Headlamp adjustment tool question

#1

Drifting

Thread Starter

What star size sockets will I need to adjust the headlights. I see one is for up/down and the other left/right but not clear on which one does what. Appreciate the help.

#2

Melting Slicks

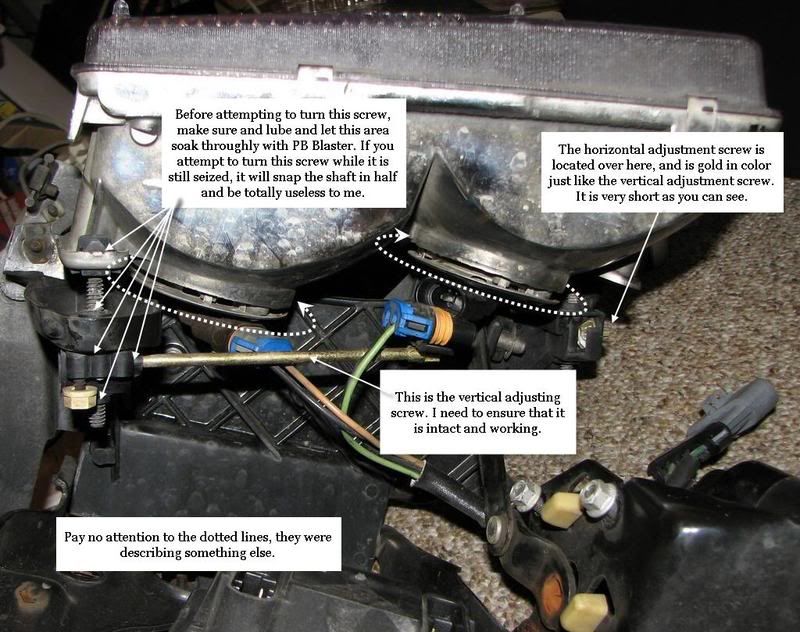

