0-60 mph - MAF graph

#1

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

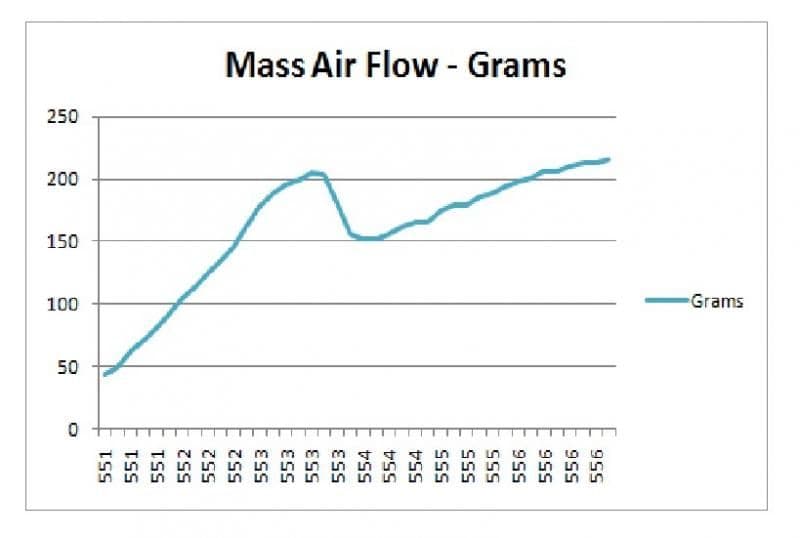

This is a graph of my MAF flow (grams per second) for a part throttle, 0-60 mph run on my 87 with the tranny in D with a gear change occurring at 4000 rpm. Is there anything one can conclude from this? Does this show the limit of the engines breathing ability? Is it normal for the air flow to drop so much mid run when the trans shifts up a gear?

Last edited by Lemme; 08-12-2010 at 09:51 PM.

#3

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

Yes it does make sense as one would expect the air flow to be generally proportional to the rpm. As the tranny shifted at 4000 rpm in this example maybe this graph isn't showing the breathing limits of the intake and heads.

Maybe I should just leave it in 2nd and do a run up to 5500 rpm and take another look at the graph. Maybe then I will see it gasp for air!

Maybe I should just leave it in 2nd and do a run up to 5500 rpm and take another look at the graph. Maybe then I will see it gasp for air!

#4

Advanced

Member Since: Jul 2010

Location: Bolingbrook IL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Since airflow is a function of RPM you'll ALWAYS see a drop at the shift point. Same as you would for Horsepower or Torque.

That willl show a smooth, increasing curve up to your redline.

You're not seeing it "gasping" for air. An engine doesn't "want" more air. It pumps what it is designed to pump.

Why are you watching your airflow?

Rick - '92 LT1

Maybe I should just leave it in 2nd and do a run up to 5500 rpm and take another look at the graph.

Maybe then I will see it gasp for air!

Why are you watching your airflow?

Rick - '92 LT1

#5

Safety Car

If you run a TPI engine to 5500 I doubt the air flow will decrease as it runs out of breath, instead you will see a decrease in the rate of change in the airflow. (it will level off or increase slowly)

#6

Advanced

Member Since: Jul 2010

Location: Bolingbrook IL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

You'll see a drop in airflow at some point. As you pass the engines designed maximum volumetric efficiency the airflow will drop off because the Throttle Body, intake runners, intake ports, valve size, etc., can no longer flow enough to fill the cylinder efficiently at the increasing RPM.

Rick - '92 LT1

Rick - '92 LT1

#7

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

I keep reading that on an L98 the TPI is the big limitation for horsepower at higher RPM because of the intake runners. In addition people always talk about high flowing intakes, cams, heads and freed up exhausts.

So thats why I am looking at the air flow. I want to see where the 'breathing' problem is so I can improve it.

So thats why I am looking at the air flow. I want to see where the 'breathing' problem is so I can improve it.

