Hi speed miss fire

#1

Le Mans Master

Thread Starter

Member Since: Jan 2003

Location: Portland Oregon

Posts: 8,596

Likes: 0

Received 16 Likes

on

15 Posts

Well after months and months of dicking around and testing this and that I am about at my wits end. I am still working on Glens car with a 383 LT4 with a T trim Vortec making 12 PSI of boost. This thing makes over 600 RWHP at 6000 RPM but right at that RPM something breaks down and the power just falls off, it feels like it drops a cylinder or two but it does keep pulling at over 560hp when it does drop off to 6500.

engine specs:

383 CID

AFR 210cc Comp ported eliminator heads

Custom Arias Pistons

Billet rods

Custom ground hydraulic roller cam 236/248 600 lift on a 115 LSA

9:1 compression

True dual 3" exhaust LT headers, custom X pipe. NO CATs, BB Exhaust

Balanced and blueprinted by a very very **** machinist of which I have known for over 20 years.

I have tried:

3 different coils, stock LT4, a new stock LT4, and a MSD Blaster

2 different Opti Sparks, one a MSD and another GM Opti with a MSD cap

2 different modules

3 different ignition boxes, a crane, MSD 6al, and a MSD 6al with Boost timing retard, currently running on a standard 6al

new plug wires

various spark plugs including iridiums at different gaps from .022 to .045

Replaced opti spark wire harness

Verified all engine grounds and power wiring to PCM

Swapped out 3 different PCMs, one being a OBD1 PCM that came out of my personal car

Then there was a suspicion of valve float caused by boost acting against the intake valve. So first I shimmed the valve springs .050 bringing up the installed height to 1.750 with the seat pressure at about 150#

Next, lighter weight rocker arms were swapped in to replace the heavier Comp Hi-Tech SS rocker arms.

Next came different springs because the original AFR 210s had 1.500 roller springs rated at 210# seat pressure. In the original configuration the engine ran to 7000 without missing a beat. At least as far as I can remember it.

Finally I swapped out the old comp cams Comp-R lifters for some modified stockers. These lifters are basically solids with .020" of hydraulic travel that can withstand much higher spring pressures than a stock style hydraulic roller lifter.

So far nothing has really helped, it was orginally crapping out at between 5200 and 5600, now its up to 6200 or there abouts, it happens real fast when it gets to 6000, and one just can't hold it there.

The other concern is that the blower is at its limits, spinning the engine up to 6500 means that the blower is being spun about 7000 RPM beyond its designed efficient curve.

This engine came back to me last year due to an oil consumption issue. It was taken out of the car and sent to the machine shop where they replaced the pistons with a set of custom Arias pistons and were torque plate honed to fit. Most parts were reused other than the bearings, down to the camshaft and lifters as they had very low miles on them. The only real new parts were the heads which I had requested replacement from AFR due to the new design of the Eliminator heads which gave us much better designed oil return passages as well as a better combustion chamber. The engine runs like a raped Ape until it hits the upper RPMs, it makes huge torque and power numbers until then.........

It is NOT a tuning issue, I had it runing on the original tune and have fine tuned it over and over. Fuel trims in closed loop are perfect. WOT fueling is at nearly a straight 11:1 and running with METH/Water injector after 6 PSI, I also tried different concentrations of METH from 50/50 to 75% mix. Like I said it runs perfect until the trouble spot at over 6000.

And to make matters worse, the engine will spin past 6500 if I remove the blower belt.

So if any one got any ideas I am all ears.........I have run out of ideas as many of my friends have, and of course I need to get Glens car back to him before we all get too old to drive

engine specs:

383 CID

AFR 210cc Comp ported eliminator heads

Custom Arias Pistons

Billet rods

Custom ground hydraulic roller cam 236/248 600 lift on a 115 LSA

9:1 compression

True dual 3" exhaust LT headers, custom X pipe. NO CATs, BB Exhaust

Balanced and blueprinted by a very very **** machinist of which I have known for over 20 years.

