Rear Differential Gear Setup-pinion runout problems?

#1

Pro

Thread Starter

Hey Gary/Mike and others,

I'm experiencing the joy of setting up differential gears, and I think you might be interested in what I'm finding in this set. It's a new Tom's/US Gear 3.55 set that's doing something odd. I can't be sure if this is due to runout in the pinion or the bearings, but to me the pinion is probably more suspect than the bearings.

Background:

I have a good pattern but am having trouble getting 0.005-0.007 backlash. I am running a .0208" pinion shim, 0.2342" left total shim, 0.2503" total right shim in a '76 case. The previous differential didn't have any known gear problems, but the posi carrier is new due to a worn crosspin bore in the original. I was getting 0.004-0.005 (checked in only 3-4 teeth) and Gary suggested "too tight, shift a little for 0.005-0.007 backlash".

OK, should be straighforward enough- I rearranged the shims to take out .001" from the left and add it to the right.

Now, I have been reading a LOT of descriptions on how to set these things up, and one paper I read suggested measuring runout of the ring gear, mark the max and min spots, and make sure you check backlash at these spots. OK, I did that- I marked those teeth and made sure I repeatedly checked those spots. With the above shift, my new measurements were 0.005-0.007- PERFECT.

However, I have a bit of six sigma training (I can just hear you guys groaning now!) so I decided to take MORE DATA. What I found doesn't make me real comfortable. With 10 data points, I discovered a range in backlash of 0.0035-0.0075 (not good at all).

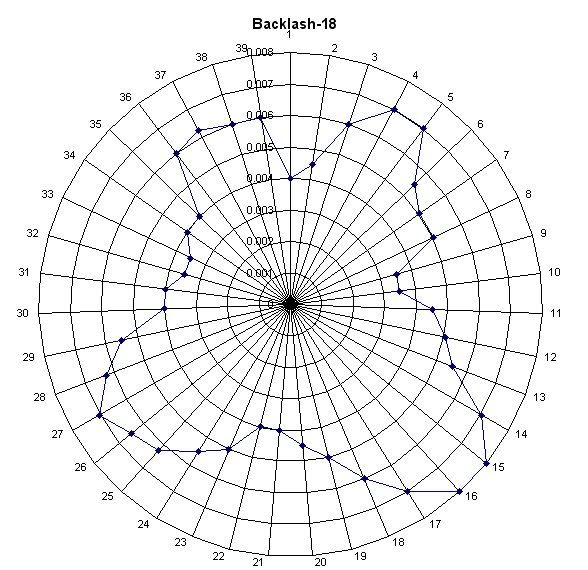

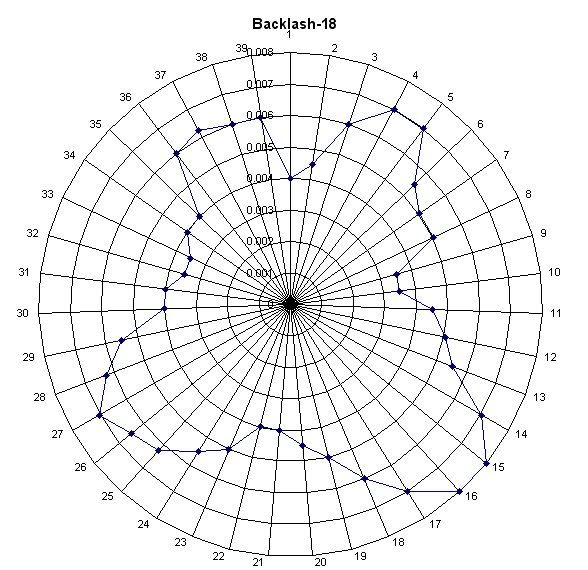

So, I re-shimmed again, moving it another .001 to shift the average and hopefully get the 0.005-0.007 target. This time I went all out- I checked backlash at every tooth. Look at what this data shows:

