Differential Raising

#1

Instructor

Thread Starter

How many people out there have raised their differential per the Greenwood VIP article and drive their car on the street? I am looking at doing this, but I am concerned that there will be a bad vibration getting rid of the rubber bushing and mounting the cross member solid.

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

I was thinking of adding a 1/8" thick piece of rubber or hard durometer plastic between the sombrero and the plate, as well as between the crossmember and frame just for some isolation similar to what Jason Staley had done. Any opinions on this?

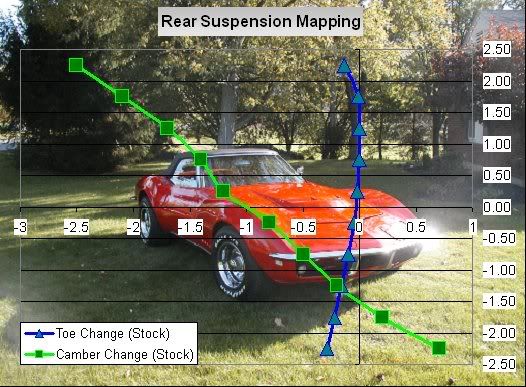

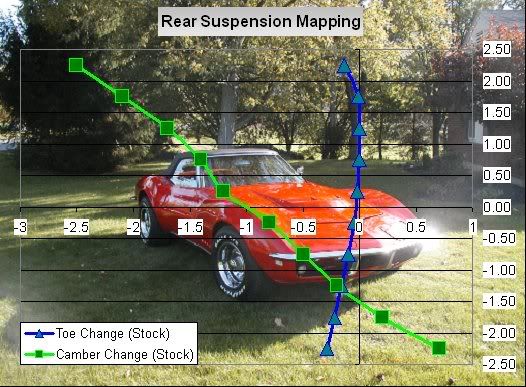

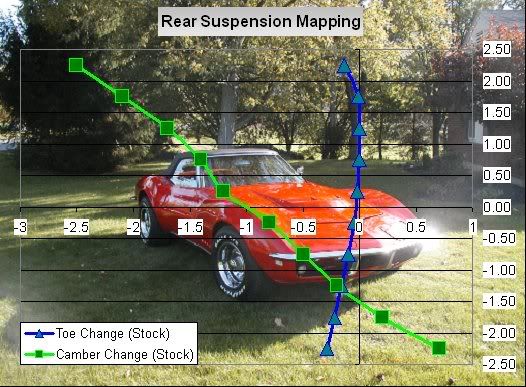

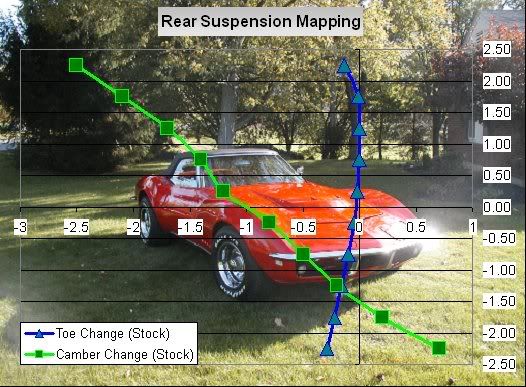

Here is what I got when I mapped out my rear suspension. I don't think the toe is completely correct. Has anyone else done this?

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

I was thinking of adding a 1/8" thick piece of rubber or hard durometer plastic between the sombrero and the plate, as well as between the crossmember and frame just for some isolation similar to what Jason Staley had done. Any opinions on this?

Here is what I got when I mapped out my rear suspension. I don't think the toe is completely correct. Has anyone else done this?

#2

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,350

Received 767 Likes

on

549 Posts

Prior to putting in my C4 suspension, I considered raising the differential. Modifying the bushings seemed like a lot of hassle, whereas modifying and and rewelding the center section of the crossmember seemed easier. (The pinion mount would have to be tweaked also to keep the driveshaft angles correct.)

#3

Safety Car

Member Since: Aug 2001

Location: North Easton Mass

Posts: 4,883

Likes: 0

Received 8 Likes

on

8 Posts

How many people out there have raised their differential per the Greenwood VIP article and drive their car on the street? I am looking at doing this, but I am concerned that there will be a bad vibration getting rid of the rubber bushing and mounting the cross member solid.

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

EDIT: After looking at my frame I see that the gap and hat on your frame are fine. The end of the crossmember should be straight across though, but the bends shouldn't affect anything.