I have tried:

3 different coils, stock LT4, a new stock LT4, and a MSD Blaster

2 different Opti Sparks, one a MSD and another GM Opti with a MSD cap

2 different modules

3 different ignition boxes, a crane, MSD 6al, and a MSD 6al with Boost timing retard, currently running on a standard 6al

new plug wires

various spark plugs including iridiums at different gaps from .022 to .045

Replaced opti spark wire harness

Verified all engine grounds and power wiring to PCM

Swapped out 3 different PCMs, one being a OBD1 PCM that came out of my personal car

Then there was a suspicion of valve float caused by boost acting against the intake valve. So first I shimmed the valve springs .050 bringing up the installed height to 1.750 with the seat pressure at about 150#

Next, lighter weight rocker arms were swapped in to replace the heavier Comp Hi-Tech SS rocker arms.

Next came different springs because the original AFR 210s had 1.500 roller springs rated at 210# seat pressure. In the original configuration the engine ran to 7000 without missing a beat. At least as far as I can remember it.

Finally I swapped out the old comp cams Comp-R lifters for some modified stockers. These lifters are basically solids with .020" of hydraulic travel that can withstand much higher spring pressures than a stock style hydraulic roller lifter.

So far nothing has really helped, it was orginally crapping out at between 5200 and 5600, now its up to 6200 or there abouts, it happens real fast when it gets to 6000, and one just can't hold it there.

The other concern is that the blower is at its limits, spinning the engine up to 6500 means that the blower is being spun about 7000 RPM beyond its designed efficient curve.

This engine came back to me last year due to an oil consumption issue. It was taken out of the car and sent to the machine shop where they replaced the pistons with a set of custom Arias pistons and were torque plate honed to fit. Most parts were reused other than the bearings, down to the camshaft and lifters as they had very low miles on them. The only real new parts were the heads which I had requested replacement from AFR due to the new design of the Eliminator heads which gave us much better designed oil return passages as well as a better combustion chamber. The engine runs like a raped Ape until it hits the upper RPMs, it makes huge torque and power numbers until then.........

It is NOT a tuning issue, I had it runing on the original tune and have fine tuned it over and over. Fuel trims in closed loop are perfect. WOT fueling is at nearly a straight 11:1 and running with METH/Water injector after 6 PSI, I also tried different concentrations of METH from 50/50 to 75% mix. Like I said it runs perfect until the trouble spot at over 6000.

And to make matters worse, the engine will spin past 6500 if I remove the blower belt.

So if any one got any ideas I am all ears.........I have run out of ideas as many of my friends have, and of course I need to get Glens car back to him before we all get too old to drive

Last edited by tjwong; 11-19-2008 at 12:58 AM.

#2

Pro

Far be it for me to suggest an action to some one with your skill and ability. However, have you considered changing the blower pulley and dropping the boost if only for comparison sake? I had an identical problem. It was ignition orientated. The Delteq system I had simply could not handle the ignition requirements demanded at 5000+ rpm. Replacing the Delteq with a MSD Opti in my case did the job.

Then again I'm sure youv'e considered belt slippage at that rpm level.

Then again I'm sure youv'e considered belt slippage at that rpm level.

#3

Safety Car

Are you making the same boost with the newer heads and the same RPM?

Where do you fall on the compressor map?

Where do you fall on the compressor map?

Last edited by LTxDave; 11-19-2008 at 09:49 AM.

#5

Melting Slicks

Any possibility that the impeller tip-speed or inlet airflow is going supersonic? This is what limits the airflow capacity of centrifugal superchargers. Maybe you've reached this limit.

You may want to calculate the tip speed or inlet air velocity for a sanity check compared to the speed of sound.

The article belw suggests that the T-trim will deliver up to about 58,000 rpm with 55,000 rpm being the max at peak efficiency. The compressor map shows 50,000 max.

Looking at the compressor map, If I understand your +7,000 rpm statement, then you're already spinning it at something like 57,000 rpm or very close to the suggested limit. Perhaps the airflow velocity is high enough to go supersonic in the inlet.

http://www.mustang50magazine.com/tec...son/index.html

You may want to calculate the tip speed or inlet air velocity for a sanity check compared to the speed of sound.

