[ANSWERED] DI Impact on Valves

#41

Melting Slicks

I don't see anything wrong with Tadge's response. People need to remember he plays a very political role, read between the lines to find the truth. Tadge isn't hiding anything in his response, you have to give him credit for that. What I gathered is: Yes, with SIDI you will have carbon build up. However, the amount is much less than most other SIDI engines and it will not have an effect on how the engine performs during its expected life cycle.

Will some people have a problem with carbon build up? I am sure they will, but they will probably also use a low-quality fuel and are heavy on the throttle.

Will some people have a problem with carbon build up? I am sure they will, but they will probably also use a low-quality fuel and are heavy on the throttle.

So lets have a civil discussion here as we don't want to "hide" from those making investments in these vehicles and when they find out they were misled, may leave GM due to trust issues (and ALL automakers have this tight control on actual issues....just look back at the ignition switch debacle as one of many through the years. We were all aware of this years before GM was forced to take action...no different than Ford with the ecoboost engine failures or the GM 2.0T 4L piston failures we are currently working on, this is NOT a slam at GM as they are my #1 loyalty...but I do not play PR games, I state facts that are easily verifiable). We do not want that right now with this Modern Muscle HP wars that many have fond memories of in the 60's and early 70's. So, the issue is real, and is severe. We are seeing vavle guides wore at 20-30k miles...something that had gone the way of the dinosaur, so we thought when PI came into being and away from TB injection and carbureted. Todays techs have for the most part never seen the valve guide wear and upper end rebuilds that were standard at 50k or so miles of the past as the detergents in todays fuel kept PI engine valves near spotless. So, this will all become very widespread and even though no auto maker wants to admit it, the blow-back is coming. We can't hide issues this severe from the public w/out harming the brand/customer loyalty. So, please explain for us all how using a top tier fuel has any effect on these deposits? And how could they when the fuel never touches the backsides of the valve so it is physically impossible (thus the new Shell add's are very misleading). These deposits are due to the combustion byproducts and the oil mist (compounded by todays VVT systems) being baked on to the back sides. The deposits on the stems is pulled up into the guides with every stroke, so that wear is unavoidable as well. We know that Audi and others have added small port injectors to "Improve off idle throttle response" has done little to alleviate these deposits from form so severely, but HAS increased the incidence of detonation that DI has nearly done away with as any fuel entering the combustion chamber early has a tendency to cause. We also know that GM and Ford (and pretty much all others) have patents on fuel event timing strategies that in theory looked promising only to find it also has little long term effect on reducing these deposits that form. So, since all fuel comes (no matter the brand) from the same bulk tanks for all, and it is only after the delivery tanker is filled that brand specific additives are introduced, but since none of the fuel ever touches anything but the injector internals (the fuel is introduced in the final 10% or so of the compression stroke at 2,000 PSI plus vs PI at 45-55, and does not even hardly make contact with the piston top before the burn has been completed...so only present in the combustion chamber for milliseconds, so the fuel you use (at least in the USA) will have zero effect on the coking (regardless of the marketing agreements between all).

Now, lets address your statement (and Nate, I am not here to pick a fight...only have an ACCURATE discussion with facts only, not opinions...and you know I and others can prove and have documented how quickly power and economy degrade as deposits build) that the deposits have no effect on the engines performance. The valves, ports, piston top design (including quench area and dome/relief designs) have all been designed for the best possible blend of utmost efficiency and economy as far as production, and the disruption in air flow to each cylinder becomes more pronounced the greater the deposits. Yet the injectors are still commanded to deliver the same precise amount of fuel to each, so we end up with a greater move from the ideal A/F ratio for each as the deposits are generally worse in the cylinders nearest the PCV vacuum inlet where the greatest amount of oil, water, sulfuric acid, abrasive soot and carbon particles and other hydrocarbon related compounds enter, and less on those furthest from the ingestion point, so as these deposits grow, some cylinders will be richer than intended and others leaner (the upstream O2's as well as the MAF & MAP sensors will provide data for the PCM to determine fuel delivery so it is taking the average of all cylinders in that bank and the short term fuel trims will add or subtract fuel as needed to keep within the acceptable parameters set in the tune). As this disparity grows over time along with these deposits, so does the risk of a lean condition existing in those cylinders furthest from the ingestion point. The closest will run on the rich side, which is not as troubling as the lean ones. This can be seen in reading the plugs as the miles rack up. So, every spec of air entering in both CFM of flow and velocity, is affected by these deposits.