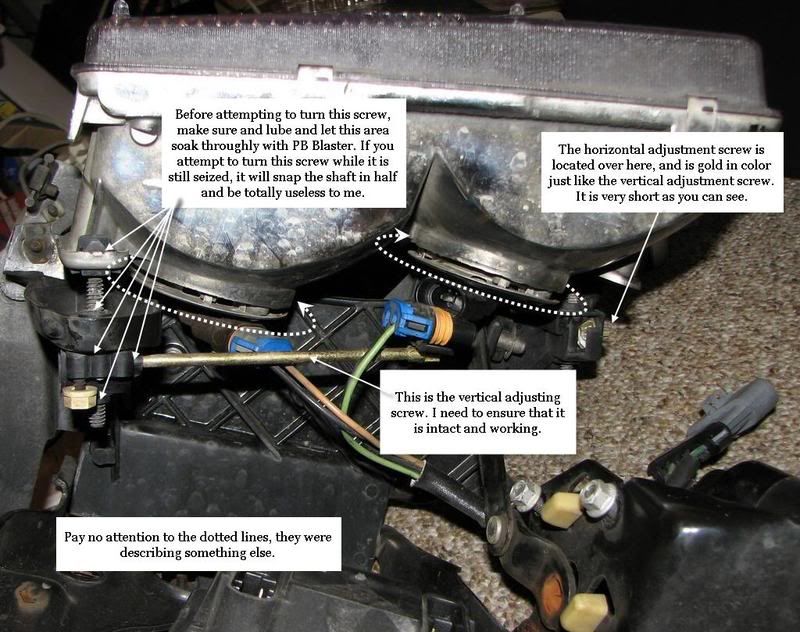

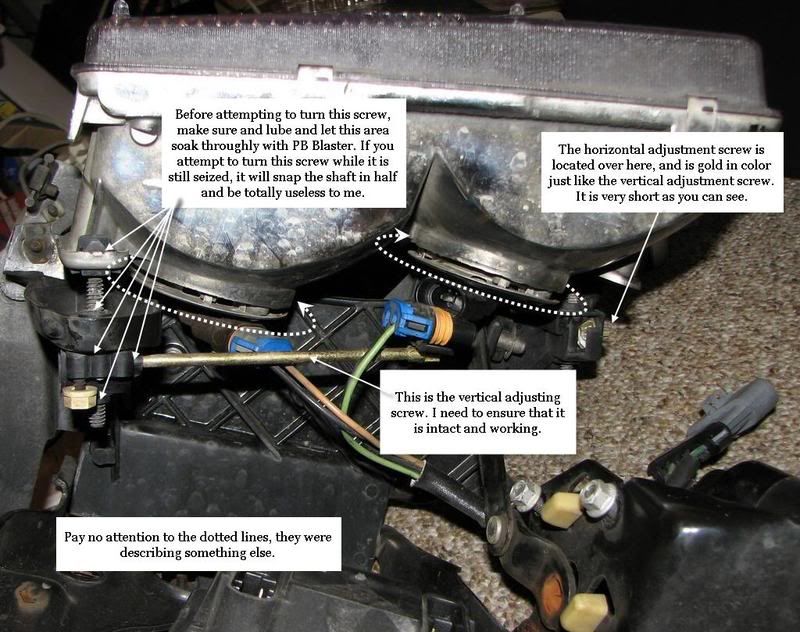

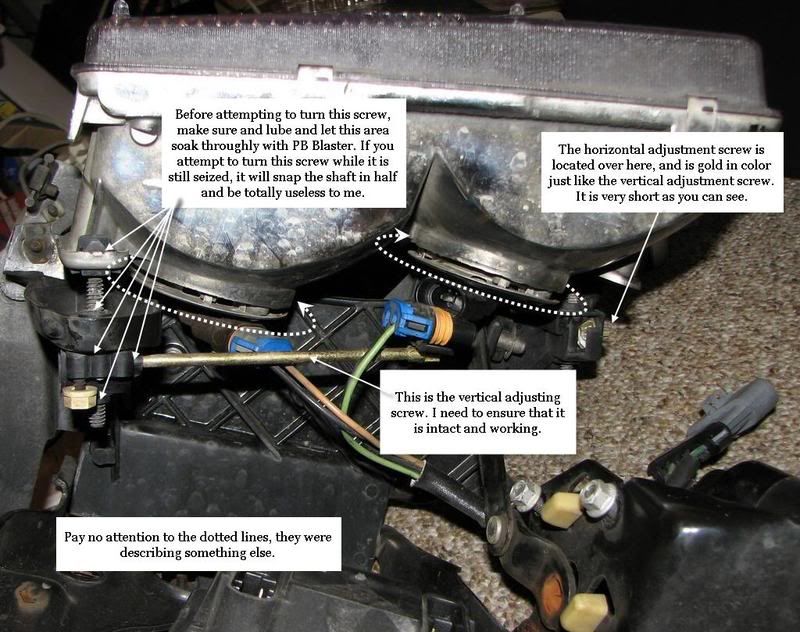

Odd little widget, innit? I have no idea what weird inverted Torx thingie fits over the outside, but the hole in the middle of the adjuster takes a standard T15 bit.