The article belw suggests that the T-trim will deliver up to about 58,000 rpm with 55,000 rpm being the max at peak efficiency. The compressor map shows 50,000 max.

Looking at the compressor map, If I understand your +7,000 rpm statement, then you're already spinning it at something like 57,000 rpm or very close to the suggested limit. Perhaps the airflow velocity is high enough to go supersonic in the inlet.

http://www.mustang50magazine.com/tec...son/index.html

Last edited by tequilaboy; 11-19-2008 at 10:40 AM.

#6

Le Mans Master

Thread Starter

Member Since: Jan 2003

Location: Portland Oregon

Posts: 8,596

Likes: 0

Received 16 Likes

on

15 Posts

Any possibility that the impeller tip-speed or inlet airflow is going supersonic? This is what limits the airflow capacity of centrifugal superchargers. Maybe you've reached this limit.

You may want to calculate the tip speed or inlet air velocity for a sanity check compared to the speed of sound.

You may want to calculate the tip speed or inlet air velocity for a sanity check compared to the speed of sound.

I have used NGK plugs from a BKR6E to a BKR7E, these are extended electrode in both iridium and copper. The original engine ran the BKR6E.

Far be it for me to suggest an action to some one with your skill and ability. However, have you considered changing the blower pulley and dropping the boost if only for comparison sake? I had an identical problem. It was ignition orientated. The Delteq system I had simply could not handle the ignition requirements demanded at 5000+ rpm. Replacing the Delteq with a MSD Opti in my case did the job.

Then again I'm sure youv'e considered belt slippage at that rpm level.

Then again I'm sure youv'e considered belt slippage at that rpm level.

More later, I gotta get going to the shop.

More later, I gotta get going to the shop.

#7

Melting Slicks

how are you doing with the MAF, is it maxxed out? have you ditched it for speed density? the new 2 bar tune for tunercats is pretty trick and would be right up your alley on that car since it is just under 2 bar of boost.

Is he running a stock oil pan? and a high volume oil pump? if so it may be draining the pan, I thinkthe Vortech blower are oil fed correct?

my MSD coil is good so far to 22psi and 6800 rpm I was suprised actually figured I would be needing to switch to CPC at this level.

does he have anough fuel? what is his fuel system composed of? injectors, pump, lines, etc.. are filters clean? is the filter sock new? I have had these collapse on themselves and cause high flow fuel demand issues.

can you make a run and shut it down at the top before it drops down to normal operating? see if the plugs are wet ( misfire)? see if it is dropping a cylinder which one(s) they are and hunt the issue on a cylinder specific basis. what is the gap on the plugs? maybe it is too wide? I gap mine at .028-.030"

Are you running a check valve on the brake boost to intake manifold connection? just curious as I have seen these leak at +10psi intermittently and it wreaked havoc on my tuning process.

Hope that gives you some ideas!

I hate mystery problems...

Chris

Is he running a stock oil pan? and a high volume oil pump? if so it may be draining the pan, I thinkthe Vortech blower are oil fed correct?

my MSD coil is good so far to 22psi and 6800 rpm I was suprised actually figured I would be needing to switch to CPC at this level.

does he have anough fuel? what is his fuel system composed of? injectors, pump, lines, etc.. are filters clean? is the filter sock new? I have had these collapse on themselves and cause high flow fuel demand issues.

can you make a run and shut it down at the top before it drops down to normal operating? see if the plugs are wet ( misfire)? see if it is dropping a cylinder which one(s) they are and hunt the issue on a cylinder specific basis. what is the gap on the plugs? maybe it is too wide? I gap mine at .028-.030"

Are you running a check valve on the brake boost to intake manifold connection? just curious as I have seen these leak at +10psi intermittently and it wreaked havoc on my tuning process.

Hope that gives you some ideas!

I hate mystery problems...

Chris

#8

Safety Car

Do you think the heads are flowing that much better than the originals or do you think the lower boost is a symptom of the problem causing the miss?

