Rebuilding the Ghost, aka Great White

#481

Melting Slicks

Thread Starter

Yes removing some material in a precise area would help, but welding in a diverter plate that extends into the housing wouldn't be beneficial. These housings aren't very thick in this area and the distance from the T3 flange to this opening is short. Changing the angle from 90 degrees to 45 degrees is not going to be possible.

I could see how elongating the inner portion of the port and blending it in like a pseudo NACA shaped duct or abstract tear drop might have a some effect. I need a 10 psi decrease. I don't think it will happen with the pressure differentials between the wg port and turbine outlet.

Don't be misled by the datalog. I can put the 10# spring back in and turn the boost controller on and this thing will make 20 psi before 4000 rpm and then creep to 24 or more psi by redline. The impeller is being overwhelmed by the pressure.

I could see how elongating the inner portion of the port and blending it in like a pseudo NACA shaped duct or abstract tear drop might have a some effect. I need a 10 psi decrease. I don't think it will happen with the pressure differentials between the wg port and turbine outlet.

Don't be misled by the datalog. I can put the 10# spring back in and turn the boost controller on and this thing will make 20 psi before 4000 rpm and then creep to 24 or more psi by redline. The impeller is being overwhelmed by the pressure.

Last edited by Turbo-Geist; 11-17-2015 at 05:42 PM.

#482

Melting Slicks

Thread Starter

#485

Drifting

I hear you and pulling a nice clean setup apart again blows. The location just seems to be a low pressure point, like taking gate pressure off a straight pipe or inside of a bend instead of the outside.

#486

Melting Slicks

Thread Starter

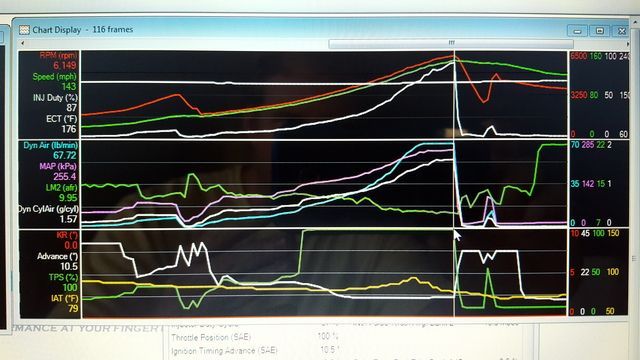

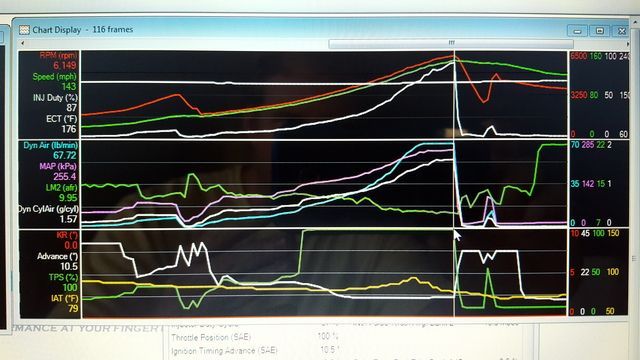

Latest Update:

Ordered and installed a 3-bar map sensor from Dedicated Motorsports Solutions designed by DSX Tuning. This was in an effort to continue tuning at higher rpms and higher anticipated MAP values.

Also installed BR7EF plugs, new wires, and put the waste gates back on the car with the 6# springs installed. It looks like the turbos have finally reached an equilibrium point.

Outside temp was in the 50s. Meth set point was on at 12 psi and full at 22 psi. Still need to adjust these points. Timing is only around 10 degrees and A/F is ~ 10:1.

RPM -------- Boost

3200 -------- 6.9 psi

3600 -------- 8.2 psi

4000 -------- 10.3 psi

4400 -------- 13.1 psi

4800 -------- 16.1 psi

5200 -------- 18.6 psi

5600 -------- 21.1 psi

6200 -------- 22.3 psi

Ordered and installed a 3-bar map sensor from Dedicated Motorsports Solutions designed by DSX Tuning. This was in an effort to continue tuning at higher rpms and higher anticipated MAP values.

Also installed BR7EF plugs, new wires, and put the waste gates back on the car with the 6# springs installed. It looks like the turbos have finally reached an equilibrium point.

