Anyone Use Wilwood Brake/Clutch Pedals on C-3

#1

Racer

Thread Starter

I'm building a 69 Restomod with LS3/Tremec Magnum 6sp and have been evaluating hydraulic clutch options. Anyone used Wilwood Clutch/Brake Billet Pedals in this type of drivetrain conversion? I like the fact that the hyd. slave master cylinder is mounted right next to brake master cylinder so everything is parallel to the ground. I would appreciate any feedback and/or other options on setting up the hyd. clutch to work with stock clutch pedal. Thanks in advance for input to my question!

#2

I'm building a 69 Restomod with LS3/Tremec Magnum 6sp and have been evaluating hydraulic clutch options. Anyone used Wilwood Clutch/Brake Billet Pedals in this type of drivetrain conversion? I like the fact that the hyd. slave master cylinder is mounted right next to brake master cylinder so everything is parallel to the ground. I would appreciate any feedback and/or other options on setting up the hyd. clutch to work with stock clutch pedal. Thanks in advance for input to my question!

Since this install I have changed the clutch to a twin disc to get the pedal feel closer to a C6 6 speed. The original single disc is much heavier than a C6. I used parts from American Power Train for the hydraulics. But the key note on the pedal setup is the ratio the clutch cylinder and the hydraulic throw out bearing require.

The parts I used require a 5-6 to 1 ratio. The stock peal setup didn't have enough travel so the problem I had is the neutral safety switch would not engage. I have in the notes what I did to fix the problem.

https://www.corvetteforum.com/forums...-corvette.html

#3

Racer

Thread Starter

Not the same car or engine but this is my T56 Magnum install notes.

Since this install I have changed the clutch to a twin disc to get the pedal feel closer to a C6 6 speed. The original single disc is much heavier than a C6. I used parts from American Power Train for the hydraulics. But the key note on the pedal setup is the ratio the clutch cylinder and the hydraulic throw out bearing require.

The parts I used require a 5-6 to 1 ratio. The stock peal setup didn't have enough travel so the problem I had is the neutral safety switch would not engage. I have in the notes what I did to fix the problem.

https://www.corvetteforum.com/forums...-corvette.html

Since this install I have changed the clutch to a twin disc to get the pedal feel closer to a C6 6 speed. The original single disc is much heavier than a C6. I used parts from American Power Train for the hydraulics. But the key note on the pedal setup is the ratio the clutch cylinder and the hydraulic throw out bearing require.

The parts I used require a 5-6 to 1 ratio. The stock peal setup didn't have enough travel so the problem I had is the neutral safety switch would not engage. I have in the notes what I did to fix the problem.

https://www.corvetteforum.com/forums...-corvette.html

Chuck

#4

Thanks for posting.....very informative! Would it be possible to send me more info on crossmember modification? I installed a removal center section using flanges from a member of this forum. Based on my 69 factory one piece crossmember (now modified to remove) I'm going to have to modify the center section considerably lower to accommodate the tall Magnum trans mount flange. I have a new urathane trans mount that is 2" tall. Based on using this size urathane mount, I have to cut center section down to almost the bottom of the factory crossmember removable section. This will allow me to get the trans as high as possible inside tunnel. Any suggestions would be appreciated! Also, more info on the recessed bolts for shifter place would help! Thanks!

