Who here has done a leak down test?

#1

Drifting

Thread Starter

Im about to pull my heads to send back to Tony Mamo for some upgrades and bigger cam  Before I pull them I decided to do a leak down test on my motor. My car has 40k on it and Iím getting 8-10% leak down between all cylinders. This is done on a cold motor and bringing up to 100psi. From what Iíve read 10% seems to be max you would want to see but I have also read upwards of 15-20% is acceptable as long as itís the same across the board.

Before I pull them I decided to do a leak down test on my motor. My car has 40k on it and Iím getting 8-10% leak down between all cylinders. This is done on a cold motor and bringing up to 100psi. From what Iíve read 10% seems to be max you would want to see but I have also read upwards of 15-20% is acceptable as long as itís the same across the board.

Before I pull them I decided to do a leak down test on my motor. My car has 40k on it and Iím getting 8-10% leak down between all cylinders. This is done on a cold motor and bringing up to 100psi. From what Iíve read 10% seems to be max you would want to see but I have also read upwards of 15-20% is acceptable as long as itís the same across the board.

Before I pull them I decided to do a leak down test on my motor. My car has 40k on it and Iím getting 8-10% leak down between all cylinders. This is done on a cold motor and bringing up to 100psi. From what Iíve read 10% seems to be max you would want to see but I have also read upwards of 15-20% is acceptable as long as itís the same across the board.

#2

squirt some oil down the holes, rotate a few and re-check. That will tell you where some of the blowby is going.Leak-down is not exact but a very relible (and most accurate ) way to guage the engine your working on.On a dry/cold engine thats good numbers.

#3

Drifting

Thread Starter

I have my intake and exhaust off. I put painters tape over ports to make sure nothing was coming out of heads. These heads only have 1k miles on them and the had no leak from what I saw. This was a cold/dry leak down test

#4

Burning Brakes

I ran a leak down test, last spring, after the car had been sitting all winter. My lowest cylinder was 94%, and the best was 97%. With the rest reading 95-96%.

What upgrades are going into your MMS265 heads?

What upgrades are going into your MMS265 heads?

#5

Drifting

Thread Starter

We we going with high lift springs, hand porting the exhaust side, bigger exhaust valves and just going through them to make sure everything is perfect also milling them for a 12.5:1 compression to take advantage of the E85.

#6

Burning Brakes

I would try a little oil in the cylinders, and see if that doesn't up the numbers. If it does, then when warmed up and oil on the walls you have good sealing. Also, turning the motor over a little will also help settle the rings for a better seal.

IT really is all about the combo. I'm not familiar with yours, but if it isn't a matched combo, results will not be there.

I like that you' re upping the compression...IT improves throttle response, sounds meaner at idle, and makes more power everywhere. IF Tony is spec'ing your cam, then you're in excellent hands. Now it is just down to your tuner...

IT really is all about the combo. I'm not familiar with yours, but if it isn't a matched combo, results will not be there.

I like that you' re upping the compression...IT improves throttle response, sounds meaner at idle, and makes more power everywhere. IF Tony is spec'ing your cam, then you're in excellent hands. Now it is just down to your tuner...

#7

Drifting

Thread Starter

I would try a little oil in the cylinders, and see if that doesn't up the numbers. If it does, then when warmed up and oil on the walls you have good sealing. Also, turning the motor over a little will also help settle the rings for a better seal.

IT really is all about the combo. I'm not familiar with yours, but if it isn't a matched combo, results will not be there.

I like that you' re upping the compression...IT improves throttle response, sounds meaner at idle, and makes more power everywhere. IF Tony is spec'ing your cam, then you're in excellent hands. Now it is just down to your tuner...

IT really is all about the combo. I'm not familiar with yours, but if it isn't a matched combo, results will not be there.

I like that you' re upping the compression...IT improves throttle response, sounds meaner at idle, and makes more power everywhere. IF Tony is spec'ing your cam, then you're in excellent hands. Now it is just down to your tuner...

#8

Test at bdc and try rocking the piston back and forth to get the rings perpendicular to the cylinder. I would not use oil. 5% is OK, 10 is high.

