Help me out vette tech

#1

I have a 2000 ws6.

235/243 .630/.610

PRC 225 heads

ls6 intake w/ 42lb injectors

Iíve posted on ls1 tech and got not too much info.

Heres copy of my post

Long story short I have an mpvi2 that is on way back to hptuners. Fairly certain unit is defective. However here is what happened. The unit was having issues connecting. I figured it was my side of things so I uninstalled and re installed software.

I reflashed car after making some adjustments to throttle cracker and as it was writing and doing its thing I washed the car. I open the door and it was done. I start the car and immediate very high idle. Like entire brake booster hose was off. 3000rpm. I was like oh man. I pulled car into garage and thought maybe this unit is going bad. I tried to do a reflash but unchecked the high speed write. It started to erase and failed mid erase and car wouldnít start. After about a dozen controller unlocker errors I wound up disconnecting the battery and opening vcm editor from original folder and it finally reflashed. The high idle is stuck there and I start trouble shooting this. Iac valve is fully retracted and it will do nothing but vibrate when I command different counts in the scanner. Even a new ac delco will do nothing. If I manually pull out iac valve and disconnect and reinstall the car idles fine once I get it close to adjusted for set rpm. Iím almost certain itís not a mechanical issue but a software/electronic fault. I hooked up the mpvi2 to laptop today and it wonít even recognize. In the mean time has anyone had this happen? Should I go ripping into the iac harness or do you think a clean write with a will fix this? This is incredibly frustrating and stressful so I guess Iím just fishing for someone elseís experiences and solutions. Also considered bad pcm or iac drivers? Connectors on pcm harness are red/blue.

i have checked for continuity for iac harness to pcm and all was good

Also if I have iac set close and plug in iac while car is running good it will slowly retract the pintle valve until all the way retracted causing a massive amount of air and an idle of about 2500-3000 rpm

235/243 .630/.610

PRC 225 heads

ls6 intake w/ 42lb injectors

Iíve posted on ls1 tech and got not too much info.

Heres copy of my post

Long story short I have an mpvi2 that is on way back to hptuners. Fairly certain unit is defective. However here is what happened. The unit was having issues connecting. I figured it was my side of things so I uninstalled and re installed software.

I reflashed car after making some adjustments to throttle cracker and as it was writing and doing its thing I washed the car. I open the door and it was done. I start the car and immediate very high idle. Like entire brake booster hose was off. 3000rpm. I was like oh man. I pulled car into garage and thought maybe this unit is going bad. I tried to do a reflash but unchecked the high speed write. It started to erase and failed mid erase and car wouldnít start. After about a dozen controller unlocker errors I wound up disconnecting the battery and opening vcm editor from original folder and it finally reflashed. The high idle is stuck there and I start trouble shooting this. Iac valve is fully retracted and it will do nothing but vibrate when I command different counts in the scanner. Even a new ac delco will do nothing. If I manually pull out iac valve and disconnect and reinstall the car idles fine once I get it close to adjusted for set rpm. Iím almost certain itís not a mechanical issue but a software/electronic fault. I hooked up the mpvi2 to laptop today and it wonít even recognize. In the mean time has anyone had this happen? Should I go ripping into the iac harness or do you think a clean write with a will fix this? This is incredibly frustrating and stressful so I guess Iím just fishing for someone elseís experiences and solutions. Also considered bad pcm or iac drivers? Connectors on pcm harness are red/blue.

i have checked for continuity for iac harness to pcm and all was good

Also if I have iac set close and plug in iac while car is running good it will slowly retract the pintle valve until all the way retracted causing a massive amount of air and an idle of about 2500-3000 rpm

Last edited by Lt1slowerbird; 08-15-2018 at 09:57 AM.

#3

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

What does your “IAC position” reading on your scan tool ??... 0 perhaps ??...should be around 30 or so at idle. What are your long and short term fuel trims looking like at idle ??...have you clamped off the brake booster hose to see if there is an internal leak in the brake booster and your IAC counts go back to normal and the RPM’s come down ??

