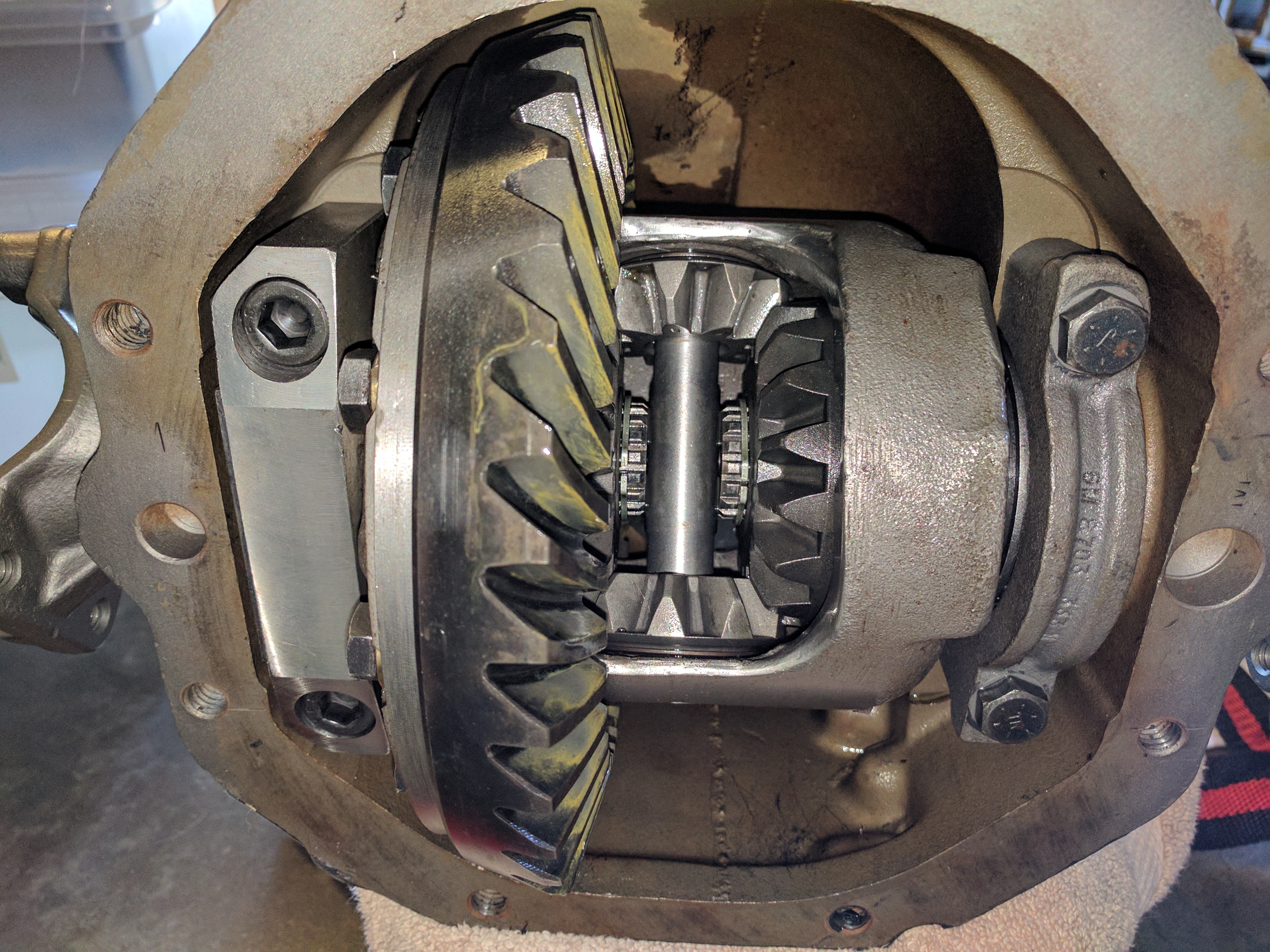

Rear reinstalled after rebuild

The following users liked this post:

Metalhead140 (06-07-2017)