Chuck

Chuck

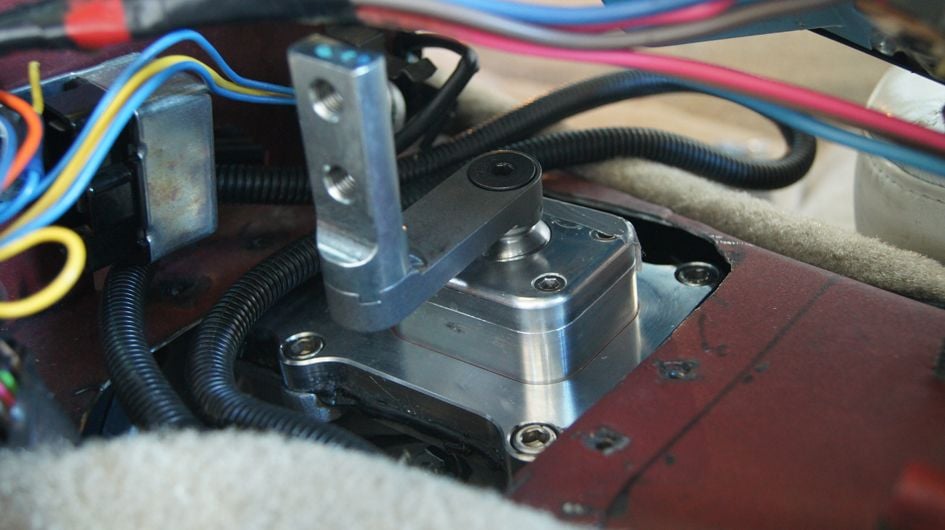

How far you can move the transmission up will depend on your tunnel. With my 78 I would have been able to move the transmission higher if I made a new mid shifter cover plate. The factory T56 magnum cover plate doesn't use counter sunk bolts or does the plate allow for counter sunk bolts.

If they looked like this (below). You can move the transmission even higher. To get the best fit I installed the transmission without the clutch. This made the install easy. To install the transmission in my 78 you cannot have the shifter installed on the transmission. There is not enough clearance to move the transmission forward and at the correct angle to align into the clutch. I left the engine in the car. Your year of car my have better or worse clearance.

Last edited by cagotzmann; 07-21-2018 at 11:37 PM.

#5

Not the same car or engine but this is my T56 Magnum install notes.

Since this install I have changed the clutch to a twin disc to get the pedal feel closer to a C6 6 speed. The original single disc is much heavier than a C6. I used parts from American Power Train for the hydraulics. But the key note on the pedal setup is the ratio the clutch cylinder and the hydraulic throw out bearing require.

The parts I used require a 5-6 to 1 ratio. The stock peal setup didn't have enough travel so the problem I had is the neutral safety switch would not engage. I have in the notes what I did to fix the problem.

https://www.corvetteforum.com/forums...-corvette.html

Since this install I have changed the clutch to a twin disc to get the pedal feel closer to a C6 6 speed. The original single disc is much heavier than a C6. I used parts from American Power Train for the hydraulics. But the key note on the pedal setup is the ratio the clutch cylinder and the hydraulic throw out bearing require.

The parts I used require a 5-6 to 1 ratio. The stock peal setup didn't have enough travel so the problem I had is the neutral safety switch would not engage. I have in the notes what I did to fix the problem.

https://www.corvetteforum.com/forums...-corvette.html

I have a '78 that has already been converted and noticed driveshaft seems toothpick size compared to what I'm used to and there seems to be room in the tunnel besides positive cable, which I have already been contemplating options for re-routing regardless if I change driveshaft to larger diameter now or not. Big issue seems to be transmission yoke u joint size on mine anyway. Not sure of other yokes available....

After reading your thread, I will reassess the conversion I have. I still need to finish the electrical connections and add speedometer adapter, but I am not to worried about "going back". No one in there right mind will ever take the 6 speed out and go back to a th350.

#6

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

I'm building a 69 Restomod with LS3/Tremec Magnum 6sp and have been evaluating hydraulic clutch options. Anyone used Wilwood Clutch/Brake Billet Pedals in this type of drivetrain conversion? I like the fact that the hyd. slave master cylinder is mounted right next to brake master cylinder so everything is parallel to the ground. I would appreciate any feedback and/or other options on setting up the hyd. clutch to work with stock clutch pedal. Thanks in advance for input to my question!

As far as the throw for the master- I don't have the numbers in front of me- the stock pin on the clutch pedal arm gives you a throw of about 1 ½"- I moved down about an inch and have about 2½" and works fine.

I also beefed up the firewall with some steel.

Oh- I saw the Wilwood guys on the Hotrod Power Tour and they have come out with a nice reservoir to replace the plastic one.

Richard