Diff Side Yoke moves in and out ALOT

#1

Instructor

Thread Starter

I hade my tyres and rims balanced today and put them back on my 1979.

Thought I would do a bearing check with a lever under the tyre and lever up.

The drivers side moved a bit, but the passenger side moved the side yoke in and out heaps.

This movement then equates to the top of the wheel flopping around.

With the wheel off I can grab the brake caliper and move the whole trailing arm up and down moving the yoke in and out.

I am assuming the clip inside the diff has come off !!!!!

1- What do I need to do now ????

2- How much movement of the YOKE in and out is acceptable ?

Andy

Thought I would do a bearing check with a lever under the tyre and lever up.

The drivers side moved a bit, but the passenger side moved the side yoke in and out heaps.

This movement then equates to the top of the wheel flopping around.

With the wheel off I can grab the brake caliper and move the whole trailing arm up and down moving the yoke in and out.

I am assuming the clip inside the diff has come off !!!!!

1- What do I need to do now ????

2- How much movement of the YOKE in and out is acceptable ?

Andy

#2

Race Director

most likely the end of the yoke has worn away, to fix you need to pull the diff and change yoke(s), one thing to think about is all that metal off the yoke floating around inside your diff, it might be time for a rebuild.

#3

Instructor

Thread Starter

So most likely result will be to pull the diff and check internals and replace what needs to be replaced, diff was rebuilt by PO 8 years ago.

If I hadn't had the tyres balanced and checked the play I would not know of the problem and kept driving.

Is it still ok to keep driving until I have time to drop Diff ???

If I hadn't had the tyres balanced and checked the play I would not know of the problem and kept driving.

Is it still ok to keep driving until I have time to drop Diff ???

#4

Team Owner

Like redvetracr said: The yokes ware away because they ride against the posi unit cross pin. But since your posi unit was rebuilt 8 years ago I tend to believe that it was rebuilt using an Eaton cone type posi unit. The male and female sides of the cone ware away allowing the yokes to have in and out play especially on the passenger side.

I believe that you need to pull the diff out and order a new posi unit

I believe that you need to pull the diff out and order a new posi unit

#5

Instructor

Thread Starter

Ok, sounds like the diff has to come out and find out what's worn or not.

The amount of movement on the passenger side makes me believe the clip has come off the yoke.

Will it hurt to still drive for a little while ?

The amount of movement on the passenger side makes me believe the clip has come off the yoke.

Will it hurt to still drive for a little while ?

#6

Instructor

I would not drive this, be glad you found it before any more damage was caused.

#7

Instructor

Thread Starter

Hey, really appreciate the quick replies to this problem.

As I am in Australia it will be a case of trying to source parts locally as freight from the USA is sooooo expensive.

Anybody have step by step instructions to remove the diff for beginners ??

Andy

As I am in Australia it will be a case of trying to source parts locally as freight from the USA is sooooo expensive.

Anybody have step by step instructions to remove the diff for beginners ??

Andy

#8

Team Owner

When the cone wares away on an Eaton posi unit. It is drivable up to the point where the external yoke will begin to have contact with the diff housing. I just did a Eaton posi in the shop a couple of years ago. They have some advantages over stock posi units

#9

Had a 1976 L-82, 4-sp

Member Since: Mar 2011

Location: Some days your the dog and some days your the hydrant.

Posts: 5,338

Received 1,199 Likes

on

925 Posts

Royal Canadian Navy

How much play do you have? "Alot" doesn't tell us much. I have about 0.10". Some will say that's alot but I'm not rushing out to do a rebuild just yet.

#10

Race Director

you can learn something by doing a search of posts by Mike Dwyer AKA tracdogg2, he is the resident diff expert here at CF, you should also crawl under the car and inspect the diff housing where the side yokes go in, you can wear the yokes enough to where the yoke wears away the housing that holds the seal and then you will need to replace the whole thing, other than pulling the rear crossmember it`s all pretty straight forward, just start taking stuff off.

#11

Had a 1976 L-82, 4-sp

Member Since: Mar 2011

Location: Some days your the dog and some days your the hydrant.

Posts: 5,338

Received 1,199 Likes

on

925 Posts

Royal Canadian Navy

I've inspected my housing for signs of wear and to date there isn't any. The dust shield or flange on the yoke is still intact. I've never seen anyone give a definitive answer on the maximum allowable end play and it's not in my service manual. I would think that it should be listed as a spec but maybe GM engineers felt otherwise for whatever reason.