#9

I don't think we really know if the heads are flowing that much better or if it's a combination of the the cats being off as well.

To all else; thanks for the replies. This issue has been driving us nuts. As mentioned earlier; I also wondered if the supercharger is maxed out or if this was an issue with spark blow out but some of you guys are running more boost and not having the same issue.

So it seems that it would leave the opti but we already swapped it out twice so I am a little leary that is the issue but who knows; maybe we got unlucky and got a bad opti...

Anyway, thanks for the suggestions; let us know if you have any others.

glenn

Last edited by GM_96LT4; 11-25-2008 at 09:51 AM.

#11

Drifting

Member Since: Aug 2002

Location: Speedo Indiana

Posts: 1,475

Likes: 0

Received 0 Likes

on

0 Posts

TJ,

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

#12

TJ,

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

I am sure TJ will chime in here but the valve train has been replaced from the lifters to rockers. I thought the same about the cam lobe but when comparing both my dyno graphs from last year to current; the two curves are almost identical.

No oil is burning; that was the original reason why the car went back to TJ and that was fixed. Plugs are clean.

Tuning looks good as well.

I believe the game plan next will be a "process of elimination" scenario. It seems to be (via collective thought) either the supercharger or the opti and since I really don't have to many options for a larger supercharger; my vote is for the opti.

What are the chances of having another bad opti? Probably slim but at least it will be a "check" off.

Has anyone had any experience with Vortech's JT-Trim?

Glenn

Last edited by GM_96LT4; 11-25-2008 at 10:00 PM.

#13

Drifting

Member Since: Aug 2002

Location: Speedo Indiana

Posts: 1,475

Likes: 0

Received 0 Likes

on

0 Posts

Tony,

I am sure TJ will chime in here but the valve train has been replaced from the lifters to rockers. I thought the same about the cam lobe but when comparing both my dyno graphs from last year to current; the two curves are almost identical.

No oil is burning; that was the original reason why the car went back to TJ and that was fixed. Plugs are clean.

Tuning looks good as well.

I believe the game plan next will be a "process of elimination" scenario. It seems to be (via collective thought) either the supercharger or the opti and since I really don't have to many options for a larger supercharger; my vote is for the opti.

What are the chances of having another bad opti? Probably slim but at least it will be a "check" off.

Has anyone had any experience with Vortech's JT-Trim?

Glenn

I am sure TJ will chime in here but the valve train has been replaced from the lifters to rockers. I thought the same about the cam lobe but when comparing both my dyno graphs from last year to current; the two curves are almost identical.

No oil is burning; that was the original reason why the car went back to TJ and that was fixed. Plugs are clean.

Tuning looks good as well.

I believe the game plan next will be a "process of elimination" scenario. It seems to be (via collective thought) either the supercharger or the opti and since I really don't have to many options for a larger supercharger; my vote is for the opti.

What are the chances of having another bad opti? Probably slim but at least it will be a "check" off.

Has anyone had any experience with Vortech's JT-Trim?

Glenn

#14

Melting Slicks

Glenn,

turbo is calling your name..lol I just got in from some tuning runs and to try out the No Lift to Shift.. the car is on 22 pounds right now on a measley mix of 5 gallons 118 10 gallons 93 pump... running good and strong at this level with 21 degrees of timing in boost! ditch the belt brotha! spool isn't that bad at all! and with this No Lift to Shift.... well check out the logs.. whoever made shifting and respool a reason they didn't want to go turbo.. well.. this oughtta show an example of modern day electronics!

http://forums.corvetteforum.com/c4-f...post1567981121

turbo is calling your name..lol I just got in from some tuning runs and to try out the No Lift to Shift.. the car is on 22 pounds right now on a measley mix of 5 gallons 118 10 gallons 93 pump... running good and strong at this level with 21 degrees of timing in boost! ditch the belt brotha! spool isn't that bad at all! and with this No Lift to Shift.... well check out the logs.. whoever made shifting and respool a reason they didn't want to go turbo.. well.. this oughtta show an example of modern day electronics!

http://forums.corvetteforum.com/c4-f...post1567981121

#15

Melting Slicks

Guys, have you tried running the car without alky injection and running reduced timing? If so, did the miss persist? How about using a smaller nozzle? What nozzle are you guys running? Is it a progressive system? If so at what point does it max out? I saw that it comes on at 6 psi. Perhaps the alky is blowing out some of the spark. Maybe there is a little more flow to one or more cylinders in the manifold.