Will the average "soccer Mom" notice in that 3-4 years average they have a new vehicle? No. We have conditioned today's vehicle buying public to not even open the hood to check oil much less be aware of what is happening inside their engines. But the average Corvette or Camaro owner WILL want to understand it, and as it only takes 10 minutes with minimal skill to remove the intake manifold and inspect their own valves, more and more become aware of the severity.

Now, until we can have a OEM solution that does stop these compounds from contacting the valves, this will not go away. Using Meth Injection has shown to help slow the buildup, but as the meth is only rarely sprayed, the actual benefits will vary. The FI guy running hard all the time will see slower build up than the one that rarely gets into boost, and the tank needs to be filled so there is a consumable to take into consideration. For the stock, or bolt on NA guys (and Gals), this is even more impractical.

The other option, which GM does NOT endorse (or did not last I was aware) is what EVERY dealer service center is pushing, and that is the use solvent based upper induction cleaning services. I realize how profit rich these are, but look at the incidence of rod bearing ( catalytic converter failures shortly after using these with DI engines with any amount of miles on them. Unlike the PI engines that only had a small amount of carbon build up on pistons and combustion chambers and nothing on the valves that these could be used on with little chance of damage, these super hard deposits that DI engines are experiencing these large chunks that break loose when the solvent is absorbed and expands them, the amount of debris that results and exits the exhaust ports hits the catalyst material and clogs and damages it. Then we look at the smaller hard particles forced between the pistons and cylinder walls and the resulting scouring, and we are compounding the blow by and oil consumption issue every time these are used. Most service centers are not even changing oil/filter immediately following a cleaning so the solvent and debris that gets past the rings enters the crankcase causing damage. This is accumulative and the more often a service is performed, the more chance for damage/failure.

There is an option that with proper training, you can implement and not only has no downside, but also generates even higher profit margins for the service center is (and again, I stress PROPERLY trained as some techs have performed this on cylinders w/out the valves closed and filled the cylinder with debris) is the crushed walnut shell media blasting systems. This should take a trained tech no more than 2-3 hours to perform (depending on engine configuration) and has on average less than $5 of consumables used per cleaning. This is what all dealer should be doing to prepare for the flood of issues as these DI engine rack up miles and not listening to the pitches from the solvent based cleaning sales reps:

Then in closing (I know, long winded here but I communicate better in technical terms that you can verify with a little research) I invite you, Tadge, and any other senior engineer to PM me for more detailed discussions as the amount of R&D we have put into the DI issues is immense, and I have tons of info I can share to lead to solutions to these, and again, I realize (coming from that side of the street) how difficult it is to balance what is disclosed to the public and what is not, and I would not want to be in any PR spokes persons shoes.

The patents are either pending or issued on the complete OEM solution that does not increase tailpipe emission, will meet all EPA requirements, does NOT need to need serviced for 100k plus miles. Testing has been done on several dozen DI vehicles for 5-100k miles over the past 5 years, and the results are almost all deposits are prevented (not all, but all but a very slight build up).

So Nate, lets continue this and I am more than happy to discuss these issues in depth.

Jason.

#42

Melting Slicks

I understand exactly what you are describing in terms of the dangers of using a top end cleaner to remove carbon deposits. Makes perfect sense.

Now, and kind of what I was getting at in an earlier post, what about their use as a preventative measure? Wouldn't it be feasible to have this listed on regular maintenance protocol, say at regular oil change intervals? Assuming this done with every oil change from new, not after the actual coking has already happened? The key being "preventative" and not "Corrective".

It just seems that the manufacturer's need to address this reality as it is. That it is indeed a fact of life with the SIDI engine, which, with it's many benefits, is and should be here to stay. However, until a better method of oil separation is developed (as the EPA emission standards are not going away either), shouldn't the manufacturer's then help the owner's with a recommended plan to reduce this negative side effect? Not just simply say, "our testing showed no effect for the expected lifetime"? Thus increasing that "expected lifetime".

Now, and kind of what I was getting at in an earlier post, what about their use as a preventative measure? Wouldn't it be feasible to have this listed on regular maintenance protocol, say at regular oil change intervals? Assuming this done with every oil change from new, not after the actual coking has already happened? The key being "preventative" and not "Corrective".

It just seems that the manufacturer's need to address this reality as it is. That it is indeed a fact of life with the SIDI engine, which, with it's many benefits, is and should be here to stay. However, until a better method of oil separation is developed (as the EPA emission standards are not going away either), shouldn't the manufacturer's then help the owner's with a recommended plan to reduce this negative side effect? Not just simply say, "our testing showed no effect for the expected lifetime"? Thus increasing that "expected lifetime".

