Dual electric 11" fan question

#21

Race Director

I have my dual fans wired according to the low-speed/high-speed schema.

It needs to be done by running them in series for the low speed. Too many amps for a resistor.

I'm very happy with my setup. Fans run low speed (not audible with engine running) whenever ignition is on. EFI triggers high speed if coolant goes above 210F. They rarely go to high.

To do the low/high speed setup you need 3 relays.

It needs to be done by running them in series for the low speed. Too many amps for a resistor.

I'm very happy with my setup. Fans run low speed (not audible with engine running) whenever ignition is on. EFI triggers high speed if coolant goes above 210F. They rarely go to high.

To do the low/high speed setup you need 3 relays.

#22

Melting Slicks

Thread Starter

I have my dual fans wired according to the low-speed/high-speed schema.

It needs to be done by running them in series for the low speed. Too many amps for a resistor.

I'm very happy with my setup. Fans run low speed (not audible with engine running) whenever ignition is on. EFI triggers high speed if coolant goes above 210F. They rarely go to high.

To do the low/high speed setup you need 3 relays.

It needs to be done by running them in series for the low speed. Too many amps for a resistor.

I'm very happy with my setup. Fans run low speed (not audible with engine running) whenever ignition is on. EFI triggers high speed if coolant goes above 210F. They rarely go to high.

To do the low/high speed setup you need 3 relays.

#24

Melting Slicks

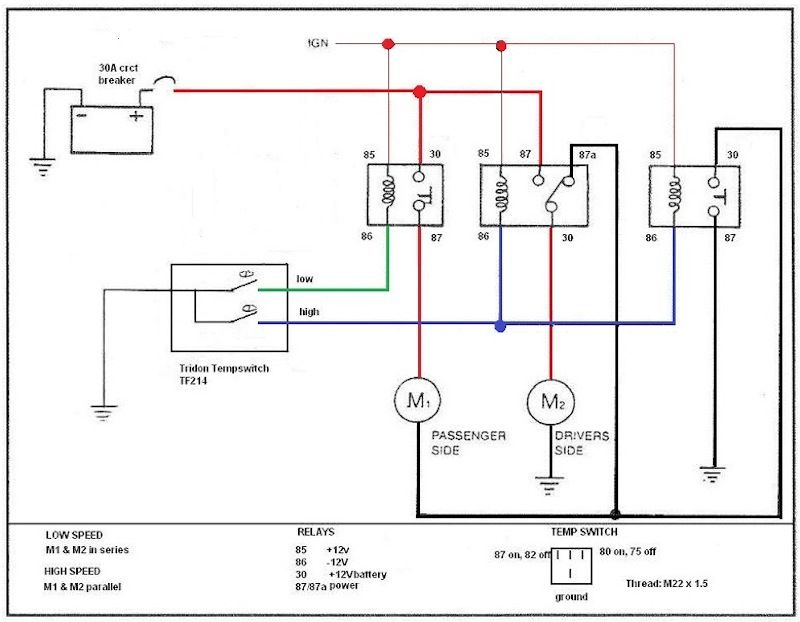

heres one i had saved from CF. i was going to do mine but never got around to it. high / low speed setup using 3 relays. red line shows current path for high speed parallel operation with temperature sensor. Low speed operation only uses relay1 and relay2, and runs the fans in series.

Last edited by speedreed8; 03-31-2015 at 08:04 PM.

#28

Racer

If you do your Power = Current^2 * Resistance, you'll find that the series-connected "low speed" is about 1/4 of the cooling of high speed. An added benefit is that the series connected schema doesn't have even close to the massive inrush currents as both fans in parallel. Another benefit is that when the fans do switch the high, their inrush current is much reduced as the fans are already spinning (and thus producing a back EMF).

#29

Le Mans Master

IN speedreed8's schematic the two fans would run in series as soon as the ignition is turned on. Another temp sensor would need to be added between relay #1 and ground to have no fans running at ignition on.

Bad bird's schematic would be no fans running at ignition on and two in series after low temp is made then two fans in parallel when high temp is made.

No fans running at ignition on is the way to go.

I also added another relay to run both fans on in high (parallel) when the A/C is selected on.

An additional switch can be added in the cabin to bypass the temp switches just in case you want the fans on prior to the temp being made or the failure of a temp switch(s)

Bad bird's schematic would be no fans running at ignition on and two in series after low temp is made then two fans in parallel when high temp is made.

No fans running at ignition on is the way to go.

I also added another relay to run both fans on in high (parallel) when the A/C is selected on.

An additional switch can be added in the cabin to bypass the temp switches just in case you want the fans on prior to the temp being made or the failure of a temp switch(s)

#30

Race Director

I disagree. The C3 engine compartment is cramped. When stopped at a light there is no airflow at all when the fans are off. Running them on low speed gets some air moving through the engine compartment and your ignition wires, any electronics, etc, will live longer.

#31

Le Mans Master

When you first start the engine cold it would be beneficial to not have the fans running. This gets the engine up to operating temperature quicker. That minimum engine operating temperature is determined by the engine coolant thermostat. Something like 95+% of engine wear occurs when the engine is below operating temperature.

Once the engine is up to operating temperature then the coolant thermostat opens and allow coolant to flow through the radiator.

If you are moving at that time there is still no need for the fans to runs to draw air through the radiator. In fact the fans turning may impede flow through the radiator at that point rather than assist it.