I had the power drop off at the top of my graph for a while. I'm running a progressive alky system with a 50/50 mix. At the top of the rpm range I would get a little spark blowout. It turned out I was running too much alky injection at too low of a boost figure which combined with way rich fueling caused the power to fall off above 5000. With centri cars the power should keep climbing start to fall off just a little beyond peak if at all; not drastically. You mention that the fueling is at 11:1 which isn't bad at all. Maybe you're throwing too much water at it.

On an efficient motor with alky injection I'd like to think that you'd make more than 600 rwhp maxing out a t trim. In regards to the JT trim, I've heard that it is lazy similar to a ys trim. Your midrange power will be down but peak may be slightly up. I'd go for a reverse rotation ysi any day of the week over the jt. The ysi makes better power everywhere and has a much higher hp limit. A mustang guy just went over 170mph in the quarter using a reverse rotation ysi on a mustang mod motor. If you want power, then that's the head unit.

Good luck with the witch hunt!

I had the power drop off at the top of my graph for a while. I'm running a progressive alky system with a 50/50 mix. At the top of the rpm range I would get a little spark blowout. It turned out I was running too much alky injection at too low of a boost figure which combined with way rich fueling caused the power to fall off above 5000. With centri cars the power should keep climbing start to fall off just a little beyond peak if at all; not drastically. You mention that the fueling is at 11:1 which isn't bad at all. Maybe you're throwing too much water at it.

On an efficient motor with alky injection I'd like to think that you'd make more than 600 rwhp maxing out a t trim. In regards to the JT trim, I've heard that it is lazy similar to a ys trim. Your midrange power will be down but peak may be slightly up. I'd go for a reverse rotation ysi any day of the week over the jt. The ysi makes better power everywhere and has a much higher hp limit. A mustang guy just went over 170mph in the quarter using a reverse rotation ysi on a mustang mod motor. If you want power, then that's the head unit.

Good luck with the witch hunt!

#16

Le Mans Master

Thread Starter

Member Since: Jan 2003

Location: Portland Oregon

Posts: 8,596

Likes: 0

Received 16 Likes

on

15 Posts

TJ,

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

Well, it's got to be electrical, mechanical, or fuel related.

Sounds like you have covered the electrical system by swapping parts, so it's probably not that.

I believe you stated that your a/f ratios are ok during the run, so it sounds like you are not running out of injector, fuel pump flow, a faulty fuel regulator, etc.

I'm leaning more towards one or more bent pushrods, worn out valve springs, and/or worn cam lobes.

Of course as others have stated, if you are not running out of blower you are very close to it. I forget if this car has an intercooler, but if it does, is it large enough to provide adequate flow?

Just curious, is this engine burning any oil? If so, you may have a bad valve guide that is causing am intermitent fouled a plug at high speed.

The engine is fresh other than being driven for 300 miles to break it in. I recently replaced all the valve springs, and lifters so I know that the push rods and valve train is in good condition, at the same time I also went to a lighter weight rocker arm by switching the Comp Cams Hi Tech SS rockers for a set of Crane Gold Race aluminum units. I don't think I got any bad lobes, otherwise I don't think it would make the power that it does, in either NA or boosted modes.

The engine is also not burning any oil, I replaced the heads with AFRs new and improved Eliminator LT4 heads and the engine was completely gone through, during that time the pistons were replaced with a set of custom Arias pistons and hellfire rings were installed for a top ring and a set of standard tension oil control rings were installed. The pistons were designed with offset pins to minimize thrust on the piston as it travels in the bore. When the plugs are removed for inspection they are all clean, in fact they burn so clean they are basically white, just like if the engine was in a stock situation.