Outside temp was in the 50s. Meth set point was on at 12 psi and full at 22 psi. Still need to adjust these points. Timing is only around 10 degrees and A/F is ~ 10:1.

RPM -------- Boost

3200 -------- 6.9 psi

3600 -------- 8.2 psi

4000 -------- 10.3 psi

4400 -------- 13.1 psi

4800 -------- 16.1 psi

5200 -------- 18.6 psi

5600 -------- 21.1 psi

6200 -------- 22.3 psi

#487

Melting Slicks

Thread Starter

#489

Melting Slicks

Thread Starter

True and they have a fixed curve given they are connected to the engine via a belt. Supercharger compressor wheel is going to spin to the same rpm every time. Agree, it's no different than a giant boost leak. What happens with a turbocharger, is it spinning faster or spinning at the same speed that it would have been anyway for the given pressure ratio?

#490

Melting Slicks

Thread Starter

One of the next plans is going to be to turn the boost controller back on and see if I can make more boost sooner in the 3500 to 4500 rpm range for the track.

On the bench test, the WG was wide open with 15psi applied and a 6# spring. I'm thinking if I add 5 psi to the top of the gate, it will increase the boost in the midrange but it should begin to level off around 20 psi and then creep to 22 psi.

Logic: Gate is wide open at 15 psi. With 5 psi on the top and 20 psi on the bottom, the differential is 15 psi. Gate should be wide open again and boost creep should then follow the current trend to ~22 psi.

Make sense?

On the bench test, the WG was wide open with 15psi applied and a 6# spring. I'm thinking if I add 5 psi to the top of the gate, it will increase the boost in the midrange but it should begin to level off around 20 psi and then creep to 22 psi.

Logic: Gate is wide open at 15 psi. With 5 psi on the top and 20 psi on the bottom, the differential is 15 psi. Gate should be wide open again and boost creep should then follow the current trend to ~22 psi.

Make sense?

Last edited by Turbo-Geist; 11-24-2015 at 10:02 PM.

#491

Drifting

It would spin faster to keep trying to achieve the original system pressure since it's a closed loop system with wastegate/s, but since you boost creeping bad it might stop early. Now at only 10psi in the intake the exhaust pressure would be lower also due to less combustion, etc. It's a complicated system to wrap ones head around, but I know my my Audi S4 twin turbo when guys have a boost leak the ecu keeps demanding the same pressure so it does end up over spinning the turbos, but that's a closed loop pressure control also.

True and they have a fixed curve given they are connected to the engine via a belt. Supercharger compressor wheel is going to spin to the same rpm every time. Agree, it's no different than a giant boost leak. What happens with a turbocharger, is it spinning faster or spinning at the same speed that it would have been anyway for the given pressure ratio?

Last edited by slow ride; 11-25-2015 at 10:36 AM.

#492

Le Mans Master

If you gated the charge side, I would think the turbos would over speed trying to hit the target pressure, yet never get there... Creating a bunch of heat and hard on the turbos...

I came across this on my turbo bike.... I would have huge boost leaks, yet still hit the target boost pressure, and still make good power. Seal up the leaks, hit target quicker, much lower IAT...spinning the turbo way less..

Gating a blower doesn't have this problem since the blower speed is determined by pullies.

Other then boost creep sucking and not allowing you to go low boost, your boost curve looks pretty decent to me..

22 psi at 6200... Perfect.

I came across this on my turbo bike.... I would have huge boost leaks, yet still hit the target boost pressure, and still make good power. Seal up the leaks, hit target quicker, much lower IAT...spinning the turbo way less..

Gating a blower doesn't have this problem since the blower speed is determined by pullies.

Other then boost creep sucking and not allowing you to go low boost, your boost curve looks pretty decent to me..

22 psi at 6200... Perfect.

#493

Melting Slicks

Thread Starter

22 psi feels great, really from 5200 rpm and up it's moving out in 4th gear. I haven't made any pulls in the lower gears. I'm going to finish dialing in the tune by leaning it out and adding some timing. I'll still leave a failsafe fuel buffer around 24 psi in case something unexpected happens.

Planning to test out using the boost controller to get it to make boost sooner in the rpm range and then go to the track and see what this combo will do.

I'm past trying to get it to make low boost. Time for some 1/4 mile hits this year and hopefully a half mile event next year.

