Road Course Upgrades Review DeWitts, Wilwood Z06 Grills

#41

I asked, but have not gotten confirmation back. Several other vendors and members here have installed the DeWitts, so while I apologize if I'm inconveniencing you, they are also (potentially) able to answer this.

At the moment, I'm working with a forum vendor to get all of the instructions done for a Z51 -> Z06 transmission cooling swap (as requested), on top of quite a few other things here.

At the moment, I'm working with a forum vendor to get all of the instructions done for a Z51 -> Z06 transmission cooling swap (as requested), on top of quite a few other things here.

Definitely looking forward to the Z51 to ZO6 tranny cooling swap -- big time. Thanks !

#42

Tech Contributor

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 219 Likes

on

110 Posts

St. Jude Donor '14-'15

No worries. I really had/have no idea on the radiator removal. I can say that when I tried to take it out myself the first go-around (long time back), I didn't see any way of getting it out without clipping it, and certainly no way of getting it back in.

And then I barely uncorked the evap line and *pfffffffffftttttt*...... Was not a good day.

And then I barely uncorked the evap line and *pfffffffffftttttt*...... Was not a good day.

#43

Also, Did you have to do anything to the rad lower mounts to gain a little [reportedly] needed space to the hood vent?

#45

i have supercharger and space is limited even before adding this bigger radiator. i basically wrestled the fan into position. i had to trim plastic radiator shroud so it would sit lower but that is due to supercharger hoses again. it was sitting higher on passengers side.

#46

Burning Brakes

Thread Starter

The DeWitts radiator is so efficient that I really have a hard time getting the car up to temp on the street. When I drove it up to Road America the bars on the tachometer never stop illuminating over 5k rpm, that is how cool everything stayed on the road.

Up at the track the temps were just amazing, never went past 220. I also highly encourage others to seriously considering the Wilwoods, the brake pedal feel is out of this world.

Without a doubt the stiffest caliper I have ever felt on a car, and the Wilwood consumables are far less than competitors.

Up at the track the temps were just amazing, never went past 220. I also highly encourage others to seriously considering the Wilwoods, the brake pedal feel is out of this world.

Without a doubt the stiffest caliper I have ever felt on a car, and the Wilwood consumables are far less than competitors.

#47

Instructor

The DeWitts radiator is so efficient that I really have a hard time getting the car up to temp on the street. When I drove it up to Road America the bars on the tachometer never stop illuminating over 5k rpm, that is how cool everything stayed on the road.

Up at the track the temps were just amazing, never went past 220.

Up at the track the temps were just amazing, never went past 220.

Thanks for the information.

#49

Report on running some changes to my setup.

Car: 2015 C7 Z51

Previous temps: 280° oil, 290° trans, 240° coolant after only 6- 2.6 mile laps. Ambient: 83°, Brakes: stock calipers, PFC 08 front pads, stock rears. Good balance. Boiled new Castrol SRF (590 dry boil 518 wet) causing track exit.

Previous highway temps: 220° oil, 150° trans, 220° coolant (at most any normal Arizona ambient temp).

Previous tires: Stock Mich PSS front: 245/35ZR/19, diameter 25.8, rear: 285/30ZR 20 dia. 26.5

Changes:

AP Competition disks and rotors, Ferodo FRP3003W pads

Tires: 305/650/18 Continental full slick (diameter 25.5)

Rims: 10.5x18

DEI wrap on exhaust by transmission.

Home made aluminum heat shield between catalytic converter and oil cooler covered on Cat side with DEI self adhesive reflective foil. Yes the adhesive did not melt. Surprise.

DEI Radiator Relief (water wetter) 32 oz replaced that much stock coolant and engine brought up to operating temp and cooled twice prior to driving to track (175 miles).

DeWitts radiator NOT put in yet.

Report:

On 2.7 mile Inde MotorSports Ranch track (Willcox, AZ), fast and technical, 9 laps/20 min session

Tires fit in car ok with limitations. i,e., limited to one turn of steering wheel without rubbing (at 1-1/8 turn) on brake air deflector (not a problem for me). They stick out just proud of fender lip (with 2° neg camber) and rub slightly on track when suspension is depressed on limit of adhesion cornering coupled with little bumps. Did not damage rolled edge of Expel Ulitmate 8 mil car bra. However, the square setup I personally really like. I could drive the car at the limit of tire adhesion (in Track/Race) and steer it with the gas pedal MUCH better than with the stock size offset front to rear and MUCH better than in the other modes which make the car numb and unpredictable (and heats brakes).

Track Max Temps: 240° oil, 240° trans, 220° coolant !!! Ambient temps 65° AM rising to max 75° WOW ! Pleasant surprise. Same each session at maxed out speed for tires.

