Electric oil gauge conversion question

#1

Drifting

Thread Starter

Quick question for those of you who have converted from a mechanical oil gauge to an electric.

Where did you tap into for the power feed? I'm thinking I can just run a wire with a ring terminal to the post that the pink wire for the fuel gauge is attached to.

Suggestions?

Thanks,

Rick

Where did you tap into for the power feed? I'm thinking I can just run a wire with a ring terminal to the post that the pink wire for the fuel gauge is attached to.

Suggestions?

Thanks,

Rick

The following users liked this post:

chstitans42 (08-24-2017)

#2

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Yep- that'd be the power source you want to use. It's not powered when in acc and it's powered when the starter is spinning.

Richard

Richard

#3

Team Owner

Just jumper it to 12 vdc feed for another gauge.

#4

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

#5

Team Owner

I guess you could call the clock a 'gauge', but that wasn't my intention. The "engine performance instruments" [better?] don't function until the ignition key is turned to ON. Power for them is where you get the 12 vdc [operating] power for you oil gauge.

#6

Drifting

Thread Starter

Ok guys, thanks for your input.

Next question. Looking at the rear of the gauge, I've got the left post hooked to the sender wire, the right post hooked to the pink wire post for the fuel gauge, and the center post is to ground.

Key on to acc, gauge pegs to zero. Key to start, gauge sweeps up to 80 psi and stays there, regardless of rpm.

I'm thinking maybe the sender is not grounded? I believe I used some Teflon tape when I installed it, so maybe that's interfering with it grounding? Sender is new, so I'd be surprised if it was bad.

Next question. Looking at the rear of the gauge, I've got the left post hooked to the sender wire, the right post hooked to the pink wire post for the fuel gauge, and the center post is to ground.

Key on to acc, gauge pegs to zero. Key to start, gauge sweeps up to 80 psi and stays there, regardless of rpm.

I'm thinking maybe the sender is not grounded? I believe I used some Teflon tape when I installed it, so maybe that's interfering with it grounding? Sender is new, so I'd be surprised if it was bad.

#7

Team Owner

That's a possibility; or the wire connections should be different. Did you get any instructions with the gauge?

If it is a stock-type Corvette gauge, Willcox has some good documentation on how the various gauges should be connected.

If it is a stock-type Corvette gauge, Willcox has some good documentation on how the various gauges should be connected.

#8

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

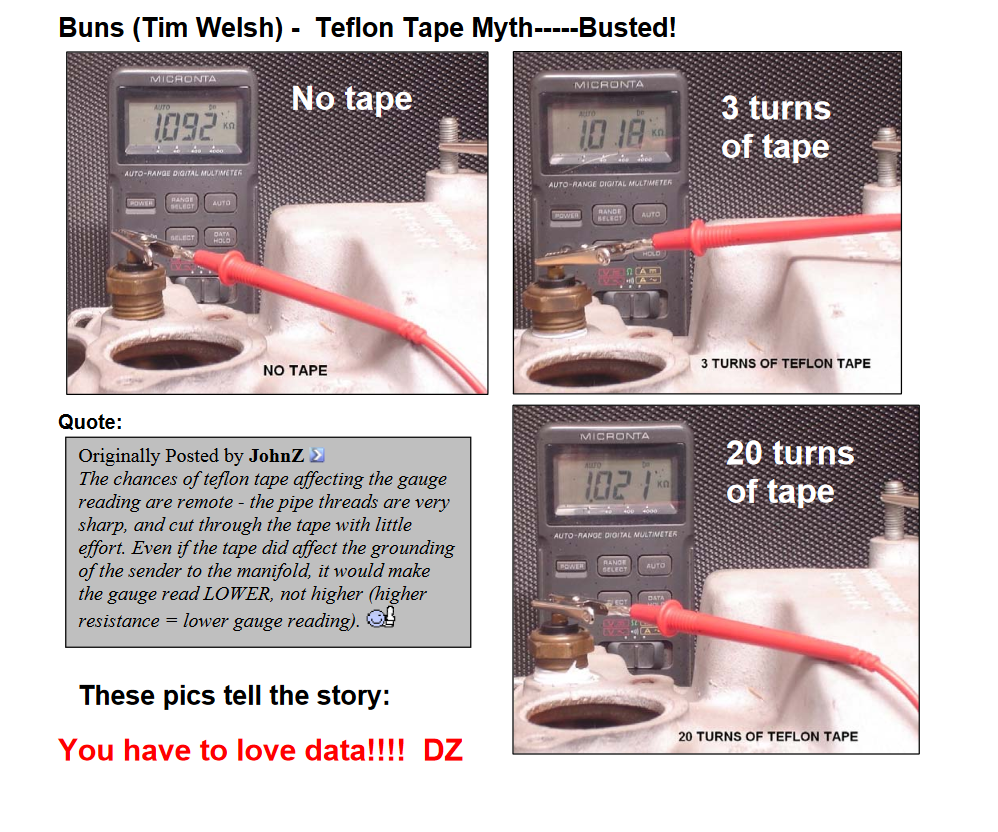

The teflon tape's purpose is to fill any gaps between the threads and reduce friction during tightening. The NPT will cut through the teflon and not prevent a ground.

When you say " Key on to acc"- you mean ignition- correct?

Key to start- while the starter is turning- or just running?