#8

Advanced

Member Since: Jul 2010

Location: Bolingbrook IL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

on an L98 the TPI is the big limitation for horsepower at higher RPM because of the intake runners.

True! The runners are small and long to increase low end torque but at a sacrifice of higher RPM power.

True! The runners are small and long to increase low end torque but at a sacrifice of higher RPM power.

So thats why I am looking at the air flow. I want to see where the 'breathing' problem is so I can improve it

You could start modding or replacing parts and see how that airflow improves (or not). Change the throttle body, check the new flow. Bolt on some larger runners, check the new flow. Swap heads, check the new flow.

But you won't be able to detect any breathing problems by monitoring it.

Rick - '92 LT1

#9

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

True! The runners are small and long to increase low end torque but at a sacrifice of higher RPM power.

True! The runners are small and long to increase low end torque but at a sacrifice of higher RPM power.But you're not going to see it by monitoring the airflow of your engine. That graph is just showing what your engine does. It has no way to show, nor is there any way to interpret, where any problem may be. It is just a graph of airflow.

You could start modding or replacing parts and see how that airflow improves (or not). Change the throttle body, check the new flow. Bolt on some larger runners, check the new flow. Swap heads, check the new flow.

But you won't be able to detect any breathing problems by monitoring it.

Rick - '92 LT1

Like many wannabes I am trying to plan ways to get my stock 87 to perform like a z06 for a fraction of the price. By graphing the current performance of the car and by making observations of different parameters vs time etc I hope to be able to set some performance goals for certain parameters.

I want to be able to see where the breathing chokes the performance and then modify it and run another test (as you suggest). I want to understand how to design and/or mod an engine to achieve predefined performance goals. Maybe air flow and torque are directly related!

#10

Race Director

By George, Dr. Watson, I think you've discovered Moriarty's devious plot to capture all of the power in the world. He's going to suck air to gain power! Utterly diabolical!

And, they said it couldn't be done...And, had never been spoken of before!

And, they said it couldn't be done...And, had never been spoken of before!

#11

Advanced

Member Since: Jul 2010

Location: Bolingbrook IL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

No, you're doing fine. I am pretty sure I understand what you're trying to do.

What I'm saying is that chart won't show you where that is. Go back and look. Now point out the 'choke point'. You can't. I can't. It can't show a choke point. If it did reach a choke point the airflow wouldn't increase from there and you wouldn't see it.

Now, if you knew someone with higher flow numbers then you'd have an idea of how much air you COULD flow. But you still wouldn't know any 'choke points'. All you could do was follow his sequence of changes and note your flow.

The TPI engine is a whole system designed as a low RPM torque engine with small runners, a small cam, small valve, low flow heads. Its not a big power engine with a small intake meant to 'choke' off power. It was never designed to make power at 5500 RPM.

But you already know the TPI doesn't flow well. Anything you could do to increase it will create more power. I'm sure there's a thread on L98 TPI buildup here somewhere.

BINGO!!  You're dead on!! Maximum airflow, and maximum volumetric efficiency, occur at peak torque!!

You're dead on!! Maximum airflow, and maximum volumetric efficiency, occur at peak torque!!

You could easily get a fraction of the performance of a Z06 for a fraction of the price!!

But seriously.... a 2001 Z06 was 385 HP! That's 135 more than the best TPI. You'd need a 54% increase to reach it. THAT'S a tall order!!

Rick - '92 LT1

I want to be able to see where the breathing chokes the performance

Now, if you knew someone with higher flow numbers then you'd have an idea of how much air you COULD flow. But you still wouldn't know any 'choke points'. All you could do was follow his sequence of changes and note your flow.

The TPI engine is a whole system designed as a low RPM torque engine with small runners, a small cam, small valve, low flow heads. Its not a big power engine with a small intake meant to 'choke' off power. It was never designed to make power at 5500 RPM.

But you already know the TPI doesn't flow well. Anything you could do to increase it will create more power. I'm sure there's a thread on L98 TPI buildup here somewhere.