Rick B.

Last edited by 72LS1Vette; 01-12-2008 at 12:23 PM.

#4

Prior to putting in my C4 suspension, I considered raising the differential. Modifying the bushings seemed like a lot of hassle, whereas modifying and and rewelding the center section of the crossmember seemed easier. (The pinion mount would have to be tweaked also to keep the driveshaft angles correct.)

#5

Racer

Member Since: Dec 2004

Location: Wichita Kansas

Posts: 410

Likes: 0

Received 0 Likes

on

0 Posts

I'm working on the same issue. I can't see how a little flex makes a big difference as it is only up and down, not side to side. I have poly bushings in my front mount and the thing doesn't move much. I would like to raise the diff a little, I have 10 inch bolts. SCCA rules won't let me cut and reweld the brace. Can you just remove the rubber bushings and put in a big steel washer? I'm taking it apart tomorrow and MIGHT understand it a bit better then.

#6

Team Owner

Member Since: Oct 2004

Location: Springfield MO

Posts: 23,831

Likes: 0

Received 6 Likes

on

6 Posts

St. Jude Donor '07

I'm working on the same issue. I can't see how a little flex makes a big difference as it is only up and down, not side to side. I have poly bushings in my front mount and the thing doesn't move much. I would like to raise the diff a little, I have 10 inch bolts. SCCA rules won't let me cut and reweld the brace. Can you just remove the rubber bushings and put in a big steel washer? I'm taking it apart tomorrow and MIGHT understand it a bit better then.

#7

Le Mans Master

Quoting Bat's post on the solid mounts...

...They appear to be based off of something noted (but not pictured very well) on page 6-4 of the Chevy Power Manual, 5th edition. They totally eliminate the rubber bushings - the stepped portions fit snugly into the crossmember bores. I'm fairly sure that they're steel, but I'm not 100% certain. All dimensions are approximate.

Upper ring dimensions:

total thickness - 9/16"

thickness of wide section - 7/16"

thickness of narrow section - 1/8"

diameter of wide section - 4"

diameter of narrow section - 3 13/16"

diameter of hole - 2 9/16" (it appears to taper a bit as it goes downward - it's around 2 1/2" - 2 17/32")

Lower plate dimensions:

total thickness - 7/8"

thickness of wide section - 7/16"

thickness of narrow section- 7/16"

diameter of wide section - 4 1/4"

diameter of narrow section - 3 13/16"

diameter of hole - 1/2"

BTW, I talked to Guldstrand about these not long ago. They used to sell them, but don't bother asking for Dick to scrounge (yes, he's been known to do that when he thinks he might have something) for a set as apparently there aren't any just laying around. Haven't asked Greenwood...

...They appear to be based off of something noted (but not pictured very well) on page 6-4 of the Chevy Power Manual, 5th edition. They totally eliminate the rubber bushings - the stepped portions fit snugly into the crossmember bores. I'm fairly sure that they're steel, but I'm not 100% certain. All dimensions are approximate.

Upper ring dimensions:

total thickness - 9/16"

thickness of wide section - 7/16"

thickness of narrow section - 1/8"

diameter of wide section - 4"

diameter of narrow section - 3 13/16"

diameter of hole - 2 9/16" (it appears to taper a bit as it goes downward - it's around 2 1/2" - 2 17/32")

Lower plate dimensions:

total thickness - 7/8"

thickness of wide section - 7/16"

thickness of narrow section- 7/16"

diameter of wide section - 4 1/4"

diameter of narrow section - 3 13/16"

diameter of hole - 1/2"

BTW, I talked to Guldstrand about these not long ago. They used to sell them, but don't bother asking for Dick to scrounge (yes, he's been known to do that when he thinks he might have something) for a set as apparently there aren't any just laying around. Haven't asked Greenwood...

#8

Burning Brakes

How many people out there have raised their differential per the Greenwood VIP article and drive their car on the street? I am looking at doing this, but I am concerned that there will be a bad vibration getting rid of the rubber bushing and mounting the cross member solid.

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

I was thinking of adding a 1/8" thick piece of rubber or hard durometer plastic between the sombrero and the plate, as well as between the crossmember and frame just for some isolation similar to what Jason Staley had done. Any opinions on this?

Here is what I got when I mapped out my rear suspension. I don't think the toe is completely correct. Has anyone else done this?

