FIRST Intake Arrived; Looking It Over

#61

Melting Slicks

Thread Starter

Adam

Last edited by NewbVetteGuy; 01-25-2018 at 07:04 PM.

#62

Melting Slicks

Thread Starter

Adam

#63

Melting Slicks

Thread Starter

Should be heading to the coater to get the base, runners, and plenum thermal barrier coated this afternoon.

Still torn on whether to coat the throttle body or not... (Although I forgot to throw it in the car so that may make my decision for me...)

Adam

Still torn on whether to coat the throttle body or not... (Although I forgot to throw it in the car so that may make my decision for me...)

Adam

#65

Melting Slicks

Thread Starter

Installed it and checked the port alignment with my heads and they were ever-so-slightly off (FIRST intake sat high on the ports, which I think is because I went with a .015" Felpro shim gasket)- I did some final port matching and got it all bolted together.

Had to make a couple of tweaks to my Holley HP EFI harness for things like my knock sensor.

Fender mounted the adjustable fuel pressure regulator (probably farther away from the intake than it should be, ideally, but it works really well there.

Then I wanted to get rid of any engine bay rust and paint it (of course I ground it down to bare metal AND THEN applied "Rust Converter Paint" in a major rookie mistake...). Install electric headlight conversions from Richard 454.

Do new front suspension, QA1 coilovers, had Vansteel rebuild the A-Arms (moog ball joints; Delrin bushings), I did the Wilwood big brake kit and Wilwood alum MC on the front and moved to stainless lines while the engine was out.

New champion radiator.

Then I broke the AC line, so I redid all of the AC system and converted it over to R134a. (Just finished this yesterday evening with the exception of the internal blower fan ground that I have left to do.)

-I removed the original starter-to-battery cable yesterday, too and I have a new AWG 0 wire, but I need to source and make ends for it. I have the start-side end showing up at my local NAPA tomorrow, but I still need to figure out the battery side.

-AFAIK, this is the last thing I need to do to get the engine back in the car, and get connecting everything and moving over to EFI tuning.

[Edit] I accidentally bought the higher pressure Melling SharkTooth pump and lots of people have been reporting issues with super high oil pressure on them, so I'm going to pull the pan and the oil pump, and switch over to the Yellow spring before I put the engine back in, too... UGH...

I get between 4 and 8 hours a month to work on the car right now, so I'm beyond molasses slow, but I finally made some really good progress on the AC system after running into every problem imaginable. (Broke the old orifice valve off in the evaporator and couldn't even drill the bits out, couldn't figure out if my car was 79 early or 79 late (my car didn't get delivered until late November 1979, so we thought it was a 79 late, but the car apparently got assembled EARLY and was delayed in being completed because it was waiting on L82 engine that was apparently backed up that year, so even though it was delivered late in 1979 it's a "1979 Early" car based upon all parts (speedometer, rear storage doors, AC system)) so I bought one of each high side AC lines and installed both twice before I figured it out; made my own life hell by trying to go with a Silverado internal fan and on-and-on comedy-of-errors style...