#4

I cannot verify atm as scanner is at hptuners. If I recall it made no attempt to lower idle however set the po507 code. Shut car off and iac valve was completely retracted every time. Was the same position even when unplugged during motor operating Incase pcm sets iac to ďparkĒ position at shutdown. The only thing is the iac valve is not opening at all. At 0 steps it should be extending to shut down airflow but itís not. The motor receives signal as you can feel it vibrate and see pintle vibrate but it doesnít move outwards. Like itís getting a command to retract even though itís already fully retracted. However if I manually set iac to completely close off it will not run without throttle. So once you set it to about where it needs to be it will run and idle perfectly until you plug in iac. Before issue I had iac counts to about 50-60 at 210 hot idle fans off tps voltage was .67 via hptuner reading. Also when I set iac manually my shorts are around -1 to -4 and I am not using long terms

Last edited by Lt1slowerbird; 08-16-2018 at 02:36 AM.

#5

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

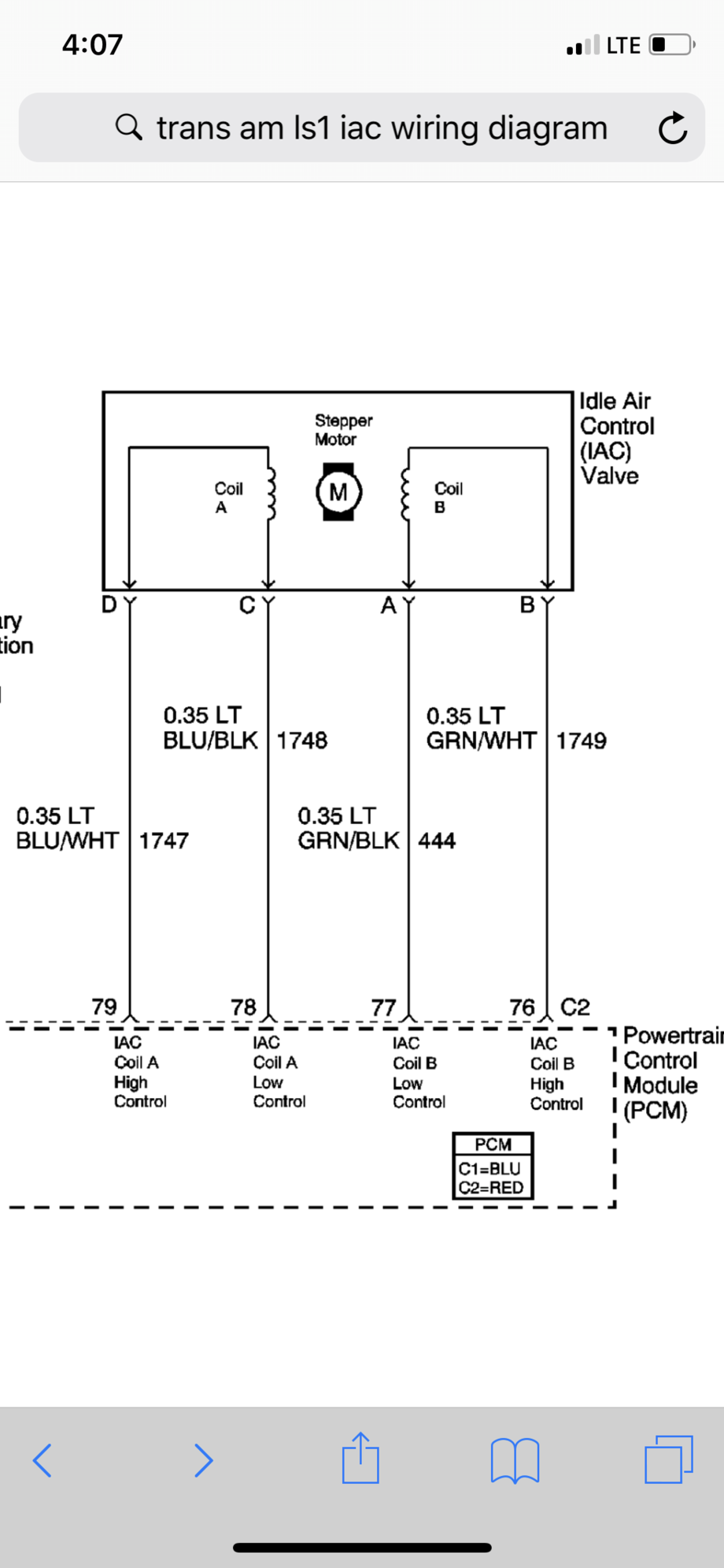

How did you check the IAC harness electrically??...it’s “ground side switched” at the PCM so if it’s a 4 wire stepper motor you would connect a 12 volt test light to battery POSITIVE and with the harness unplugged touch each of the 4 wires and the test light should flash as the engine is revved !!...if no flash either a wiring issue or bad PCM...have you done that??...I was asking about the long terms because if they were way positive we might have a vacuum leak...an 0507 isn’t always a bad IAC...something else is causing the high idle like a big vacuum leak !!

#6

I simply tested for continuity from each lead to the respective Pinout for the pcm. And I checked operation by commanding it to extend or retract via vcm scanner special controls. I have no idea what the issue is. Itís not the iac valve. It operates exactly the same be it a 40 dollar bwd valve or an 80s dollar AC Delco. Both give me the same result and when plugged the car dies. But set right and then disconnected car runs fine. Revs up and comes right back down to idle. And Iím pretty certain there is no vac leak as the issue is 100% resolved when manually setting the iac. Plus for 3000+rpms id think the vac leak would be huge. Car has new pcv and is fairly new topend build. Intake has new gaskets and is torqued to I think a touch over spec. Like 95in lb

