2012 Dry Sump Reassembly Confusion

#1

Advanced

Thread Starter

Member Since: Mar 2017

Location: West Palm beach Florida

Posts: 81

Likes: 0

Received 3 Likes

on

3 Posts

Ive tried searching and looking on here and YouTube, but I cant seem to find out a good clear answer on reassembly of my LS3 Grand Sport with DRY sump. I changed the cam, and gears and valve springs and now ready to install the oil pump. My confusion is that I see some people say you MUST disassemble the pump and shim the ring, some say you can just install it assembled as long as you have the bushings in the bolt holes, some say just set the bottom edge even with the bottom of the block and others just say they bolt it up and be done with it. I know that Ill be setting the bottom edge as close as possible to the specification for the bottom of the block (doing the best i can with the oil pan in place, but loosened) then tightening the pump, then pulling the oil pan back up. But is what is the real procedure for the internals of the oil pump? I hate to break it open if I dont have too. Also ive seen both ways of how to line up the pump rings, some say the oil passages in alignment, others say staggered. What is the real deal? I know its important to not cut the oil pan gasket seal (it slid off easy when pan loosened). Has anyone used good old fashioned waxed paper as a safety shim over the seal when installing the pump? with the oil and the waxed paper, I would think it should slip over like butter then slide right out. I plan to chamfer the leading of the pump to reduce any cutting possibility.

My cam and supercharger install is going along well, but just want to make certain I dont have to go back into this again for an oil issue.

Thanks for all the advice, this site has made the job so much easier.

My cam and supercharger install is going along well, but just want to make certain I dont have to go back into this again for an oil issue.

Thanks for all the advice, this site has made the job so much easier.

#2

Burning Brakes

when I did my cam I replaced the oil pump with a Melling M295, stock replacement. Melling said you can bolt it right up, for their high performance pumps they want you to use feeler gauges to center the impeller, I put my pump on the crank snout. I threaded the bolts in by hand to just loose I rotated the crank a couple of times tightened the bolts WA-LA! 35 psi hot idle, I've seen the open the pump, but I wouldn't but if I was really worried I would do the feeler gauge centering. you can buy a long feeler gauge in your desired thickness and then cut three pieces to use. BE more worried about getting the pick up tube o-ring in the pump properly, this is were most of the trouble lies with your oil pump.

Last edited by jonjoy; 05-02-2019 at 02:07 AM.

#3

Pro

when I did my cam I replaced the oil pump with a Melling M295, stock replacement. Melling said you can bolt it right up, for their high performance pumps they want you to use feeler gauges to center the impeller, I put my pump on the crank snout. I threaded the bolts in by hand to just loose I rotated the crank a couple of times tightened the bolts WA-LA! 35 psi hot idle, I've seen the open the pump, but I wouldn't but if I was really worried I would do the feeler gauge centering. you can buy a long feeler gauge in your desired thickness and then cut three pieces to use. BE more worried about getting the pick up tube o-ring in the pump properly, this is were most of the trouble lies with your oil pump.

#4

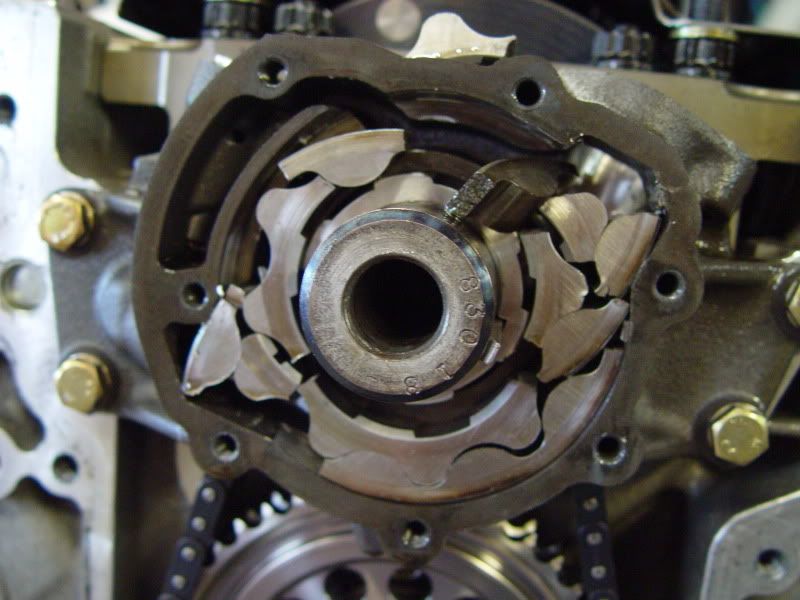

If you don't get the pump parts/housing aligned to the shaft so you have all the needed clearances, then this can happen.

Because of this, and not having the needed J tool, most will just use the feeler gauge method isntead.