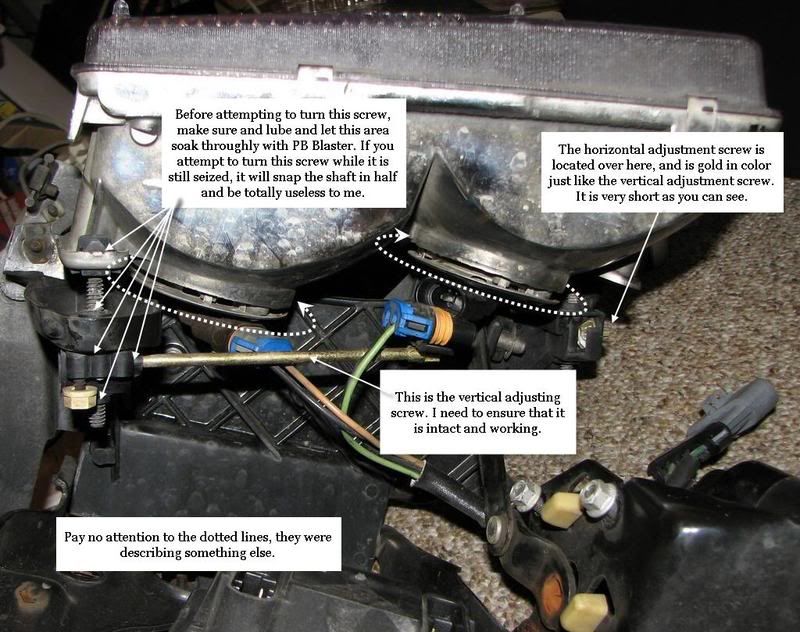

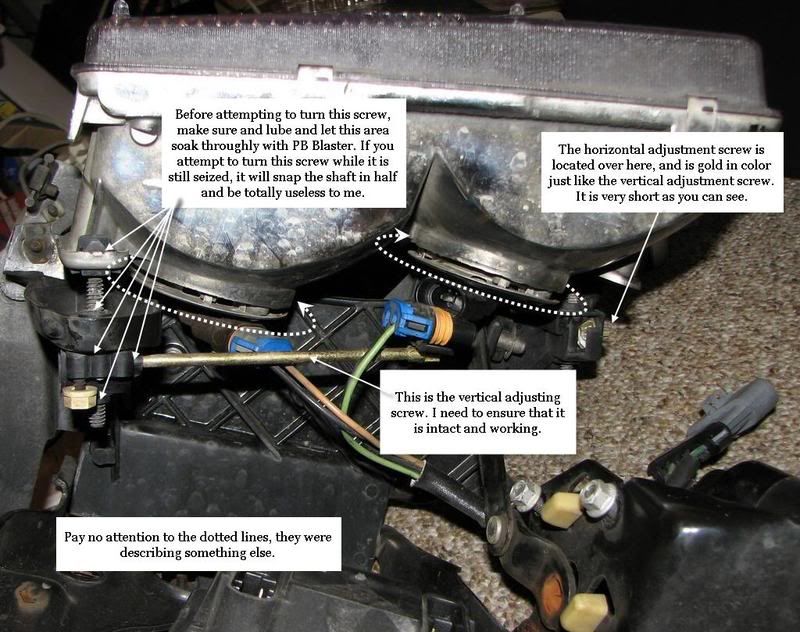

The one directly behind the plug is horizontal, the one below it is vertical.

The one directly behind the plug is horizontal, the one below it is vertical.

Last edited by Lee DeRaud; 06-17-2014 at 03:24 PM.

#5

I just had to do one of mine - my state inspection indicated it was pointing too low and to much to one side. I opened the headlights - carefully put a little penetrating oil on the adjustment rods - and the next day - with a 1/4 socket on an extension - very ginergly turned a quarter turn to loosen, then 1/4 turn back to tighten just to work the adjustment rods - then a couple more - moving to 1/2 turn in and 1/2 turn out, etc - until I was confident (as confident as I could be) that the rods would not bind up. Then I made my adjustments. It is scary when you get a look at how long and thin that one adjuster is - knowing that to break it means a new headlamp bucket. Just be careful, as already stated by someone.

Last edited by seu318; 06-18-2014 at 09:28 AM.

#6

Tech Contributor

Member Since: Dec 2003

Location: Horncastle Lincolnshire, England

Posts: 19,384

Likes: 0

Received 79 Likes

on

61 Posts

2023 C5 of the Year Finalist - Unmodified

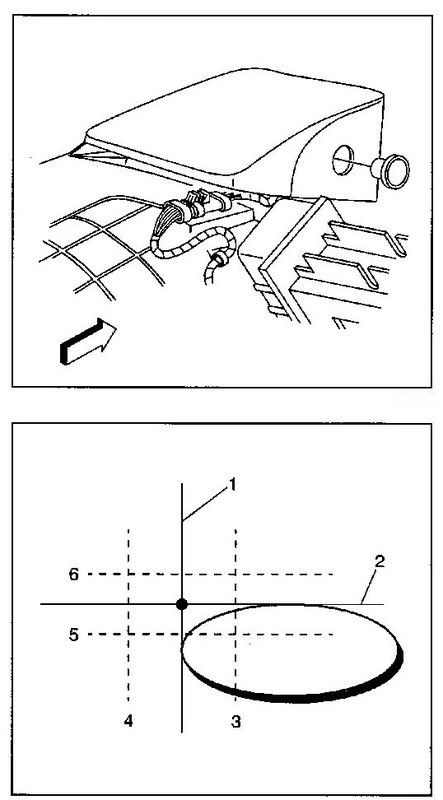

Does this help? I posted this a few years ago.