Last edited by Lt1slowerbird; 08-16-2018 at 04:00 AM.

#8

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

No IAC on the C5 Corvette !!

#10

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

I usually won’t touch a “tuned” car, I’d tell the owner to take it back to the tuner !!...you have to know circuit design to troubleshoot the circuit (I bet you followed the FSM flow chart)...a continuity test won’t tell you everything !!...you have to make sure you don’t have an “open coil”, “shorted control wire”, or “shorted PCM driver”... that’s about it for this circuit design !!...being that this circuit is ground side switched with the key on the test light should illuminate when touched to the control wire...turn the key on and off a few times and the light will come on and go out...well, that’s about it Bubba !!

Last edited by C5 Diag; 08-16-2018 at 05:59 AM.

#11

Continuity from harness to pin leaves the rest of those instances being a pcm error correct? Iím not sure what you mean by control wire? Is there a wiring diagram of iac that Iím not aware of? Please do elaborate. Iím not a very Adept Tuner and the electrical nightmare is not my strong point.

#12

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

Continuity from harness to pin leaves the rest of those instances being a pcm error correct? Iím not sure what you mean by control wire? Is there a wiring diagram of iac that Iím not aware of? Please do elaborate. Iím not a very Adept Tuner and the electrical nightmare is not my strong point.

#13

So if I have continuity on wires to harness then the wiring is good and pcm may be at fault correct? I am thinking when I had a failed erase on my programmer it corrupted my iac drivers. I know itís not the IAC Motor itself. This has been 2 new iac motors after the original which I honestly think is still good. I will try to get a test light and test that if my lead is long enough

#14

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

So if I have continuity on wires to harness then the wiring is good and pcm may be at fault correct? I am thinking when I had a failed erase on my programmer it corrupted my iac drivers. I know itís not the IAC Motor itself. This has been 2 new iac motors after the original which I honestly think is still good. I will try to get a test light and test that if my lead is long enough