#3

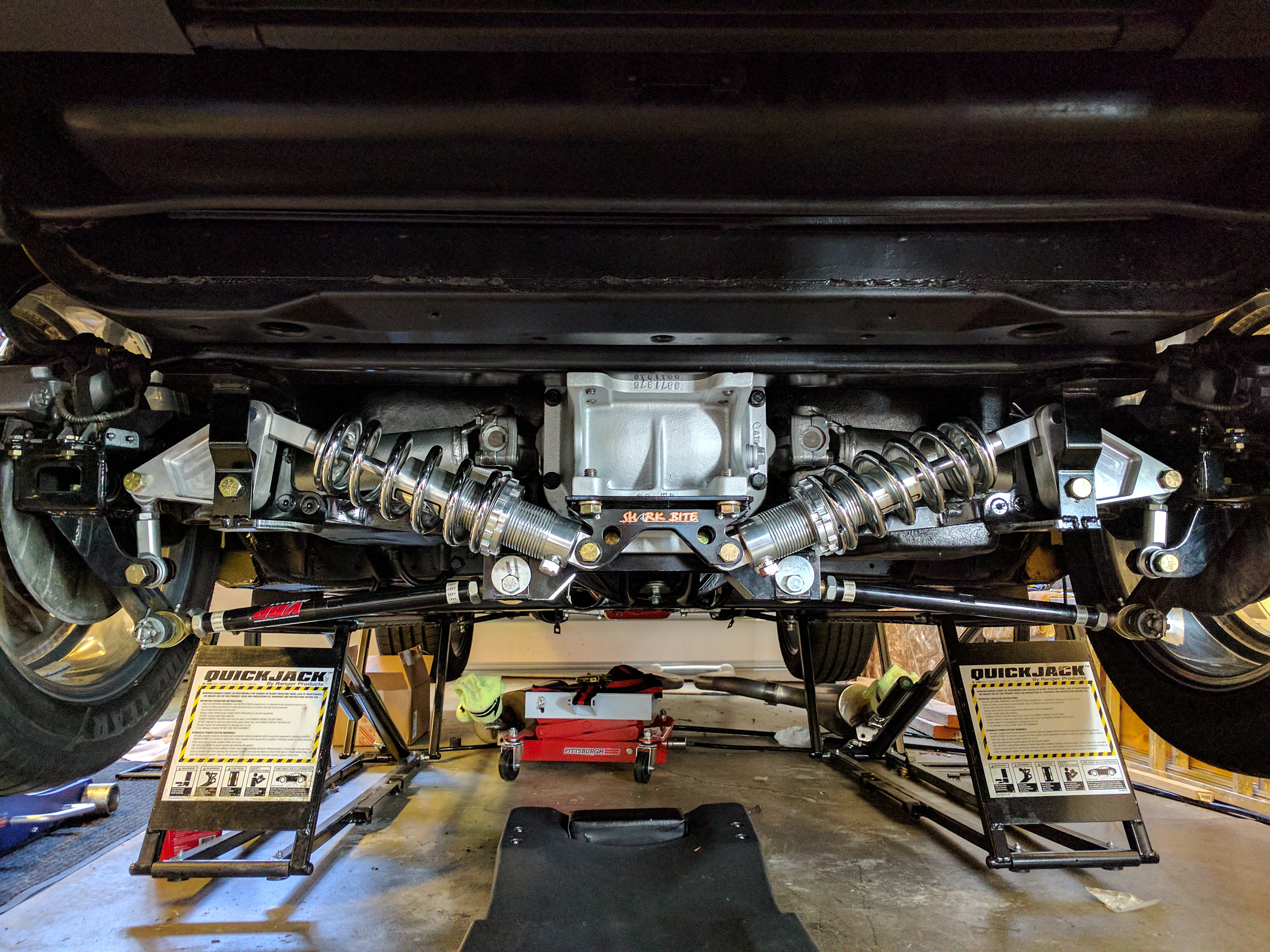

Just got my diff (rebuilt to 3.54 from 3.08) back from Mike recently as well. Starting the process of putting all back together. I won't go quite as far as you with the coil overs, etc., but am going to a fiberglass spring, QA1 shocks, heim-joint adjustable strut rods, etc.

Does your quick-jack always sit with one end up off the ground?

Does your quick-jack always sit with one end up off the ground?

#5

Le Mans Master

Thread Starter

It's on a forward slop so it's tilted a little forward. Engine is on the slop side as it doesn't happen when I pull in the garage.

Rock steady. I was kicking the crap out of the exhaust to get it back in place and it doesn't move.

Rock steady. I was kicking the crap out of the exhaust to get it back in place and it doesn't move.

#11

Race Director

Member Since: Nov 2006

Location: Athens GA

Posts: 19,446

Received 351 Likes

on

304 Posts

St. Jude Donor '12-'13, '15- '16-'17-'18-'19, '21

Especially for 500hp.

Also notice that the ring gear bolts are just grade eights with lock washers...why not use ARPs there?

Very little posi polishing too.

Good luck with that baby.

Hope to have mine done in July. Shooting for 600hp so extra work like cryo and hardening of the inner axles, spiders, etc.

With a stick and 12" rear rims...now is not the time to go cheap.

Have fun.....

#12

Burning Brakes

Really just looks beautiful. Nice work!

The following users liked this post:

mark79,80 (09-18-2017)

#13

Race Director

Member Since: Nov 2006

Location: Athens GA

Posts: 19,446

Received 351 Likes

on

304 Posts

St. Jude Donor '12-'13, '15- '16-'17-'18-'19, '21

Was this just a rebuild that included the new billet cap and a tuned posi?

I have a 2nd differential that does not need a Super 10 build and trying to get ideas of work done, cost and HP it will handle.

Trying to see what the differences between this and a Super 10 build looks like.

Thanks for any info you can provide.

Bman

I have a 2nd differential that does not need a Super 10 build and trying to get ideas of work done, cost and HP it will handle.