Brake temps: never got above 300° at the front calipers (used temp strips) -- and I ran most every corner as deep as possible. What a difference lighter, better built, better cooling brakes makes. Big weight savings too. Brake fliud at caliper that has been bleed previously after hot temps on stock caliper was darker. Fluid bleed this AM was clear. Sessions had at least one hour between and I cool front brakes in the paddock with 150 CFM 2.6A boat bilge fans into the brake duct (3"ABS angled up into brake duct just before exit to wheel well. Fits in there well). I'll post some pics if anyone's interested.)

Highway driving: 180° oil, 140° trans, 180° coolant.

Conclusion: DEI exhaust wrap and Radiator Relief really work !! Tires fit ok, but with limitations. Would need fender flairs for continuous running. Cannot use wheel spacers to increase inside clearance for more turning (judged not a problem because I never turn the wheel that much anyway because not needed on track and causes wheel hop in paddock. Even stock tires hop at wheel lock). I will install the DeWitts anyway to lower temps even further. But unless these temps increase significantly with hotter ambient temps (I usually don't run in over 90° ambient by choice) the DeWitts will be only for the horsepower and parts longevity benefits of running coolers temps and I won't try retrofitting a ZO6 A8 tranny cooling setup or adding a fan to the stock tranny cooler -- yet.

Edit: A note that most likely affected the temp changes as well. The previous temps were recorded at AMP, a track with a 94db sound limit. So I was running in "Stealth" mode keeping the outside exhaust actuators closed since I busted that limit the last time out without letting out of it past the "listening posts." My service manager (after replacing those valves from being melted) said not to run with those valves closed on track because it causes "excessive back-pressure and therefore additional exhaust heat," although, FYI, it was the forward actuators that failed, not the outside downstream ones.

So, probably your temp changes for a similar group of changes will be less -- and, a word of warning for heat AND the warranty issue (as soon as Chevy issues a written disclaimer).

Car: 2015 C7 Z51

Previous temps: 280° oil, 290° trans, 240° coolant after only 6- 2.6 mile laps. Ambient: 83°, Brakes: stock calipers, PFC 08 front pads, stock rears. Good balance. Boiled new Castrol SRF (590 dry boil 518 wet) causing track exit.

Previous highway temps: 220° oil, 150° trans, 220° coolant (at most any normal Arizona ambient temp).

Previous tires: Stock Mich PSS front: 245/35ZR/19, diameter 25.8, rear: 285/30ZR 20 dia. 26.5

Changes:

AP Competition disks and rotors, Ferodo FRP3003W pads

Tires: 305/650/18 Continental full slick (diameter 25.5)

Rims: 10.5x18

DEI wrap on exhaust by transmission.

Home made aluminum heat shield between catalytic converter and oil cooler covered on Cat side with DEI self adhesive reflective foil. Yes the adhesive did not melt. Surprise.

DEI Radiator Relief (water wetter) 32 oz replaced that much stock coolant and engine brought up to operating temp and cooled twice prior to driving to track (175 miles).

DeWitts radiator NOT put in yet.

Report:

On 2.7 mile Inde MotorSports Ranch track (Willcox, AZ), fast and technical, 9 laps/20 min session

Tires fit in car ok with limitations. i,e., limited to one turn of steering wheel without rubbing (at 1-1/8 turn) on brake air deflector (not a problem for me). They stick out just proud of fender lip (with 2° neg camber) and rub slightly on track when suspension is depressed on limit of adhesion cornering coupled with little bumps. Did not damage rolled edge of Expel Ulitmate 8 mil car bra. However, the square setup I personally really like. I could drive the car at the limit of tire adhesion (in Track/Race) and steer it with the gas pedal MUCH better than with the stock size offset front to rear and MUCH better than in the other modes which make the car numb and unpredictable (and heats brakes).

Track Max Temps: 240° oil, 240° trans, 220° coolant !!! Ambient temps 65° AM rising to max 75° WOW ! Pleasant surprise. Same each session at maxed out speed for tires.

Brake temps: never got above 300° at the front calipers (used temp strips) -- and I ran most every corner as deep as possible. What a difference lighter, better built, better cooling brakes makes. Big weight savings too. Brake fliud at caliper that has been bleed previously after hot temps on stock caliper was darker. Fluid bleed this AM was clear. Sessions had at least one hour between and I cool front brakes in the paddock with 150 CFM 2.6A boat bilge fans into the brake duct (3"ABS angled up into brake duct just before exit to wheel well. Fits in there well). I'll post some pics if anyone's interested.)

Highway driving: 180° oil, 140° trans, 180° coolant.