Depending on the gauge- OEM had a 90Ω resister between the +12V ignition (pink wire) and the sensor. Reproductions don't use the resistor. (top pic)

The 9 O’clock terminal would be your ohms input terminal from the sender, the 3 O’clock terminal would be your power. The 6 O’clock terminal is the ground to the housing. The scale of this gauge is just like that of the fuel gauge, 0 ohms is zero, 45 ohms is 40lbs and 90 ohms is 80lbs.

I would disconnect the sensor wire-turn on the ignition(don't start the car)and see what you read. Then jump that sensor wire to good ground and the gauge should read 0.

let us know.

When you say " Key on to acc"- you mean ignition- correct?

Key to start- while the starter is turning- or just running?

Depending on the gauge- OEM had a 90Ω resister between the +12V ignition (pink wire) and the sensor. Reproductions don't use the resistor. (top pic)

The 9 O’clock terminal would be your ohms input terminal from the sender, the 3 O’clock terminal would be your power. The 6 O’clock terminal is the ground to the housing. The scale of this gauge is just like that of the fuel gauge, 0 ohms is zero, 45 ohms is 40lbs and 90 ohms is 80lbs.

I would disconnect the sensor wire-turn on the ignition(don't start the car)and see what you read. Then jump that sensor wire to good ground and the gauge should read 0.

let us know.

#9

Team Owner

Well, those NPT threads SHOULD cut through the Teflon tape. But, there is enough anecdotal evidence that folks who have used Teflon tape have had a few problems. Whether the threads cut through it or not would be a function of how many rounds of tape were used and how much torque was applied to the sending unit.

As Teflon is a very good insulator, it might be best to remove it and just use some pipe dope to seal the joint.

As Teflon is a very good insulator, it might be best to remove it and just use some pipe dope to seal the joint.

#10

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Well, those NPT threads SHOULD cut through the Teflon tape. But, there is enough anecdotal evidence that folks who have used Teflon tape have had a few problems. Whether the threads cut through it or not would be a function of how many rounds of tape were used and how much torque was applied to the sending unit.

As Teflon is a very good insulator, it might be best to remove it and just use some pipe dope to seal the joint.

As Teflon is a very good insulator, it might be best to remove it and just use some pipe dope to seal the joint.

Read this- actual testing of the teflon myth-

http://www.stl-vettes.com/65Vette/co..._and_Gauge.pdf

#12

Team Owner

#1 I don't believe that you could get a pipe plug to even start into a threaded hole if it had 20 rounds of Teflon tape on it.

#2 I am always doubtful of ANYONE who states that something will ALWAYS occur.

#3 It is nice that you are so convinced that such could not happen. Don't expect the rest of us to have that same level of confidence just because you do.

#2 I am always doubtful of ANYONE who states that something will ALWAYS occur.

#3 It is nice that you are so convinced that such could not happen. Don't expect the rest of us to have that same level of confidence just because you do.

#13

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

*Quote from "JohnZ" above...

#14

Team Owner

Richard, you are the one trying to convince folks that putting Teflon tape on pipe threads is 'no big deal'...even when that item is supposed to pass electrical ground. I'm just offering that may not be the best alternative.

#15

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Richard

#16

Drifting

Thread Starter

Connections at the gauge are good (sender to 9 o'clock, power to 3 o'clock, ground to 6 o'clock).

I used my multimeter to check continuity from the engine block to the exterior of the sender, and that was good. The sender is grounded to the block.

I turn the ignition to the first click. No reaction from the gauge. Second click to where power is on, gauge pegs to zero. Turn to engage starter, engine running, gauge sweeps over to a little past 80 psi.

I guess my next step is to check the ohms coming from the sender.

I used my multimeter to check continuity from the engine block to the exterior of the sender, and that was good. The sender is grounded to the block.

I turn the ignition to the first click. No reaction from the gauge. Second click to where power is on, gauge pegs to zero. Turn to engage starter, engine running, gauge sweeps over to a little past 80 psi.

I guess my next step is to check the ohms coming from the sender.

#18

Drifting

Thread Starter

#19

Team Owner

Glad your conversion is going so well for you.

#20

Drifting

Thread Starter

Connections at the gauge are good (sender to 9 o'clock, power to 3 o'clock, ground to 6 o'clock).

I used my multimeter to check continuity from the engine block to the exterior of the sender, and that was good. The sender is grounded to the block.

I turn the ignition to the first click. No reaction from the gauge. Second click to where power is on, gauge pegs to zero. Turn to engage starter, engine running, gauge sweeps over to a little past 80 psi.

I guess my next step is to check the ohms coming from the sender.

I used my multimeter to check continuity from the engine block to the exterior of the sender, and that was good. The sender is grounded to the block.

I turn the ignition to the first click. No reaction from the gauge. Second click to where power is on, gauge pegs to zero. Turn to engage starter, engine running, gauge sweeps over to a little past 80 psi.

I guess my next step is to check the ohms coming from the sender.

All connections seemed right and I had verified the sending unit was grounded to the block. Gauge was functional, just not reading correctly and the reading would not fluctuate with engine rpm.

I pulled the old sending unit off off my '75 coupe and installed it on the '69. Fired up the engine and voila! The gauge works fine. I installed the new sending unit on the '75 and that gauge exhibited the same problems as described before. So, lesson learned...brand new sending unit is JUNK!

Glad to have this mystery finally solved so I can get my dash put back together.