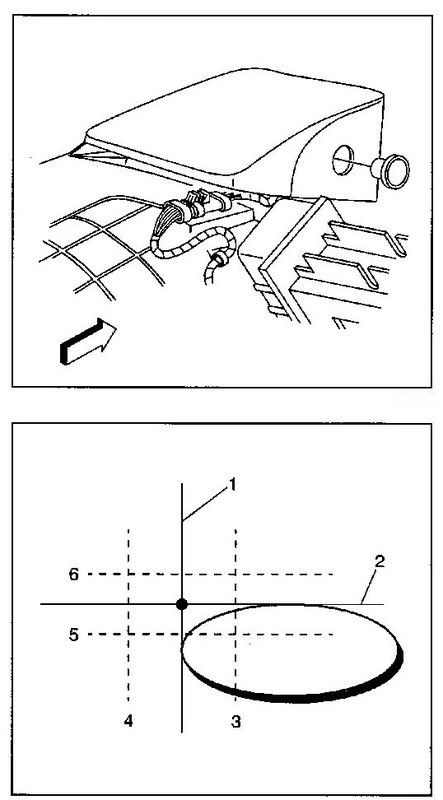

Aiming Stock Headlights

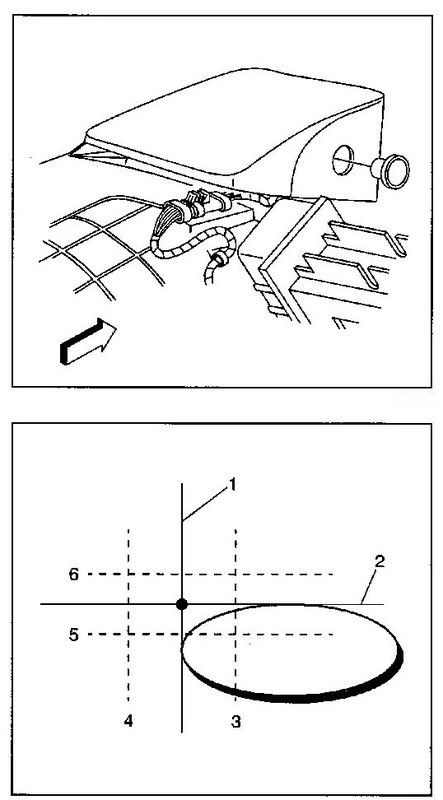

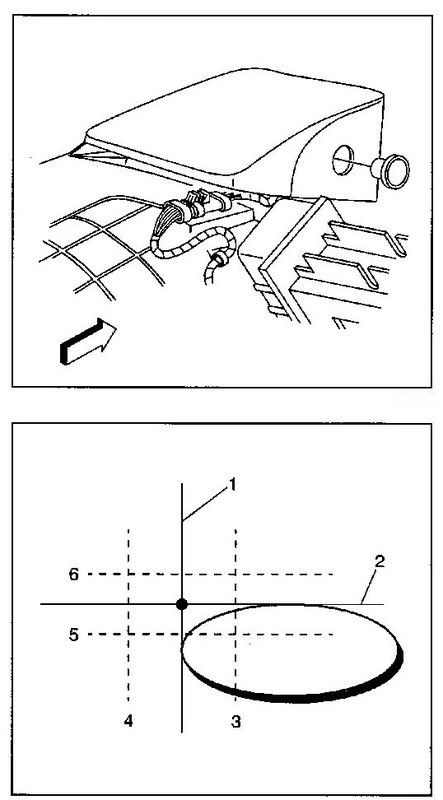

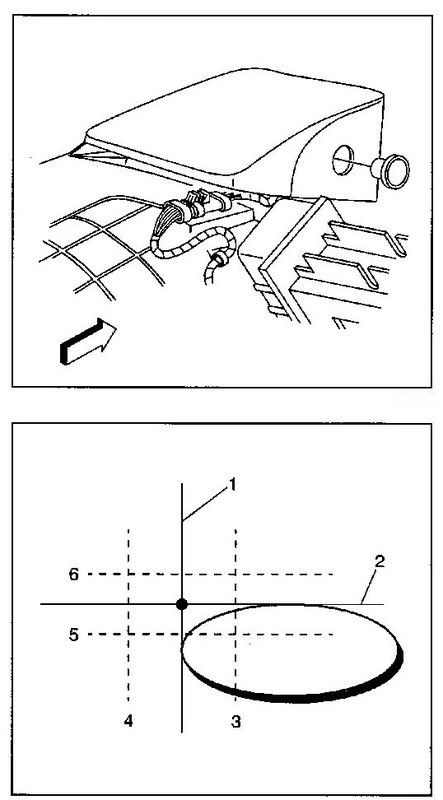

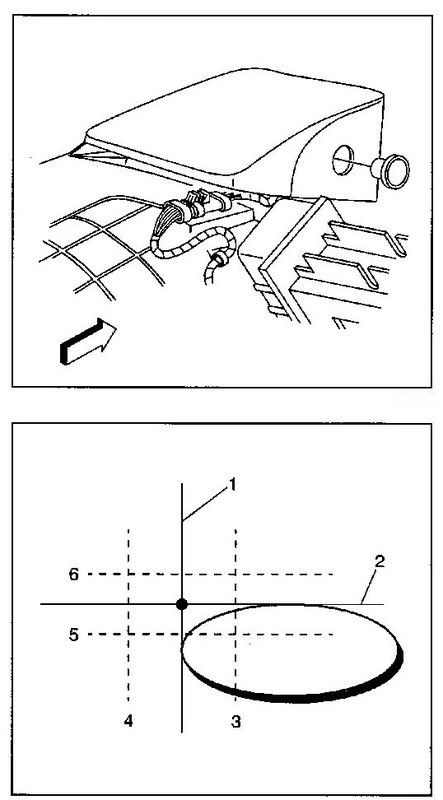

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

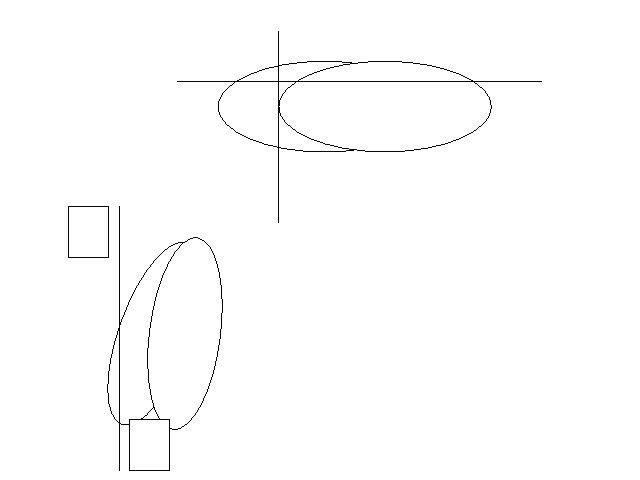

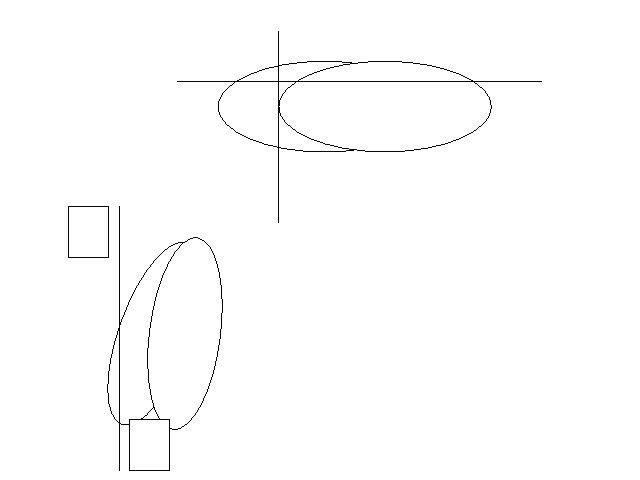

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

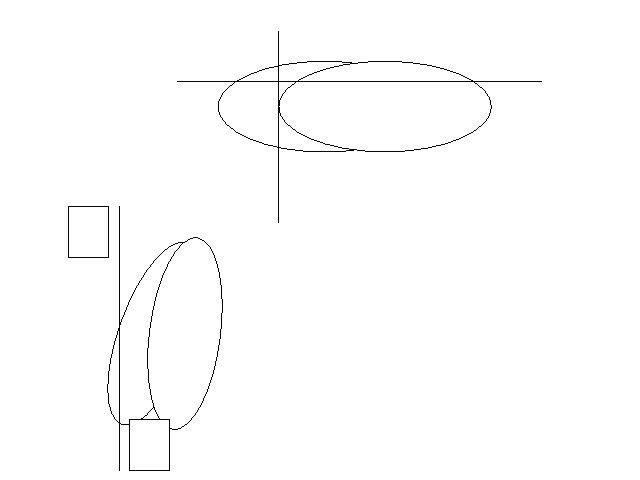

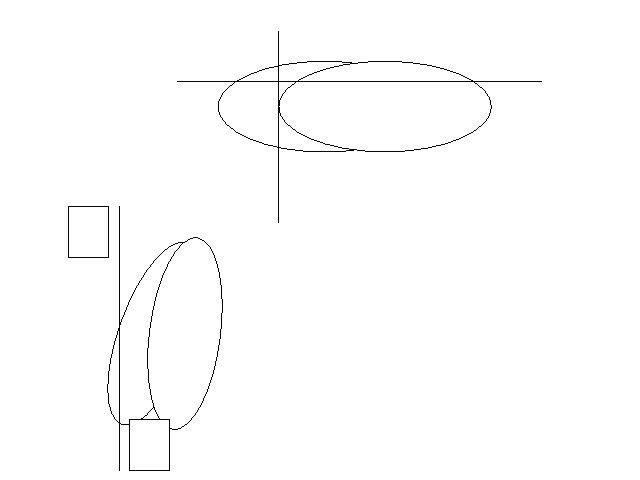

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

Aiming Stock Headlights

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

#7

Intermediate

Member Since: Dec 2014

Location: Washington

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

Does this help? I posted this a few years ago.

Aiming Stock Headlights

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

Aiming Stock Headlights

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

#8

1/4 mile/AutoX

Does this help? I posted this a few years ago.

Aiming Stock Headlights

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

Aiming Stock Headlights

Preparation

Chose a white wall to project the lights onto

Mark a vertical centreline on the screen in line with the center of the car (black tape?)