Last edited by Michael_D; 03-31-2018 at 08:24 PM.

#9

Drifting

Thread Starter

#10

Drifting

Thread Starter

ok I brought the piston down to bottom and lossened my rockers. I also tried rocking my piston at bottom. I checked my worst one and Iím getting 8% leak. This motor only has 40k. Do I need to pull it? I really donít want to. Iím thinking if I did I would just throw forged pistons and maybe sleeves.

#11

Le Mans Master

ok I brought the piston down to bottom and lossened my rockers. I also tried rocking my piston at bottom. I checked my worst one and Iím getting 8% leak. This motor only has 40k. Do I need to pull it? I really donít want to. Iím thinking if I did I would just throw forged pistons and maybe sleeves.

Sure, you have 3 or 4 more percent leakdown from "perfect", but, you also have 40K miles on it, and at these power levels, cylinder walls / rings are probably going to wear at a slightly accelerated rate. Unless you are chasing some national championship somewhere, I'd leave it be for now.

Do you know how to listen to see which of the 3 exit paths the pressure is escaping from?

#12

Drifting

Thread Starter

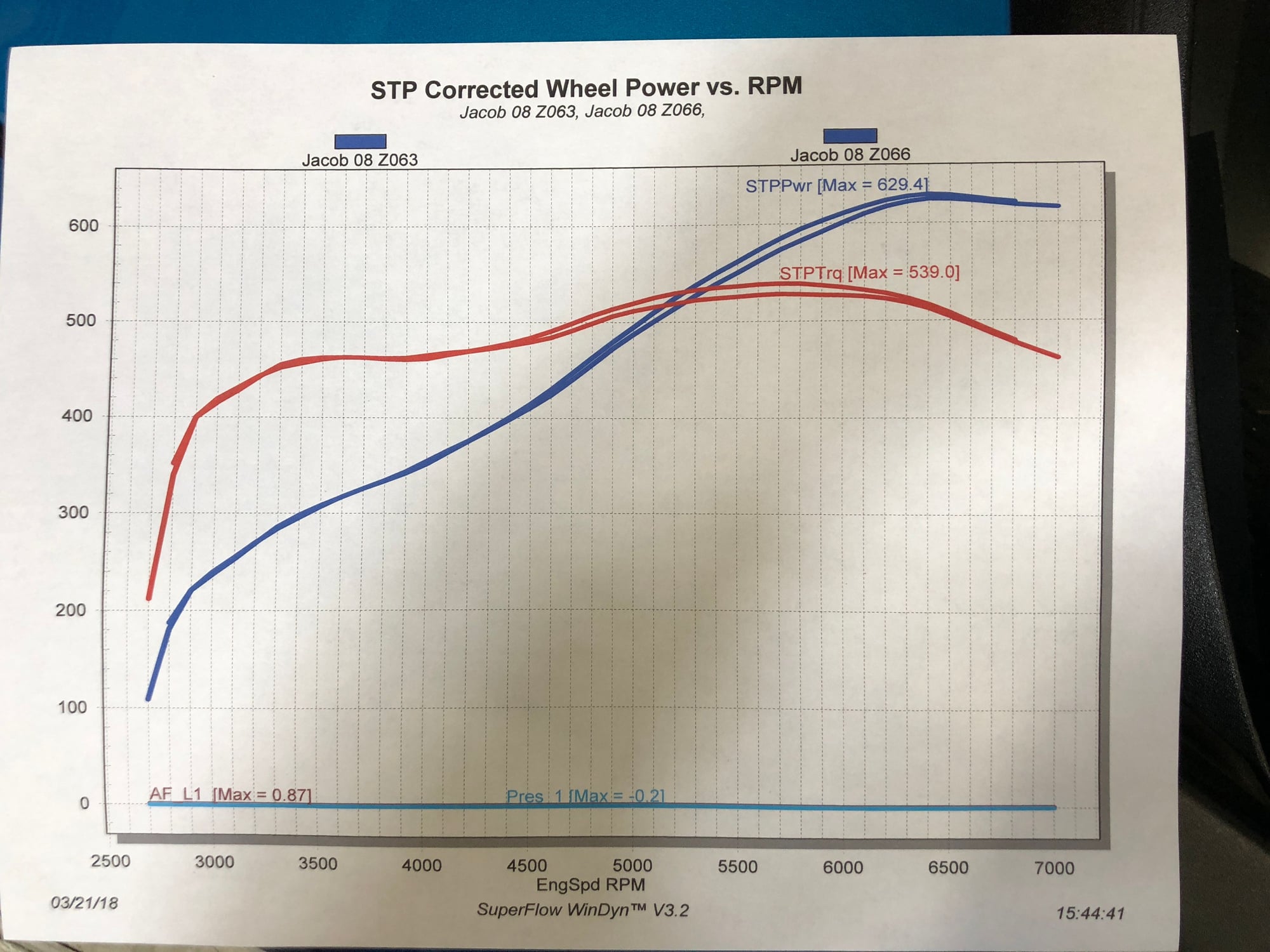

You are making (non-FI) 630HP to the wheels and you are thinking about pulling the engine?

Sure, you have 3 or 4 more percent leakdown from "perfect", but, you also have 40K miles on it, and at these power levels, cylinder walls / rings are probably going to wear at a slightly accelerated rate. Unless you are chasing some national championship somewhere, I'd leave it be for now.

Do you know how to listen to see which of the 3 exit paths the pressure is escaping from?

Sure, you have 3 or 4 more percent leakdown from "perfect", but, you also have 40K miles on it, and at these power levels, cylinder walls / rings are probably going to wear at a slightly accelerated rate. Unless you are chasing some national championship somewhere, I'd leave it be for now.

Do you know how to listen to see which of the 3 exit paths the pressure is escaping from?

my intake and headers are removed so i have tape over them. I can hear it coming from inside the motor. Valve covers are also off and no bubbles in the coolant. The car runs strong

#13

Drifting

Thread Starter

