598 cid and 4-link Stingray Build

#44

Drifting

Unbelievable , very nice work, should be a beast!

#45

Advanced

Thread Starter

You can but I highly recommend cutting the end off and having a new 1350 end welded back on. You will definitely want to avoid putting weak links in this chain when you drop the hammer on the 598. Jim Moore 427Hotrod suggested a wall thickness to me at the time and I was able to find it and just made a whole new shaft with 1350's on both ends. I can't recall the thickness but the driveshaft shop said it would hold up well. Jim may can give you some input.

And your welds look great!

-Patrick

And your welds look great!

-Patrick

#46

Advanced

Thread Starter

#48

Advanced

Thread Starter

Talked to Josh at Autofab today about the cracked weld on the 4-link arm and the missing shock mounts. He was great and said that he would rather send us a new 4-link arm than having me weld another pass on it. He wanted to see it in person so he could find out why it cracked. He also said the shock mounts are on their way. They've been really responsive and great to deal with.

#51

Advanced

Thread Starter

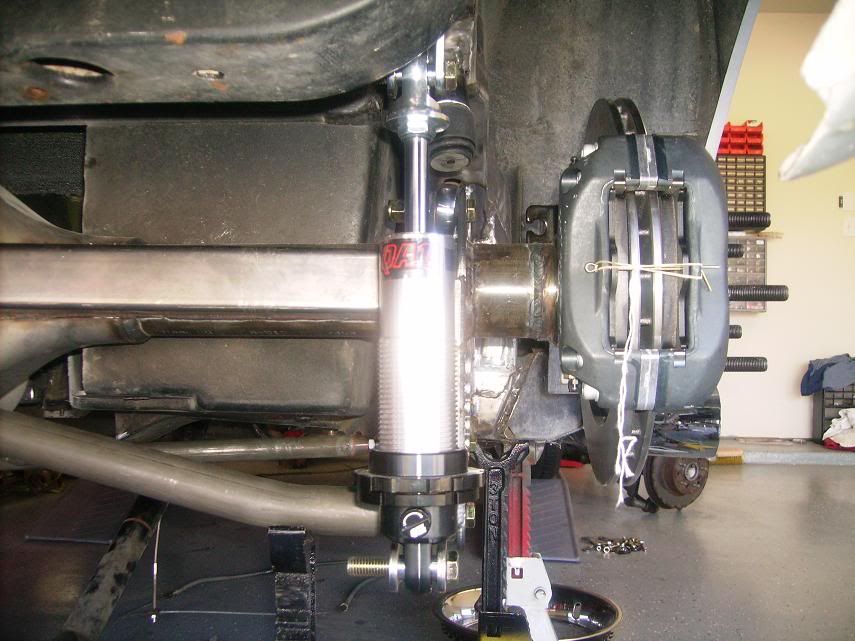

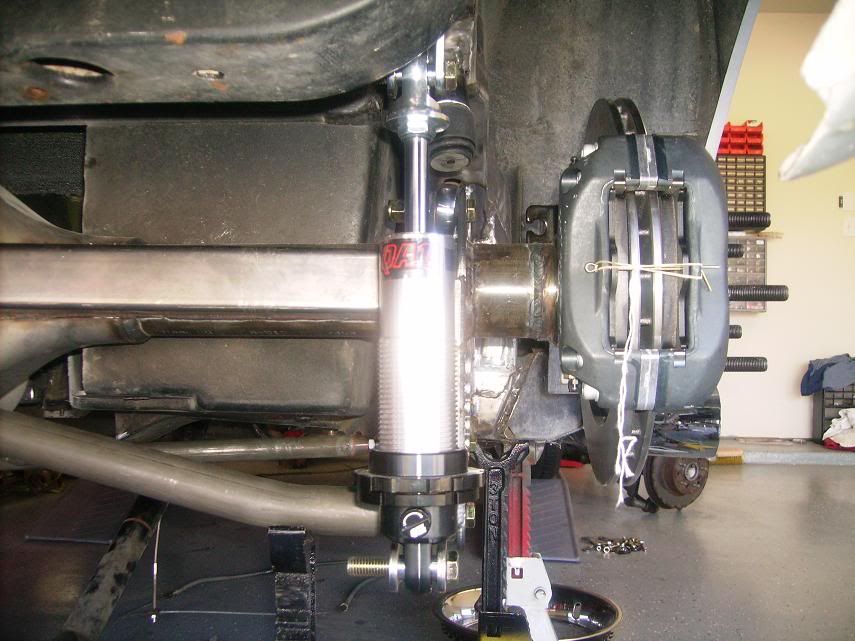

A little more progress this weekend. Adjusted all of the link bars, centered the axle and set the pinion angle. We moved the axle back a little further than the Autofab instruction said (3/8") to make sure there is plenty of tire to frame clearance up front. We welded in the shock mounts, trimmed some more clearance for the diff and made some bump stops to make sure we could have a low and mean stance without any expensive axle to fiberglass "whoopsies." The steel to finish the cross member should be in early this week. We also decided on rims and tires. We're going to keep it retro with 15x8" rallys with 4.5" backspacing and 26x11.5 Hooser Quick Time Pros, which we'll order on Monday.

#52

Advanced

Member Since: Jun 2010

Location: Pulaski Wisconsin

Posts: 86

Likes: 0

Received 0 Likes

on

0 Posts

That is the hot set-up . Some day soon I will have to do the same conversion. Question, the wheel studs look like 5/8 inch and I would like to know how the rally wheels passed over them?

. Some day soon I will have to do the same conversion. Question, the wheel studs look like 5/8 inch and I would like to know how the rally wheels passed over them?

. Some day soon I will have to do the same conversion. Question, the wheel studs look like 5/8 inch and I would like to know how the rally wheels passed over them?

. Some day soon I will have to do the same conversion. Question, the wheel studs look like 5/8 inch and I would like to know how the rally wheels passed over them?

#53

Advanced

Thread Starter

What fitting is everyone using to adapt the main brake line to the new lines? The original distribution block by the rear driver's side frame has two outlets which won't work with the new setup.

#54

Advanced

Member Since: Jun 2010

Location: Pulaski Wisconsin

Posts: 86

Likes: 0

Received 0 Likes

on

0 Posts

Not sure if its 1/8 or 3/16 line back there but you probably are going to -3 or -4 AN steel braided brake line. Check these out.

https://www.racerswholesale.com/prod...m?InvKey=41496

https://www.racerswholesale.com/product.cfm?InvKey=4394

https://www.racerswholesale.com/prod...m?InvKey=41496

https://www.racerswholesale.com/product.cfm?InvKey=4394

#56

Advanced

Thread Starter

It'll be a little bit. We're trying to get the 4-link done before the engine for the Nova comes back. (I blew it up at 28 psi of boost) After the Nova is back on the road, we'll start on the engine and tranny for the vette. We'll probably do the cage for the vette before the engine and tranny too.

#60

Burning Brakes