(look over the roof of the car to get the line)

Measure the height from the floor to the center of the headlight capsule

Mark a horizontal aiming line on the screen

Measure the distance between the centreline of the right headlight module and the center of the left headlight module.

Position the vertical tapes this distance to the right and left of the screen centreline

Lubricate the adjustment screws before adjusting See Note

Adjustments

Raise the hood

Raise the headlights

Remove the headlamp adjustment screw plug

Turn on the low beam headlights and block the light from projecting onto the screen from the passenger headlight

Check the horizontal aim

Adjust the horizontal aim adjusting screw to align the left edge of the high intensity zone with the headlight vertical centreline

The left edge of the beam should lie within 4” to the left and 4” to the right

of the vertical centreline.

Check the vertical aim

Adjust the vertical aim adjusting screw to align the top edge of the high intensity zone with the headlight horizontal centreline

The left edge of the beam should lie within 2” above and 2.5” below the lamp horizontal centreline.

Reinstall the headlamp adjustment screw plug

Repeat for the other headlight

Turn off the lights and close the hood

This is the pattern you're looking for

Advice Frome LonestarFRC:

Lubrication may not be enough. The problem is that the spray can't actually penetrate to where it's needed. There's a little internal gear-drive mechanism involved.

Important! If you attempt to make any adjustments, especially one involving the up/down adjuster and it doesn't move, or you meet a lot of resistance, stop right there. Do NOT attempt to force things. You will ABSOLUTELY break the long "goldenrod' (gold colored rod about 3" long). This is not an "if" or "maybe". Do NOT force it by twisting your wrench/nut-driver harder and harder. Once broken, these pieces are NOT available as a separate repair piece from GM. They will only sell you the entire headlight assembly.

If yours are frozen up, do a search on this issue. Many many posts about it. "Goldenrods" is one if the terms that may be helpful when doing a search. There IS a way to unfreeze the gear-drive mechanism but it involves removal of the headlight assembly to get access.

(Thanks to Junkman2008 for the picture)

#9

Le Mans Master

[QUOTE=DeeGee;1587161338]Does this help? I posted this a few years ago.

Aiming Stock Headlights

NICE job man...perfect. Copied and pasted to my C5 files...

Aiming Stock Headlights

NICE job man...perfect. Copied and pasted to my C5 files...