Second question I had about this modification is that the article calls out for a hole in the 1/4" plates to be 23/32's in diameter, but the bolt is only 7/16". I would think this would allow the differential to shift with the holes being oversized so much?

Lastly, on the upper part of the frame it bends down a little bit. I assume that this needs to be bent up in order to set the cross member flat.

I was thinking of adding a 1/8" thick piece of rubber or hard durometer plastic between the sombrero and the plate, as well as between the crossmember and frame just for some isolation similar to what Jason Staley had done. Any opinions on this?

Here is what I got when I mapped out my rear suspension. I don't think the toe is completely correct. Has anyone else done this?

#9

Instructor

Thread Starter

72LS1Vette - Then ends of the cross member are bent down from me using a 6ft prybar trying to get the rubber bushings out

Vesa - I plan on doing the smart struts or some variation, I was just curious if this is close to what others have checked.

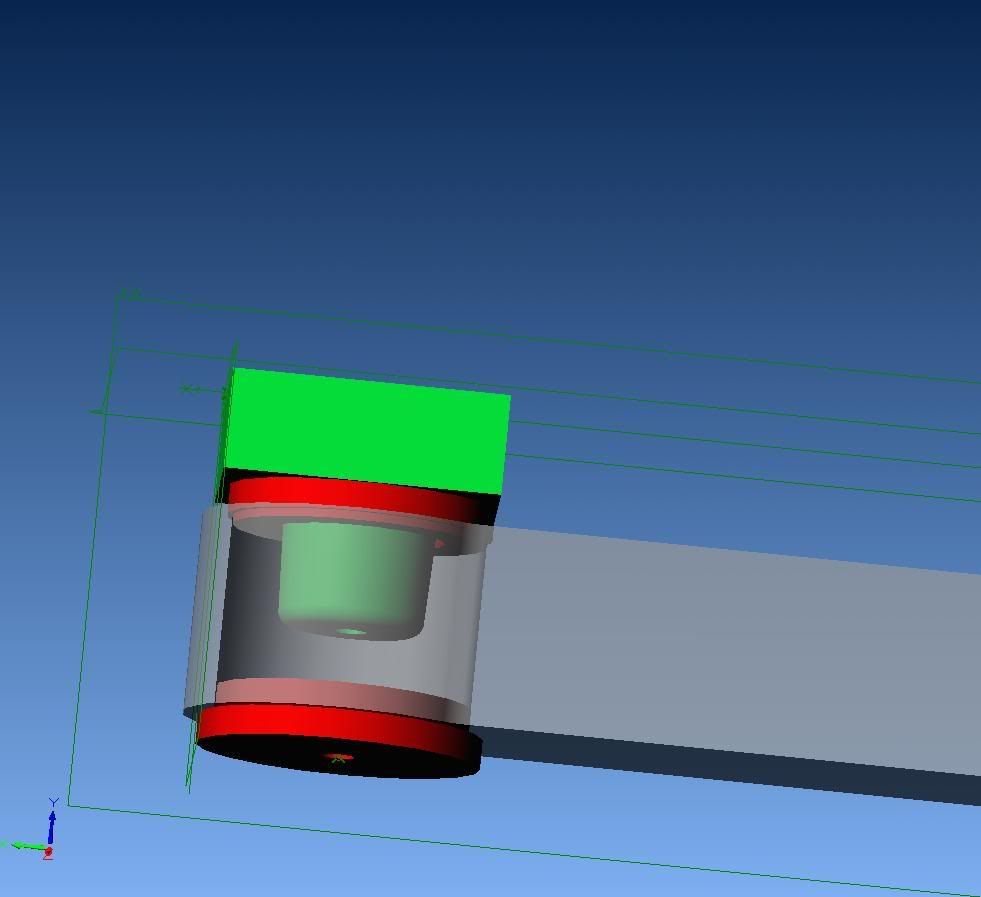

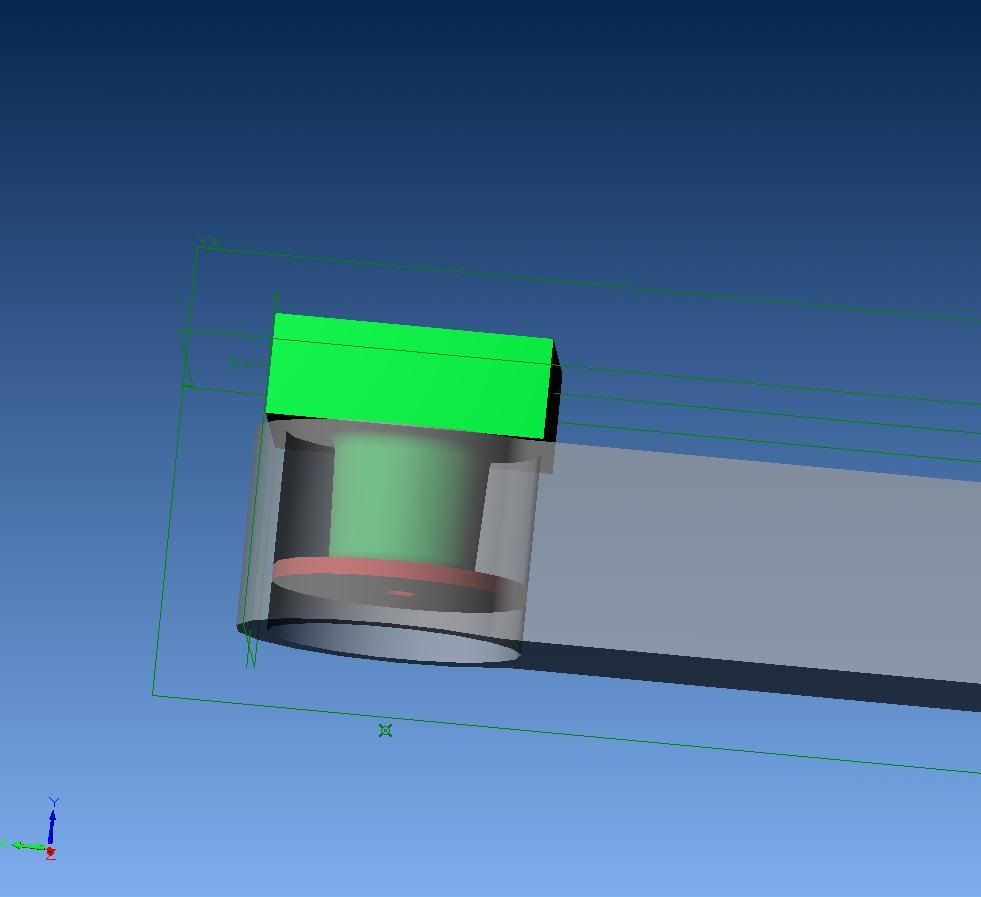

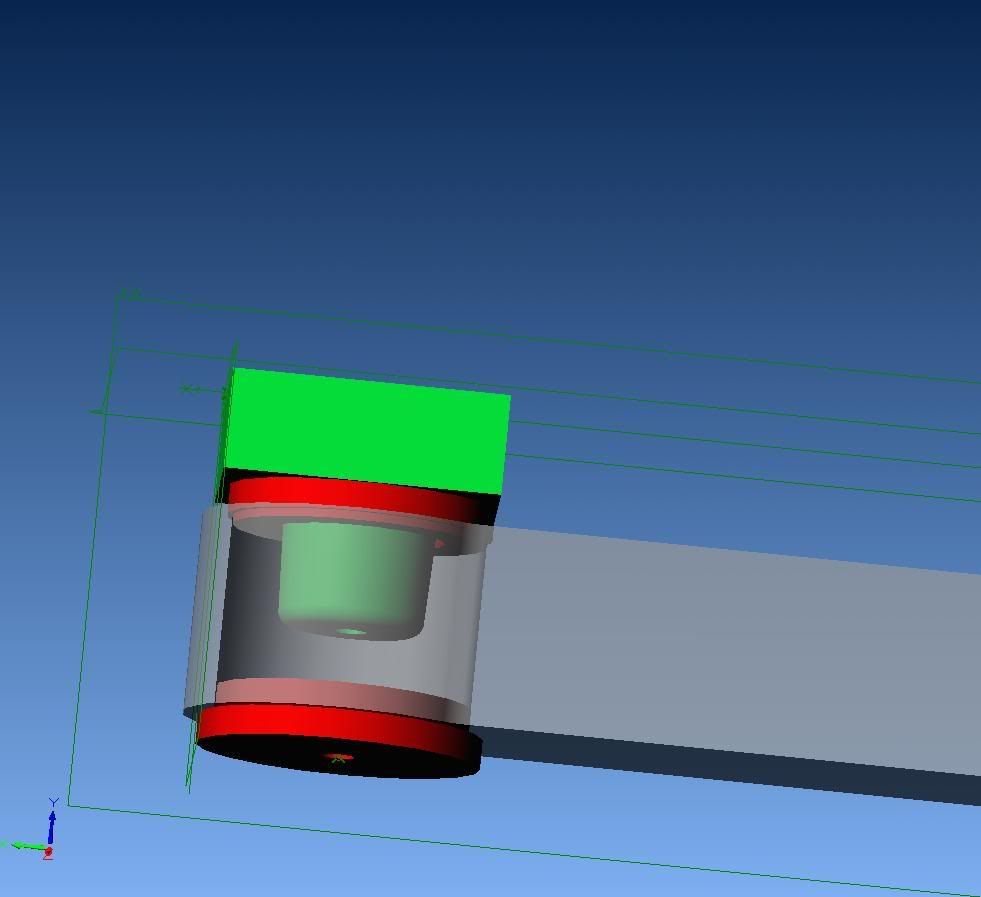

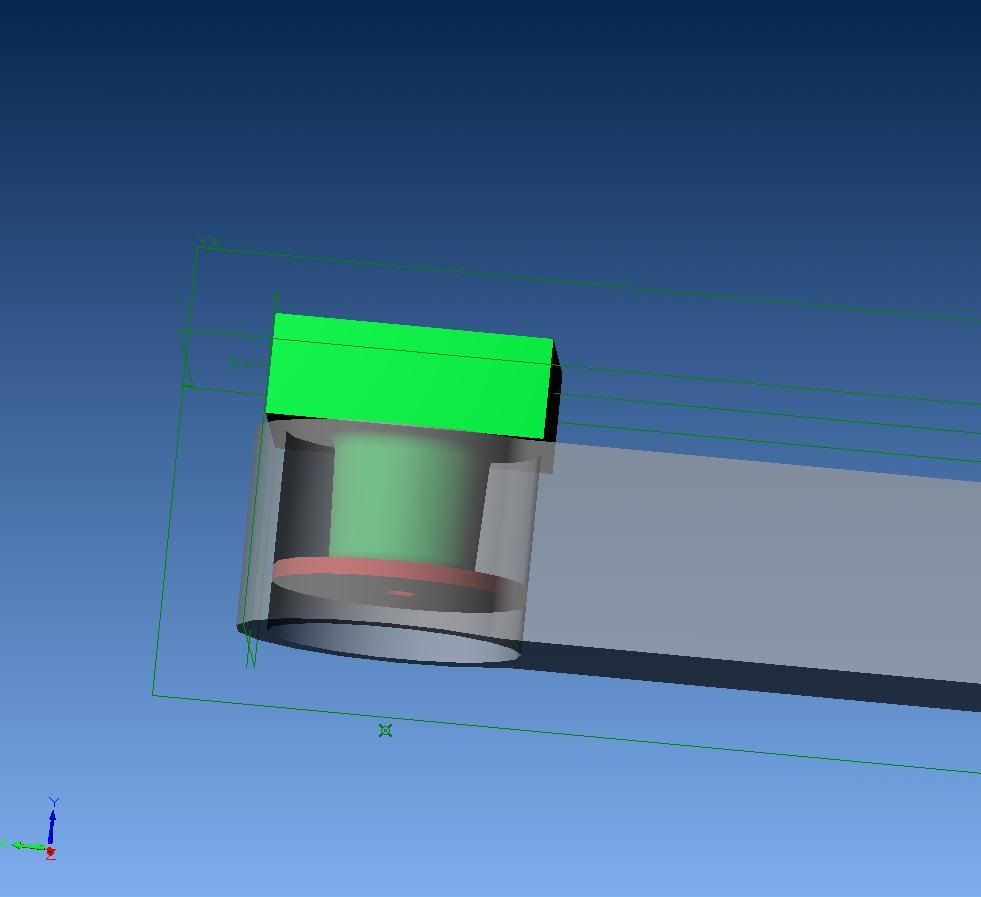

TheSkunkWorks & I'm Batman - Does this look like what you are describing?

This is the way I understand the Greenwood VIP article. (except I reduced the hole from 23/32nds to 1/2")

Vesa - I plan on doing the smart struts or some variation, I was just curious if this is close to what others have checked.

TheSkunkWorks & I'm Batman - Does this look like what you are describing?

