y'all're really gonna hate me now...

#41

I know rear mounted turbo setups are not liked due to the lag they make and the issues with oil pumps ******** the bed... But i bet you if someone was to run a compound turbo setup with 3 turbo's 2x small feeding into 1 larger one mounted in the back like the sts kits.. you would have remarkable power with extremely low EGT's... and the engine life would last due to the engine requiring less boost to make the same goals other kits would make.

I run compound turbo setup on my VW track car and the EGT's were cut in half switching to compound turbos vs running the single large turbo i initially ran. Also my powerband became HUGE!!!...

Here is a good example of a company showing the difference between 1 single large turbo vs same large turbo but a smaller turbo helping it out.. the overall setup expanded the powerband ALOT!!!, also they used 7psi less with the compound setup to get the same overall power thus way lower EGT's for better reliability. The key to compound turbos is to pick a turbo or turbo's that expands across the range you will use it the most?? that meets your target HP on its own, then you take the PEAK boost line from that turbo and you find a turbo that places that spool line as close as possible to the center of the efficiency map.. this puts them in sync with huge gains from them both running more efficient and producing way less heat due to inefficient compression.

This is the setup i plan to do when i purchase my next vette to toy with. I am wanting to only make around 600whp reliably.. but i dont want to run a charger due to the fact they require maintenance and everyone i have spoken to that has a charger on there car and had it on for more than 25k miles is wishing they went turbo due to leaking seals and such.. or belts wearing out or snapping.. this seems to be the norm on a street car pushing a charger. I have also come across 10+ people in the past 2 weeks alone when asking more about the C6 that there bearings on there charger going out just after a year owning it.. on the street...

I love the reliability of turbo's and how efficient and easy they are to work with. Heck with a compound kit i bet you could create one with 3 turbo's using all oiless turbo's and they would live happy due to the heat being way less in the rear of the car.

I run compound turbo setup on my VW track car and the EGT's were cut in half switching to compound turbos vs running the single large turbo i initially ran. Also my powerband became HUGE!!!...

Here is a good example of a company showing the difference between 1 single large turbo vs same large turbo but a smaller turbo helping it out.. the overall setup expanded the powerband ALOT!!!, also they used 7psi less with the compound setup to get the same overall power thus way lower EGT's for better reliability. The key to compound turbos is to pick a turbo or turbo's that expands across the range you will use it the most?? that meets your target HP on its own, then you take the PEAK boost line from that turbo and you find a turbo that places that spool line as close as possible to the center of the efficiency map.. this puts them in sync with huge gains from them both running more efficient and producing way less heat due to inefficient compression.

This is the setup i plan to do when i purchase my next vette to toy with. I am wanting to only make around 600whp reliably.. but i dont want to run a charger due to the fact they require maintenance and everyone i have spoken to that has a charger on there car and had it on for more than 25k miles is wishing they went turbo due to leaking seals and such.. or belts wearing out or snapping.. this seems to be the norm on a street car pushing a charger. I have also come across 10+ people in the past 2 weeks alone when asking more about the C6 that there bearings on there charger going out just after a year owning it.. on the street...

I love the reliability of turbo's and how efficient and easy they are to work with. Heck with a compound kit i bet you could create one with 3 turbo's using all oiless turbo's and they would live happy due to the heat being way less in the rear of the car.

#43

Zebra, it sounds like you are set on compounding so give it a go and keep us all posted on progress and how it turns out! It will definitely be cool and unique. As said before dont scrimp on the intercooling (I would use a2w for the turbos as cell as the SC for ease will lots of HE - I can post example pics!!!) and spray lots of meth before the SC. make sure you have a very good ECU in there (probably Halltech?) as things are not going to be as predictable as a turbo or SC only setup. Don't forget to size the turbos correctly. Better to go big on the turbine with a tighter AR than the other way around! I would guess you need to be looking at 80mm + turbos after seeing LMRs corvette! And make sure the rear of the car is upto it.

Chris.

Chris.

#44

Former Vendor

Well if you already have the blower.......

I would still have to agree with storxusmc, if you want a really cool setup, and a project to play with, compound a series of turbos, and still ditch the SC.

If you're still dead set on it, and I suppose you're already 1/2 way there, then good luck to you. Your biggest challenge is going to be controlling the IAT's. On our setup the IC before the SC we were still seeing 260* IAT's....at idle.... It ended up melting the plastic protector off the GM IAT. Figure out a way to super chill the IAT's like with an AC re fridge system.