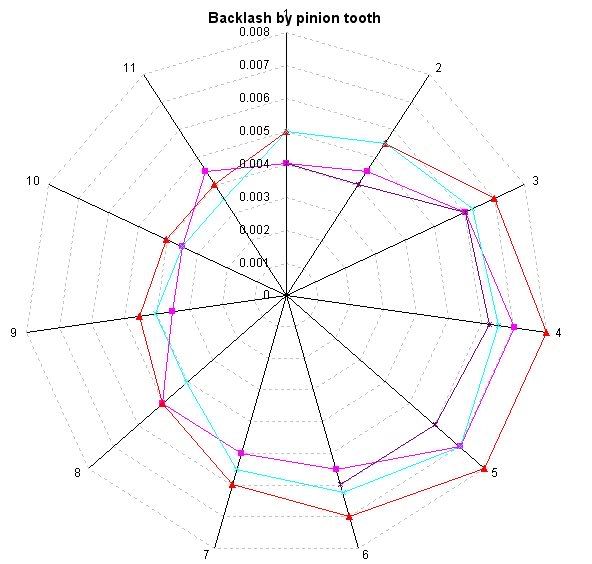

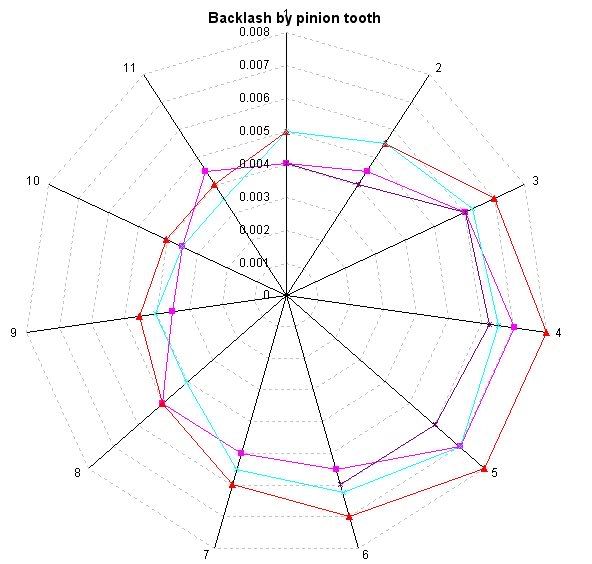

Do you see that there appears to be a pattern? It's obvious when I plot the data by pinion teeth (there are 11 pinion teeth) instead of by ring teeth:

It's obvious when I plot the data by pinion teeth (there are 11 pinion teeth) instead of by ring teeth:

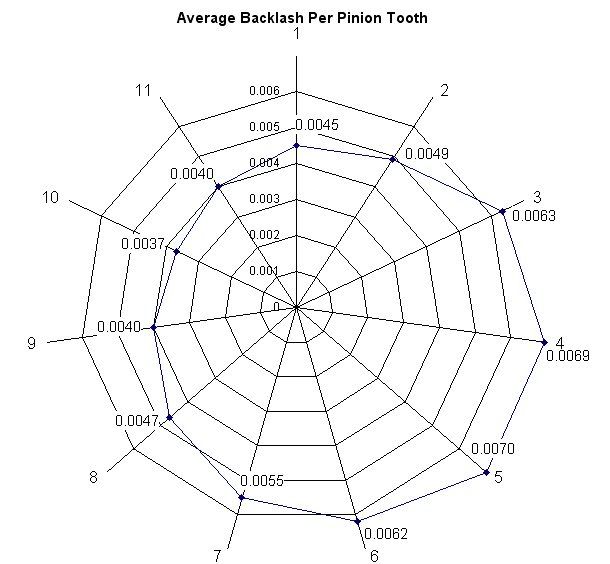

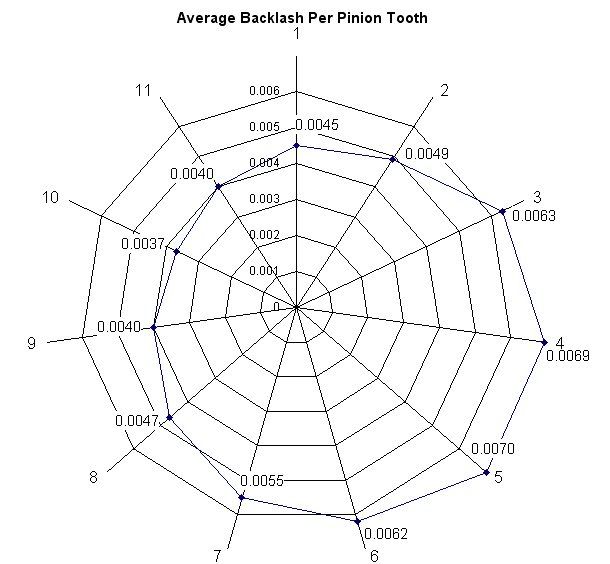

This looks to me to clearly be pinion runout- something I absolutely cannot control. It could be in the pinion bearing or in the pinion gear itself, but it's there. If I average the data taken on each tooth and plot it, here's what it looks like:

It could be in the pinion bearing or in the pinion gear itself, but it's there. If I average the data taken on each tooth and plot it, here's what it looks like:

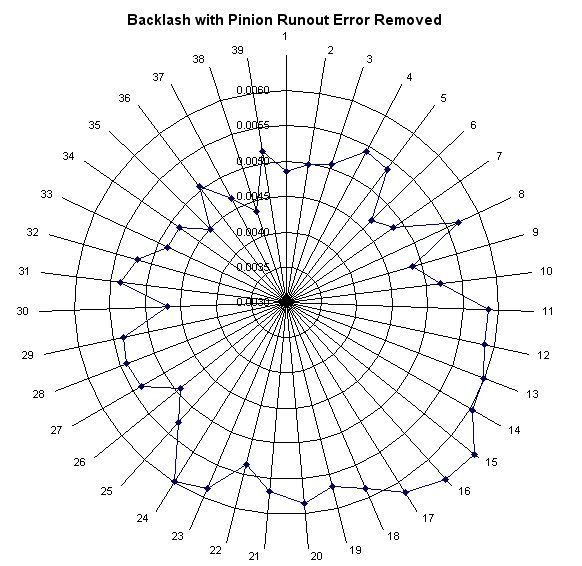

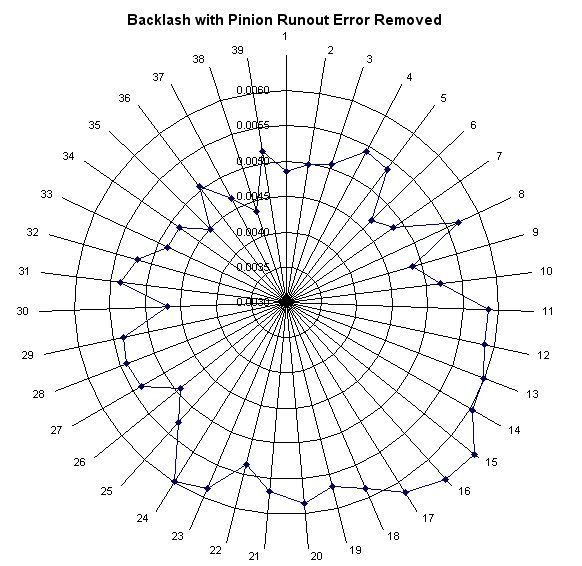

Interestingly, I can take these averages per tooth- which is really backlash caused by the pinion runout- and subtract it from the total average to find out the effect of the runout on each tooth. Once I know what the tooth's runout variation is, I can subtract that value from the original data to get a "corrected" backlash value for each ring gear tooth. Here's what that plot looks like:

You can even start to see the effect of ring gear runout here.

What's the point of all of this? Well, I have a large source of variability in backlash that I can't control- by itself, it's responsible for 0.0033" of backlash variation (with standard deviation of 0.0012"). With it present, I cannot get my backlash to within the 0.005-0.007 range.

So, what is acceptable under these circumstances? I'm sure my present 0.0035-0.009" backlash is NOT acceptable, but I have a darn good pattern here, and probably more data than anyone else bothers to take, so maybe I'm just concerned about nothing. On the other hand, maybe my gears are defective- I dunno.