Great question. Let's see more. I also would like to ask Tadge to verify that defeating/deleting the functions of the PCV system and just venting pressure WILL result in engine damage over time and premature engine wear as it allows nearly all the damaging compounds to remain in the crankcase accumulating and contaminating the oil, and especially the ones that have open hoses hanging down by the ground.

This is a far bigger concern of mine that people do not understand the critical functions the PCV system performs in not only emissions, but engine longevity as well. Tadge, PM me to discuss this in more detail as well.

#43

Melting Slicks

Here is another good video to show the results of removing the deposits. This guy does not realize in the tank does nothing, but he can attest to the improvement in power and economy:

Sorry these are mostly BMW, but BMW has been dealing with this years before most others.

Sorry these are mostly BMW, but BMW has been dealing with this years before most others.

Last edited by COSPEED; 07-30-2015 at 03:36 PM.

#44

Platinum Supporting Dealership

It is obvious that you are very well informed and versed in this topic. I am not. I have learned a lot from reading your posts. I don't have any additional information other than from what I have read in Tadge's response and your posts. Unfortunately a debate would have to come from someone other than I. I was only assuming that low quality fuel further increases carbon build up.

#45

Platinum Supporting Dealership

Actually a couple things that I did think of for discussion:

does a stiffer valve spring play a role in carbon build up?

Would periodic chemical cleaning help, before heavy build up (prevents chunking)?

does a stiffer valve spring play a role in carbon build up?

Would periodic chemical cleaning help, before heavy build up (prevents chunking)?

#46

Melting Slicks

Stiffer springs have no effect, neither does a more radical cam profile. This is completely caused by the PCV vapors contacting the hot valves and then these compounds baking onto them. With the old port injection, we can tear down heads of abused c5's and c6's after 100-150-200k miles and the valves are deposit free from the detergents in the fuel keeping them clean as the fuel would constantly spray onto them so the compounds never got a chance to adhere and bake on (valves on PI engines also run cooler from this drenching).

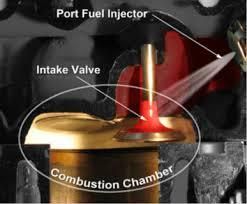

I know these have been posted before, but here is how the port injection worked to keep intake valves deposit free. And if you search, you will see back in the 60's-70's the Feds mandated minimum detergent additives in all gasoline sold in the US to combat this back when carbureted engines were the norm and this was a huge issue at that time (and a fraction of what it is now):

This eliminated the common valve jobs techs had to perform on most all engines in the 60's/70's.

Now here is direct injection and you can see fuel (and any additives) have zero contact with the valves allowing them to run far hotter that PI and also no cleaning as it never touches them:

The results are not pretty. Nate, talk to a few of the senior techs where you are and have one let you know when they pull down any DI motors next to show you in person. The more knowledgeable you are, the more you make the competition look clueless.

Just comparing a valve from a DI engine with no service to the one on the right that has been manually cleaned shows how drastic this all can be:

Here is a Non DI LY7 engine (3.6L GM) from 2007 with over 120k miles on it. No cleanings ever. The port injection kept this clean (the small particles are just debris from removing the intake manifold):

And here is that same engine but a 2008 DI version, the LLT with only 20k miles on it:

I will PM you more info.

Thanks Nate!

#47

Somba master

Seems as though GM engine guys didn't quite beat the issue of coking and build up on the valves that they said they did. Tadge clearly stated that there IS build up on the valves over time ( even though he said consumers wouldn't notice). And, with the shorter warranty, by the time power loss was noticed, and valve guides scored, the car would be out of warranty.

But wait. Isn't there a federally mandated 100,000 mile warranty on the emission control systems of every engine? And isn't the PCV system part of the emission control system? So, if there is crud built up on the valves, causing loss of power etc, isn't GM on the hook for valve cleaning services?

Sent from my iPad

But wait. Isn't there a federally mandated 100,000 mile warranty on the emission control systems of every engine? And isn't the PCV system part of the emission control system? So, if there is crud built up on the valves, causing loss of power etc, isn't GM on the hook for valve cleaning services?

Sent from my iPad

#48

Seems as though GM engine guys didn't quite beat the issue of coking and build up on the valves that they said they did. Tadge clearly stated that there IS build up on the valves over time ( even though he said consumers wouldn't notice). And, with the shorter warranty, by the time power loss was noticed, and valve guides scored, the car would be out of warranty.

But wait. Isn't there a federally mandated 100,000 mile warranty on the emission control systems of every engine? And isn't the PCV system part of the emission control system? So, if there is crud built up on the valves, causing loss of power etc, isn't GM on the hook for valve cleaning services?

