Sad state of affairs - trying to get a clutch balanced

#1

Race Director

Thread Starter

Installing a new aluminum flywheel with my McLeod clutch. I had the clutch balanced with my old flywheel many years ago and they did drill a couple small holes in the pressure plate to balance it.

I knew the machine shop I used previously was closed now so I called up the biggest engine builder in Little Rock to see if they could do it. Nope - no arbor for the flywheel. Bring us the crank too and we can probably balance all of it together. No thanks - not ready to tear down the engine yet.

Called up the local speed shop who used to do race engine builds. No, we stopped doing engine builds and don't have an arbor to mount a flywheel on our old balancer anymore. So I asked if they knew someone who does? They gave me the name of a marine shop who builds lots of high performance engines for cars and boats and has a machine shop and many of the employees from the closed machine shop now work there.

I call them and ask - can you balance this? No, we don't have the arbor to mount the flywheel - it's a minor piece of equipment but has a big price tag. But he ventures that a new flywheel should be fine to mount the clutch on - if it's off just a little I will probably only feel it when I let the clutch out. I asked if they could tell me of anyone still doing clutch balancing and he said no, the equipment from the old machine shop was sold to an individual who now uses it only for himself and they don't know of anyone else who might be able to do it if the "major engine builder" at the top of the thread can't do it.

I asked if they could tell me of anyone still doing clutch balancing and he said no, the equipment from the old machine shop was sold to an individual who now uses it only for himself and they don't know of anyone else who might be able to do it if the "major engine builder" at the top of the thread can't do it.

Crud - I know of another engine builder about 120 miles from here who balanced my flywheel/clutch when they built the engine for my Cobra - but that's a long ways to go. So would you just slap it all together and hope for the best or go ahead and buy a new pressure plate to mount on the flywheel? I can't believe the state of well equipped machine shops around here has gotten so dismal.

I knew the machine shop I used previously was closed now so I called up the biggest engine builder in Little Rock to see if they could do it. Nope - no arbor for the flywheel. Bring us the crank too and we can probably balance all of it together. No thanks - not ready to tear down the engine yet.

Called up the local speed shop who used to do race engine builds. No, we stopped doing engine builds and don't have an arbor to mount a flywheel on our old balancer anymore. So I asked if they knew someone who does? They gave me the name of a marine shop who builds lots of high performance engines for cars and boats and has a machine shop and many of the employees from the closed machine shop now work there.

I call them and ask - can you balance this? No, we don't have the arbor to mount the flywheel - it's a minor piece of equipment but has a big price tag. But he ventures that a new flywheel should be fine to mount the clutch on - if it's off just a little I will probably only feel it when I let the clutch out.

I asked if they could tell me of anyone still doing clutch balancing and he said no, the equipment from the old machine shop was sold to an individual who now uses it only for himself and they don't know of anyone else who might be able to do it if the "major engine builder" at the top of the thread can't do it.

I asked if they could tell me of anyone still doing clutch balancing and he said no, the equipment from the old machine shop was sold to an individual who now uses it only for himself and they don't know of anyone else who might be able to do it if the "major engine builder" at the top of the thread can't do it. Crud - I know of another engine builder about 120 miles from here who balanced my flywheel/clutch when they built the engine for my Cobra - but that's a long ways to go. So would you just slap it all together and hope for the best or go ahead and buy a new pressure plate to mount on the flywheel? I can't believe the state of well equipped machine shops around here has gotten so dismal.

#2

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

Can you use a bubble balancer for a tire/wheel?

#3

Race Director

Thread Starter

#4

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

If your previous shop balanced the clutch flywheel together, it's possible/likely(?) they drilled the flywheel to balance them. This means you likely have an out of balance flywheel.

#5

Race Director

Thread Starter

But who knows if the old Hays flywheel was well balanced? I see drilled holes in the outer edge but it was so warped when I purchased it that I had to have it surfaced twice to get it flat. That's why I wanted to balance the clutch back to the new flywheel to be safe.

I hate to keep throwing money at this transmission overhaul but I'm sort of leaning towards a new pressure plate.