What do you think? :

:

I'm experiencing the joy of setting up differential gears, and I think you might be interested in what I'm finding in this set. It's a new Tom's/US Gear 3.55 set that's doing something odd. I can't be sure if this is due to runout in the pinion or the bearings, but to me the pinion is probably more suspect than the bearings.

Background:

I have a good pattern but am having trouble getting 0.005-0.007 backlash. I am running a .0208" pinion shim, 0.2342" left total shim, 0.2503" total right shim in a '76 case. The previous differential didn't have any known gear problems, but the posi carrier is new due to a worn crosspin bore in the original. I was getting 0.004-0.005 (checked in only 3-4 teeth) and Gary suggested "too tight, shift a little for 0.005-0.007 backlash".

OK, should be straighforward enough- I rearranged the shims to take out .001" from the left and add it to the right.

Now, I have been reading a LOT of descriptions on how to set these things up, and one paper I read suggested measuring runout of the ring gear, mark the max and min spots, and make sure you check backlash at these spots. OK, I did that- I marked those teeth and made sure I repeatedly checked those spots. With the above shift, my new measurements were 0.005-0.007- PERFECT.

However, I have a bit of six sigma training (I can just hear you guys groaning now!) so I decided to take MORE DATA. What I found doesn't make me real comfortable. With 10 data points, I discovered a range in backlash of 0.0035-0.0075 (not good at all).

So, I re-shimmed again, moving it another .001 to shift the average and hopefully get the 0.005-0.007 target. This time I went all out- I checked backlash at every tooth. Look at what this data shows:

Do you see that there appears to be a pattern?

It's obvious when I plot the data by pinion teeth (there are 11 pinion teeth) instead of by ring teeth:

It's obvious when I plot the data by pinion teeth (there are 11 pinion teeth) instead of by ring teeth:

This looks to me to clearly be pinion runout- something I absolutely cannot control.

It could be in the pinion bearing or in the pinion gear itself, but it's there. If I average the data taken on each tooth and plot it, here's what it looks like:

It could be in the pinion bearing or in the pinion gear itself, but it's there. If I average the data taken on each tooth and plot it, here's what it looks like:

Interestingly, I can take these averages per tooth- which is really backlash caused by the pinion runout- and subtract it from the total average to find out the effect of the runout on each tooth. Once I know what the tooth's runout variation is, I can subtract that value from the original data to get a "corrected" backlash value for each ring gear tooth. Here's what that plot looks like:

You can even start to see the effect of ring gear runout here.

What's the point of all of this? Well, I have a large source of variability in backlash that I can't control- by itself, it's responsible for 0.0033" of backlash variation (with standard deviation of 0.0012"). With it present, I cannot get my backlash to within the 0.005-0.007 range.

So, what is acceptable under these circumstances? I'm sure my present 0.0035-0.009" backlash is NOT acceptable, but I have a darn good pattern here, and probably more data than anyone else bothers to take, so maybe I'm just concerned about nothing. On the other hand, maybe my gears are defective- I dunno.

What do you think?

:

:

Last edited by dstaley; 05-27-2009 at 01:15 AM.

#2

Le Mans Master

I'm for sure NOT an expert like Mike or Gary on these rears, but I can tell you I built a differential or nine when I was working at a Chevy dealer some years ago. One in particular I could not get the pattern or the "feel" right. I finally stripped the ring gear off the case, (this one got a new case, all the gears and bearings. Took the old one out with a magnet!) mounted the bare case back into the housing and did a runout on the ring gear mounting face. I forget the exact runout but it was something like .015. Got a new case from parts- went together with no problems.

#3

Pro

Thread Starter

Wow, that is interesting.

The last plot kind of suggests there might be 0.002 or so backlash due to runout (or similar) in the carrier. The ring gear case could sure do that.

Man, it would be a real shame to have a problem with this case after polishing it and all that work- mine and Gary's- in tuning the posi.

I guess at this point I'd rather see the pinion be the root cause of most of my problems than the carrier- the ring gear can be returned for an exchange with little related hassle. I'd have to start over with the ring/pinion shims, but at least the posi would be untouched.

I guess I could check the back side of the gear to see if I notice any significant runout there.