#10

1/4 mile/AutoX

#11

Burning Brakes

Here is something I found out. I had the golden rod problem in the stock headlights after not liking the Apex projectors which a former owner had put it. They were out of adjustment so bad that you could not see. I golden rods were froze. The P B Blaster didnt work and I broke one off. With nothing to loose I took the light golden rod gear box a part. It just snaps together. With the gear that is froze on the shaft out, you can work it loose. I never have seen on the forum that you can take them apart and fix them. With the broken shaft, I just cut a slot in the shaft end for a screw driver after I had it all loosened up. Now they both adjust. Took the other apart and fixed it too.

#12

Intermediate

Member Since: Dec 2014

Location: Washington

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

I am full aware of how to aim headlights. The adjusting gear freezing up which I have seen no one post that you can just take it apart and free it. Been doing this over 50 yrs and only trying to fill in the hole on a fix that is the best and not that hard. Hope all the headlight aiming will help someone. I know most people have no idea on how to aim the headlights. I don't want my state to be like Caif. They have to take the cars in for emissions and they check brakes , lights and other stuff where I feel you are treated like an idiot.

#13

Burning Brakes

I am full aware of how to aim headlights. The adjusting gear freezing up which I have seen no one post that you can just take it apart and free it. Been doing this over 50 yrs and only trying to fill in the hole on a fix that is the best and not that hard. Hope all the headlight aiming will help someone. I know most people have no idea on how to aim the headlights. I don't want my state to be like Caif. They have to take the cars in for emissions and they check brakes , lights and other stuff where I feel you are treated like an idiot.

Here is the link I went by. I thought at first I found it on here but it was the digital corvettes site I found my info from.

http://www.digitalcorvettes.com/foru...d.php?t=103322

#14

Team Owner

For those interested, the correct socket that fits the adjuster rods are called "external Torx" sockets, which are configured the exact opposite of a regular "Torx" bit.

The sizes run the same as the regular Torx (which some people call "star" fasteners), except there is an "E" prefix, signifying "External".

Thus, a regular Torx bit of a size 20 is referred to as a "T20", and it's counterpart would be an "E20". You can either buy small inexpensive 1/4" drive socket sets, OR you can buy individual sockets of a particular size for the job. These are found at most all the popular AP stores.

HTH

The sizes run the same as the regular Torx (which some people call "star" fasteners), except there is an "E" prefix, signifying "External".

Thus, a regular Torx bit of a size 20 is referred to as a "T20", and it's counterpart would be an "E20". You can either buy small inexpensive 1/4" drive socket sets, OR you can buy individual sockets of a particular size for the job. These are found at most all the popular AP stores.

HTH

#15

Burning Brakes

For those interested, the correct socket that fits the adjuster rods are called "external Torx" sockets, which are configured the exact opposite of a regular "Torx" bit.

The sizes run the same as the regular Torx (which some people call "star" fasteners), except there is an "E" prefix, signifying "External".

Thus, a regular Torx bit of a size 20 is referred to as a "T20", and it's counterpart would be an "E20". You can either buy small inexpensive 1/4" drive socket sets, OR you can buy individual sockets of a particular size for the job. These are found at most all the popular AP stores.

HTH

The sizes run the same as the regular Torx (which some people call "star" fasteners), except there is an "E" prefix, signifying "External".

Thus, a regular Torx bit of a size 20 is referred to as a "T20", and it's counterpart would be an "E20". You can either buy small inexpensive 1/4" drive socket sets, OR you can buy individual sockets of a particular size for the job. These are found at most all the popular AP stores.

HTH

I actually got away with using a long extension and a 1/4" socket to adjust mine.

#16

Le Mans Master

#17

Instructor

#18

I just had to do one of mine - my state inspection indicated it was pointing too low and to much to one side. I opened the headlights - carefully put a little penetrating oil on the adjustment rods - and the next day - with a 1/4 socket on an extension - very ginergly turned a quarter turn to loosen, then 1/4 turn back to tighten just to work the adjustment rods - then a couple more - moving to 1/2 turn in and 1/2 turn out, etc - until I was confident (as confident as I could be) that the rods would not bind up. Then I made my adjustments. It is scary when you get a look at how long and thin that one adjuster is - knowing that to break it means a new headlamp bucket. Just be careful, as already stated by someone.

Extremely cautious with those first one or two turns of the adjusting rods.

Even though they no longer need to be adjusted, I spray them with blaster every three months, just to keep them operational, if the time ever comes I need to adjust them again.

Bob.