CK

I would still have to agree with storxusmc, if you want a really cool setup, and a project to play with, compound a series of turbos, and still ditch the SC.

If you're still dead set on it, and I suppose you're already 1/2 way there, then good luck to you. Your biggest challenge is going to be controlling the IAT's. On our setup the IC before the SC we were still seeing 260* IAT's....at idle.... It ended up melting the plastic protector off the GM IAT. Figure out a way to super chill the IAT's like with an AC re fridge system.

CK

#46

here is the info.. origionally started it all out on a 1.9L TDI engine.. and went to a 2009 to take advantage of the infinite amount of fuel a commonrail can supply as long as the injectionpump is large enough to keep up the supply.... long story short.. pump i currently run is a cp3 off a Duramax 6.6L pushing the power through a 2.0L 4 cylinder....daily boost 45psi, track 61psi... due to 61 being the most the turbo's make to date...

#48

Are they 2-stroke diesels? If so the engines will need the blowers until the turbos are up and running as I don't think those engines have any way of pressurising the intake air to force it into the cylinder.

Have you seen Volvos latest engines? They are to feature a PD supercharger and a turbo. However they will have the SC feeding into the turbo with a bypass so once the turbo is upto speed they bypass the SC. looks a neat solution and if they can clutch the SC should have very little losses!

Have you seen Volvos latest engines? They are to feature a PD supercharger and a turbo. However they will have the SC feeding into the turbo with a bypass so once the turbo is upto speed they bypass the SC. looks a neat solution and if they can clutch the SC should have very little losses!

#49

Yes- 2 stroke. Very different application than any vehicle setup since that particular diesel only needs to run at synchronous speed/ RPM for the generator. I actually wrote a paper a few years ago which touched on the Volvo compound setup. I don't remember anything about it haha.

#50

I dont think you realize the benefits of the compounding of turbocharges CORRECTLY...

When you run a turbo car at a track the intake system quickly becomes heat soaked because as the EGT's increase the charged air coming from the turbo is increase in heat purely because its next to this glowing heat source. When you compound a turbocharger setup it takes much much longer for the heat soak effect to happen if it even happens at all. I have done laps on my car for 20-30 mins without pulling timing.. but when i had the single large turbo it pulled timing by the time i hit 2nd or 3rd pull under WOT....

Compounds rear mounted would benefit HUGELY because you have all that room for the intake charged pipes to cool the air sum like a huge air to air intercooler system. Then it goes into an intercooler to reduce it more.

The cons of rear mount turbo's is the exhuast looses alot of its heat on its way through the exhuast so by the time the turbo has received the exhuast energy to spool the turbo. Its cooled a few hundred degrees already over the length of the exhuast which causes the turbos to have a lag compared to engine mounted same size turbo's. This is where the compound setup would make up for this loss of energy. The smaller turbos can be size smaller to reduce lag from the rear mounting issue, But the 2x smallers feeding the larger single or maybe 2 larger turbos if you could fit it, could take the cooler exhuast energy through the smaller turbo's, As they compress the exhuast they increase in heat going into the larger turbo/turbos. This is where extra heat is gained that could increase the response when on the track. But the benefit is the turbo's will not be working to hard making super high heat thus the intake temps wouldnt be effected as much, thus when the cooler intake air travels to the engine and is cooled through the intercooler... then the EGT's of that cycle becomes cooler and the temps become more stable and MUCH MUCH lower overall which keeps the engine from pulling timing and keeps the engien from running so hot.

On my current engine:

When i was running a Single Large turbo:

My EGT's would hit 1095c (2003f) on the first WOT (45psi) straight away,

Because of this my IAT would shoot to 115f (240f) and would pull timing and fuel toward the end of the straight and when i would accelerate out of the next corner my timing from heat has not recovered.. this was the big issue running the large single turbo

When i switched to compounds with the same exact large turbo for my big turbo in the setup...

My EGT's hit 660c (1220f) max now and i pull none if very little timing after 20 mins of racing. My IAT temps never exceed 71c(160f) during WOT.