EDIT: I just ran out and checked it. About 0.002" total variaton (parallel to the axis of rotation) as measured on the back of the gear.

The last plot kind of suggests there might be 0.002 or so backlash due to runout (or similar) in the carrier. The ring gear case could sure do that.

Man, it would be a real shame to have a problem with this case after polishing it and all that work- mine and Gary's- in tuning the posi.

I guess at this point I'd rather see the pinion be the root cause of most of my problems than the carrier- the ring gear can be returned for an exchange with little related hassle. I'd have to start over with the ring/pinion shims, but at least the posi would be untouched.

I guess I could check the back side of the gear to see if I notice any significant runout there.

EDIT: I just ran out and checked it. About 0.002" total variaton (parallel to the axis of rotation) as measured on the back of the gear.

Last edited by dstaley; 05-27-2009 at 01:42 AM.

#4

Tech Contributor

Doug,

Step away from the differential. Close the garage door and cut the grass. You may be suffering from Differential Pattern Fatigue(DPF). Possibly a fatal condition, brought on by excessive automotive compulsion. I thought I was looking a ISO,LEAN,and who knows how many other QC/production programs in this post.

It is not uncommon to find BL varying up to 005". Usually Tom's gears are in the 002-003 range. One decieving thing is backlash in an indicator or one that is sticking- had it happen to me once and it drove me crazy.

Confirm your BL is 005 min up to 009 max. It will open 001 when broken in. All the Tom's gears I setup, especially with new cases, were in the 005--007,008 range. You can remove the RG if you want and check the flange for runout. Be sure there are no burrs on the RG or flange.

Check the lash at 90* positions on the RG. You will go crazy checking every tooth, I've seen patterns deep on one tooth, high on the other.

Get the BL between 5-8 check the pattern, and go from there. You were real close before so you're not far now, but first take a break from it.

Step away from the differential. Close the garage door and cut the grass. You may be suffering from Differential Pattern Fatigue(DPF). Possibly a fatal condition, brought on by excessive automotive compulsion. I thought I was looking a ISO,LEAN,and who knows how many other QC/production programs in this post.

It is not uncommon to find BL varying up to 005". Usually Tom's gears are in the 002-003 range. One decieving thing is backlash in an indicator or one that is sticking- had it happen to me once and it drove me crazy.

Confirm your BL is 005 min up to 009 max. It will open 001 when broken in. All the Tom's gears I setup, especially with new cases, were in the 005--007,008 range. You can remove the RG if you want and check the flange for runout. Be sure there are no burrs on the RG or flange.

Check the lash at 90* positions on the RG. You will go crazy checking every tooth, I've seen patterns deep on one tooth, high on the other.

Get the BL between 5-8 check the pattern, and go from there. You were real close before so you're not far now, but first take a break from it.

Last edited by GTR1999; 05-27-2009 at 11:32 AM.

#5

Drifting

Hi Douglas,

Aren't these things fun!

Going by your charts you have pinion runout. Are you using a set-up bearing that has been honed? Did you polish the pinion shaft prior to installing the bearings?

I'm curious to see your gear tooth pattern. 0.021 (0.0208) sounds a little too shallow for a 76 housing.

The honing pattern on the gears has a big effect on the backlash. A small amount of runout will be magnified when running across the honed portion. .002-.003 runout is not unusual. .007 is. I would take a closer look at the pinion bearings. I'm assuming you are using TimkenUSA bearings.

The only way to pinpoint what is causing the runout is to remove the pinion bearings and reinstall them 120 degrees. Then rerun the tests comparing the backlash tooth for tooth to the previous readings. After numbering each tooth you will have to do at least 5 ring gear rotations to measure variation of each tooth comparing it to each previous rotation.

Of course we are assuming there is only one entity causing the runout. In reality there are several. The gears made nowadays are not nearly as precise. 20 years ago these problems were rare. And was almost always runout from the carrier.

The best you can hope for is a good average. Change the pinion bearings and the shim and recheck. Measure the shim in several locations to make sure it is flat. Is the shim the correct inner diameter or does it flop around on the pinion?

Mike

Aren't these things fun!

