgJor_D_BwE

6” spiral sewn wheel (for buffing) https://www.pjtool.com/extra-thick-s...iABEgI8s_D_BwE

6” cotton fluff (polishing) https://www.google.com/search?q=6”+cotton++buffing+wheel&tbm=is ch&ved=2ahUKEwigkYWZr7TfAhUUT1MKHZ6KCXoQ 2-cCegQIABAC&oq=6”+cotton++buffing+wheel&g s_l=mobile-gws-wiz-img.3...14280.14882..15529...0.0..0.56.2 58.5......0....1.........30i10.si0s235o4 O8&ei=5KoeXKCPL5SezQKelabQBw&prmd=sivn&b iw=375&bih=553#imgrc=Gix8j7e6roJ-mM

Misc Dialux brand Jewelers rouges (use the chart for rogue type for metal type but experience and practice is best..

Dremel 4000

Flex shaft

Dremel Right angle

Lots of misc dremel bits (they’re cheap)

400 grit 1” /25mm diameter flap sanding wheel for Dremel this one is awesome for tight spaces and very smooth finish (eBay)

Other various size flap wheels and grits (ebay etc)

Misc Dremel felt polishing tips

1200grit EZ Bore Clover brand lapping compound $10 ebay/Amazon

Tungsten disulfide $10 eBay/Amazon

Boron nitride powders $10 ebay/Amazon

Boron paint aerosol $50 ebay/Amazon

boron brushable $30 ebay/Amazon

Molybdenum disulfide $10 what/Amazon

Cerakote products (a little goes a very very long way) (cerakotehightemp.com) they have great promos

Harbor freight blaster 37025 https://m.harborfreight.com/portable...not%20provided

Ebay blast media (120 grit aluminum oxide type?) $50ish 30ish lbs?

Ebay airbrush kit model: Masters ABD Kit-3ab-20 $99ish or less

Central pneumatic 61454 air compressor $159?

3M 07193 paint respirator $20

I would suggest another full face respirator for use with the blasting and wearing coveralls...I did

Nitrile gloves

Paper towels

Acetone

Squirt bottles

Tape

Ingenuity

0000 steel wool

Jewelers loupe 40-60x

old blue jeans

tiny little file set

chamfer bits

Misc flex hones

Manley 40174 valvespring chamfer bit (pac racing makes a cool one as well)

Ummm probably forgetting something

I personally learned about polishing and buffing metal from reading, watching YouTube, and doing it. Patience!!!!

Chicago electric 6” bench top buffer (eye protection and respirator are a MUST!!!)

https://www.google.com/shopping/product/1?lsf=seller:8049,store:3588810996349851 405&prds=pid:10496129544473542068,oid:34 75870454359161297&q=hrbor+freight+biuffe r&hl=en&ei=FaoeXMzzO8O9ggfJ6JuYBg&lsft=g clid:EAIaIQobChMI44i9tq603wIVAsDICh1jXQP FEAQYASABEgJor_D_BwE

6” spiral sewn wheel (for buffing) https://www.pjtool.com/extra-thick-s...iABEgI8s_D_BwE

6” cotton fluff (polishing) https://www.google.com/search?q=6”+cotton++buffing+wheel&tbm=is ch&ved=2ahUKEwigkYWZr7TfAhUUT1MKHZ6KCXoQ 2-cCegQIABAC&oq=6”+cotton++buffing+wheel&g s_l=mobile-gws-wiz-img.3...14280.14882..15529...0.0..0.56.2 58.5......0....1.........30i10.si0s235o4 O8&ei=5KoeXKCPL5SezQKelabQBw&prmd=sivn&b iw=375&bih=553#imgrc=Gix8j7e6roJ-mM

Misc Dialux brand Jewelers rouges (use the chart for rogue type for metal type but experience and practice is best..