Running at a stop light the function of the fans is to draw air through the radiator to cool the engine, the A/C condensor if applicable, the transmission fluid via the radiator if applicable, and maybe an additional transmission or engine oil cooler if installed.

Primarily, the engine coolant and therefore the engine.

If you want to runs the fans below the engine coolant thermostat temperature then that could be done with fans on at ignition or a fan thermostat that is set to a temperature below that of the engine coolant thermostat.

Keeping the engine bay cool is not a function of a radiator/engine cooling fan.

The air aft of the radiator is ultimately going to be at or above the engine coolant temperature while sitting at a stop light and so is the air being blown into the engine bay by the cooling fans.

#32

Melting Slicks

Thread Starter

A couple of thoughts from my side to this : since I use efi, I can have the ecu control the relays in the sense that I could switch the series fan on say at 180°F and have them run parallel at 200°F. Will need 2 adc outputs for that though. Temperature settings can be changed all the time with just connecting up a laptop and putting in a number.

Personally I have an iox board that will let me even control my oil cooler fan and accusump by the ecu.

I'm not convinced that the way the radiator shroud is angled would help much with air cooling engine parts. The air would be directly mostly at the bottom and below the engine.

In this respect the factory shroud is better. I do not think that it was designed like that for that reason however.

Personally I have an iox board that will let me even control my oil cooler fan and accusump by the ecu.

I'm not convinced that the way the radiator shroud is angled would help much with air cooling engine parts. The air would be directly mostly at the bottom and below the engine.

In this respect the factory shroud is better. I do not think that it was designed like that for that reason however.

#33

Le Mans Master

On second thought Zwede may have pointed something out that I may not have considered for your earlier model vettes. The earlier models did draw their intake air from under the hood.

At that time though no electric fans were in use, but still the engineers may have given air flow through the under hood area some thought as perhaps a beneficial bi-product of using fixed fans.

It would keep air moving through even if it was 200+* air and keep the carb jetting happier than if air were to stagnate and the temp continued to rise under the hood.

With electric fans though we do have the choice of when to run the fans and circulate that air.

Typically we think of the engine thermostat being closed or open but in my observation, it has variation within the range of it's opening temperature.

An 180* thermostat starts to open at around 175* and is not fully open till 185* to 190*. So flow is initiated prior and after the set temperature, whether the fans are running or not running would make a difference (depending on OAT) as to whether the thermostat continues to open or closes again.

At that time though no electric fans were in use, but still the engineers may have given air flow through the under hood area some thought as perhaps a beneficial bi-product of using fixed fans.

It would keep air moving through even if it was 200+* air and keep the carb jetting happier than if air were to stagnate and the temp continued to rise under the hood.

With electric fans though we do have the choice of when to run the fans and circulate that air.

Typically we think of the engine thermostat being closed or open but in my observation, it has variation within the range of it's opening temperature.

An 180* thermostat starts to open at around 175* and is not fully open till 185* to 190*. So flow is initiated prior and after the set temperature, whether the fans are running or not running would make a difference (depending on OAT) as to whether the thermostat continues to open or closes again.

#34

Melting Slicks

Thread Starter

I do not think you would want to draw hot air from the radiator for air intake since (i) it's very hot and (ii) it's turbulent air.

I can see the fan moving air around cooling the outside of the engine much faster. Modern cars do not seem to use that anymore.

I can see the fan moving air around cooling the outside of the engine much faster. Modern cars do not seem to use that anymore.

#35

Le Mans Master

Where do you think the engine is getting it's air when using an open element air cleaner?

#36

Melting Slicks

Thread Starter

#37

Melting Slicks

Thread Starter

I just took of the fans.

This is indeed a stupid system to fix the fans on the shaft. The split pin is way to thin and basically just cuts through the plastic when the fans kick in and they are submitted to the force.

The plastic slots extend beyond the face of fan back and the pin is rather deep, so I assume it rides close to the edge of the slots. I'm also wondering what keeps the fans from hitting the motor.

This is indeed a stupid system to fix the fans on the shaft. The split pin is way to thin and basically just cuts through the plastic when the fans kick in and they are submitted to the force.

The plastic slots extend beyond the face of fan back and the pin is rather deep, so I assume it rides close to the edge of the slots. I'm also wondering what keeps the fans from hitting the motor.

#38

Melting Slicks

Thread Starter

Meanwhile I measured the depth that the metal pin is from the split ring and measured back inside the fan. The metal pin resides in a the recess in a rounded seating. That keeps the fan from hitting the motor. It seemed that the pin is far enough into the hole to have the epoxy provide extra support.

This is my 'repair' to prevent an issue.

This is my 'repair' to prevent an issue.

#39

Le Mans Master

Looks like it should do something. Have to wait and see how long it lasts.

#40

Melting Slicks

Thread Starter

Coming back to this : I ran the engine up to temp. As I said I run a 195°F thermostat.

Before I knock myself in the head for installing the fans : I see the engine cycling between 195 and 205°F. The fans kick in and seem to drop the temps but not really fast and it seems to stay around 198°F.

Temp sensor is in the head.

Is this a sign the fans are not strong/big enough ?

Before I knock myself in the head for installing the fans : I see the engine cycling between 195 and 205°F. The fans kick in and seem to drop the temps but not really fast and it seems to stay around 198°F.

Temp sensor is in the head.

Is this a sign the fans are not strong/big enough ?