What should I pay for a complete 400 sbc?

#1

Le Mans Master

Thread Starter

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

I'm trying to make some room in my garage for a 400 sbc that the owner wants/asking $500 for. He says is out of a pickup truck and was running 5 years ago when he bought it. Casting number shows 2 bolt main and he said motor never rebuilt before. Motor still has q-jet on it too. Mileage unknown and can't be certain of condition (w/o a bore scope check). But at least I won't have to pull it out at the boneyard.

Don't really need the motor now but a 400" sbc would/will be my replacement when my car and me are ready.

Whatch ya all think I should spend for this whole 400" motor w/carb??

Don't really need the motor now but a 400" sbc would/will be my replacement when my car and me are ready.

Whatch ya all think I should spend for this whole 400" motor w/carb??

Last edited by cardo0; 10-08-2016 at 02:38 PM.

#2

Melting Slicks

SO I will throw out my recent experience. I built up a 350 from an '86 vette, complete with TPI set up. Started with an UNKNOWN block, did everything as cheap as possible but still the right parts, nothing fancy. Had a nice valve job done on stock aluminum heads, a cam, some roller rockers, bored out with a eagle balanced rotating assy. By the time I was done with the complete engine, it would have been a close match to the same amount of money buying crate engine. With a warranty. I WANTED to say I built it, and that is something a lot of us on the forum lust after, but if you are looking at dollars and cents, think long and hard about a crate set up. On the other hand, you really can't put a price on "I built it"!

#3

Le Mans Master

Member Since: May 2002

Location: Lebanon Township New Jersey

Posts: 5,005

Received 706 Likes

on

401 Posts

It would be a good idea to have a 400 in reserve. I have a 400 block, just in case. As for the price, you're really only going to use the block and maybe the crank. The Qjet is worth some $ if unmolested. So, $500 might be a little high - but don't let it get away.

#4

Drifting

Start low and work toward the middle.

The first to mention a money amount in a negotiation generally loses, so....he's already at a disadvantage. I'd shoot for about $350.

Short of an aftermarket block, I don't know any engine companies that sell a 400 crate engine.

The first to mention a money amount in a negotiation generally loses, so....he's already at a disadvantage. I'd shoot for about $350.

Short of an aftermarket block, I don't know any engine companies that sell a 400 crate engine.

#5

Melting Slicks

35 years ago the 400's were the rage and they were getting snapped up quick for engine builds. And the price went up accordingly. But that was then, and with the modern replacement blocks that are now available the rage is long over. The 400's with there Siamese Cylinders are known for Cracking. There is also and issue with Core shifting and not enough material to bore the Cylinders. So back when these blocks were being used for performance builds they might go threw a few of them before they found a good one. With the cost of machining , the higher than a 350 block chance of cracks or core shifting makes most builders just buy a new aftermarket Block. As said above besides the block the rest of the motor will just be discarded in a performance build. So back to your original question of what a 400 is worth, not much.

#7

Le Mans Master

Thread Starter

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Well it's not so much that it's $500 as that's not a whole lot more than bare 400 blocks cleaned and inspected with even a guarantee sell for here. I find eBay 400 blocks like that at $425 + shipping and tax.

It's more of an issue whether the block will be any good once stripped and inspected. $500 loss hurts a lot more than $350 if the block is bad.

Yea, I know better than to build a killer mouse w/stock block. But for <500 HP short cam street motor I might just use that stock crank to.

Been shopping for a 400" motor and this one does save me from pulling one out at the boneyard. Just that really wanted a 4 bolt main block but see one those maybe once a year on CL.

It's more of an issue whether the block will be any good once stripped and inspected. $500 loss hurts a lot more than $350 if the block is bad.

Yea, I know better than to build a killer mouse w/stock block. But for <500 HP short cam street motor I might just use that stock crank to.

Been shopping for a 400" motor and this one does save me from pulling one out at the boneyard. Just that really wanted a 4 bolt main block but see one those maybe once a year on CL.

#8

Racer

really a ll you're after is the block and crank...all other parts will be replaced, I assume...

the Bare block should be worth about $250-$300. The heads are likely worthless, as are the internals other than the crank...

As stated above, you should be able to get something (maybe $50) for the carb, if it is untouched otherwise...

If you cannot get it for less than the $350...I say let it go, and keep your eyes out for another block/crank...