How do you typically adjust your BOV on the turbo Busa to get it opening correctly?

#494

Le Mans Master

Well, on the Busa, the blow off valve is on the plenum (sheet metal air box), then it has a vacuum hose connected to a port tapped into the plenum, so it only sees vacuum in HIGH vacuum situations, (chopping the throttle, decel etc). The BOV has a 8lb spring in it so it basically stays closed all the time, until the throttle is chopped and high vacuum occurs, pulling it open. On the flip side of that, under boost, the BOV sees the same boost pressure as the engine, so the pressure is equalized at whatever boost level it's at, plus the base 8lb pressure..

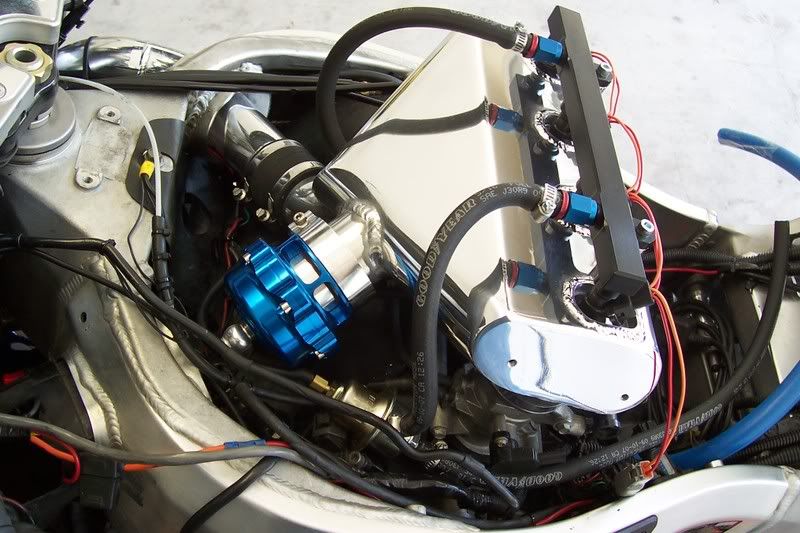

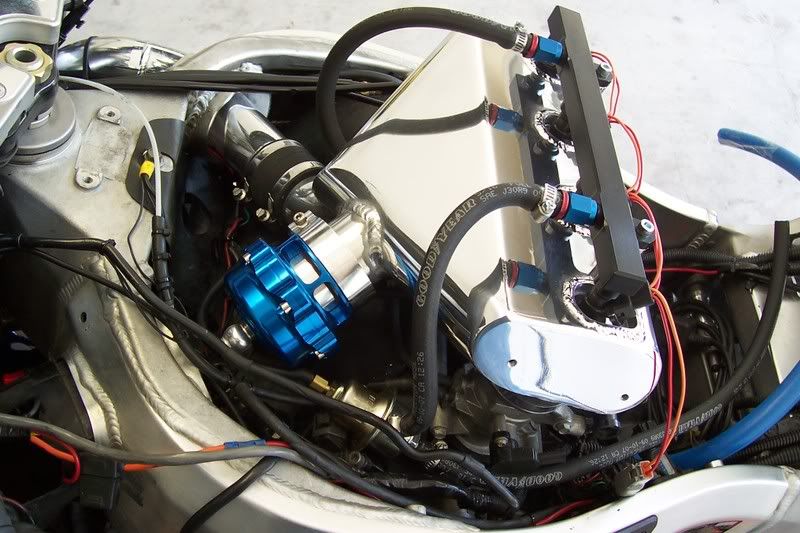

The wastegate is externally gated with a 38mm tial, the T3 turbine (5 bolt) has an internal gate port that feeds the external gate. This internal port is ported/blended to 38mm.

I usually run a 10lb spring, it yields 8.5-9 psi, then I use an AMS1000 running on manifold pressure to add boost. It is shift based, so after every shift, the AMS jumps to the next setting.. Works pretty well..

Honestly tho, most of the time, I run a 1 bar spring (14.5 psi) in the gate and turn the AMS off.. It makes the turbo spool MUCH harder/quicker... Even at part throttle, it's a lot more fun to ride, very violent, crazy torquey when it starts to spool... The ported gate holds the boost pressure perfect at 14.5-15.0. As seen here, watch the boost display on the AMS:

14.5lb spring yielding 14.5 psi.