Going by your charts you have pinion runout. Are you using a set-up bearing that has been honed? Did you polish the pinion shaft prior to installing the bearings?

I'm curious to see your gear tooth pattern. 0.021 (0.0208) sounds a little too shallow for a 76 housing.

The honing pattern on the gears has a big effect on the backlash. A small amount of runout will be magnified when running across the honed portion. .002-.003 runout is not unusual. .007 is. I would take a closer look at the pinion bearings. I'm assuming you are using TimkenUSA bearings.

The only way to pinpoint what is causing the runout is to remove the pinion bearings and reinstall them 120 degrees. Then rerun the tests comparing the backlash tooth for tooth to the previous readings. After numbering each tooth you will have to do at least 5 ring gear rotations to measure variation of each tooth comparing it to each previous rotation.

Of course we are assuming there is only one entity causing the runout. In reality there are several. The gears made nowadays are not nearly as precise. 20 years ago these problems were rare. And was almost always runout from the carrier.

The best you can hope for is a good average. Change the pinion bearings and the shim and recheck. Measure the shim in several locations to make sure it is flat. Is the shim the correct inner diameter or does it flop around on the pinion?

Mike

#7

Tech Contributor

#9

Pro

Thread Starter

Thanks for your help guys- Gary, your response had me laughing out loud here at work. Thanks, I needed that!

I completely agree- I think the largest single factor is pinion runout.

I am using Timken USA bearings. Brand new ones, pressed on- I thought I was going through final double-check when I stumbled into this. I did not make any attempt to polish the pinion shaft except at the yoke end of the pinion- and that was by hand with scotch-brite to smooth out the coating. The outer pinion bearing is still very snug as I have to tap the pinion nose (using a very small rubber tipped hammer) or use a press to bump the pinion through the bearing when I disassemble.

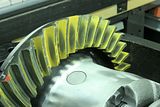

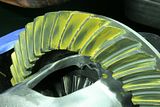

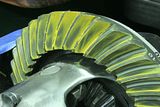

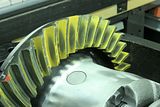

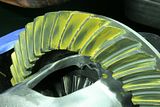

I haven't photographed a pattern check (and I'm at work right now) with the latest attempt at getting backlash right. It seemed visually unchanged since the last check, which is here:

The shim does not have the correct diameter. It flops around. I got it in the master kit that I bought from Gary. I can pull everything apart and check to see if it's flat, and/or I can replace it- do you have a source for shims that you can recommend with the correct ID?

I can remove and re-install the bearing, and/or a new bearing. I don't know if my setup bearing had the same problem, but since it's internally modified by me I don't have any faith that it will be any more true than the unmodified, new one from Timken.

Unfortunately, 39/11 is a fully reduced quotient, so there is no way to optimize which pinion tooth engages which ring gear tooth. Good idea, I did consider that, but every ring gear tooth will eventually engage every ring gear tooth, so there is no way to synchronize / optimize them.

There wasn't any instruction sheet enclosed with my gear set from Tom's. Is there usually one there? Does he/they publish any allowable tolerances for these things?

I completely agree- I think the largest single factor is pinion runout.

I am using Timken USA bearings. Brand new ones, pressed on- I thought I was going through final double-check when I stumbled into this. I did not make any attempt to polish the pinion shaft except at the yoke end of the pinion- and that was by hand with scotch-brite to smooth out the coating. The outer pinion bearing is still very snug as I have to tap the pinion nose (using a very small rubber tipped hammer) or use a press to bump the pinion through the bearing when I disassemble.

I haven't photographed a pattern check (and I'm at work right now) with the latest attempt at getting backlash right. It seemed visually unchanged since the last check, which is here:

The shim does not have the correct diameter. It flops around. I got it in the master kit that I bought from Gary. I can pull everything apart and check to see if it's flat, and/or I can replace it- do you have a source for shims that you can recommend with the correct ID?

I can remove and re-install the bearing, and/or a new bearing. I don't know if my setup bearing had the same problem, but since it's internally modified by me I don't have any faith that it will be any more true than the unmodified, new one from Timken.

