Steering column work

#21

Melting Slicks

Thanks for calling that out!

Stay cool everyone!

Dave Z

#22

Drifting

Thread Starter

However, I think I solved it! I had "by mistake" ordered a new top column bearing and decided to compare the two. The old one was sloppy compared to the new one. I swapped them and also made sure the compression spring was fully tightened. So far everything seems to be working. Will need a test drive to verify. I will send an update later. Before I drive I again I noticed my fan belt is cutting into my lower radiator hose. No more test drives until I get a shorter belt to stop that potential disaster.

Thanks, all!

#23

Le Mans Master

I was getting about desperate enough to try something like that!!!

However, I think I solved it! I had "by mistake" ordered a new top column bearing and decided to compare the two. The old one was sloppy compared to the new one. I swapped them and also made sure the compression spring was fully tightened. So far everything seems to be working. Will need a test drive to verify. I will send an update later. Before I drive I again I noticed my fan belt is cutting into my lower radiator hose. No more test drives until I get a shorter belt to stop that potential disaster.

Thanks, all!

However, I think I solved it! I had "by mistake" ordered a new top column bearing and decided to compare the two. The old one was sloppy compared to the new one. I swapped them and also made sure the compression spring was fully tightened. So far everything seems to be working. Will need a test drive to verify. I will send an update later. Before I drive I again I noticed my fan belt is cutting into my lower radiator hose. No more test drives until I get a shorter belt to stop that potential disaster.

Thanks, all!

Compressing the spring fully with no play defeats the purpose of the spring and could result in excessive pressure and binding.

#24

Drifting

Thread Starter

I think you're about there and on the right track. The bottom spring compressing all of the parts together is actually supposed to have a few thousandths spacing between a pair of the adjoining coils so as to be "almost", but not quite fully compressed. I forget the amount, but it is only a few thousandths, and is obtained by placing the proper shim between the coils prior to compressing and tightening, and removal of the shim after tightening. The amount is spec'd in aftermarket Corvette repair manuals, which almost always are a repeat of the factory manual.

Compressing the spring fully with no play defeats the purpose of the spring and could result in excessive pressure and binding.

Compressing the spring fully with no play defeats the purpose of the spring and could result in excessive pressure and binding.

#25

Melting Slicks

Thanks. I knew there was a spec in the manual. I think it is .01 to .02 but I did not measure. It was difficult enough for me to get it compressed without a third arm. So it's pretty close and much closer than I had gotten before. I think the bearing made a big difference. We'll see when I get going again.

I have fixed the file. The "green thing" is gone. I also added call-outs (colored boxes) to the notes on the AIM diagram (Pg. 8) in the attached revised PDF regarding the adjustment of the axial movement of the column using the spring and the stop (#17 in the diagram).

Hope that gets rid of the confusion.

Dave Z

#26

Drifting

Thread Starter

Hello all.

I have fixed the file. The "green thing" is gone. I also added call-outs (colored boxes) to the notes on the AIM diagram (Pg. 8) in the attached revised PDF regarding the adjustment of the axial movement of the column using the spring and the stop (#17 in the diagram).

Hope that gets rid of the confusion.

Dave Z

I have fixed the file. The "green thing" is gone. I also added call-outs (colored boxes) to the notes on the AIM diagram (Pg. 8) in the attached revised PDF regarding the adjustment of the axial movement of the column using the spring and the stop (#17 in the diagram).

Hope that gets rid of the confusion.

Dave Z

Thanks again for all the help!