Adam

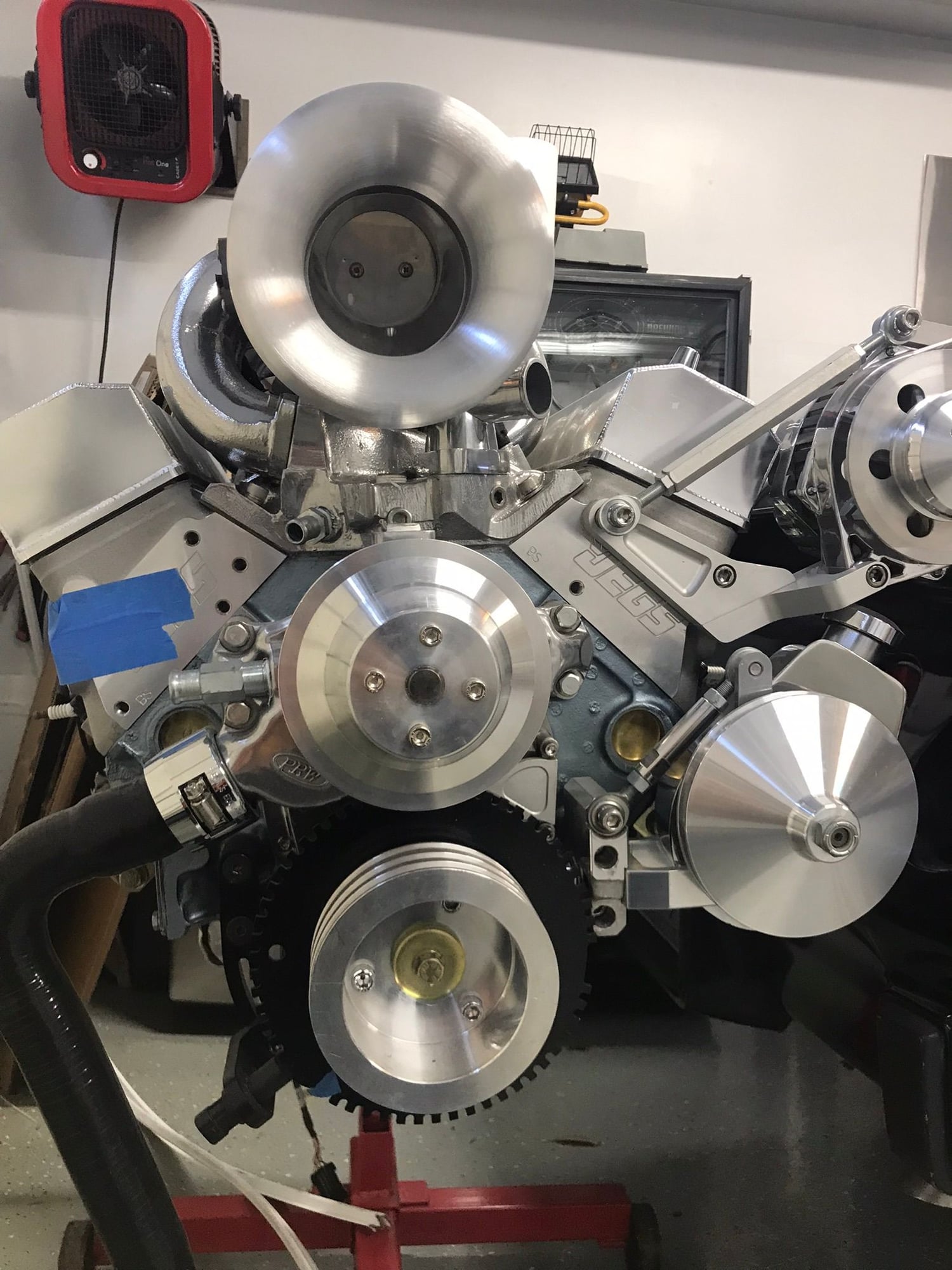

Engine done; working on accessories and brackets now

Hacked together some random aluminum brackets to make it all work

QA1 single adjustables with 450lb springs and Vansteel rebuilt A-Arms, Moog ball joint, Delrin bushings

Wilwood big brake 4 piston front brakes

Last edited by NewbVetteGuy; 09-12-2022 at 12:24 PM.

The following users liked this post:

Bill Chase (09-25-2022)

#66

Melting Slicks

Thread Starter

I have no idea how I'm going to get the AC Brackets installed with the crank trigger where it is, but that's literally the only place possible for me to install the crank trigger sensor.

-I'm going to remove it before installing the engine because I'm honestly not sure it's going to fit the tight clearance with the front C3 crossmember and I definitely don't want to crunch it on engine install as the whole setup is discontinued by Holley now...