This is the way I understand the Greenwood VIP article. (except I reduced the hole from 23/32nds to 1/2")

#10

Le Mans Master

This isn't about camber curve, rather combating toe-steer during rear suspension travel. Be careful how much camber gain you dial out.

mpettus, I understand the whys and wherefores and have this on my list, but so I don't make a false assumption and give you inaccurate info you'll have to ask the Bat to verify this, as I've yet to perform this one...

mpettus, I understand the whys and wherefores and have this on my list, but so I don't make a false assumption and give you inaccurate info you'll have to ask the Bat to verify this, as I've yet to perform this one...

Last edited by TheSkunkWorks; 01-13-2008 at 12:57 AM.

#11

Team Owner

Member Since: Oct 2004

Location: Springfield MO

Posts: 23,831

Likes: 0

Received 6 Likes

on

6 Posts

St. Jude Donor '07

Last edited by I'm Batman; 01-13-2008 at 02:23 AM.

#13

Instructor

Thread Starter

Thanks,

#15

Racer

Member Since: Dec 2004

Location: Wichita Kansas

Posts: 410

Likes: 0

Received 0 Likes

on

0 Posts

I finally got around to taken everything apart. The male insert on the frame looks like it bottoms out in the diff crossmember bushings. It looks like the design is for the diff to be able to rock up and down a little at the front mount. I have poly front diff mount which probably stops if from moving much. I also have the aluminum cross member reinforcing donuts which I don't think do any good. Seems to me that cutting a hole large enough in the aluminum donuts to fit over the male frame locators would make a pretty firm set up. The only way I see to raise the diff is to remanufacture the cross member. I'm not sure any of this is worth the trouble.

#16

Melting Slicks

The cross member can be raised up to 3/4" without modifying it, but the rubber bushings have to be removed and the metal flange on the frame has to be hammered flat. I got 5/8" because I placed a 1/8" piece of rubber between the cross member and frame to keep gear noise to a minimum.

#17

Racer

Member Since: Dec 2004

Location: Wichita Kansas

Posts: 410

Likes: 0

Received 0 Likes

on

0 Posts

Jason;

How does the cross member stay centered. I haven't removed my rubber bushings so don't know what it lookd like with out them. Also did you then put a spacer between the diff and strut bar bracket to make up for the difference. I assume the strut rods are way out of alignment since they have been raised?

How does the cross member stay centered. I haven't removed my rubber bushings so don't know what it lookd like with out them. Also did you then put a spacer between the diff and strut bar bracket to make up for the difference. I assume the strut rods are way out of alignment since they have been raised?

#18

Instructor

Thread Starter

Jason;

How does the cross member stay centered. I haven't removed my rubber bushings so don't know what it lookd like with out them. Also did you then put a spacer between the diff and strut bar bracket to make up for the difference. I assume the strut rods are way out of alignment since they have been raised?

How does the cross member stay centered. I haven't removed my rubber bushings so don't know what it lookd like with out them. Also did you then put a spacer between the diff and strut bar bracket to make up for the difference. I assume the strut rods are way out of alignment since they have been raised?

I don't believe raising up the rear differential should change your suspension curves, just your starting point in the curve. Your relationship of half shaft pivots and strut bar pivots will remain the same. With that said lowering the strutbars with either a plate or the "smart struts" will change that curve.

Jim,

I saw you were at Nationals last year in Topeka. I am sure I checked out your car at one point throughout the week. Hopefully I will get to make it out there again next year (although it won't be in the vette).

#19

Le Mans Master

#20

Racer

Member Since: Dec 2004

Location: Wichita Kansas

Posts: 410

Likes: 0

Received 0 Likes

on

0 Posts

I haven't researched the SCCA rules about raising the diff. Since the car has been lowered then adjusting the diff to match would seem OK. Smart struts aren't legal because they change the locating points of the struts. Putting in a plate 1/2 inch between the diff and bracket would take it back to about the stock angles. A reall y grey area in the rules. I really should just sell the car and buy something newer, but ol red is the longest relationship I've ever had.:o I really need to falir the car and go to 315 rubber. Back to the orginal subject seems the best way to mount the cross member is to machine a plate that has the correct center hole and and a flange that goes into the large hole and centers the cross member. I'm just going to put mine back together and live with it. I'm not worried about the half shafts angle as the car is a trailer queen. I control the toe issue by having 3/8 toe in.