#6

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

That does concern me. The guy I talked to at the Marine motors shop used to work at the machine shop that balanced the assembly years ago. He said he didn't think they would have touched the flywheel - just the bolted together flywheel/clutch assembly and dilled the clutch to get close to zero.

But who knows if the old Hays flywheel was well balanced? I see drilled holes in the outer edge but it was so warped when I purchased it that I had to have it surfaced twice to get it flat. That's why I wanted to balance the clutch back to the new flywheel to be safe.

I hate to keep throwing money at this transmission overhaul but I'm sort of leaning towards a new pressure plate.

But who knows if the old Hays flywheel was well balanced? I see drilled holes in the outer edge but it was so warped when I purchased it that I had to have it surfaced twice to get it flat. That's why I wanted to balance the clutch back to the new flywheel to be safe.

I hate to keep throwing money at this transmission overhaul but I'm sort of leaning towards a new pressure plate.

#7

Hi Dan, by all means get it balanced or you will never know if you have an issue whether or not it is the flywheel/clutch!

It's hard to believe there are no "arbors" where these guys have the balancing equipment. I would think they would at least have one of their assemblies to balance and could mount your parts on it, this is easy to do??

A few years ago we did a build for a member up here, shipped it to him, he had his guy do the clutch install in his town and wound up with a very bad vibration. First call by his guy was the build we did, so we had him send us the new Hays flywheel AND pressure plate, his installer never checked it for balance. Wouldn't have mattered much, the NEW flywheel was deemed "defective" by Hays. They got involved in this dilemma when we notified them there were NO counter-bores present for the pressure-plate bolt shoulders in the new wheel. They shipped us a new replacement wheel, no charge, no frgt!

Thanks, Gary in N.Y.