If you do find one/buy this one, below is my parts list--I built a 509 400 block into a really fun, street-able 406 in my Camaro:

Machine work:

Block: cook and Magnaflux $60.00

Block: Bore and hone $110.00

bearings/freezeplugs $93.03

Heads: disassemble and clean $40.00

Heads: comp valve job $85.00

Heads: setup spring presure and assemble $50.00

Balance assembly $125.00

Drill steam holes $0.00

Resurface flywheel $25.00

Comp Cams 7609 pushrods $90.42

Machine shop total $678.45

Parts:

Cam Kit: K12-432-8 $983.27

cam kit discount ($49.16)

Roller rockers--CCA-17004-16 $165.95

Rods--Scat--SCA-25700 $283.97

Pistons--SLP-H615CP30 $168.39

Harmonic balancer PFS-80001 $60.00

water pump-SUM-311006 $67.95

Timing tab SPE-4237 $4.95

Head bolts NAL-12495499 $33.97

oil pan bolts SUM-G1570HS $4.95

Timing cover bolts SUM-G1574HS $2.95

Head gaskets-FEL-1014 $77.50

oil pump $31.95

oil pump screen assembly $7.95

oil pump pushrod MOR-22070 $14.95

Parts total: $1,859.54

Total: $2,537.99

It should be noted that I used a pair of Dart Iron Eagle 200cc intake (64cc combustion) I already had avaialble....add a set of heads to the price, and you can have a rock solid, roller cam, runner for around $3,500!

the Bare block should be worth about $250-$300. The heads are likely worthless, as are the internals other than the crank...

As stated above, you should be able to get something (maybe $50) for the carb, if it is untouched otherwise...

If you cannot get it for less than the $350...I say let it go, and keep your eyes out for another block/crank...

If you do find one/buy this one, below is my parts list--I built a 509 400 block into a really fun, street-able 406 in my Camaro:

Machine work:

Block: cook and Magnaflux $60.00

Block: Bore and hone $110.00

bearings/freezeplugs $93.03

Heads: disassemble and clean $40.00

Heads: comp valve job $85.00

Heads: setup spring presure and assemble $50.00

Balance assembly $125.00

Drill steam holes $0.00

Resurface flywheel $25.00

Comp Cams 7609 pushrods $90.42

Machine shop total $678.45

Parts:

Cam Kit: K12-432-8 $983.27

cam kit discount ($49.16)

Roller rockers--CCA-17004-16 $165.95

Rods--Scat--SCA-25700 $283.97

Pistons--SLP-H615CP30 $168.39

Harmonic balancer PFS-80001 $60.00

water pump-SUM-311006 $67.95

Timing tab SPE-4237 $4.95

Head bolts NAL-12495499 $33.97

oil pan bolts SUM-G1570HS $4.95

Timing cover bolts SUM-G1574HS $2.95

Head gaskets-FEL-1014 $77.50

oil pump $31.95

oil pump screen assembly $7.95

oil pump pushrod MOR-22070 $14.95

Parts total: $1,859.54

Total: $2,537.99

It should be noted that I used a pair of Dart Iron Eagle 200cc intake (64cc combustion) I already had avaialble....add a set of heads to the price, and you can have a rock solid, roller cam, runner for around $3,500!

#9

Racer

Well it's not so much that it's $500 as that's not a whole lot more than bare 400 blocks cleaned and inspected with even a guarantee sell for here. I find eBay 400 blocks like that at $425 + shipping and tax.

It's more of an issue whether the block will be any good once stripped and inspected. $500 loss hurts a lot more than $350 if the block is bad.

Yea, I know better than to build a killer mouse w/stock block. But for <500 HP short cam street motor I might just use that stock crank to.

Been shopping for a 400" motor and this one does save me from pulling one out at the boneyard. Just that really wanted a 4 bolt main block but see one those maybe once a year on CL.

It's more of an issue whether the block will be any good once stripped and inspected. $500 loss hurts a lot more than $350 if the block is bad.

Yea, I know better than to build a killer mouse w/stock block. But for <500 HP short cam street motor I might just use that stock crank to.

Been shopping for a 400" motor and this one does save me from pulling one out at the boneyard. Just that really wanted a 4 bolt main block but see one those maybe once a year on CL.

#10

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,960

Received 3,890 Likes

on

2,562 Posts

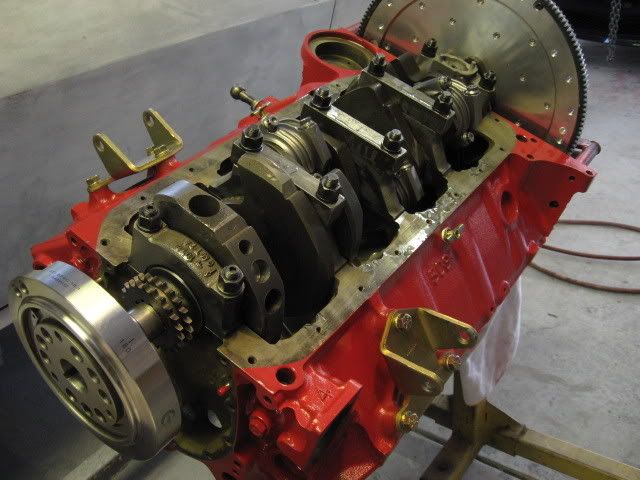

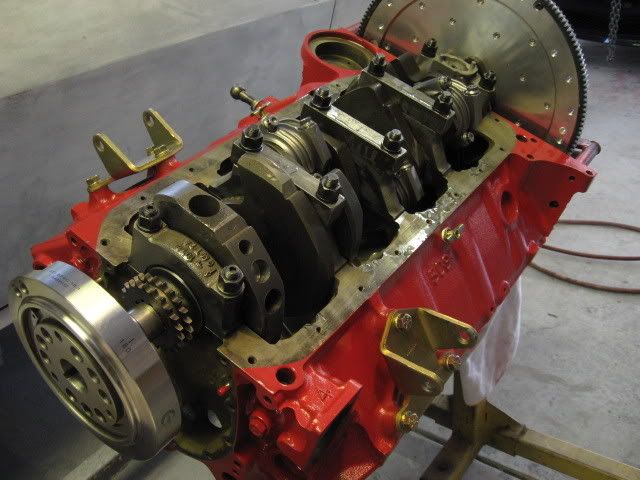

The block and crank were all I reused on my build......

