New Optispark fails after 50 miles

#42

Safety Car

#43

Safety Car

TX. emissions stations can not read a OBD-1 of any year.. I asked and the guy said : no Tx. inspections stations have the computer to read a OBD-1..just OBD-2

#45

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Yes, I see that too. It’s a slow process and the oil stains the plastic as it makes its way to the center of the Optispark and the rotating assembly that will eventually sling it into the optical sensor and shut everything down. I’d say 20% of the failures come through the connector.

I do wonder the reliability of the AIP optical sensor even though the rest of the opti/housing maybe poor quality. Now MSD advertises their sensor is good for 10,000rpm and reasons they would use a reliable sensor with the engineering support they have. So what I'm saying/asking is what's killing those Opti's? Sensor? Housing?

#46

Safety Car

Here is a very interesting read regarding how the OptiSparks work

http://www.superchevy.com/how-to/031...ing-modifying/

http://www.superchevy.com/how-to/031...ing-modifying/

#47

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Yes I recall reading that article at least once before. Is there something you want to point out with that? Do you see any solution to the Opti problems? I guess I'm saying I didn't see anything in that article I hadn't before.

#49

Intermediate

Tried to order a reman from Rock Auto but they didn't have one. Came here to see other options since I can't afford to pay over $400 with all the other parts I'm buying. Went to Summit - should have known $167ish for MSD was just for the cap and rotor (still a good deal). I ended up buying the Summit along with the Summit coil. I'll keep you posted, it did have some great reviews.

The following users liked this post:

cardo0 (11-20-2018)

#50

Drifting

There's some good information in this thread. And there's some other stuff.

Here's the GM video describing the ABITS system, it's proper operation, and diagnostic procedures.

You'll see a demonstration of how to test the vent system. You'll hear that the ICM has no "limp mode" by design (thanks, GM!)

Kinda fun watching a couple of engineer types trying to roll this Opti-turd in powdered sugar and call it a jelly donut.

Here's the GM video describing the ABITS system, it's proper operation, and diagnostic procedures.

You'll see a demonstration of how to test the vent system. You'll hear that the ICM has no "limp mode" by design (thanks, GM!)

Kinda fun watching a couple of engineer types trying to roll this Opti-turd in powdered sugar and call it a jelly donut.