Also one thing that might be important. If pressurize my leak down test without it connected to the hose going to head and I bring the first gauge to 100psi the second gauge shows 98% so if Iím sitting at 92% with it hooked to the head that might mean I only really have 6% leak down?

#14

Melting Slicks

Member Since: Jun 2005

Location: Rochester NY

Posts: 2,734

Received 1,678 Likes

on

878 Posts

2018 C6 of Year Finalist

St. Jude Donor '10, '17

In my opinion you are fine and no possible way I pull a motor over what you are seeing. Anything under 10% is good and what you are looking for is consistency across cylinders.

When I popped two pistons last year, my readings looked something like this:

Cyl 1: 6%

Cyl 2: 7%

Cyl 3: 6%

Cyl 4: 5%

Cyl 5: 42%

Cyl 6: 6%

Cyl 7: 51%

Cyl 8: 6%

This is when you know you have a problem.

And your dyno is using STD correction. Take off 4-6% for a more accurate comparison to SAE (what most dynos use as a correction standard). You are closer to 600whp SAE. (which is still extremely stout).

What injectors/fuel pump are you using? I would start to be concerned with running out of fuel at those levels. Especially with E85.

When I popped two pistons last year, my readings looked something like this:

Cyl 1: 6%

Cyl 2: 7%

Cyl 3: 6%

Cyl 4: 5%

Cyl 5: 42%

Cyl 6: 6%

Cyl 7: 51%

Cyl 8: 6%

This is when you know you have a problem.

And your dyno is using STD correction. Take off 4-6% for a more accurate comparison to SAE (what most dynos use as a correction standard). You are closer to 600whp SAE. (which is still extremely stout).

What injectors/fuel pump are you using? I would start to be concerned with running out of fuel at those levels. Especially with E85.

#15

Melting Slicks

I think you are in a good area I agree consistency is what you are looking at. I would also see what your cranking compression is. The test is a little easier than the static one (not having to get pistons in right place oil in cylinder etc.). You can also do it a little quicker while engine is still warm - pull plugs, a couple of fuses, air cleaner inlet. A good pump gas motor should be like 190-200 psi after 3-4 strokes. If you are really high compression E85 then maybe like 220 psi. Once again consistency is the key so if one or two are at 145 psi and the rest are at 190 psi then you have a problem.

