Lifter preload cross reference

#1

Racer

Thread Starter

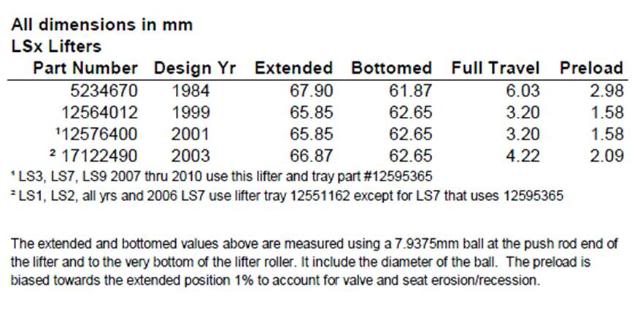

I have some spefications for various GM lifters with part numbers, but I have a lifter part number in my build that is not listed in the table. As seen in the table, different lifters have different preloads. I have the 12499225 LS7 lifters so can anyone verify if these are the same specs as 17122490?

#3

Former Vendor

Thanks

Kevin

www.PartsTaxi.com

#4

Safety Car

Member Since: Feb 2008

Location: TEXOMA

Posts: 3,712

Likes: 0

Received 3 Likes

on

3 Posts

St. Jude Donor '08-'09

I have some spefications for various GM lifters with part numbers, but I have a lifter part number in my build that is not listed in the table. As seen in the table, different lifters have different preloads. I have the 12499225 LS7 lifters so can anyone verify if these are the same specs as 17122490?

-Carl

#5

Racer

Thread Starter

Great thanks, this helps a lot. 1.66 turns it is. The 12499225 is qty 16 and 17122490 is qty 8 but where it had me confused is that 17122490 is also qty 1, it's just not listed to purchase as qty 1.

#6

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 15 Likes

on

15 Posts

St. Jude Donor '09-'10-'11

If there was component changes from stock, the rocker to valve stem wipe pattern should be checked and change pushrod length if needed to obtain the proper preload.

#10

No it does not cause it but if you only have about .020 in preload from the pushrod then it can only pump up that amount not the .200 or so it says to put in.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

Last edited by phkned; 01-18-2012 at 06:32 AM.

#11

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 15 Likes

on

15 Posts

St. Jude Donor '09-'10-'11

No it does not cause it but if you only have about .020 in preload from the pushrod then it can only pump up that amount not the .200 or so it says to put in.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

Valve float is the single cause of lifter pump up. The definition of float is simple, it is when the valvetrain is forced pasted its design parameters. Changing a single component in the valvetrain system can cause a change in the dynamics and lowering the rpm that float occurs.

The valve spring is a key component in the system. The valve springís job is to store enough energy to return all components, and keep all in sync and back to the base circle of the cam lobe. As engine rpm increases, so does the inertia mass of the valvetrain components. As this occurs there is a point where the spring doesnít have enough stored energy to complete its job and the valvetrain components go out of sync. When this happens the loading on the hydraulic lifter will reach a point that its internal spring will force the lifter to do its job of trying to take up free space. This is known as valve float.

The same thing can and does occur regardless if the engine has solid or hydraulic lifters.

You are not changing the valvetrain dynamics by using less preload on the lifter. This only limits the effective range that the lifter can compensate for valve seat erosion and normal thermal growth of the engine. Not a good thing in my opinion. There are real and better ways to insure the proper operation of the valvetrain for the given application other than messing with the preload of the hydraulic lifter.

The numbers given in the table in the first post of this thread are the proper preload for the part number lifters given. Setting up with anything else does nothing to improve valvetrain system dynamics.

#12

Racer

Thread Starter

I agree with Eric. It is important to understand the check ball and spring inside the lifter rely on the equations of motion for reciprocating motion (acceleration and mass) during normal operation. When valve float occurs all this goes up in tire smoke The deceleration of the lifter during the cam lobe lift does not begin at max lift but occurs after allowing to much oil into the plunger cavity. Valve float negates smooth closing as well so the lifter will usually bounce on the closing lift cam lobe. This bounce will allow the check ball to come off seat allowing even more oil into the plunger cavity.

The deceleration of the lifter during the cam lobe lift does not begin at max lift but occurs after allowing to much oil into the plunger cavity. Valve float negates smooth closing as well so the lifter will usually bounce on the closing lift cam lobe. This bounce will allow the check ball to come off seat allowing even more oil into the plunger cavity.