#51

Drifting

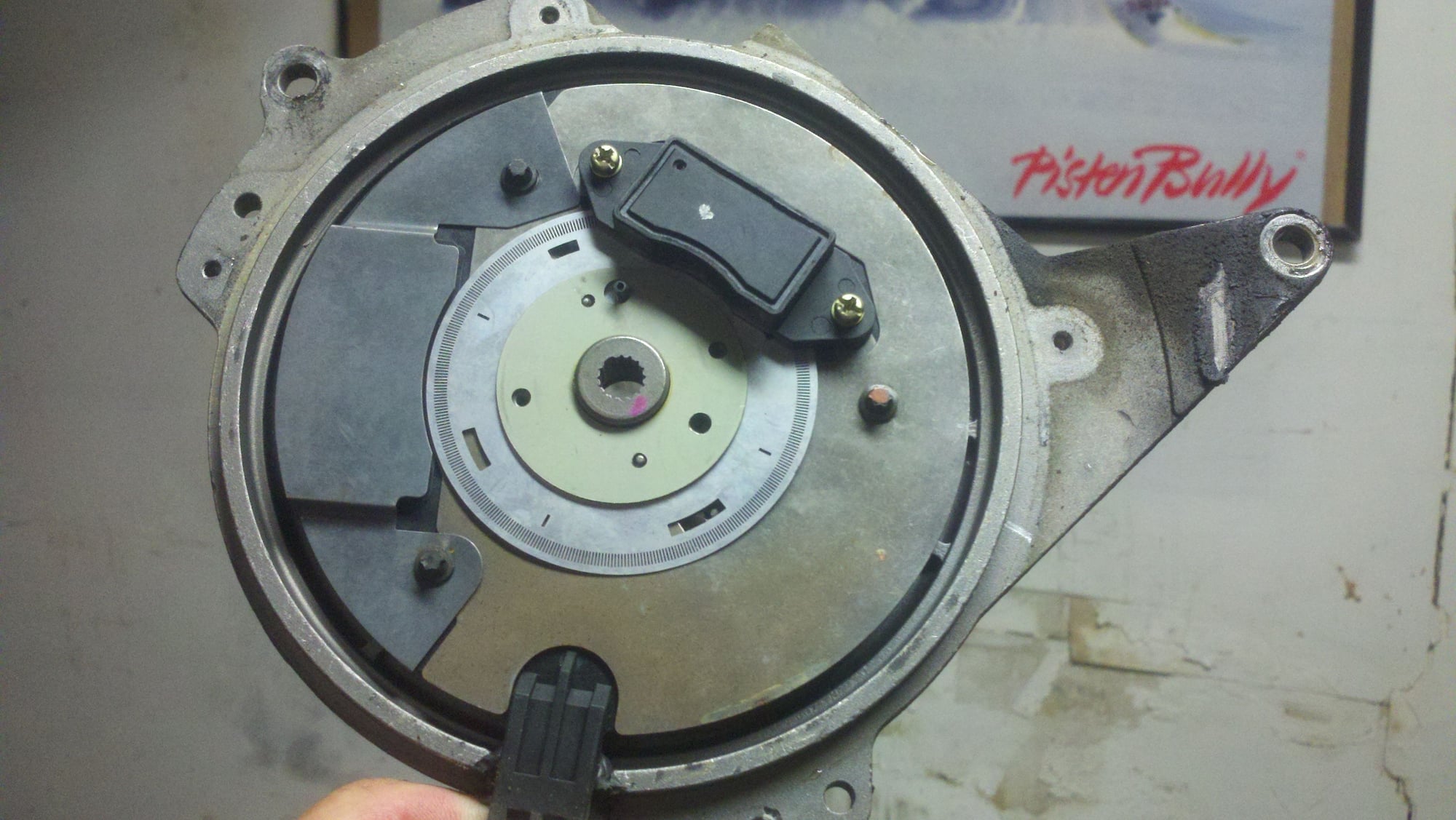

Here is a tip (along with some background) that should give you some confidence in your optispark II: The 1st generation optispark suffers from poor ventilation which leads to corrosion. I frequently get optispark I cores that look like a science experiment inside. The corrosion creates a very dirty environment that eventually prevents the optical sensor from being able to see the disk. The optispark II in your 96 will not have that problem. I rarely see significant corrosion in the optispark II cores. If your optispark II fails, it's most likely going to be full of oil or antifreeze. So, here we are: Oil or antifreeze inside an optispark I is rare, while it's common in the II. Corrosion is common in the I and rarely exists in the II. The reason for the difference is the forced air ventilation system on the optispark II. The slight vacuum that is pulled on the optispark II forces it to seek fresh air. The supplied inlet hose is the design intention to supply this fresh air, but it will take it from the easiest place it can find. Keep in mind that the pressure inside the engine air supply duct is below ambient pressure. This makes ambient air more appealing as a source to supply air. As the optispark gets older, it will lose its sealed status and the forced air ventilation system will start to draw from other places. One popular place is the bearing area. It sits right on the timing chain cover where all the leaking oil is hanging out. Another weak area is the seal between the base plate and plastic center section just below the water pump drive shaft. MSD addressed this area by adding another bolt to secure the base plate firmly to the center section and cap.

Here is how you gain some confidence: Take the fresh air supply hose (to the optispark II) out of the engine air duct. Place a small piece of paper over the end of the hose (size of a pencil eraser). With the engine at idle, see if the paper is held onto the end of the hose by the slight pull of the ventilation system. If it is, you're in good shape. If the paper easily falls off the hose, your optispark II is not sealed and it is freely drawing air from other places. Don't spend much time with the supply hose plugged and don't use your finger to test it. The slight vacuum will accumulate over time and become quite a force. You wouldn't want to pull on it hard and create a leak while testing it.

This test will show that your optical sensor is probably clean and dry because your ventilation system is drawing clean, dry air into it from the engine air duct. The high voltage side could develop an issue (like the OP encountered), but I notice the common failure is an optical sensor that can not see the optical disk.

I hope this helps.

Brad

Here is how you gain some confidence: Take the fresh air supply hose (to the optispark II) out of the engine air duct. Place a small piece of paper over the end of the hose (size of a pencil eraser). With the engine at idle, see if the paper is held onto the end of the hose by the slight pull of the ventilation system. If it is, you're in good shape. If the paper easily falls off the hose, your optispark II is not sealed and it is freely drawing air from other places. Don't spend much time with the supply hose plugged and don't use your finger to test it. The slight vacuum will accumulate over time and become quite a force. You wouldn't want to pull on it hard and create a leak while testing it.

This test will show that your optical sensor is probably clean and dry because your ventilation system is drawing clean, dry air into it from the engine air duct. The high voltage side could develop an issue (like the OP encountered), but I notice the common failure is an optical sensor that can not see the optical disk.

I hope this helps.

Brad

FWIW, my AIP Optispark has lasted 15 months now. Still passes the vacuum test. Accordingly, I had to come back and re-read this thread. It explains so much. Including why my Petris Opti failed. Chris Petris can't source double shoulder bearings either. To summarize, the second gen cannot be rebuilt to OEM specs by anyone. '95-'96 are to be avoided. Second gen was a step backward because leaks will happen. You're better off with the first gen Optispark combined with the LTCC to remove the high voltage science project remnants. With nothing but low voltage in the cap, it should have a more typical distributor service life. Even if one were to do the LTCC with the second gen and skip the vent, the bearing is the weak link. Great info. Thanks again Brad.

#52

Melting Slicks

#53

Team Owner

Pro Mechanic

The 1st generation optispark suffers from poor ventilation which leads to corrosion. I frequently get optispark I cores that look like a science experiment inside. The corrosion creates a very dirty environment that eventually prevents the optical sensor from being able to see the disk.

#54

Team Owner

Pro Mechanic

And my first opti....it looked kind of cruddy....but when it failed it would work great....until it reached about 210*F