#12

Melting Slicks

Might be time to break out a dial gauge to measure the amount of play.

End play:

Less than .025 No problem

.025 - .050 Starting to wear, consider inspection

.050 - .100 Beyond normal cluth wear, possible clutch damage

and/or heavy stub axle wear. Needs attention

.100-.150 Excessive wear and/or damage. Needs immediate

attention.

.150 -.200 Severe wear and case damage

Please credit above info from fellow CF member Tracdogg2.

Bill

End play:

Less than .025 No problem

.025 - .050 Starting to wear, consider inspection

.050 - .100 Beyond normal cluth wear, possible clutch damage

and/or heavy stub axle wear. Needs attention

.100-.150 Excessive wear and/or damage. Needs immediate

attention.

.150 -.200 Severe wear and case damage

Please credit above info from fellow CF member Tracdogg2.

Bill

#13

Burning Brakes

Member Since: Jul 2009

Location: ESCONDIDO CA

Posts: 1,200

Received 252 Likes

on

112 Posts

C3 of Year Finalist (appearance mods) 2019

Driving it depends on what you do with your car. A cruise, a trip up the coast, not much problem. Road racing, flogging it down a twisting mountain road--not so good. There are other parts that keep things from falling off for normal driving.

Usually easy to remove--just remove the parts attached to it-not rocket science-you'll figure it out.

Don't order a thing until you can look inside. Eight years from rebuild, limited miles, might be nothing more than ring came off. I understand that running your car's drive train while on jack stands can knock off the rings fairly easily.

Good luck Aussie...

Usually easy to remove--just remove the parts attached to it-not rocket science-you'll figure it out.

Don't order a thing until you can look inside. Eight years from rebuild, limited miles, might be nothing more than ring came off. I understand that running your car's drive train while on jack stands can knock off the rings fairly easily.

Good luck Aussie...

#14

Drifting

Might be time to break out a dial gauge to measure the amount of play.

End play:

Less than .025 No problem

.025 - .050 Starting to wear, consider inspection

.050 - .100 Beyond normal cluth wear, possible clutch damage

and/or heavy stub axle wear. Needs attention

.100-.150 Excessive wear and/or damage. Needs immediate

attention.

.150 -.200 Severe wear and case damage

Please credit above info from fellow CF member Tracdogg2.

Bill

End play:

Less than .025 No problem

.025 - .050 Starting to wear, consider inspection

.050 - .100 Beyond normal cluth wear, possible clutch damage

and/or heavy stub axle wear. Needs attention

.100-.150 Excessive wear and/or damage. Needs immediate

attention.

.150 -.200 Severe wear and case damage

Please credit above info from fellow CF member Tracdogg2.

Bill

Good snap rings on good stub axles don't fall off unless the installer was not paying attention.

1969RAY is correct. Don't order anything until it is all torn down and inspected.

I can walk you thru the entire process if you need. Let me know if you want my contact info. Redvetracr has it also.

Mike

#15

Drifting

Mike

#16

Burning Brakes

My diff had the same problem and a previous owner drove it like that for quite a while. Eventually the yoke contacted the diff housing and the housing was junk. Just like gkull said, address it before that happens. I ended up dropping (through a driveline shop) $1300 on a replacement housing and diff/posi rebuild reusing my original gears.

Last edited by AboveTheLogic; 07-31-2016 at 01:48 PM.

#17

Team Owner

#18

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,926 Likes

on

1,931 Posts

I had my tyres and rims balanced today and put them back on my 1979.

Thought I would do a bearing check with a lever under the tyre and lever up.

The drivers side moved a bit, but the passenger side moved the side yoke in and out heaps.

This movement then equates to the top of the wheel flopping around.

With the wheel off I can grab the brake caliper and move the whole trailing arm up and down moving the yoke in and out.

I am assuming the clip inside the diff has come off !!!!!

1- What do I need to do now ????

2- How much movement of the YOKE in and out is acceptable ?

Andy

Thought I would do a bearing check with a lever under the tyre and lever up.

The drivers side moved a bit, but the passenger side moved the side yoke in and out heaps.

This movement then equates to the top of the wheel flopping around.

With the wheel off I can grab the brake caliper and move the whole trailing arm up and down moving the yoke in and out.