Maybe air flow and torque are directly related!

You're dead on!! Maximum airflow, and maximum volumetric efficiency, occur at peak torque!!

You're dead on!! Maximum airflow, and maximum volumetric efficiency, occur at peak torque!!

I am trying to plan ways to get my stock 87 to perform like a z06 for a fraction of the price

But seriously.... a 2001 Z06 was 385 HP! That's 135 more than the best TPI. You'd need a 54% increase to reach it. THAT'S a tall order!!

Rick - '92 LT1

#12

Melting Slicks

Neglecting frictional losses, the airflow is proportional to hp.

I dug out some old datalogs that were made during a dyno pull. In my case, the airflow peaked about 400 rpm after the hp peak. Even though the airflow was still increasing, the losses were increasing at an even greater rate.

Peak HP was 245 @ 4800 rpm, Peak airflow was 207 gm/sec at 5200 rpm and then declined as a function of rpm.

I dug out some old datalogs that were made during a dyno pull. In my case, the airflow peaked about 400 rpm after the hp peak. Even though the airflow was still increasing, the losses were increasing at an even greater rate.

Peak HP was 245 @ 4800 rpm, Peak airflow was 207 gm/sec at 5200 rpm and then declined as a function of rpm.

#14

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

Neglecting frictional losses, the airflow is proportional to hp.

I dug out some old datalogs that were made during a dyno pull. In my case, the airflow peaked about 400 rpm after the hp peak. Even though the airflow was still increasing, the losses were increasing at an even greater rate.

Peak HP was 245 @ 4800 rpm, Peak airflow was 207 gm/sec at 5200 rpm and then declined as a function of rpm.

I dug out some old datalogs that were made during a dyno pull. In my case, the airflow peaked about 400 rpm after the hp peak. Even though the airflow was still increasing, the losses were increasing at an even greater rate.

Peak HP was 245 @ 4800 rpm, Peak airflow was 207 gm/sec at 5200 rpm and then declined as a function of rpm.

In another post I saw a member aiming for 320 g/s max! Not sure if it was a L98 though.

#15

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

The choke points are already known by people on this forum (and hopefully in time by me). I don't need to rediscover them (Dr Watson!). My goal is to remove them in a cost effective and systematic fashion that takes me in the right direction of straight line performance.

Thanks for your post.

#16

Race Director

Of course there's NOS or FI too. You're not going to find Z06 performance by doing scans. THAT'S the part you haven't done a good job conveying!

#17

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

I gotta admit I'm one of the most "wordy" people I know, but that's gotta be one of the most techically complex ways of saying: you need to get rid of your OEM runners/intake, greatly improve your heads, then stroke and cam your motor that I've ever seen!

Of course there's NOS or FI too. You're not going to find Z06 performance by doing scans. THAT'S the part you haven't done a good job conveying!

Of course there's NOS or FI too. You're not going to find Z06 performance by doing scans. THAT'S the part you haven't done a good job conveying!

You guys have the answers. I admire that. At the moment I have a lot of questions.

I am certainly not looking for performance gains by doing a scan. However, I would at least like to satisfy myself that I have got some bang for my buck so far.

#18

Burning Brakes

What I'm saying is that chart won't show you where that is. Go back and look. Now point out the 'choke point'. You can't. I can't. It can't show a choke point. If it did reach a choke point the airflow wouldn't increase from there and you wouldn't see it.

Now, if you knew someone with higher flow numbers then you'd have an idea of how much air you COULD flow. But you still wouldn't know any 'choke points'. All you could do was follow his sequence of changes and note your flow.

Now, if you knew someone with higher flow numbers then you'd have an idea of how much air you COULD flow. But you still wouldn't know any 'choke points'. All you could do was follow his sequence of changes and note your flow.