#15

Yes I understand however the issue never happened before the failed write. I had a bit of idle hang but my throttle cracker tables needed a slight tweak. I donít think itís my wiring. I have continuity to the pcm pinout so that means each lead is not broken correct?. So they should work and be able to transfer power. Unless I donít understand continuity. Lol. I think my pcm is the issue. After the failed write the car wouldnít start and gauges went stupid bouncing from left to right. A reflash let the car start but ever since the iac idle control has been messed up. Coincidentally the thing I was changing in the tune was the throttle cracker which is directly related to the IAC. I know itís getting power because when I commanded steps The motor would vibrate . Just the pintle would not move in the proper direction it seemed it only tried to retract. Even at 0 counts which should be fully extended. Which is why I checked for continuity wire by wire thinking I may have rubbed through and be jumping leads but I think Iíve corrupted the iac drivers and it may just need a write entire tune.

My end theory is my wiring is good by continuity check. Iac circuitry is a closed circuit when manually operated with a scanner and I either fíd the pcm by the failed write or I corrupted some driver files in the software. See what Iím saying? Iím off this weekend and will find my test light at the shop

My end theory is my wiring is good by continuity check. Iac circuitry is a closed circuit when manually operated with a scanner and I either fíd the pcm by the failed write or I corrupted some driver files in the software. See what Iím saying? Iím off this weekend and will find my test light at the shop

#16

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

Yes I understand however the issue never happened before the failed write. I had a bit of idle hang but my throttle cracker tables needed a slight tweak. I donít think itís my wiring. I have continuity to the pcm pinout so that means each lead is not broken correct?. So they should work and be able to transfer power. Unless I donít understand continuity. Lol. I think my pcm is the issue. After the failed write the car wouldnít start and gauges went stupid bouncing from left to right. A reflash let the car start but ever since the iac idle control has been messed up. Coincidentally the thing I was changing in the tune was the throttle cracker which is directly related to the IAC. I know itís getting power because when I commanded steps The motor would vibrate . Just the pintle would not move in the proper direction it seemed it only tried to retract. Even at 0 counts which should be fully extended. Which is why I checked for continuity wire by wire thinking I may have rubbed through and be jumping leads but I think Iíve corrupted the iac drivers and it may just need a write entire tune.

My end theory is my wiring is good by continuity check. Iac circuitry is a closed circuit when manually operated with a scanner and I either fíd the pcm by the failed write or I corrupted some driver files in the software. See what Iím saying? Iím off this weekend and will find my test light at the shop

My end theory is my wiring is good by continuity check. Iac circuitry is a closed circuit when manually operated with a scanner and I either fíd the pcm by the failed write or I corrupted some driver files in the software. See what Iím saying? Iím off this weekend and will find my test light at the shop

#17

I believe all vettes were drive by wire. Trans ams and Camaro got drive by cable until I think 01 or 02?? I might be wrong. Anyway to control idle airflow the cable driven throttle bodies have an iac valve to let bypass air. The throttle cracker table is an airflow ADDER that allows airflow past when you close throttle plate. It slows rpm drop to help with shifting but itís main cause is that without it some cars will overshoot idle rpm and bog or even stall. Itís like a cushion to allow a more controlled rpm drop. Too much ďcushionĒ and idle will hang from too much air

#18

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts

I believe all vettes were drive by wire. Trans ams and Camaro got drive by cable until I think 01 or 02?? I might be wrong. Anyway to control idle airflow the cable driven throttle bodies have an iac valve to let bypass air. The throttle cracker table is an airflow ADDER that allows airflow past when you close throttle plate. It slows rpm drop to help with shifting but itís main cause is that without it some cars will overshoot idle rpm and bog or even stall. Itís like a cushion to allow a more controlled rpm drop. Too much ďcushionĒ and idle will hang from too much air

#20

Moderator, Tech Contributor

Member Since: Sep 2013

Location: Cape Coral, Florida

Posts: 9,521

Received 2,124 Likes

on

1,689 Posts