Unfortunately, 39/11 is a fully reduced quotient, so there is no way to optimize which pinion tooth engages which ring gear tooth. Good idea, I did consider that, but every ring gear tooth will eventually engage every ring gear tooth, so there is no way to synchronize / optimize them.

There wasn't any instruction sheet enclosed with my gear set from Tom's. Is there usually one there? Does he/they publish any allowable tolerances for these things?

#11

Tech Contributor

Doug,

The shims are fine, I use them all the time. Once the bearing is pressed on then it will space the bearing. I don't like to remove the new bearings unless needed. Most is done with the setup bearings and usually those are in spec with new. Sometimes I have to replace a pinion shim with another size when new bearings are installed and if so it's about 002 difference.

I see the setup bearings going bad after about 3 rebuiilds. The torque wrench starts to jump all over the place.

Before I would remove anything, I would go back to start, fresh and see where you are. As Mike said, the gears are not like the original GM's and will not center like Text book patterns. You were close in that picture and maybe just a grease issue as well.

I went back to my notes on a 73 diff I used 355's in and the final shim was 026,18 ib/lb ,239/243 shims, 5-7 BL and the pattern was dead on. The car is on the road quiet and smooth.

It take a lot of time to do it right. Take your time.

The shims are fine, I use them all the time. Once the bearing is pressed on then it will space the bearing. I don't like to remove the new bearings unless needed. Most is done with the setup bearings and usually those are in spec with new. Sometimes I have to replace a pinion shim with another size when new bearings are installed and if so it's about 002 difference.

I see the setup bearings going bad after about 3 rebuiilds. The torque wrench starts to jump all over the place.

Before I would remove anything, I would go back to start, fresh and see where you are. As Mike said, the gears are not like the original GM's and will not center like Text book patterns. You were close in that picture and maybe just a grease issue as well.

I went back to my notes on a 73 diff I used 355's in and the final shim was 026,18 ib/lb ,239/243 shims, 5-7 BL and the pattern was dead on. The car is on the road quiet and smooth.

It take a lot of time to do it right. Take your time.

#12

Le Mans Master

Did Tom say: "Dude you need between 0.004-0.006" or "Dude set it here"? I would go with the pattern first then worry about back-lash, it looks to me like your right in the ballpark (0.004 backlash is TOO TIGHT for any gearset in my book and I launch my Vettes at 3200RPM on slicks at times.) You should run-in the gear set for 15-20 minutes and get in a good "heat set" before actually going out and driving them, there IS a reason you break-in gear sets (run them in, let them cool for several hours.) You should have watched me set up my 4.56 differential, I took 6 hours to get the pattern where I could live with before I was finished with the job, I even went to my friend Dave Herlinger's Corvette Repair to get a 2nd opinion and he helped me finish the job (gear set was used!) Those "junk" 4.56 gears have been used for over 8,000 miles and lots of strip action now. Nothing is Perfect, you have done a good job, settle for "near prefection" which it looks like you have achieved.

#14

Pro

Thread Starter

Thanks for the new posts guys. Honestly I didn't notice him call me "dude", but I'm not sure it didn't happen!

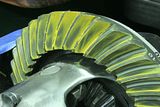

Two more iterations tonight, and I think I might have it. Here are the patterns, taken at 0 degrees (in front of the big window), and 90, 180, 270, etc. for drive and coast. I broke out the good camera for these posterity pictures.

Drive:

Coast:

So, does this look acceptable as far as pattern?

Iteration 20 details:

Pinion shim: 0.0208"

Left (ring gear side) shim: 0.2342", Right (non-ring gear side) shim: 0.2503"

Backlash: 0.0050 - 0.0095 (yes, I did measure every tooth again!)

I believe I'm satisfied with the pattern from what tiny bit I know, and after talking to Gary I guess I'm satisfied that the backlash is as good as it's going to get without heroic efforts (buying more gearsets in futile and likely meaningless attempt to get a "happier" backlash range). If it performs, doesn't fail, and is quiet enough that I don't hear it over the exhaust, I'm probably happy.