Adam

-I'm going to remove it before installing the engine because I'm honestly not sure it's going to fit the tight clearance with the front C3 crossmember and I definitely don't want to crunch it on engine install as the whole setup is discontinued by Holley now...

Adam

#67

Melting Slicks

Thread Starter

Following on some other stuff in the thread. I had to grind the complete and total CRAP out of my FlowTech headers to get them to match the heads' exhaust ports. I used a crayon to trace the exhaust ports and bolt holes and then cut the holes out and installed them backwards on the headers and marked where the headers needed grinded to fit with a magic marker and ported them all. The bolt holes also DID need elongated to move the header up on the exhaust ports.

I still consider the FlowTech headers my temporary "break-in" headers.

I found a company that makes a header flange that fits my heads very well, and I had hoped that ARH would agree to make a set of their shelf C3 headers, just utilizing that flange, if I send it to them, but they refused. Once I get the engine in and running with a reasonable tune, I'm probably going to have Bruce Reed, who has taken over making the Stan's Tri-Y design and who is local to me, make me a stainless version as he's the only one I've found who is willing to make a header with the flange that these heads need to fit properly. (I seriously regret buying the raised exhaust port Profiler heads; even Chad Speier now orders his Profilers with the standard height exhaust ports...I KNOW the S-Factor line is all standard height profiler exhaust ports now.)

I bought a cheap $40 C5 CAI air bridge, so I'm hoping that that works for going over the radiator support for cold air intake, too. (The Pontiac GTO Vararam works with some cutting I know, but if I can make a $50 C5 bridge work....)

Adam

I still consider the FlowTech headers my temporary "break-in" headers.

I found a company that makes a header flange that fits my heads very well, and I had hoped that ARH would agree to make a set of their shelf C3 headers, just utilizing that flange, if I send it to them, but they refused. Once I get the engine in and running with a reasonable tune, I'm probably going to have Bruce Reed, who has taken over making the Stan's Tri-Y design and who is local to me, make me a stainless version as he's the only one I've found who is willing to make a header with the flange that these heads need to fit properly. (I seriously regret buying the raised exhaust port Profiler heads; even Chad Speier now orders his Profilers with the standard height exhaust ports...I KNOW the S-Factor line is all standard height profiler exhaust ports now.)

I bought a cheap $40 C5 CAI air bridge, so I'm hoping that that works for going over the radiator support for cold air intake, too. (The Pontiac GTO Vararam works with some cutting I know, but if I can make a $50 C5 bridge work....)

Adam

#68

Race Director

many modern cars have the crank trigger on the flywheel instead of at the balancer. dunno if possible, but looking into it can't hurt...

#69

Pro

Hey Adam, what brand & part number is the 58x crank trigger kit you used? I picked up the holley vortec timing cover, and efi connection 24x reluctor, with msd cam sync oil pump drive for my next small block project to do coil near plug. but on my c4 I used the dual sync. had one die with minimal use and low miles. so I plan to convert it to crank trigger. since i am using the cloyes hex-a-just timing set and cloyes cover I need a crank trigger, was planning on the msd 86101, but given the idle-6000 rpm range of the 383 in the c4 I feel like a 58x crank trigger would provide better resolution and drivability. my thought was to use the 58x, with another msd cam sync. make them both use the same sensor, so when traveling i would only have to carry one spare sensor. the trouble with aftermarket efi is if you dont have a spare you could be stranded for 24 or more hours waiting on parts. so anytime you can do the system and utlize oem sensors its better. looks like your 58x uses an oem sensor.