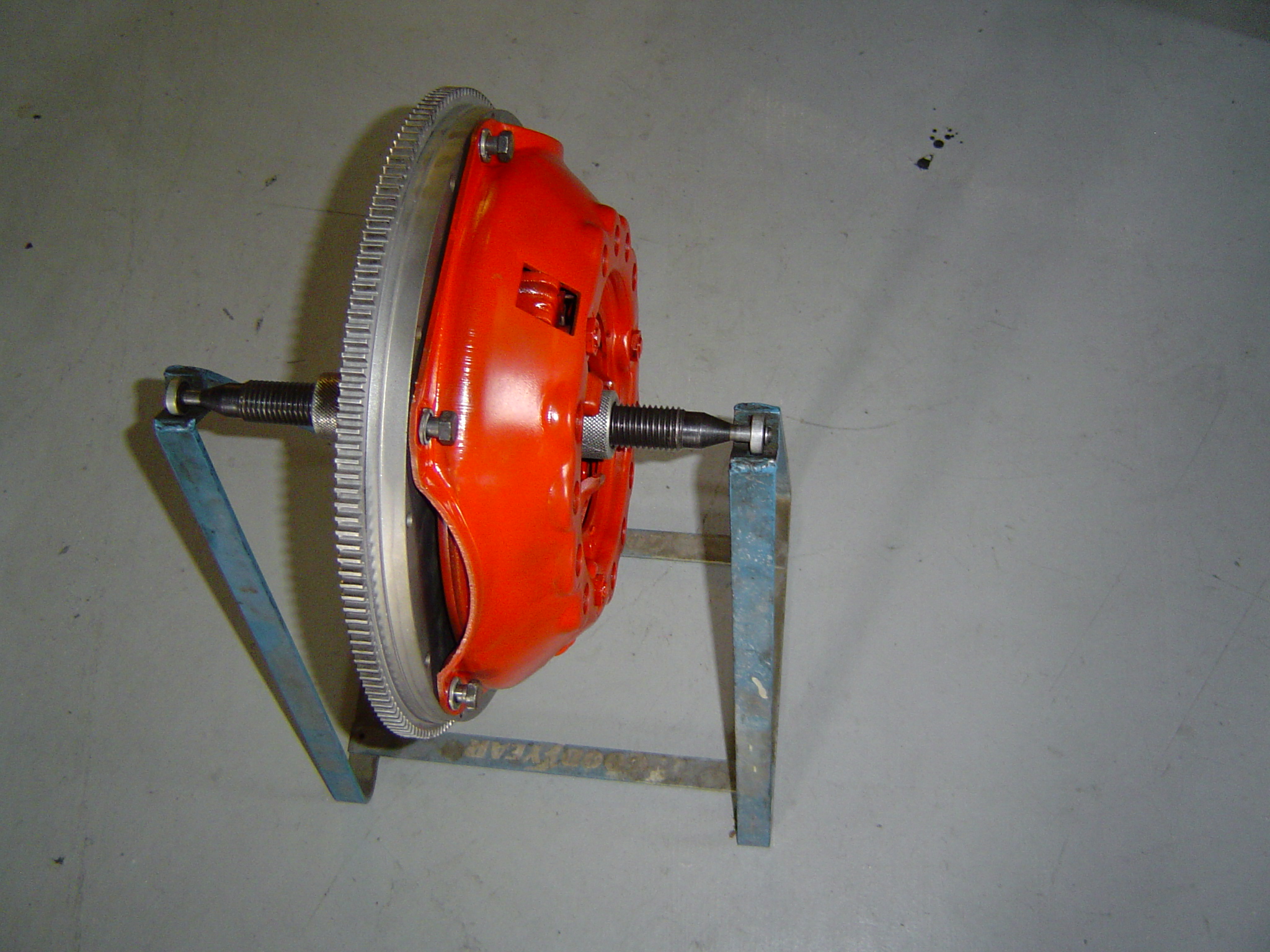

P.S. Assuming this is an "independent" balanced unit you bolt the pressure-plate to the flywheel with the CORRECT bolts, index it, and do all the correction on the wheel, not the plate. You cannot do it this way on a "dependent" balanced unit however. Here's a shot of an "indexed" ***'y.

It's hard to believe there are no "arbors" where these guys have the balancing equipment. I would think they would at least have one of their assemblies to balance and could mount your parts on it, this is easy to do??

A few years ago we did a build for a member up here, shipped it to him, he had his guy do the clutch install in his town and wound up with a very bad vibration. First call by his guy was the build we did, so we had him send us the new Hays flywheel AND pressure plate, his installer never checked it for balance. Wouldn't have mattered much, the NEW flywheel was deemed "defective" by Hays. They got involved in this dilemma when we notified them there were NO counter-bores present for the pressure-plate bolt shoulders in the new wheel. They shipped us a new replacement wheel, no charge, no frgt!

Thanks, Gary in N.Y.

P.S. Assuming this is an "independent" balanced unit you bolt the pressure-plate to the flywheel with the CORRECT bolts, index it, and do all the correction on the wheel, not the plate. You cannot do it this way on a "dependent" balanced unit however. Here's a shot of an "indexed" ***'y.

#8

Pro

As a young man I worked in a high performance custom machine shop, building and balancing pressure plates. I built and balanced thousands of units ,everything from antique vehicles to NHRA and Nascar.

When we balanced a pressure plate to go into our shelf stock we used the same neutral balance flywheel on an arbor. If we were balancing a motor, the crank, with its bob weights, was done first then the harmonic and flywheel were added and when done it was essentially a neutral balance assembly, and any of our off the shelf pressure plates could be used .

When balancing a pressure plate ,the corrections are made to the plate, not the flywheel, your clutch is still balanced .

When we balanced a pressure plate to go into our shelf stock we used the same neutral balance flywheel on an arbor. If we were balancing a motor, the crank, with its bob weights, was done first then the harmonic and flywheel were added and when done it was essentially a neutral balance assembly, and any of our off the shelf pressure plates could be used .

When balancing a pressure plate ,the corrections are made to the plate, not the flywheel, your clutch is still balanced .

#10

Race Director

Member Since: Jan 2000

Location: Corsicana, Tx

Posts: 12,616

Received 1,877 Likes

on

915 Posts

2020 C2 of the Year - Modified Winner

2020 Corvette of the Year (performance mods)

C2 of Year Winner (performance mods) 2019

2017 C2 of Year Finalist

I've never balanced a clutch to an assy. If it was marked for balance as an assy. "like my Soft Lok from McLeod or the previous dual disc one...I kept them all together. But otherwise I've never messed with it and never noticed any issues. I don't like marrying parts together that wear or limit swapping.