When the problem hits it isn't like it runs out of fuel, I can definitely feel a cylinder or two that seems to drop out for a millisecond or two, you can see the power drop off in the dyno graph, I will post one later, the run goes clean until it hits around 6000 RPM then the graph definitely shows something going away.

When the engine is run with the blower disconnected, I can make a clean run to 6500, it don't make near the power but even a 9:1 the engine makes 400 to the wheels, it is a stout 383 even with low compression.

Guys, have you tried running the car without alky injection and running reduced timing? If so, did the miss persist? How about using a smaller nozzle? What nozzle are you guys running? Is it a progressive system? If so at what point does it max out? I saw that it comes on at 6 psi. Perhaps the alky is blowing out some of the spark. Maybe there is a little more flow to one or more cylinders in the manifold.

I had the power drop off at the top of my graph for a while. I'm running a progressive alky system with a 50/50 mix. At the top of the rpm range I would get a little spark blowout. It turned out I was running too much alky injection at too low of a boost figure which combined with way rich fueling caused the power to fall off above 5000. With centri cars the power should keep climbing start to fall off just a little beyond peak if at all; not drastically. You mention that the fueling is at 11:1 which isn't bad at all. Maybe you're throwing too much water at it.

On an efficient motor with alky injection I'd like to think that you'd make more than 600 rwhp maxing out a t trim. In regards to the JT trim, I've heard that it is lazy similar to a ys trim. Your midrange power will be down but peak may be slightly up. I'd go for a reverse rotation ysi any day of the week over the jt. The ysi makes better power everywhere and has a much higher hp limit. A mustang guy just went over 170mph in the quarter using a reverse rotation ysi on a mustang mod motor. If you want power, then that's the head unit.

Good luck with the witch hunt!

I had the power drop off at the top of my graph for a while. I'm running a progressive alky system with a 50/50 mix. At the top of the rpm range I would get a little spark blowout. It turned out I was running too much alky injection at too low of a boost figure which combined with way rich fueling caused the power to fall off above 5000. With centri cars the power should keep climbing start to fall off just a little beyond peak if at all; not drastically. You mention that the fueling is at 11:1 which isn't bad at all. Maybe you're throwing too much water at it.

On an efficient motor with alky injection I'd like to think that you'd make more than 600 rwhp maxing out a t trim. In regards to the JT trim, I've heard that it is lazy similar to a ys trim. Your midrange power will be down but peak may be slightly up. I'd go for a reverse rotation ysi any day of the week over the jt. The ysi makes better power everywhere and has a much higher hp limit. A mustang guy just went over 170mph in the quarter using a reverse rotation ysi on a mustang mod motor. If you want power, then that's the head unit.

Good luck with the witch hunt!

I ran it without meth, with meth, reduced timing, different plug gaps from .022 to .045. Iridium plugs, copper plugs, all NGK plugs from a 6 heat range to a 7 heat range, all with extended tip design. Maybe I should try a race type plug with a recessed tip like what one would use in a HD truck application. I don't think I want to go to a YSi trim, the cost and amount of fabrication to make it work is going to be cost prohibitive. Even at its current power levels, if this car is going to be driven hard, there likely going to be other issues in the drivetrain that is going to rear its ugly head soon so I don't really want to incease power any more than what it is now, it already is a handful when its driven aggressively.

I willl post more when I get back into the car. I have a new baby that will arrive on December 2nd next month so that is going to take up a lot of time. And with my work load in the shop this week I won't be getting back on the car until after the baby arrives.

#17

Melting Slicks

Adding inlet guide vanes may help to reduce the inlet relative mach number.

As ridiculous as it may sound, it may be worth trying a 3.75" diameter "tornado" (part number ki-95) to add some pre-whirl to the compressor inlet. I don't know of any other readily available devices that could serve as an inlet guide vane.