#70

Melting Slicks

Thread Starter

Hey Adam, what brand & part number is the 58x crank trigger kit you used? I picked up the holley vortec timing cover, and efi connection 24x reluctor, with msd cam sync oil pump drive for my next small block project to do coil near plug. but on my c4 I used the dual sync. had one die with minimal use and low miles. so I plan to convert it to crank trigger. since i am using the cloyes hex-a-just timing set and cloyes cover I need a crank trigger, was planning on the msd 86101, but given the idle-6000 rpm range of the 383 in the c4 I feel like a 58x crank trigger would provide better resolution and drivability. my thought was to use the 58x, with another msd cam sync. make them both use the same sensor, so when traveling i would only have to carry one spare sensor. the trouble with aftermarket efi is if you dont have a spare you could be stranded for 24 or more hours waiting on parts. so anytime you can do the system and utlize oem sensors its better. looks like your 58x uses an oem sensor.

Mine looks identical to the Holley 556-111 bigblock crank trigger kit Holley EFI 556-111 Big Block Chevy Crank Trigger Kit -originally mine was called a "BBC /SBC" kit, I THINK so that might even be the same part # but I think the bracket is different.

Holley now recommends the 556-116 36-1 kit for SBCs instead: Holley EFI 556-116 Holley EFI Crank Trigger System - SBC

Holley had problems with the 58x sensors not reading right at high RPM or with any kind of crank flex or movement forward if the sensor wasn't shimmed PERFECTLY. They documented some of the issues here: 60-2 Crank Trigger Wheel Kit DISCONTINUED? Now this makes sense. - Holley Performance Products Forums

I remember a smallish EFI tuner who was custom making his own very similar 58x crank trigger wheels designed to go between the balancer and the crank pulley, too and if you could get one of those and add the holley brackets and the OEM sensor and some shims you could probably make a 58x setup work much cheaper than Holley's ridiculously priced 31-6 kit ($550 -?!?!).

Adam

#71

Melting Slicks

Thread Starter

Also not cheap, but if a customer is paying for it the integrated crank trigger shells from ATI are a cool option that doesn't screw up pulley / accessory spacing: https://www.atiracing.com/products/d...ger-shells.htm

Adam

Adam

The following users liked this post:

Bill Chase (10-01-2022)

#72

Melting Slicks

Thread Starter

8.5" diameter.

https://www.holley.com/products/disc.../parts/556-110

Bill: I posted on the "Holley EFI Classified" FB Group to see if any Holley dealers happen to still have one sitting on a shelf somewhere, if you're on there.

Update: These guys in Iowa claim to have one in stock for $260: https://www.northernautoparts.com/part/ho-556-110

Adam

Last edited by NewbVetteGuy; 09-26-2022 at 06:31 PM.

#73

Safety Car

I use the 60-2 set up from Holley and shift at 6700 .. Never missed a beat (SBC 434) Using Holley Hp, coil near plug multi port sequential injection .. And to maximize TQ in daily driving. I would have used the 4l60e and a set of 3.55 gears out back. I run the TPIS Mini Ram II 1206 ports and the 1250 Big mouth Throttle Body a 4l80 and 4.11 out back. Never an issue with daily driving under any conditions. ( After some set up help from Zweed)

The following users liked this post:

NewbVetteGuy (09-26-2022)

#74

Melting Slicks

Thread Starter

I use the 60-2 set up from Holley and shift at 6700 .. Never missed a beat (SBC 434) Using Holley Hp, coil near plug multi port sequential injection .. And to maximize TQ in daily driving. I would have used the 4l60e and a set of 3.55 gears out back. I run the TPIS Mini Ram II 1206 ports and the 1250 Big mouth Throttle Body a 4l80 and 4.11 out back. Never an issue with daily driving under any conditions. ( After some set up help from Zweed)

I do have the 4L60e and the stock 3.55 rear gears in my car. I have the stock 835 CFM throttle body, but they'll port it to 1020 CFM if I pay for mail round trip to Wisconsin. It's one of those details that I waffle on as I'm not convinced that an overly high flow throttle body on port EFI matters THAT MUCH and it might help the air make the turn into the couple runners that turn more than 90 degrees straight back if the airflow is going slower through the throttle body... -I'm going to start with it at 835CFM and hope that I can get to a place where I can worry about such things.