Like angle milling heads and then cutting an intake to fit. The right way is to mill the intake face of the heads so any intake will fit.

JIM

Like angle milling heads and then cutting an intake to fit. The right way is to mill the intake face of the heads so any intake will fit.

JIM

#11

Race Director

Thread Starter

P.S. Assuming this is an "independent" balanced unit you bolt the pressure-plate to the flywheel with the CORRECT bolts, index it, and do all the correction on the wheel, not the plate. You cannot do it this way on a "dependent" balanced unit however. Here's a shot of an "indexed" ***'y.

#12

Race Director

Thread Starter

I've never balanced a clutch to an assy. If it was marked for balance as an assy. "like my Soft Lok from McLeod or the previous dual disc one...I kept them all together. But otherwise I've never messed with it and never noticed any issues. I don't like marrying parts together that wear or limit swapping.

Like angle milling heads and then cutting an intake to fit. The right way is to mill the intake face of the heads so any intake will fit.

JIM

Like angle milling heads and then cutting an intake to fit. The right way is to mill the intake face of the heads so any intake will fit.

JIM

Thanks

#13

Safety Car

Why do you have to do this? New wheel should be balanced and new clutch should be balanced as well. No need to balance as an assembly. If it were me I'd get a new clutch and install the new wheel and be done with it.

Last edited by 65tripleblack; 06-04-2017 at 09:23 AM.

#14

Race Director

Thread Starter

I have a Centerforce clutch with about 500 miles on it sitting up in the attic already and hate to give it another low mileage stablemate collecting dust up there (along with my old Hays flywheel now).

If I can't find someone to balance it - buying a new one and bolting the whole thing together is my Plan B.

#15

We run 2 engine balancers here, A "Stewart-Warner" and a newer "CWT", and we have not seen a single "NEW" flywheel OR pressure-plate that was up to our standards to just be installed?? Not one!

Thanks, Gary in N.Y.

P.S. Let me give you small tip about balancing, there will ALWAYS be a certain amount of "imbalance" remaining in a balanced piece. If you are balancing 2 separate pieces (flywheel & plate) independent of each other and have that very slight imbalance remaining in BOTH pieces the risk is higher than balancing the BOTH pieces as a separate unit. You can "tighten" the remaining imbalance doing it as a single entity, indexed! You need to be real careful when balancing at a 7.000" radius (1/2 the flywheel diameter) the "small" imbalance becomes multiplied by the larger diameter! Again, this way will NOT work on "dependently-balanced" units.

#17

Race Director

Thread Starter

Thanks Gary - ultimately I would like to see it balanced as an indexed assembly like I had before. I guess I'll keep looking and see if Craft Performance Engines down the road about 120 miles can still do this. They did the unit in my Cobra replica.

#18

Burning Brakes

Member Since: Aug 2013

Location: palm springs ca

Posts: 1,063

Likes: 0

Received 314 Likes

on

178 Posts

Sorry about the pic only, but it only took 1 hour.

First I balance the flywheel, then bolt the pressure plate (no disc) and do a final balance with the plate in place.

Did all 4 discs on my 67 and the harmonic balancer this way also.

Dom

First I balance the flywheel, then bolt the pressure plate (no disc) and do a final balance with the plate in place.

Did all 4 discs on my 67 and the harmonic balancer this way also.

Dom

#19

Safety Car

You would think most any engine shop would have an internally balanced chevy balance job in work. They could throw your flywheel and pp on it and get it done for you. Assuming this is for your 427.

#20

Race Director

COOL TOOL..and I am a tool *****. I now see I have to get another tool and begin having fun with it.

COOL TOOL..and I am a tool *****. I now see I have to get another tool and begin having fun with it.I get my clutches and flywheels for SPEC and they are already balanced.

DUB

Last edited by DUB; 06-04-2017 at 06:40 PM.

- now this is beginning to sound like a snipe hunt.

- now this is beginning to sound like a snipe hunt.