Dremel 4000

Flex shaft

Dremel Right angle

Lots of misc dremel bits (they’re cheap)

400 grit 1” /25mm diameter flap sanding wheel for Dremel this one is awesome for tight spaces and very smooth finish (eBay)

Other various size flap wheels and grits (ebay etc)

Misc Dremel felt polishing tips

1200grit EZ Bore Clover brand lapping compound $10 ebay/Amazon

Tungsten disulfide $10 eBay/Amazon

Boron nitride powders $10 ebay/Amazon

Boron paint aerosol $50 ebay/Amazon

boron brushable $30 ebay/Amazon

Molybdenum disulfide $10 what/Amazon

Cerakote products (a little goes a very very long way) (cerakotehightemp.com) they have great promos

Harbor freight blaster 37025 https://m.harborfreight.com/portable...not%20provided

Ebay blast media (120 grit aluminum oxide type?) $50ish 30ish lbs?

Ebay airbrush kit model: Masters ABD Kit-3ab-20 $99ish or less

Central pneumatic 61454 air compressor $159?

3M 07193 paint respirator $20

I would suggest another full face respirator for use with the blasting and wearing coveralls...I did

Nitrile gloves

Paper towels

Acetone

Squirt bottles

Tape

Ingenuity

0000 steel wool

Jewelers loupe 40-60x

old blue jeans

tiny little file set

chamfer bits

Misc flex hones

Manley 40174 valvespring chamfer bit (pac racing makes a cool one as well)

Ummm probably forgetting something

Last edited by Petraszewsky; 12-22-2018 at 05:06 PM.

#130

The pics are blurry because I used my wife’s phone and then texted them and then screenshot them.