I am assuming the clip inside the diff has come off !!!!!

1- What do I need to do now ????

2- How much movement of the YOKE in and out is acceptable ?

Andy

As long as the shafts have not worn so far that the snap ring groove has been consumed, you can repair the shafts by installing hardened steel caps on the ends of the shafts. You need to pull the differential out of the car to do this.

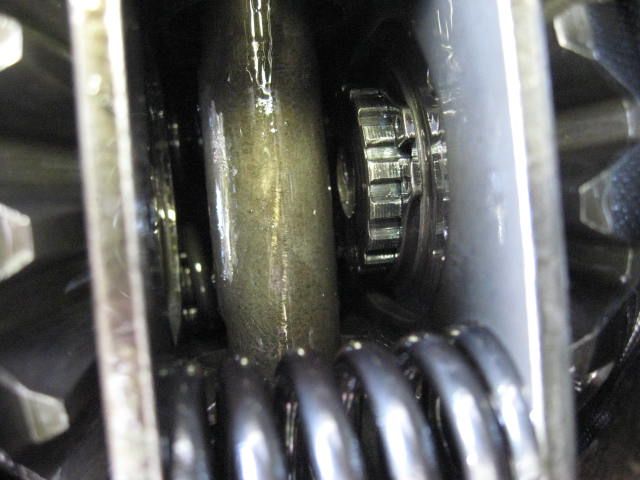

Here I’m measuring the amount of slop at the ends of the stub shafts:

Notice the amount of shaft movement from “in” position to the “out” position:

Spider gear pin pulled, snap rings removed, and shafts pulled out for repair:

Photo shows the severe wear on the end of the one stub shaft. Noting the endplay measured, we then added the amount to be machined off to create a flat surface. The factory center point was modified to create a counterbore:

Machined shaft end with counterbored center to accept a new thrust surface with press-in center nub:

A custom washer was then machined with a nub in the middle for pressing it into the counterbore created in the shaft. The thickness of the washer was determined by adding the measured shaft slop to the amount of material removed off the shaft and adding .010” for endplay clearance. The washers were then heat treated to Rockwell Rc40 and pressed onto the ends of the shafts. Machined and hardened custom thrust washers:

Completed shaft mod ready for install:

This saves the factory shafts and avoids needing to replace them with expensive and inferior aftermarket Chinese-made shafts. Many of these aftermarket shafts are not correctly heat treated, and they fail very quickly due to the soft non-heat-treated shaft ends.

Lars

Last edited by lars; 07-31-2016 at 07:19 PM.

The following users liked this post:

dmaxx3500 (07-31-2016)

#19

Instructor

Thread Starter

The movement I have is more like 15 to 20mm that the Yoke moves in and out.

The receipt from the PO from the rebuild he did says a $650 rebuild of the diff but put in second hand Yokes.

I agree it is best to remove the diff and have a look at what needs replacing, hopefully will start this process in the next couple of days.

Really appreciate all the replies and helpful feedback guys.

tracdogg2 will get in contact if I get into trouble

lars thanks for the pictures explaining the movement

Andy

The receipt from the PO from the rebuild he did says a $650 rebuild of the diff but put in second hand Yokes.

I agree it is best to remove the diff and have a look at what needs replacing, hopefully will start this process in the next couple of days.

Really appreciate all the replies and helpful feedback guys.

tracdogg2 will get in contact if I get into trouble

lars thanks for the pictures explaining the movement

Andy

#20

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,926 Likes

on

1,931 Posts

The movement I have is more like 15 to 20mm that the Yoke moves in and out.

The receipt from the PO from the rebuild he did says a $650 rebuild of the diff but put in second hand Yokes.

I agree it is best to remove the diff and have a look at what needs replacing, hopefully will start this process in the next couple of days.

Really appreciate all the replies and helpful feedback guys.

tracdogg2 will get in contact if I get into trouble

lars thanks for the pictures explaining the movement

Andy

The receipt from the PO from the rebuild he did says a $650 rebuild of the diff but put in second hand Yokes.

I agree it is best to remove the diff and have a look at what needs replacing, hopefully will start this process in the next couple of days.

Really appreciate all the replies and helpful feedback guys.

tracdogg2 will get in contact if I get into trouble

lars thanks for the pictures explaining the movement

Andy

Lars