Ported gate port :

The wastegate is externally gated with a 38mm tial, the T3 turbine (5 bolt) has an internal gate port that feeds the external gate. This internal port is ported/blended to 38mm.

I usually run a 10lb spring, it yields 8.5-9 psi, then I use an AMS1000 running on manifold pressure to add boost. It is shift based, so after every shift, the AMS jumps to the next setting.. Works pretty well..

Honestly tho, most of the time, I run a 1 bar spring (14.5 psi) in the gate and turn the AMS off.. It makes the turbo spool MUCH harder/quicker... Even at part throttle, it's a lot more fun to ride, very violent, crazy torquey when it starts to spool... The ported gate holds the boost pressure perfect at 14.5-15.0. As seen here, watch the boost display on the AMS:

14.5lb spring yielding 14.5 psi.

Ported gate port :

Last edited by ajrothm; 11-25-2015 at 02:22 PM.

#495

Race Director

Member Since: May 2004

Location: Raleigh, NC

Posts: 16,664

Received 1,195 Likes

on

1,053 Posts

St. Jude Donor '15

#497

Melting Slicks

Thread Starter

Thanks, Alan it looks like a fun setup.

Go look up proper waste gate positioning and notice that placing the waste gate inlet 90 degrees to the intended flow direction is at the bottom of the list when it comes to being effective at controlling boost.

It works ok on a 346 with a restrictive 2.5" exhaust and older technology turbos. Switch to a 427 with 3" free flowing exhaust and a high flow compressor wheel and the result in this case is no control of boost till 2.5 bar. This will vary depending on many factors. Intake, cylinder heads, camshaft, compression ratio, etc., will all play a role.

Another interesting thing to note when searching,

General Rules of Thumb for WG sizing (Turbosmart):

A big turbo run at low boost requires a big wastegate but a big turbo run at high boost actually needs a smaller wastegate.

A small turbo run at high boost also needs a small wastegate, but a small turbo run at low boost needs a bigger wastegate.

Furthermore, engine configuration will play a significant role in deciding what size wastegate to use, and there are a few applications that require larger gates simply due to their design and exhaust flow.

It works ok on a 346 with a restrictive 2.5" exhaust and older technology turbos. Switch to a 427 with 3" free flowing exhaust and a high flow compressor wheel and the result in this case is no control of boost till 2.5 bar. This will vary depending on many factors. Intake, cylinder heads, camshaft, compression ratio, etc., will all play a role.

Another interesting thing to note when searching,

General Rules of Thumb for WG sizing (Turbosmart):

A big turbo run at low boost requires a big wastegate but a big turbo run at high boost actually needs a smaller wastegate.

A small turbo run at high boost also needs a small wastegate, but a small turbo run at low boost needs a bigger wastegate.

Furthermore, engine configuration will play a significant role in deciding what size wastegate to use, and there are a few applications that require larger gates simply due to their design and exhaust flow.

Last edited by Turbo-Geist; 11-25-2015 at 04:38 PM.

#499

Drifting

I understand what you are saying. I've been messing with turbos since the 90s man I'm old as dirt. I'm just saying I think I could port and modify that location to work with enough time and experimentation. Extreme problems call for extreme measures so you might need to cut into the side of the housing more to get the angle you need and then weld up some spots on the outside etc. it's either that or do it like some others and weld right to the housing in a higher priority location. After looking at 5 bolt housings more it seems very thin by the gate before it transitions to the flange so I figured some material added to that point might allow a better shot or angle at the gate tube. It's hard to put what I have in my head to words.

I wouldn't want to see such a good engine setup run restricted since the parts are so nice. I'm sure it will make some retarded power when you get it sorted. Good luck with it.

I wouldn't want to see such a good engine setup run restricted since the parts are so nice. I'm sure it will make some retarded power when you get it sorted. Good luck with it.

Last edited by slow ride; 11-25-2015 at 10:47 PM.

#500

Safety Car

Seems like you're making things complicated, when the system is proven to work and control boost with mufflers. How much HP do you think it will lose, 50-100hp? If you want every last bit then have cutouts activated in 3rd gear.

Just has to be a way to get that gate location to work out ok.

Just has to be a way to get that gate location to work out ok.