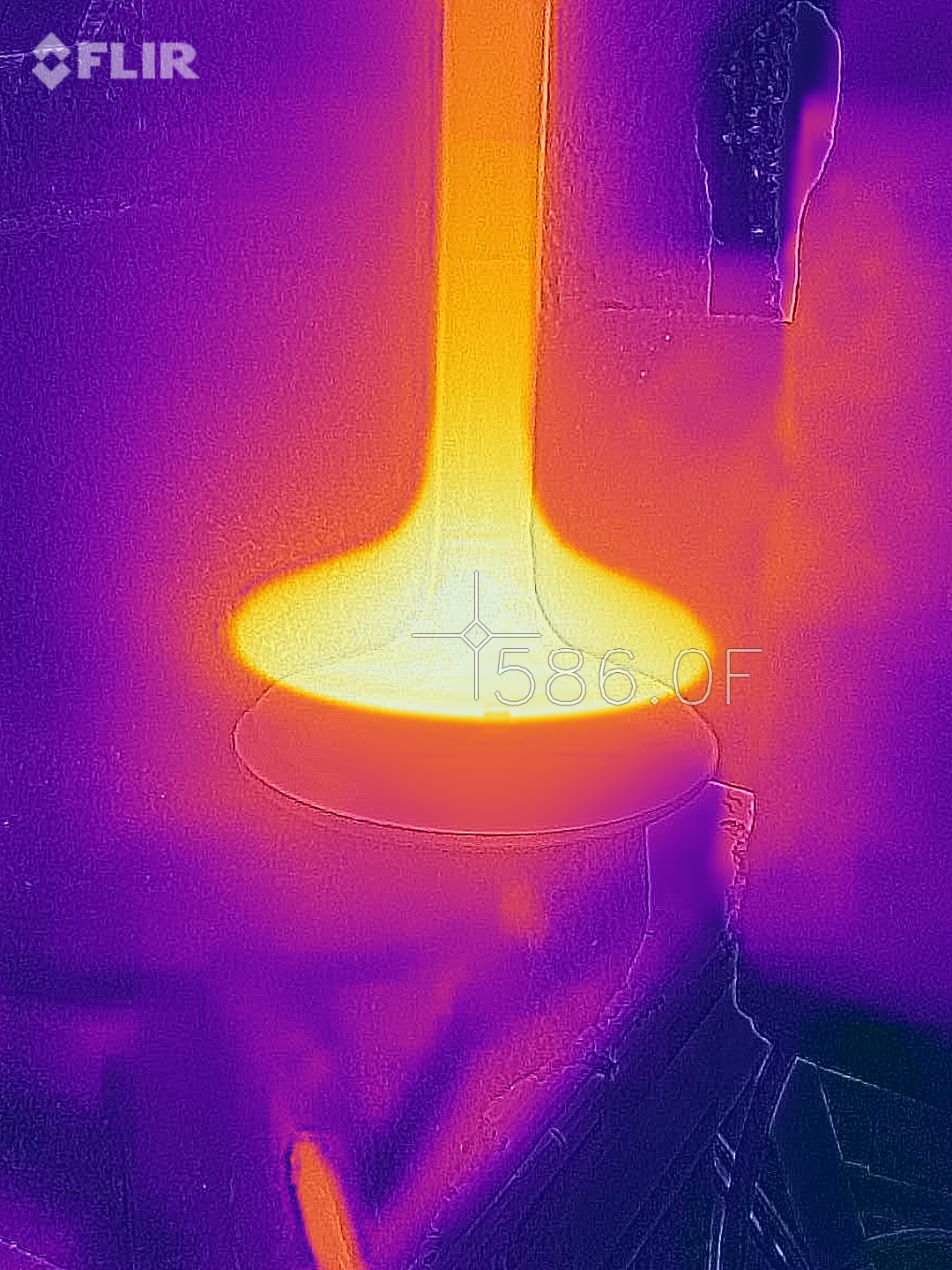

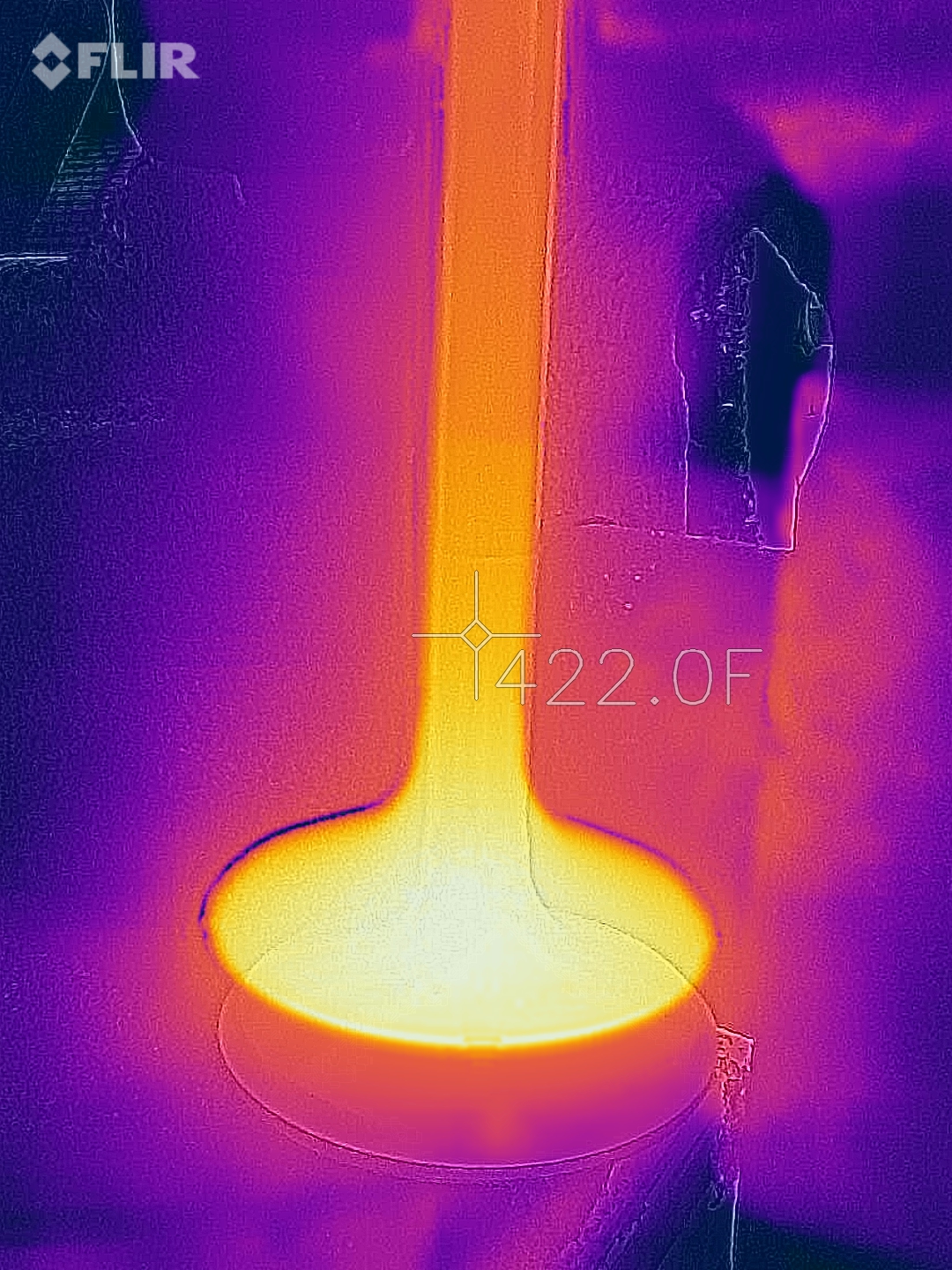

LSX B8 piston (note uneven temperature distribution)

My coated piston (more even distribution)

LSX B8 piston (note uneven temperature distribution)

My coated piston (more even distribution)

#132

Been trying to figure out how to allow the oil pump spring to rotate freely as it cycles and came up with .010” thick ptfe homemade shims.

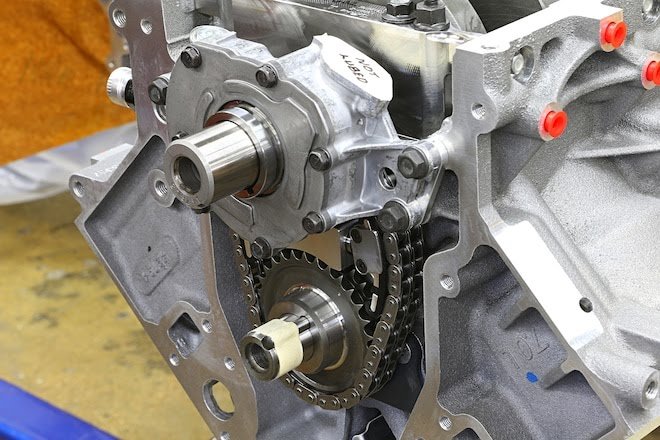

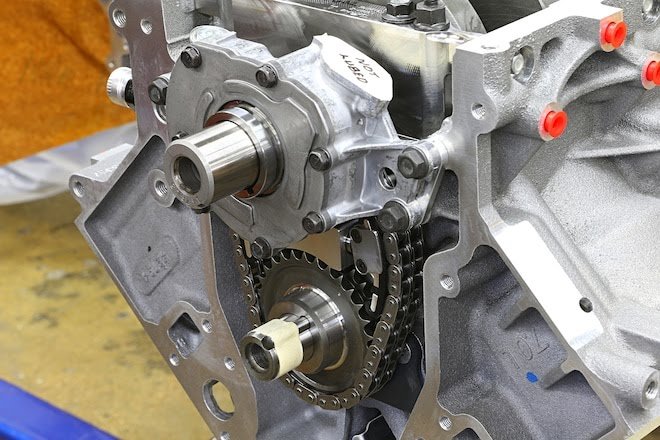

I have been busy designing a better chain dampener and have a couple of different hydraulic versions I’ve been tinkering with. I was looking up some other stuff and ran across this image..sb4 Dohc ls7 with a really nice chain dampener. It caught my eye instantly. I know I know dohc etc etc but still a nicer dampener

I have been busy designing a better chain dampener and have a couple of different hydraulic versions I’ve been tinkering with. I was looking up some other stuff and ran across this image..sb4 Dohc ls7 with a really nice chain dampener. It caught my eye instantly. I know I know dohc etc etc but still a nicer dampener

#133

#134

Yeah instead of the bypassed oil “butting heads” with the inlet flow it will now be acting as a jet to increase inlet flow. I might also Y off that line and route a hose to the pickup as well.

#135

Have you done any CFD Analysis to see the effects of injecting sporadic, pressure fluctuating oil into the tube? What about routing the bypass oil to be spring oilers or piston squirters? I would assume that oil is bypassed at startup when the oil is cold and more viscous, and maybe at upper rpmís as a result of rpm driven pressure increase... first case while cold may help startup friction and dry start on valve train and second would help both piston cooling and spring lube.