LS1 MAF's are about the same diameter but will read up to 512 g/s i do believe. The ecm and sensor are just calibrated and setup to handle that large airflow

My 383 HSR motor peaked the MAF at 4500-4800 rpm. It read 255 and stopped reading. BUT i made 400whp at 6300 rpm and pulled to 6600 without falling off. 4500 rpm is about where I peaked torque. It was flat from 4000-almost 5000

So the 3" MAF was not a restriction. I changed to a 3.5" setup and it did not help power from what I could see at the track.

#19

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

YOu wont discover a choke point with the MAF sensor by looking at graphs of the g/s. The ecm is only going to display 255 gram/sec flow max, but that does not mean the MAF is choked out. It will pass MORE air than what it can measure.

LS1 MAF's are about the same diameter but will read up to 512 g/s i do believe. The ecm and sensor are just calibrated and setup to handle that large airflow

My 383 HSR motor peaked the MAF at 4500-4800 rpm. It read 255 and stopped reading. BUT i made 400whp at 6300 rpm and pulled to 6600 without falling off. 4500 rpm is about where I peaked torque. It was flat from 4000-almost 5000

So the 3" MAF was not a restriction. I changed to a 3.5" setup and it did not help power from what I could see at the track.

LS1 MAF's are about the same diameter but will read up to 512 g/s i do believe. The ecm and sensor are just calibrated and setup to handle that large airflow

My 383 HSR motor peaked the MAF at 4500-4800 rpm. It read 255 and stopped reading. BUT i made 400whp at 6300 rpm and pulled to 6600 without falling off. 4500 rpm is about where I peaked torque. It was flat from 4000-almost 5000

So the 3" MAF was not a restriction. I changed to a 3.5" setup and it did not help power from what I could see at the track.

Last edited by Lemme; 08-12-2010 at 11:00 PM.

#20

Drifting

Thread Starter

Member Since: Nov 2009

Location: Perth Western Australia

Posts: 1,340

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

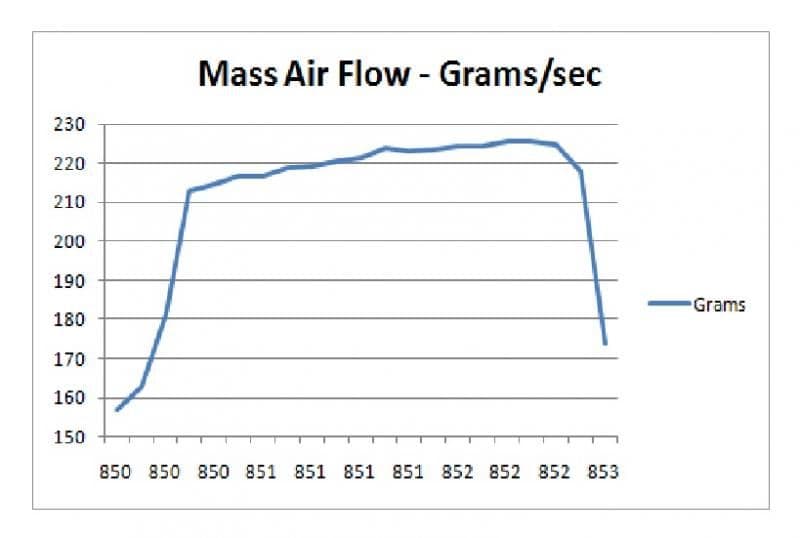

Actually, I found a better graph that I had done on the same day (5 minutes later) which was at WOT

My conclusion from this is I'm not going to get more than 225 g/s (occurred at 4500 rpm) out of this motor as it is. What would be nice to know is what would a stock 87 be maxing out at? Hopefully less than 225 g/s! Unfortunately I only got my datalogging gear after I'd started modifying. Also what is the best g/s one could expect from a highly modified L98?

My conclusion from this is I'm not going to get more than 225 g/s (occurred at 4500 rpm) out of this motor as it is. What would be nice to know is what would a stock 87 be maxing out at? Hopefully less than 225 g/s! Unfortunately I only got my datalogging gear after I'd started modifying. Also what is the best g/s one could expect from a highly modified L98?

Last edited by Lemme; 08-12-2010 at 10:59 PM.