Think of the hyd lifter as the dampener for you suspension. It is good to have it's stroke half of max at normal ride height.

The deceleration of the lifter during the cam lobe lift does not begin at max lift but occurs after allowing to much oil into the plunger cavity. Valve float negates smooth closing as well so the lifter will usually bounce on the closing lift cam lobe. This bounce will allow the check ball to come off seat allowing even more oil into the plunger cavity.

The deceleration of the lifter during the cam lobe lift does not begin at max lift but occurs after allowing to much oil into the plunger cavity. Valve float negates smooth closing as well so the lifter will usually bounce on the closing lift cam lobe. This bounce will allow the check ball to come off seat allowing even more oil into the plunger cavity.Think of the hyd lifter as the dampener for you suspension. It is good to have it's stroke half of max at normal ride height.

#13

Guy's I totaly understand how engines work I am an engine machinist and have built racing heads for over 14 yrs. I appreciate the thought in trying to help me but all you did was just explain the very same thing I said in another way. You did not answer the question of why this LS lifter needs so much preload other then to say that is what Chevy says to use in simple terms.

It is not the spring in the lifter that causes it to fill with oil during valve float,it is the oil pressure. The spring is only strong enough to hold the pushrod snug when not running.

Btw just let me say if you do have .020 of of seat or valve erosion you have much bigger problems then the lifter preload. It's time to tear down when you lose that much lash.

It is not the spring in the lifter that causes it to fill with oil during valve float,it is the oil pressure. The spring is only strong enough to hold the pushrod snug when not running.

Btw just let me say if you do have .020 of of seat or valve erosion you have much bigger problems then the lifter preload. It's time to tear down when you lose that much lash.

#14

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 15 Likes

on

15 Posts

St. Jude Donor '09-'10-'11

Guy's I totaly understand how engines work I am an engine machinist and have built racing heads for over 14 yrs. I appreciate the thought in trying to help me but all you did was just explain the very same thing I said in another way. You did not answer the question of why this LS lifter needs so much preload other then to say that is what Chevy says to use in simple terms.

It is not the spring in the lifter that causes it to fill with oil during valve float,it is the oil pressure. The spring is only strong enough to hold the pushrod snug when not running.

Btw just let me say if you do have .020 of of seat or valve erosion you have much bigger problems then the lifter preload. It's time to tear down when you lose that much lash.

It is not the spring in the lifter that causes it to fill with oil during valve float,it is the oil pressure. The spring is only strong enough to hold the pushrod snug when not running.

Btw just let me say if you do have .020 of of seat or valve erosion you have much bigger problems then the lifter preload. It's time to tear down when you lose that much lash.

Last edited by Eric D; 01-18-2012 at 08:49 PM.

#15

Safety Car

Member Since: Feb 2008

Location: TEXOMA

Posts: 3,712

Likes: 0

Received 3 Likes

on

3 Posts

St. Jude Donor '08-'09

No it does not cause it but if you only have about .020 in preload from the pushrod then it can only pump up that amount not the .200 or so it says to put in.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

If lifter preload amounts don't contribute to pump up then what does?

Pump up is caused when the lifter loses contact with the cam lobe and the lifter fills with more oil then it would normally have to fill the extra space made by the lost contact with the cam. When the lifter regains contact with the lobe the extra oil can't get out fast enough and the valve stays open. This is why you don't see this problem with solid lifter motors.

ls1tech shows .100 - 0.80 as the prefered preload . the 2mm = 0.080mm btw

-Carl

#17

But either way the distance is really irrelavent to my question since in reality i have never bothered to measure how much depresion 1/4 turn was anyway and used .020 just as a reference value.

I understand why Chevy does this because they want the motor to run no matter how much wear is in the valvetrain but I cannot understand why anyone else building an LS would.I would just use a slightly shorter pushrod to get the geometery correct and do 1/4 turn.

#18

You mean the very same engineers who are responsible for all the LS7 dropped exhaust valves? Or the engineers who designed the targa roofs that seperate? OH maybe you are talking about the ones who designed the diff in 05's.....

#19

Drifting

I'm getting confused here so maybe someone can answer this question. What's the proper procedure for preloading lifters on an LS3 and how many turns are needed?

Thanks in advance.

Thanks in advance.

#20

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 15 Likes

on

15 Posts

St. Jude Donor '09-'10-'11