Temps on current setup @45psi

Preturbo 482c (900f) average

Between turbo's 633c (1171f) average

After large turbo 660c (1220) average

When you run a turbo car at a track the intake system quickly becomes heat soaked because as the EGT's increase the charged air coming from the turbo is increase in heat purely because its next to this glowing heat source. When you compound a turbocharger setup it takes much much longer for the heat soak effect to happen if it even happens at all. I have done laps on my car for 20-30 mins without pulling timing.. but when i had the single large turbo it pulled timing by the time i hit 2nd or 3rd pull under WOT....

Compounds rear mounted would benefit HUGELY because you have all that room for the intake charged pipes to cool the air sum like a huge air to air intercooler system. Then it goes into an intercooler to reduce it more.

The cons of rear mount turbo's is the exhuast looses alot of its heat on its way through the exhuast so by the time the turbo has received the exhuast energy to spool the turbo. Its cooled a few hundred degrees already over the length of the exhuast which causes the turbos to have a lag compared to engine mounted same size turbo's. This is where the compound setup would make up for this loss of energy. The smaller turbos can be size smaller to reduce lag from the rear mounting issue, But the 2x smallers feeding the larger single or maybe 2 larger turbos if you could fit it, could take the cooler exhuast energy through the smaller turbo's, As they compress the exhuast they increase in heat going into the larger turbo/turbos. This is where extra heat is gained that could increase the response when on the track. But the benefit is the turbo's will not be working to hard making super high heat thus the intake temps wouldnt be effected as much, thus when the cooler intake air travels to the engine and is cooled through the intercooler... then the EGT's of that cycle becomes cooler and the temps become more stable and MUCH MUCH lower overall which keeps the engine from pulling timing and keeps the engien from running so hot.

On my current engine:

When i was running a Single Large turbo:

My EGT's would hit 1095c (2003f) on the first WOT (45psi) straight away,

Because of this my IAT would shoot to 115f (240f) and would pull timing and fuel toward the end of the straight and when i would accelerate out of the next corner my timing from heat has not recovered.. this was the big issue running the large single turbo

When i switched to compounds with the same exact large turbo for my big turbo in the setup...

My EGT's hit 660c (1220f) max now and i pull none if very little timing after 20 mins of racing. My IAT temps never exceed 71c(160f) during WOT.

Temps on current setup @45psi

Preturbo 482c (900f) average

Between turbo's 633c (1171f) average

After large turbo 660c (1220) average

#51

Modern turbos can run around 4:1 compression ratio in a single arrangement. In your setup you are probably running 5-6:1 presure ratio and that's the reason why you benifit from compound turbo charging. I'm not saying it dosent work because it bloody well dose, but only when you need over 4:1 presure ratio. With a LS engine you are talking about 2-3:1 presure ratio only!

So in your setup with a single turbo you would be well north of the peak efficeny Plato with the presure you require.however when you split the responsibility between two turbos you are probably much closer to the peak efficney for each!

So in your setup with a single turbo you would be well north of the peak efficeny Plato with the presure you require.however when you split the responsibility between two turbos you are probably much closer to the peak efficney for each!

Last edited by chuntington101; 10-26-2013 at 03:49 PM.

#52

The really intresting thing with compound turbos is that for any given manifold presure the drive presure, and thus egt, is reduced. This is why some diesels run upto 3 turbos in compound. So you could want say 60psi intake manifd presure (5 bar absolute) yet only need 3 bar (absolute) exhaust manifold presure!

#53

The really intresting thing with compound turbos is that for any given manifold presure the drive presure, and thus egt, is reduced. This is why some diesels run upto 3 turbos in compound. So you could want say 60psi intake manifd presure (5 bar absolute) yet only need 3 bar (absolute) exhaust manifold presure!

#54

Modern turbos can run around 4:1 compression ratio in a single arrangement. In your setup you are probably running 5-6:1 presure ratio and that's the reason why you benifit from compound turbo charging. I'm not saying it dosent work because it bloody well dose, but only when you need over 4:1 presure ratio. With a LS engine you are talking about 2-3:1 presure ratio only!

So in your setup with a single turbo you would be well north of the peak efficeny Plato with the presure you require.however when you split the responsibility between two turbos you are probably much closer to the peak efficney for each!

So in your setup with a single turbo you would be well north of the peak efficeny Plato with the presure you require.however when you split the responsibility between two turbos you are probably much closer to the peak efficney for each!

Target HP 650whp just for random fixed variable...

I am not trying to pick on UPP in any way but i am just showing examples on how the data lines up when you map the turbo's of kits on the actual compressor maps. So CK plz dont take this offensive in any way.