Conclusion: DEI exhaust wrap and Radiator Relief really work !! Tires fit ok, but with limitations. Would need fender flairs for continuous running. Cannot use wheel spacers to increase inside clearance for more turning (judged not a problem because I never turn the wheel that much anyway because not needed on track and causes wheel hop in paddock. Even stock tires hop at wheel lock). I will install the DeWitts anyway to lower temps even further. But unless these temps increase significantly with hotter ambient temps (I usually don't run in over 90° ambient by choice) the DeWitts will be only for the horsepower and parts longevity benefits of running coolers temps and I won't try retrofitting a ZO6 A8 tranny cooling setup or adding a fan to the stock tranny cooler -- yet.

Edit: A note that most likely affected the temp changes as well. The previous temps were recorded at AMP, a track with a 94db sound limit. So I was running in "Stealth" mode keeping the outside exhaust actuators closed since I busted that limit the last time out without letting out of it past the "listening posts." My service manager (after replacing those valves from being melted) said not to run with those valves closed on track because it causes "excessive back-pressure and therefore additional exhaust heat," although, FYI, it was the forward actuators that failed, not the outside downstream ones.

So, probably your temp changes for a similar group of changes will be less -- and, a word of warning for heat AND the warranty issue (as soon as Chevy issues a written disclaimer).

Last edited by CeeSeven; 05-31-2015 at 09:28 PM. Reason: Additional information.

#50

I was asked to post some pics of the oil cooler shield I fabricated on another thread. So I'll do so on this thread since it is in better context here. Please keep in mind that this was a home made job with in-shop materials. It would be one piece if I had aluminum plate wide enough and a one piece strap to the spare hole next to the oil drain plug if I were good enough to do all that weird angle bending and not weaken the aluminum from too much bending. I'd also weld everything if I could weld aluminum. So go easy on me. I'd still make it out of the 1/8" material though rather than thin sheet because it is mounted to the engine - vibration.

The stick-on heat shielding is DEI material. I had doubts about the adhesive's ability to stay stuck right next to the cat. But after one track weekend it's still there.

See the post above for effectiveness.

The stick-on heat shielding is DEI material. I had doubts about the adhesive's ability to stay stuck right next to the cat. But after one track weekend it's still there.

See the post above for effectiveness.

#51

Race Director

Member Since: Jul 2007

Location: Texas Hill Country

Posts: 10,763

Received 2,379 Likes

on

1,238 Posts

how much wrap did it take to do both pipes by the trans? did you do one slightly overlapping wrap or did you go out and back (double wrap)?

#52

A note about the stainless pull ties you'll buy to secure the ends: You can't pull them tight enough like a plastic wire tie without a little technique. I pulled them as tight as possible with a 2 handed approach: hold the clasp with a flat head screw driver and pull the tie with long nose pliers. That would get it tight enough for the second part: grab the tie end next to the clasp with long nosed pliers (at a point the plier ends are getting a little bigger) and twist the pliers backwards against the clasp and toward the clasp forcing the tie to tighten. It distorts the end of the clasp slightly. But the clasp did not break and it tightens nicely and stays. All other methods I tried resulted in loose ties.

They come in packs of way more than needed so you don't need to worry about messing some up.

#53

Race Director

Member Since: Jul 2007

Location: Texas Hill Country

Posts: 10,763

Received 2,379 Likes

on

1,238 Posts

thanks

#54

Safety Car

I was asked to post some pics of the oil cooler shield I fabricated on another thread. So I'll do so on this thread since it is in better context here. Please keep in mind that this was a home made job with in-shop materials. It would be one piece if I had aluminum plate wide enough and a one piece strap to the spare hole next to the oil drain plug if I were good enough to do all that weird angle bending and not weaken the aluminum from too much bending. I'd also weld everything if I could weld aluminum. So go easy on me. I'd still make it out of the 1/8" material though rather than thin sheet because it is mounted to the engine - vibration.

#56

Yeah..... I don't think so. I'm trying real hard not to make yet another business. But there are some REAL fabricators on the forum who will probably run with it soon. So, in the mean time go to Home Depot and buy some 1/8"x3" aluminum angle and a rivet gun. I just took a picture, sized it to actual dimensions and made a flat paper template to get rough cutting and drilling dimensions and locations. I cut it up on my band saw (for wood with a bi-metal blade) or a plain old jig saw would work fine. Then fit and refine -- about 5 trips in and out from under the car, and voila, a real messy but functional shield.

Note: Do Not attach anything to that nice flat strap that begs you to drill into it. That would be joining the body and the engine. Crack.....Ripppp......

Oh, and use some anti seize on the 8x1.25mm x 3/4" bolt you buy assuming you can get only nickel plated. That will cut down on galvanic reaction (corrosion)that would get started because the aluminum is in contact. Then use a split washer on it so it stays put. Don't use stainless steel. It doesn't get along with aluminum at all. Ideal would be one of those fancy Chevy galvanized bolts, but I couldn't find one.

