[Z06] Top Tier LS7 Heads

#41

Micheal d thanks for chancing my misquote ...indeed is not spiral cut it is as you said.

I wasn't paying attention...I was looking at my heads....hopefully will be running today if family responsibilities allow enough time to complete.

I wasn't paying attention...I was looking at my heads....hopefully will be running today if family responsibilities allow enough time to complete.

#42

I just didn't want anyone getting the wrong impression. Spiral cut would mean they were knurled. Well, that's assuming someone reading it would even know what the hell knurling is.......like 548chevell.

#44

That's quite interesting that the bronze guides have similar hardness to the OEM powdered metal. I love seeing actual data and not just empty claims. I'll certainly be giving you guys a call when I get ready to re-do my heads!

#45

Supporting Vendor

Thread Starter

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

Thank you for the compliment.

We should have some core heads back on the shelf and ready to go later this week. The core heads are hard to keep in stock.

http://www.americanheritageperformance.com/

A Dyno Graph Just sent to us by one of our customer across the country running our Package 4 Heads:

608RWHP

We should have some core heads back on the shelf and ready to go later this week. The core heads are hard to keep in stock.

http://www.americanheritageperformance.com/

A Dyno Graph Just sent to us by one of our customer across the country running our Package 4 Heads:

608RWHP

Last edited by American Heritage; 01-05-2016 at 09:51 PM.

#46

Supporting Vendor

Thread Starter

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

Thank you. We spent a lot of time and money acquiring the valve guide date we posted. Thank you for pointing that out. GM was concerned about the valve guide oiling at higher RPM's. This is why on our hardened PM guides we use oil spirals (not knurling) to help maintain high rpm oil lubrication.

Last edited by American Heritage; 01-06-2016 at 04:36 AM.

#47

On new GM LS7 heads (never been run) we have observed .003"-.005" run out on the intake valve seats. GM's Valve Jobs leave alot to be desired from a concentricty standpoint.

We hold much much tighter machining tolerances than GM does.

We produce some of the most concentric valve jobs you will find on the market today.

We hold much much tighter machining tolerances than GM does.

We produce some of the most concentric valve jobs you will find on the market today.

#48

all I can say is when I received my heads they looked like a piece of art..... and it took true talent to do the work that was done on the ports. Plus I trust him. Seems to be a stand up guy.

#49

Le Mans Master

He is who I will turn to when the time comes for my heads!

#50

Team Owner

#51

Supporting Vendor

Thread Starter

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

On average our valve jobs have .0005"-.0008" Valve Seat Run out.

Our max valve seat runout tolerance is .001" anything over that and we are not satisfied with it.

We take our time when we do our valve jobs this insures we get the least amount of runout possible. We valve quality of work over all else.

Last edited by American Heritage; 01-15-2016 at 06:18 PM. Reason: Entered incorrect Data before correction

#52

Instructor

Member Since: Feb 2010

Location: Bay Area California

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Forgot to Mention we now fully endorse and offer our Proprietary Moldstar90 guides. Hard like a Hardened PM (powder metal) and better heat property's than any bronze guide on the market.

Our Moldstar90 Valve Guides were a $420 upgrade. Well worth it. Same material used in F1, Indy Car and MotoGP bikes.

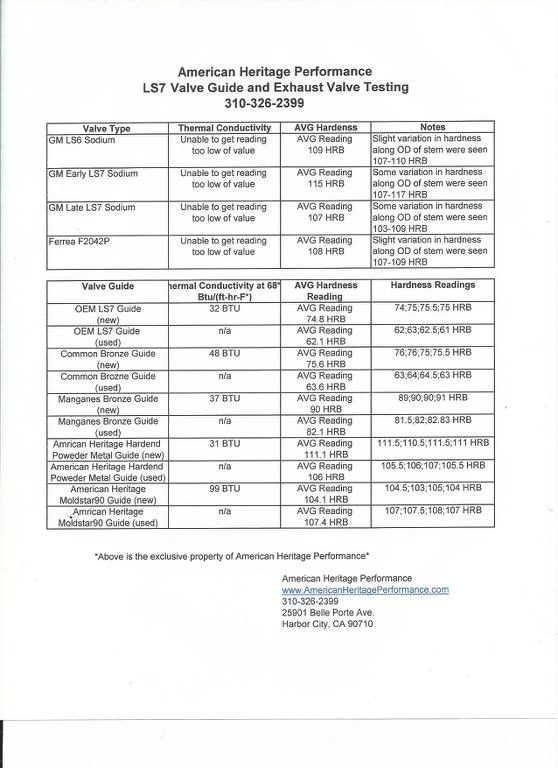

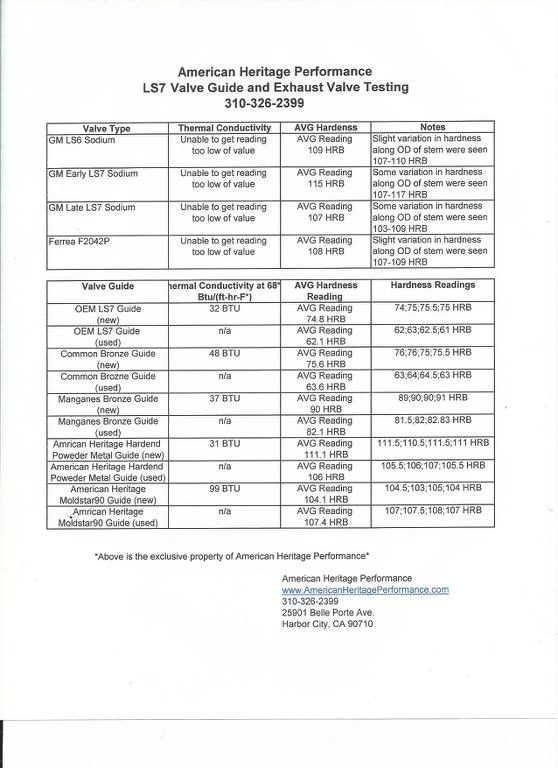

Some valve guide data that we posted months ago but thought we would re post it (testing was done by an independent non biased facility):

Our Moldstar90 Valve Guides were a $420 upgrade. Well worth it. Same material used in F1, Indy Car and MotoGP bikes.

Some valve guide data that we posted months ago but thought we would re post it (testing was done by an independent non biased facility):

would you recommend your moldstar 90 valve guides on a street car,

would there be any benefit for this compared to your powder metal guide ? would they last longer ?

#55

Team Owner

As far as what I've been able to tell, thanks to a couple forum members that have dissected these (dangerous procedure with the sodium fill), is that there seems to be a slight increase in stem wall thickness. I know this was documented in an old thread...

#57

Team Owner

#58

Supporting Vendor

Thread Starter

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

MoldStar90 is superior in every way to both bronze and PM. If price is not an issue Moldstar90 guides are at the "premium" of valve guide pricing) and the best guide possible is wanted then MoldStar90 is what you want. You will have no issues running MoldStar90 on the street or at the track.