Engine LS1 stock

Base UPP twin turbo kit 650whp target

2 x T04B turbo's

See how the spool line is in the 50% efficiency range during spool up. This is why there is a slight lagg, nothing like rear mount but, but the turbo's are not perfect for this size engine and HP target. The engine sits outside of 70% efficiency all the way tell it hits 5800rpms.

So if i was to pick a better set of turbo's to combine with the stock ls1 engine then these would give you much better spool time and would produce less IAT with just the twin turbo's alone...Most of the powerband is within the bulk of the effeciency map on the turbo.

Turbo T04E 50Trim

Now if you want to get more out of it since this is perfect spool turbo, but the hp on this turbo is limited compared to the origional turbo's in the kit, You would compound these into a turbo with the HP Target in the center of the efficiency map.... wala you have perfect compounds.

#55

Ok, so what would be the ideal turbos to compound the T04Es? Where are you going to mount them? How are you going to get the boosted air back to the inlets of the turbos?

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

Last edited by chuntington101; 10-27-2013 at 03:08 AM.

#56

Then you get the bypass control and the restrictions and complications that adds. How do you design your exhaust manifolds (arguably not a delve t point for the LS as you don't really have room for a good manifold)? Do you go for good response or outright flow? What about the intake pipework? You are probably going from 3inch and necking down as you go through the smaller turbo. What effect dose this have on overall performance?

You mention road race engines how dose the engine feel on a road race setup? Is it as predictable as a conventional turbo setup?

Once again I'm NOT saying they don't work for some applications just not for every application!

PS: it's nice to actualy have these kind of discussions without them turning into slagging matches! I know we have kinda taken over the thread but what a great topic and some really great info coming out!

You mention road race engines how dose the engine feel on a road race setup? Is it as predictable as a conventional turbo setup?

Once again I'm NOT saying they don't work for some applications just not for every application!

PS: it's nice to actualy have these kind of discussions without them turning into slagging matches! I know we have kinda taken over the thread but what a great topic and some really great info coming out!

#57

Melting Slicks

Ok, so what would be the ideal turbos to compound the T04Es? Where are you going to mount them? How are you going to get the boosted air back to the inlets of the turbos?

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

#58

Ok, so what would be the ideal turbos to compound the T04Es? Where are you going to mount them? How are you going to get the boosted air back to the inlets of the turbos?

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

Then you need to start thinking about what you are actually doing with the engine. What's the operating rpm? A drag car with a decent stall can live with a little lag from larger turbos. A road race car, not that you see many turbo road race vetts, will spend most of its life over 3k and would need full spool by about 4k. With a bit of anti-lag you can have a perfectly responsive setup with no lag that's a lot simpler and lighter than a compounded setup.

The next question is if compounding is the ultimate solution to little to no lag and a highly responsive turbocharged engine, why haven't oem's invested in it? Instead they select the best match turbo(s) for the engines requirements. Oh and so do all the racers out there.

Here are a few examples of engines that have been produced in compound turbo setup by OEM. But they really never made it to mass production due to cost.