#16

Drifting

Thread Starter

In my opinion you are fine and no possible way I pull a motor over what you are seeing. Anything under 10% is good and what you are looking for is consistency across cylinders.

When I popped two pistons last year, my readings looked something like this:

Cyl 1: 6%

Cyl 2: 7%

Cyl 3: 6%

Cyl 4: 5%

Cyl 5: 42%

Cyl 6: 6%

Cyl 7: 51%

Cyl 8: 6%

This is when you know you have a problem.

And your dyno is using STD correction. Take off 4-6% for a more accurate comparison to SAE (what most dynos use as a correction standard). You are closer to 600whp SAE. (which is still extremely stout).

What injectors/fuel pump are you using? I would start to be concerned with running out of fuel at those levels. Especially with E85.

When I popped two pistons last year, my readings looked something like this:

Cyl 1: 6%

Cyl 2: 7%

Cyl 3: 6%

Cyl 4: 5%

Cyl 5: 42%

Cyl 6: 6%

Cyl 7: 51%

Cyl 8: 6%

This is when you know you have a problem.

And your dyno is using STD correction. Take off 4-6% for a more accurate comparison to SAE (what most dynos use as a correction standard). You are closer to 600whp SAE. (which is still extremely stout).

What injectors/fuel pump are you using? I would start to be concerned with running out of fuel at those levels. Especially with E85.

also my tuner Matt Grower. One of the best in the Bay Area very straight forward guy. Told me this dyno is stingy and itís STD numbers compares to SAE numbers on cars he has tuned on other dynos. Not that it really matters.

Last edited by Jayfabs; 04-01-2018 at 10:41 AM.

#17

Melting Slicks

Pro Mechanic

Member Since: Nov 2013

Location: Ex DPRK, now just N of Medford, OR

Posts: 2,928

Received 742 Likes

on

547 Posts

My preferred method for evaluating engine condition is still the compression test. I've never been a big fan of using the leakdown test for that. I just typically use it to locate where the missing compression went when there's an issue.

Standard compression test format... engine warm, injectors off, full charge battery, all plugs out, throttles open if ITB.

Watch the first bounce of the gauge, it should be roughly half the final compression pressure. It's a good measure of static ring seal, not relying on pressure buildup to force the rings against the cylinder wall.

If they come up low, that's when I break out the CLT.

But I'm sure everyone has their own method...

Standard compression test format... engine warm, injectors off, full charge battery, all plugs out, throttles open if ITB.

Watch the first bounce of the gauge, it should be roughly half the final compression pressure. It's a good measure of static ring seal, not relying on pressure buildup to force the rings against the cylinder wall.

If they come up low, that's when I break out the CLT.

But I'm sure everyone has their own method...

#18

Le Mans Master

Also one thing that might be important. If pressurize my leak down test without it connected to the hose going to head and I bring the first gauge to 100psi the second gauge shows 98% so if Iím sitting at 92% with it hooked to the head that might mean I only really have 6% leak down?

#19

Drifting

Thread Starter

my hose had a small leak at the head end where it swivels. I glued that end up so I could make sure I had a very tight seal.

#20

Drifting

Thread Starter

My preferred method for evaluating engine condition is still the compression test. I've never been a big fan of using the leakdown test for that. I just typically use it to locate where the missing compression went when there's an issue.

Standard compression test format... engine warm, injectors off, full charge battery, all plugs out, throttles open if ITB.

Watch the first bounce of the gauge, it should be roughly half the final compression pressure. It's a good measure of static ring seal, not relying on pressure buildup to force the rings against the cylinder wall.

If they come up low, that's when I break out the CLT.

But I'm sure everyone has their own method...

Standard compression test format... engine warm, injectors off, full charge battery, all plugs out, throttles open if ITB.

Watch the first bounce of the gauge, it should be roughly half the final compression pressure. It's a good measure of static ring seal, not relying on pressure buildup to force the rings against the cylinder wall.

If they come up low, that's when I break out the CLT.

But I'm sure everyone has their own method...