In this link, the use of inlet guide vanes is covered at least in some detail:

http://books.google.com/books?id=HM-...sult#PPA134,M1

As ridiculous as it may sound, it may be worth trying a 3.75" diameter "tornado" (part number ki-95) to add some pre-whirl to the compressor inlet. I don't know of any other readily available devices that could serve as an inlet guide vane.

In this link, the use of inlet guide vanes is covered at least in some detail:

http://books.google.com/books?id=HM-...sult#PPA134,M1

Last edited by tequilaboy; 11-26-2008 at 05:27 PM.

#19

Unfortunately, I've replaced a few optis in my day, and I would say that it is not your problem if the car is pulling smoothly up to a certain rpm. It is my experience that an opti either works or it doesn't. If the above mechanical and fuel problems are ruled out, you are either blowing the plugs out at high boost (I run about a .020 gap at 20+psi), or you are running out of blower/intercooler. Although I would think if you are running out of blower on the top end your A/F ratios would be pretty wacky since you would likely experience an oscillating rich/lean condition with an unstable intake flow into the engine.

Glenn,

turbo is calling your name..lol I just got in from some tuning runs and to try out the No Lift to Shift.. the car is on 22 pounds right now on a measley mix of 5 gallons 118 10 gallons 93 pump... running good and strong at this level with 21 degrees of timing in boost! ditch the belt brotha! spool isn't that bad at all! and with this No Lift to Shift.... well check out the logs.. whoever made shifting and respool a reason they didn't want to go turbo.. well.. this oughtta show an example of modern day electronics!

turbo is calling your name..lol I just got in from some tuning runs and to try out the No Lift to Shift.. the car is on 22 pounds right now on a measley mix of 5 gallons 118 10 gallons 93 pump... running good and strong at this level with 21 degrees of timing in boost! ditch the belt brotha! spool isn't that bad at all! and with this No Lift to Shift.... well check out the logs.. whoever made shifting and respool a reason they didn't want to go turbo.. well.. this oughtta show an example of modern day electronics!

Seriously, trust me when I say I haven't thought about it.....that is one of the reasons I asked the questions awhile back....the only thing that is holding me back is this economy....let's just say that my business is not doing so hot.....of course; not like you guys don't know this already....

However, you never know; if it is an issue, I might be calling you....

Tom actually ran the car both ways; once with the elbow disconnected and one without the belt; car made a clean pass all the way to the top. This concerns me because you would think the opti would then be good but honestly; not sure.

I also thought it was spark blow out but I have my doubts because I would think you would hear more about it from others.....

Also, we tried different plugs and different ignition boxes. The only other option is to find me a delteq system and a msd dis-4. However, that is one expensive test to find out.....

I think I will bang my head a few more times before we try it......

here is the funny part or not so funny part; watch it be something really minor....

if that happens; I am buying drinks for everyone....

if that happens; I am buying drinks for everyone....

Everyone; happy turkey day....now go get fat.....

glenn

#20

Team Owner

Member Since: Mar 2001

Location: Boston, Dallas, Detroit, SoCal, back to Boston MA

Posts: 30,607

Received 239 Likes

on

167 Posts

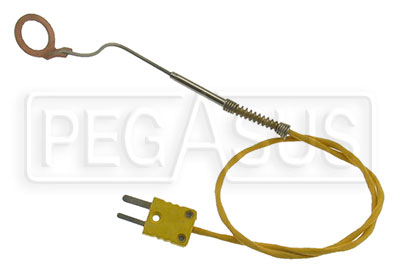

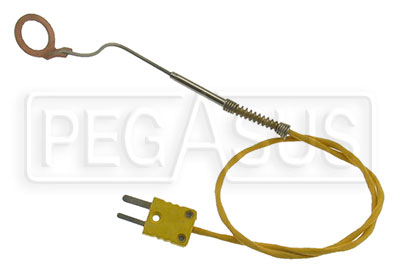

If you have data aquisition you can hook up an cylinder head temp sensor via this thermocouple that goes under the spark plug. Then you can see if it's just one cylinder or a general trend.

http://www.pegasusautoracing.com/pro...asp?RecID=5113

http://www.pegasusautoracing.com/pro...asp?RecID=5113