What do you think?

fred

What do you think?

fred

#136

Drifting

Question for ya ... I see you listed "Dialux brand Jewelers rouges" in one of your posts. Do you know (or have any experience) if one of the rouges will polish a scratch out of glass?

I was driving my C5 one day when one of those trucks carrying glass panes had a pane shatter in front of me (yeah I know, how could you be that lucky). I was far enough behind him to avoid the glass but little did I know a tiny piece of glass lodge between the window glass and weather stripping on the passengers window

(yeah more luck). The next time I rolled the window down the piece of (lucky) glass scratched the window about 6". Of course I didn't see it until I rolled the window up and I guess it dislodged cause I could never find that (lucky) piece of glass in the weather stripping. It isn't real deep but noticeable. I've always wondered if jewelers rouge would polish the glass enough to take it out. Any opinion or experience?

Great job on your project.

I was driving my C5 one day when one of those trucks carrying glass panes had a pane shatter in front of me (yeah I know, how could you be that lucky). I was far enough behind him to avoid the glass but little did I know a tiny piece of glass lodge between the window glass and weather stripping on the passengers window

(yeah more luck). The next time I rolled the window down the piece of (lucky) glass scratched the window about 6". Of course I didn't see it until I rolled the window up and I guess it dislodged cause I could never find that (lucky) piece of glass in the weather stripping. It isn't real deep but noticeable. I've always wondered if jewelers rouge would polish the glass enough to take it out. Any opinion or experience?

Great job on your project.

#137

Have you done any CFD Analysis to see the effects of injecting sporadic, pressure fluctuating oil into the tube? What about routing the bypass oil to be spring oilers or piston squirters? I would assume that oil is bypassed at startup when the oil is cold and more viscous, and maybe at upper rpm’s as a result of rpm driven pressure increase... first case while cold may help startup friction and dry start on valve train and second would help both piston cooling and spring lube.

What do you think?

fred

What do you think?

fred

Question for ya ... I see you listed "Dialux brand Jewelers rouges" in one of your posts. Do you know (or have any experience) if one of the rouges will polish a scratch out of glass?

I was driving my C5 one day when one of those trucks carrying glass panes had a pane shatter in front of me (yeah I know, how could you be that lucky). I was far enough behind him to avoid the glass but little did I know a tiny piece of glass lodge between the window glass and weather stripping on the passengers window

(yeah more luck). The next time I rolled the window down the piece of (lucky) glass scratched the window about 6". Of course I didn't see it until I rolled the window up and I guess it dislodged cause I could never find that (lucky) piece of glass in the weather stripping. It isn't real deep but noticeable. I've always wondered if jewelers rouge would polish the glass enough to take it out. Any opinion or experience?

Great job on your project.

I was driving my C5 one day when one of those trucks carrying glass panes had a pane shatter in front of me (yeah I know, how could you be that lucky). I was far enough behind him to avoid the glass but little did I know a tiny piece of glass lodge between the window glass and weather stripping on the passengers window

(yeah more luck). The next time I rolled the window down the piece of (lucky) glass scratched the window about 6". Of course I didn't see it until I rolled the window up and I guess it dislodged cause I could never find that (lucky) piece of glass in the weather stripping. It isn't real deep but noticeable. I've always wondered if jewelers rouge would polish the glass enough to take it out. Any opinion or experience?

Great job on your project.

Last edited by Petraszewsky; 03-09-2019 at 07:55 PM.

#138

Instructor

What polishing compound did you use to start and finish. I want to start this next week. I just purchased the list you had, and am pulling engine next week. Do you have any pictures of finished product.

#139

Finally felt well enough to do some work....I seem to like to be the life of party and I donít party and donít want to be the life of it. Whew....

Started putting the timserts in each head bolt hole to add strength for the increased clamping force of the CA625+ studs and developed torque angle method. Sorry if the pic resizing doesnít work

#140

Not that I recommend it because of risking damage to the threads, gasket, and head deck surface/holes but if you wanted/needed to install the head with all studs in place you could