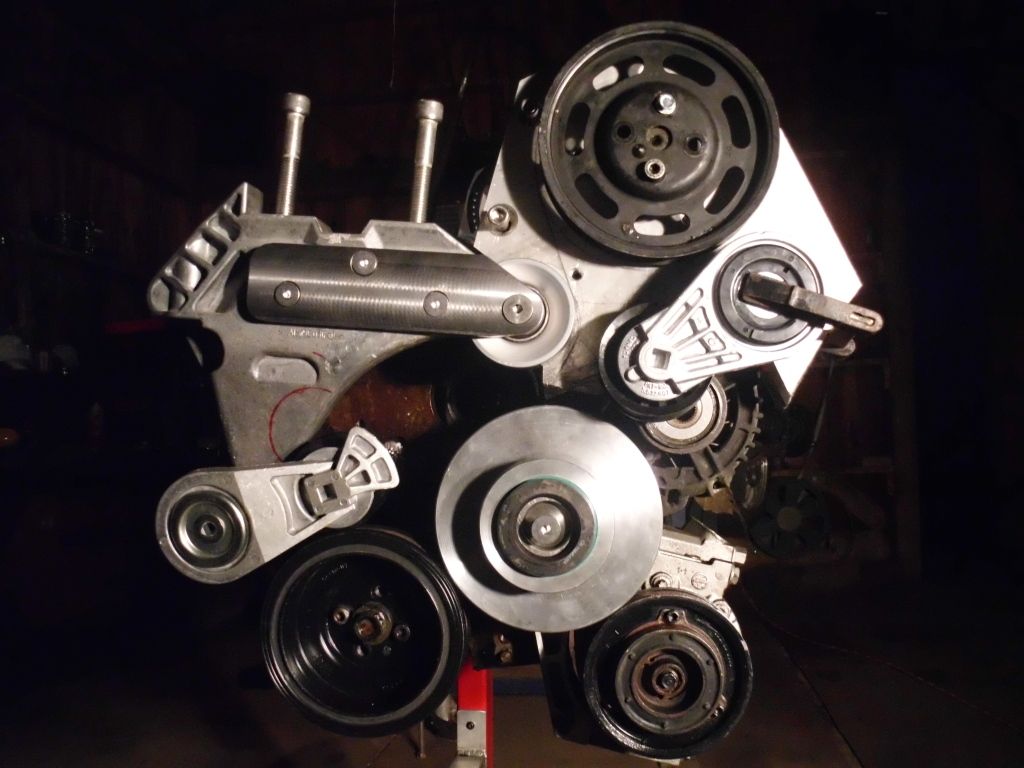

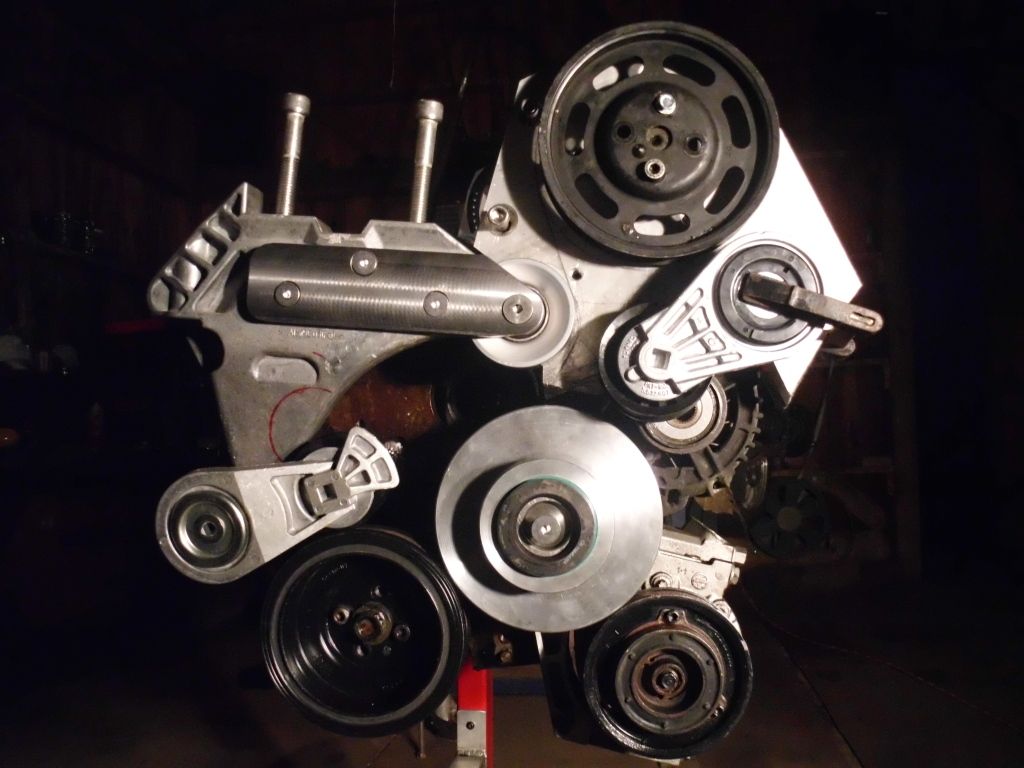

An Audi

An BMW

An VW TDI engine

Here is the AUDI LEMONS TDI ENGINE V12

The first 2 turbo's are so small they make full boost @ 1100 rpms before they are bypassed. The 2 larger turbo's are at full boost @ 2700rpms and they make full power all the way to 6800rpm redline. So it makes 800tq from 1100rpms to 6800rpms and this engine runs around a track for 24hours straight without overheating.

#60

Burning Brakes