To the guy asking for pics of the DEI exhaust wrap: I'm going to be on a lift tomorrow to return car to street alignment for the summer. Will shoot a pic while it's up and post tomorrow.

Note: Do Not attach anything to that nice flat strap that begs you to drill into it. That would be joining the body and the engine. Crack.....Ripppp......

Oh, and use some anti seize on the 8x1.25mm x 3/4" bolt you buy assuming you can get only nickel plated. That will cut down on galvanic reaction (corrosion)that would get started because the aluminum is in contact. Then use a split washer on it so it stays put. Don't use stainless steel. It doesn't get along with aluminum at all. Ideal would be one of those fancy Chevy galvanized bolts, but I couldn't find one.

To the guy asking for pics of the DEI exhaust wrap: I'm going to be on a lift tomorrow to return car to street alignment for the summer. Will shoot a pic while it's up and post tomorrow.

Last edited by CeeSeven; 05-26-2015 at 04:17 PM.

#57

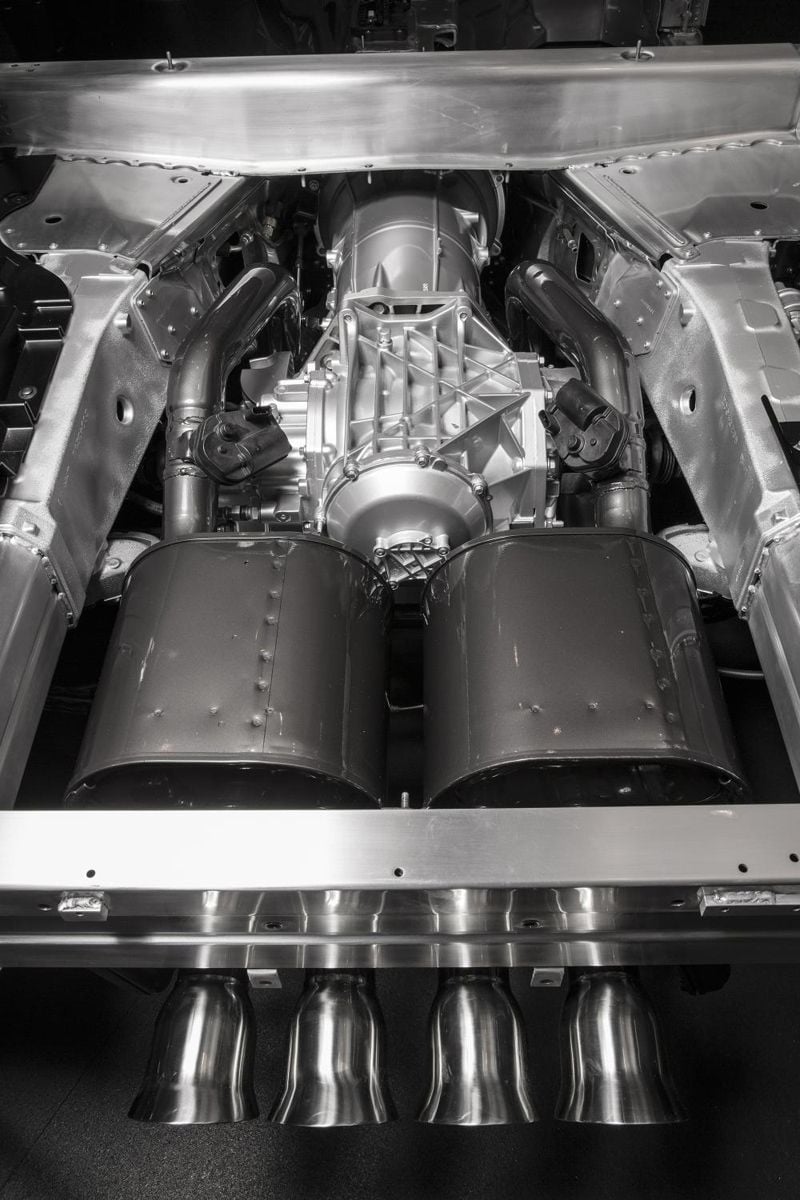

Here is a top view of the exhaust pipes near the transmission with the black AFM actuators (posted by Theta).

Sample pictures of exhaust pipe wrap job near transmission area with DEI Titanium wrap done from under the car are here:

https://www.corvetteforum.com/forums...post1589235531

Post #27

Without taking the mufflers off it is virtually impossible to wrap the entire exhaust pipes around the transmission area as there is just no access. I plan to take off the rear bumper/valence and remove the mufflers and wrap them off the car.

#58

Race Director

Member Since: Jul 2007

Location: Texas Hill Country

Posts: 10,763

Received 2,379 Likes

on

1,238 Posts

I'll probably just avoid wrapping it until I get a B&B from Ben@WX.

#59