Two more iterations tonight, and I think I might have it. Here are the patterns, taken at 0 degrees (in front of the big window), and 90, 180, 270, etc. for drive and coast. I broke out the good camera for these posterity pictures.

Drive:

Coast:

So, does this look acceptable as far as pattern?

Iteration 20 details:

Pinion shim: 0.0208"

Left (ring gear side) shim: 0.2342", Right (non-ring gear side) shim: 0.2503"

Backlash: 0.0050 - 0.0095 (yes, I did measure every tooth again!)

I believe I'm satisfied with the pattern from what tiny bit I know, and after talking to Gary I guess I'm satisfied that the backlash is as good as it's going to get without heroic efforts (buying more gearsets in futile and likely meaningless attempt to get a "happier" backlash range). If it performs, doesn't fail, and is quiet enough that I don't hear it over the exhaust, I'm probably happy.

#15

Safety Car

Are you using a setup bearing that you honed? I found that a setup bearing (new out of the package and honed) does mess around with you pattern/BL readings - it can change when you press on the final new bearing when you think you are done. Gary is right - step away from that thing for a day or two, or else you are going to drive yourself mental.

Last edited by stinger12; 05-28-2009 at 04:12 AM.

#17

Drifting

Your pics show another problem with these new gearsets. Deep pattern on drive and shallow on coast. There's nothing you can do to fix this so you have to come up with a happy compromise. You are very close. Only change I would make is add .001 to the pinion shim. But the pattern you have now will work fine.

In the last pic you can see a line in the center of the pattern. This is a good example of what I was saying about the gears not being as good as the old days.

Other than that..... good job!

Mike

In the last pic you can see a line in the center of the pattern. This is a good example of what I was saying about the gears not being as good as the old days.

Other than that..... good job!

Mike

#18

Pro

Thread Starter

Thank you Mike, I really can't thank you guys enough. I appreciate you taking time out of your busy schedules to help me out with this.

I'm at work and my shims are at home, but unless I'm mistaken I think the shims in this "master" kit come in roughly 0.002" increments. I don't have personal access to a surface grinder, so I'd have to farm it out to someone to have one made up.

I could rant about the (poor) gear quality, but thanks to Gary and you at least we know which ones are at the top of the "heap". Richmond has had problems running their business for decades, Yukon is widely rumored to be 100% offshore production with stereotypical quality issues, and few other competitors remain. Thank you for helping us keep the headaches to a minimum. I seem to generate enough of my own headaches for all of us combined! I think Gary's afraid I'm going to try to get this web site ISO compliant by the end of the year or something.

I'm at work and my shims are at home, but unless I'm mistaken I think the shims in this "master" kit come in roughly 0.002" increments. I don't have personal access to a surface grinder, so I'd have to farm it out to someone to have one made up.

I could rant about the (poor) gear quality, but thanks to Gary and you at least we know which ones are at the top of the "heap". Richmond has had problems running their business for decades, Yukon is widely rumored to be 100% offshore production with stereotypical quality issues, and few other competitors remain. Thank you for helping us keep the headaches to a minimum. I seem to generate enough of my own headaches for all of us combined! I think Gary's afraid I'm going to try to get this web site ISO compliant by the end of the year or something.

#19

Tech Contributor

The coast looks high to me and that 020 shim would be indicative of that. When I'm faced with a set that is off between the drive and coast but still in range, I concentrate on the coast setup. Usually that brings the drive in a little deeper but not too bad.

Patterning can be a trail thing, I had a set of 355's that didn't want to show a good pattern with the load from the RG bolts, once I spun it with my fixture it brought the pattern right out and it was right on.

Maybe email me some clear shots on them again so I can get a better look.

Patterning can be a trail thing, I had a set of 355's that didn't want to show a good pattern with the load from the RG bolts, once I spun it with my fixture it brought the pattern right out and it was right on.

Maybe email me some clear shots on them again so I can get a better look.

#20

Le Mans Master

I hope you are putting a load on the differential when checking the pattern. My friend Dave Herlinger at Corvette Repair (Mtn View, CA 650-969-5351) taught me to load the differnetial with a rope tied around a side yoke and loaded when checking the pattern.