#27

Melting Slicks

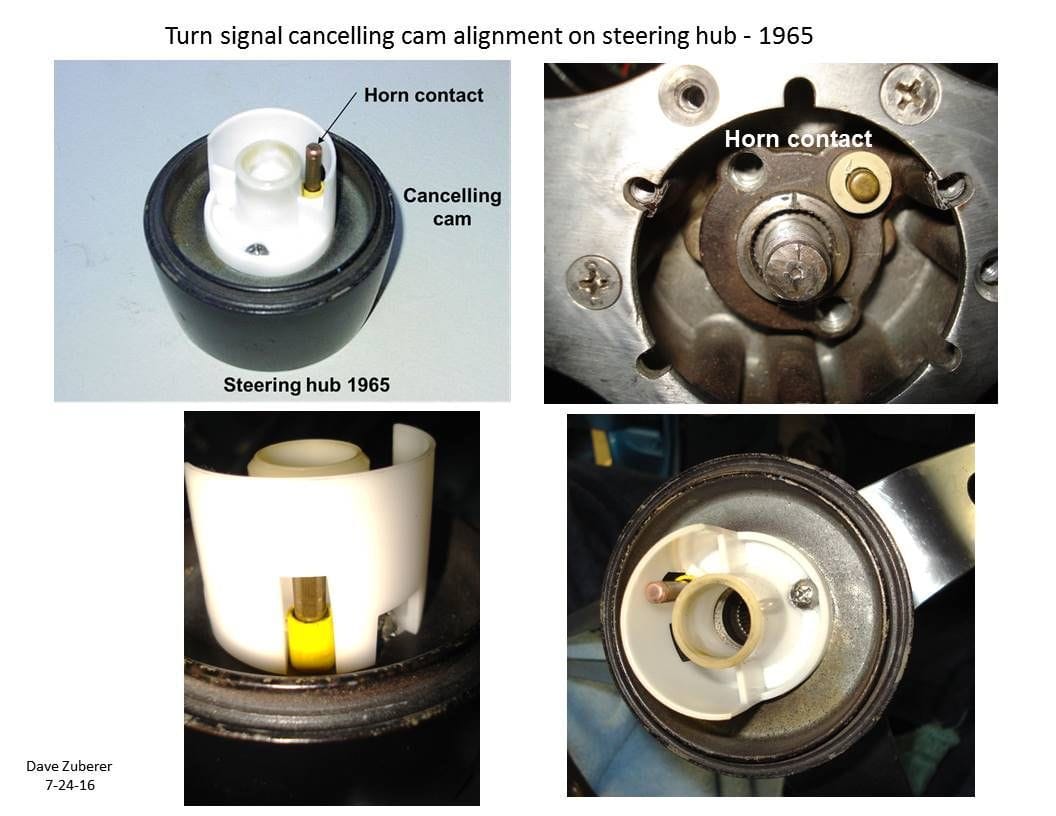

This is really great! Thank you so much for providing this document. Just one other note I want to put up is regarding the orientation of the cancelling cam. It was not obvious to me which position this half cylinder should sit (left or right). I tried both, but have not yet tested what I think is the correct position which (right). When it was mount on the left side my test drive was a failure but not 100% certain it was due to the position of the cam.

Thanks again for all the help!

Thanks again for all the help!

Others please jump in if I am missing something here.

Dave Z

(PDF Attached)

P.S.

The top left photo in the 1st jpeg should be flipped horizontally. Fixed that in the PDF.

Last edited by DZVette; 07-24-2016 at 10:57 PM. Reason: revised pdf

#28

Drifting

Thread Starter

Yes, you can assemble the cam and contact only one way - onto the bub. But once you have that sub-assembly together, you can orient it 360 degrees on the shaft. So this allows you to "center" the cam at any position as it relates to the directional switch. Clearly it should be centered on one side or the other. It was not obvious to me which side. I'm still not 100% sure.

#29

Melting Slicks

Yes, you can assemble the cam and contact only one way - onto the bub. But once you have that sub-assembly together, you can orient it 360 degrees on the shaft. So this allows you to "center" the cam at any position as it relates to the directional switch. Clearly it should be centered on one side or the other. It was not obvious to me which side. I'm still not 100% sure.

I'll take another shot at this. Regarding the orientation of the hub on the steering shaft there is a mark on the hub and there should be a mark on the shaft. For proper alignment of the components, the mark on the shaft should be a 12:00 with the wheels pointed straight ahead and the mark on the hub should be aligned with the mark on the shaft. On the 64 and 65 non-tele columns the horn contact brush sits about 2:00 and when you put the horn contact on with the elongated screw hole at 6:00, the leg on the horn contact sits on the brush and the circuit is complete.

I have tried to highlight what I think is the alignment mark on your hub which appears to be a correct 64 hub. Notice that if you put that mark at 12:00 the hole for the horn contact brush sits at 2:00.

The only other thing I can think of is that perhaps the spring-loaded bottom contact of the brush is somehow stuck in the sleeve and not moving in and out freely. That might explain its failure to reach far enough down to make contact with the circular brass contact in the turn signal switch.

I have attached a PDF in which I have tried to explain how the horn button mechanism functions.

I hope this moves you down the road a little further. Trying to be of help.

Dave Z

#30

Drifting

Thread Starter

Dave,

Thank you for the outstanding support and advice! I may have missed the alignment mark on both the shaft and the hub, but you have confirmed I have the cam in the right position on the right side of the columin when steering straight. Somewhere I thought I read to actually make the mark which I attempted but the problem is I began with an improperly assembled column and no reference points. You can see how it was ground up from being loose and without a washer. Anyway, If it holds up under driving conditions, which I believe it will at this point, then I should be all set. This is a great reference for now and for others!

I was going to inspect my work tonight against your last post but already have it together. Of course, I pulled off the horn button and it broke apart in my hands! I had to do some mcGiver work to get the button back on. Next time it comes off I will have a replacement in hand as it will surely not last with my "fix". but it works and looks good.

Greg

Thank you for the outstanding support and advice! I may have missed the alignment mark on both the shaft and the hub, but you have confirmed I have the cam in the right position on the right side of the columin when steering straight. Somewhere I thought I read to actually make the mark which I attempted but the problem is I began with an improperly assembled column and no reference points. You can see how it was ground up from being loose and without a washer. Anyway, If it holds up under driving conditions, which I believe it will at this point, then I should be all set. This is a great reference for now and for others!

I was going to inspect my work tonight against your last post but already have it together. Of course, I pulled off the horn button and it broke apart in my hands! I had to do some mcGiver work to get the button back on. Next time it comes off I will have a replacement in hand as it will surely not last with my "fix". but it works and looks good.

Greg

Last edited by gccch; 07-25-2016 at 09:40 PM.