Trying to see what the differences between this and a Super 10 build looks like.

Thanks for any info you can provide.

Bman

The following users liked this post:

bmans vette (06-09-2017)

#16

Drifting

These stub axles will easily handle 500hp all day long. Why spend the extra money,

Yes they are new grade 8 ring gear bolts with grade 8 washers. Has anyone ever seen a ring gear bolt fail? If 1200 hp won't break these, I doubt 500 will.

As for polishing, first you have to understand the forces put on the carrier. Since the ring gear is offset to one side, the load on the carrier is torsional. Not lateral, not tension, not compression. A crack always needs a starting point, That's why you polish the edges. Polishing the inside and outside, though it may look pretty, does nothing more than weaken the entire unit and reduces its torsional strength.

Mike

#17

Thanks to tracdogg2 for the great work.

Reinstalling that thing reminds me I need to work out more, or at least start working out LOL.

Attachment 48125596

Attachment 48125597

Reinstalling that thing reminds me I need to work out more, or at least start working out LOL.

Attachment 48125596

Attachment 48125597

Wow! This is Beautifull!!!!

#18

Melting Slicks

That is one Drop Dead Gorgeous Vette you got there!

#19

Race Director

Member Since: Nov 2006

Location: Athens GA

Posts: 19,446

Received 351 Likes

on

304 Posts

St. Jude Donor '12-'13, '15- '16-'17-'18-'19, '21

Good questions, so I'll address them.

These stub axles will easily handle 500hp all day long. Why spend the extra money,

Yes they are new grade 8 ring gear bolts with grade 8 washers. Has anyone ever seen a ring gear bolt fail? If 1200 hp won't break these, I doubt 500 will.

As for polishing, first you have to understand the forces put on the carrier. Since the ring gear is offset to one side, the load on the carrier is torsional. Not lateral, not tension, not compression. A crack always needs a starting point, That's why you polish the edges. Polishing the inside and outside, though it may look pretty, does nothing more than weaken the entire unit and reduces its torsional strength.

Mike

These stub axles will easily handle 500hp all day long. Why spend the extra money,

Yes they are new grade 8 ring gear bolts with grade 8 washers. Has anyone ever seen a ring gear bolt fail? If 1200 hp won't break these, I doubt 500 will.

As for polishing, first you have to understand the forces put on the carrier. Since the ring gear is offset to one side, the load on the carrier is torsional. Not lateral, not tension, not compression. A crack always needs a starting point, That's why you polish the edges. Polishing the inside and outside, though it may look pretty, does nothing more than weaken the entire unit and reduces its torsional strength.

Mike

Thanks for the post Mike. A little confused by the ring bolts comment. You posted in another thread where the OP showed all the ring bolts snapped off. Wouldn't the extra strength of an ARP 200,000 psi vs an grade 8 at 150,000 psi and improved tolerances held the ring gear on better. Of course, loctite used on the cleaned threads would have helped also.

I follow your logic on not wasting money on the stub axles but ARP bolts are only $30....cheap insurance over mass produced grade 8 bolts and cheap lock washers.

My understanding on polishing the posi is to eliminate any ridges at the seams, not just a pretty polishing job. Same reason as for polishing the window edges.....no spots for a crack to occur.

Here is that other thread.....

https://www.corvetteforum.com/forums...-locked-2.html

Txs Mike for your reply......

Can you post up a pic of one of your Super 10 builds inside? Thanks again.

Last edited by bmans vette; 09-21-2017 at 05:23 PM.

#20

Drifting

I haven't seen ring gear bolts snap off in 40 years. Referring to the other thread, that was caused by the ring gear bolts backing out and being sheared off when they hit the housing. Very common on 1976 diffs and a little less common on 1978. It's also a good reason why you should never use a ring gear spacer.

All oem carriers have casting defects where the sand molds were pressed together. This is where they always crack. Just grinding out the defect is sufficient to prevent cracking. Polishing just makes it a little smoother. Taking off too much metal creates new problems. The new eaton carriers have been redesigned in this area.

The two most common carriers are the 297 and the 117, 297 being more desirable. But there are also bad 297's since many molds were used for each. Polishing the ridge just to the right of the ring gear only weakens the carrier, nothing else. By the time you polished out every spec of sand casting, you would have a very weak unit. I do, however shot-peen the carrier and housing which relieves surface tension. And it makes it look pretty!

Mike

All oem carriers have casting defects where the sand molds were pressed together. This is where they always crack. Just grinding out the defect is sufficient to prevent cracking. Polishing just makes it a little smoother. Taking off too much metal creates new problems. The new eaton carriers have been redesigned in this area.

The two most common carriers are the 297 and the 117, 297 being more desirable. But there are also bad 297's since many molds were used for each. Polishing the ridge just to the right of the ring gear only weakens the carrier, nothing else. By the time you polished out every spec of sand casting, you would have a very weak unit. I do, however shot-peen the carrier and housing which relieves surface tension. And it makes it look pretty!

Mike