But wait. Isn't there a federally mandated 100,000 mile warranty on the emission control systems of every engine? And isn't the PCV system part of the emission control system? So, if there is crud built up on the valves, causing loss of power etc, isn't GM on the hook for valve cleaning services?

Last edited by grcor; 07-31-2015 at 09:01 PM.

#49

Based on his answer, clearly Tadge believes that everyone here is stupid. Thanks for your time, Tadge.

coSPEED2: Thank you for your very, very informative posts on this thread and others.

coSPEED2: Thank you for your very, very informative posts on this thread and others.

#51

Burning Brakes

Informative discussion!

Sounds like someone in the aftermarket needs to come up with a Cleaning system, like a Fogger/Chemical solution that is triggered on each engine shutdown that might permeate the entire Intake system, even have timed multiple events after shutdown. If not very effective, pressurize the intake system somehow, but the complexity/cost might steer away some customers. If installed on a new/newer engine, the buildup could be drastically reduced, who knows..., maybe such systems exist?

Sounds like someone in the aftermarket needs to come up with a Cleaning system, like a Fogger/Chemical solution that is triggered on each engine shutdown that might permeate the entire Intake system, even have timed multiple events after shutdown. If not very effective, pressurize the intake system somehow, but the complexity/cost might steer away some customers. If installed on a new/newer engine, the buildup could be drastically reduced, who knows..., maybe such systems exist?

#52

Burning Brakes

(https://www.corvetteforum.com/forums...h-can-pic.html)

#53

Melting Slicks

Informative discussion!

Sounds like someone in the aftermarket needs to come up with a Cleaning system, like a Fogger/Chemical solution that is triggered on each engine shutdown that might permeate the entire Intake system, even have timed multiple events after shutdown. If not very effective, pressurize the intake system somehow, but the complexity/cost might steer away some customers. If installed on a new/newer engine, the buildup could be drastically reduced, who knows..., maybe such systems exist?

Sounds like someone in the aftermarket needs to come up with a Cleaning system, like a Fogger/Chemical solution that is triggered on each engine shutdown that might permeate the entire Intake system, even have timed multiple events after shutdown. If not very effective, pressurize the intake system somehow, but the complexity/cost might steer away some customers. If installed on a new/newer engine, the buildup could be drastically reduced, who knows..., maybe such systems exist?

Me too, I wanted to see the function. That's why I added one to my '13 GS. It's completely doing what it's supposed to now that I have had some feed back from CF. I empty the CC on my car about once every two weeks or so (a few ounces at a time).

(https://www.corvetteforum.com/forums...h-can-pic.html)

(https://www.corvetteforum.com/forums...h-can-pic.html)

#54

Racer

coSpeed2: You seem to be the most knowledgeable poster on this site about the coking problem. So I have 2 questions:

1. Why is this NOT a problem with Diesel engines? Same airflow (without fuel) meaning valves should be dry, direct injection, crankcase fumes, pcv, etc. As I remember an old Mercedes diesel I had in the 1980's, the pcv system did not seem much different that a typical gas engine.

Have a (base) 2016 presently being built and want to start off on the right foot since this coking issue appears to come on pretty quickly (less than 20k miles). Intend to install a catch can, but the simplicity of that empty can (nothing to really make the fumes completely condense into liquid) makes me think a lot of oil vapor still gets past the can.

2. Does anybody have a paper filter installed AFTER the can to check the can's efficiency? I assume you would need a filter that could adequately pass the volume of air needed to keep the computer happy (an inline fuel filter for a lawnmower defies logic).

One last compliment; it is really refreshing to learn something educational reading posts like yours, instead of the endless opinions of many that seem to just want to either brag or rant. Keep the info coming.....

1. Why is this NOT a problem with Diesel engines? Same airflow (without fuel) meaning valves should be dry, direct injection, crankcase fumes, pcv, etc. As I remember an old Mercedes diesel I had in the 1980's, the pcv system did not seem much different that a typical gas engine.

Have a (base) 2016 presently being built and want to start off on the right foot since this coking issue appears to come on pretty quickly (less than 20k miles). Intend to install a catch can, but the simplicity of that empty can (nothing to really make the fumes completely condense into liquid) makes me think a lot of oil vapor still gets past the can.

2. Does anybody have a paper filter installed AFTER the can to check the can's efficiency? I assume you would need a filter that could adequately pass the volume of air needed to keep the computer happy (an inline fuel filter for a lawnmower defies logic).

One last compliment; it is really refreshing to learn something educational reading posts like yours, instead of the endless opinions of many that seem to just want to either brag or rant. Keep the info coming.....

#55

Racer

Skip the diesel question - did some research and partially answered/understood this application.