I have the bowtie overdrives arched tubular cross-member for the transmission it and for some reason it ended up putting the engine into a slightly upward angle so when I would accelerate the fan would hit the shroud. -I had a shop out here replace the parking brake and switch to stainless because it was a job I did NOT want to do, and they shimmed the transmission up higher on the mount to adjust the angle. -After I was removing the stock battery to starter hot wire (2 weekends ago) I noticed that the drive shaft is so high up in the tunnel now that it's actually hitting the parking break cable when it's pulled all the way on... -Something I'll definitely have to address soon. I can easily remove all those added shims now that I have moved to electric fans, so should be the easiest thing I've done in a while.

So like usual for me, every C3 project turns into 3...

Adam

Last edited by NewbVetteGuy; 09-26-2022 at 08:19 PM.

The following users liked this post:

diehrd (09-26-2022)

#75

Melting Slicks

Thread Starter

Did you mount the 60-2 crank sensor on the holes just in front of where a stock fuel pump would go? -Do you still have an AC Compressor in your car? (I realize the stock AC compressor bracket mounted into one of those holes yet, but I haven't started to look at or try and figure out how to make it all happy, yet.)

-Did you have any issues with the sensor hitting the frame there? (To be within 13 teeth of the gap at TDC (I think that's the Holley requirement), I had to position the hall effect sensor almost all the way at the very bottom of that bracket, so it's about as in-the-way as it can be)

Adam

-Did you have any issues with the sensor hitting the frame there? (To be within 13 teeth of the gap at TDC (I think that's the Holley requirement), I had to position the hall effect sensor almost all the way at the very bottom of that bracket, so it's about as in-the-way as it can be)

Adam

#76

Melting Slicks

Thread Starter

-Joking really, I think the speed of a 168 tooth wheel that larger at 6,000 RPM would be bonkers, but it SURE would make things both easy and crazy accurate.

Adam

The following users liked this post:

diehrd (09-27-2022)

#77

Safety Car

Ya I also run a big duration cam and the fuel injection makes idle and driving smooth and reliable. What Holley system are you using the terminator ?

#78

Safety Car

Did you mount the 60-2 crank sensor on the holes just in front of where a stock fuel pump would go? -Do you still have an AC Compressor in your car? (I realize the stock AC compressor bracket mounted into one of those holes yet, but I haven't started to look at or try and figure out how to make it all happy, yet.)

-Did you have any issues with the sensor hitting the frame there? (To be within 13 teeth of the gap at TDC (I think that's the Holley requirement), I had to position the hall effect sensor almost all the way at the very bottom of that bracket, so it's about as in-the-way as it can be)

Adam

-Did you have any issues with the sensor hitting the frame there? (To be within 13 teeth of the gap at TDC (I think that's the Holley requirement), I had to position the hall effect sensor almost all the way at the very bottom of that bracket, so it's about as in-the-way as it can be)

Adam

The following users liked this post:

NewbVetteGuy (09-27-2022)

The following users liked this post:

diehrd (09-27-2022)

#80

Safety Car

Determine which side of the engine the sensor will be mounted on. The sensor bracket can be flipped to use on either side of a SBC or BBC engine. With the engine at TDC on #1 cylinder, the sensor will be positioned such that it is lined up with the 10th tooth “after the missing teeth” on the crank trigger wheel (the 10th tooth is the tooth after the gap in the direction that the engine rotates). If this is off, it can be adjusted within the software, but this is the intended location. Install the crank trigger wheel and align the bolt holes on it such that the sensor will be near this position.

I was right its the tenth tooth. However 10 to 20 is ok because in the software you can use an off set. Lets say you only can get to tooth 15 then you set the off set to 5 .

Zweede can correct me b/c he is a genius

.. And helped me with the set up

.. And helped me with the set uphttps://www.catalograck.com/ImgVD/HOL/556-105.pdf