#56

Burning Brakes

Great thinking! I am not aware of a system that exists currently, and there are several negatives I can think of that would have to be overcome....cylinder wash-down is the first as any solvent would have to be enough to soak into the deposits so they loosen and could be expelled out the exhaust ports. The second is dealing with debris and solvents of this type and chucks breaking loose are damaging far too many catalysts in 2 ways. One, the debris clogging them, and 2., the shock of any liquid/solvent hitting the hot catalyst causes breakage and they can fold in upon themselves and also clog or restrict flow (search FI cat converter failures). Even a fuel injector failing and dumping fuel quite often destroys the cat and OEM wants to reduce the failures and warranty replacements. Great thinking though. The most effective and practical solution seems to be the upcoming external separators that will self empty and stop the compounds from reaching the hot valves. But at best those are still a few years out as nothing can be implemented quickly once a vehicle/drivetrain are in production. That is a huge undertaking and why we see changes in a specific generation are generally minor. Most don't realize just to add a few cent change as far as a design revision or related costs millions upon millions once a line is running, and no auto maker wants to EVER halt production and disclose a flaw that the competitor can seize on to gain market share.

Your to be commended for doing this! Taking a pro-active stance. I followed your threads and there are a few changes I would suggest as most of what your doing is on the cleanside alone. You can do that can to address all and not be mixing fresh and foul vapors for a more effective job. Let me know if you want some tips that can greatly improve your Mishimoto's effectiveness.

Your to be commended for doing this! Taking a pro-active stance. I followed your threads and there are a few changes I would suggest as most of what your doing is on the cleanside alone. You can do that can to address all and not be mixing fresh and foul vapors for a more effective job. Let me know if you want some tips that can greatly improve your Mishimoto's effectiveness.

#57

Advanced

This all gets back to post #20 that I did some time ago. If installing a catch can (and a clean side oil separator for dry sump engines) is being proactive and seemingly a relatively simple solution to the problem, why do the manufacturers of DI engines not install them as standard equipment?

#58

Melting Slicks

This all gets back to post #20 that I did some time ago. If installing a catch can (and a clean side oil separator for dry sump engines) is being proactive and seemingly a relatively simple solution to the problem, why do the manufacturers of DI engines not install them as standard equipment?

#59

Burning Brakes

On the thread I started a while back on my Catch Can set up;

(https://www.corvetteforum.com/forums...can-pic-2.html)

If anyone has anything to add to the set up after post #27, that's the latest/last update to my car's set up. Any changes or enhancements that should be incorporated, please add to the thread. I think I made the changes that were mentioned by Dano523 & it should be catching the oil from the correct places.

(https://www.corvetteforum.com/forums...can-pic-2.html)

If anyone has anything to add to the set up after post #27, that's the latest/last update to my car's set up. Any changes or enhancements that should be incorporated, please add to the thread. I think I made the changes that were mentioned by Dano523 & it should be catching the oil from the correct places.

#60

I will add more to guide all that want to learn in the next few days. Was out of town and just got back.

The biggest obstacle is getting the 99.9% of owners to empty it on time as you never want one to overfill. There are very few new vehicle owners that will even (or even know how) check their engine oil and other critical fluids much less have a hands on to maintenance. Several of the hand built Super Cars do include them, but then they are always brought in to the dealer for service so not much concern there, but on mass produced vehicles the trend for years has been to condition the owner to rely only on the dealers service center. Unless a DIC message pops up most only put fuel in when needed period. That said, there is a company apparently that has developed a OEM solution that is self draining/contained and never needs service for 100k plus miles. That I expect to see implemented on the manufacturer level in the next 3-4 years. Remember, nothing happens fast once a vehicle is on production. Look at the ignition switch issue and the excessive oil consumption and piston slap of the LS1/LS6 engines and how long that took to address.

The biggest obstacle is getting the 99.9% of owners to empty it on time as you never want one to overfill. There are very few new vehicle owners that will even (or even know how) check their engine oil and other critical fluids much less have a hands on to maintenance. Several of the hand built Super Cars do include them, but then they are always brought in to the dealer for service so not much concern there, but on mass produced vehicles the trend for years has been to condition the owner to rely only on the dealers service center. Unless a DIC message pops up most only put fuel in when needed period. That said, there is a company apparently that has developed a OEM solution that is self draining/contained and never needs service for 100k plus miles. That I expect to see implemented on the manufacturer level in the next 3-4 years. Remember, nothing happens fast once a vehicle is on production. Look at the ignition switch issue and the excessive oil consumption and piston slap of the LS1/LS6 engines and how long that took to address.