But as stated, do not let it get away.......

The 406 is a great bang for the buck unit if done properly....the cores are drying up if you find a good one.....do it!

They can be built for as much as a 350/383 and the extra .125 of bore makes a good head even better.....

500 horsepower is a cake walk with these....

I have $4800 into mine carb to pan with brand new Dart Heads......

$500 is a bit dear......$350 is the number to me as well.....

Jebby

But as stated, do not let it get away.......

The 406 is a great bang for the buck unit if done properly....the cores are drying up if you find a good one.....do it!

They can be built for as much as a 350/383 and the extra .125 of bore makes a good head even better.....

500 horsepower is a cake walk with these....

I have $4800 into mine carb to pan with brand new Dart Heads......

$500 is a bit dear......$350 is the number to me as well.....

Jebby

#11

Race Director

As far as a 400 block, the 2 bolt mains are actually a tad better off than the 4 bolts...the extra material removed from the mains for the 4 bolt can actually weaken the block... If you are set on a four bolt main, a machine shop can drill and tap for "splayed" end caps, but the extra cost for the machine work and caps themselves might not make sense for a build under 500 HP...

On these, 2 bolt is a little better than the 4 due to weaker webbing in the bottom end. A set of ARP studs will take care of anything that you'll likely need out of this block.

On these, 2 bolt is a little better than the 4 due to weaker webbing in the bottom end. A set of ARP studs will take care of anything that you'll likely need out of this block.Remember to drill steam holes in the heads.

#12

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,651

Received 4,916 Likes

on

1,928 Posts

The 400 is a great way to make cheap power. Yes – all you’re going to keep is the block and the crank, but that’s going to be the case whether you build a 400, 350, or any other real performance engine. And if you’re going to stroke a 350 into a 383, you’re not even going to keep the crank to get 24 cubes less than a bored 400 with a stock crank. The $500 initial purchase price is chump-change in the total cost of the project. If the engine is a standard-bore 400, buy it!

Prep on a 400 is pretty easy to make a lot of power:

The 2-bolt mains are no problem, even if you’re turning a bunch of rpm. Install a set of ARP Studs to beef it up:

If you really want to make it bullet-proof, you can mill the tops of the 3 center main caps flat and install tool steel bars across the caps. The caps will never come out:

Put some light weight components on the crank – nice light rods and light pistons. Buy the lightest parts you can afford. This will allow you to get rpm with reliability. Rpm = HP:

Use a good balancer and a lightweight flywheel. Balance it all out, and then wrap it tight with a well-fitting windage tray to keep the oil off the crank. Good windage control is worth 20 hp at rpm:

With good-flowing heads and a nice roller cam, these builds make easy 500 horsepower and a ton of torque, and steam-hole drilling is not required… (I’ve built several of these as street drivers, and never drilled the holes). A great way to go!

Lars

...oh... and put some solid mounts on it, because the torque will rip rubber engine mounts right in half... ask me how I know.

Prep on a 400 is pretty easy to make a lot of power:

The 2-bolt mains are no problem, even if you’re turning a bunch of rpm. Install a set of ARP Studs to beef it up:

If you really want to make it bullet-proof, you can mill the tops of the 3 center main caps flat and install tool steel bars across the caps. The caps will never come out:

Put some light weight components on the crank – nice light rods and light pistons. Buy the lightest parts you can afford. This will allow you to get rpm with reliability. Rpm = HP:

Use a good balancer and a lightweight flywheel. Balance it all out, and then wrap it tight with a well-fitting windage tray to keep the oil off the crank. Good windage control is worth 20 hp at rpm:

With good-flowing heads and a nice roller cam, these builds make easy 500 horsepower and a ton of torque, and steam-hole drilling is not required… (I’ve built several of these as street drivers, and never drilled the holes). A great way to go!

Lars

...oh... and put some solid mounts on it, because the torque will rip rubber engine mounts right in half... ask me how I know.

Last edited by lars; 10-09-2016 at 12:55 AM.

#13

Race Director

#14

Race Director

I agree with trying to get the engine for about $350 but if you really want it after building the engine and probably being in it for $3500 and most likely more is $150 going to be a deal breaker? That's what you're really going to have to decide.

#15

Le Mans Master

Thread Starter

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Wow! A lot of great info here. Tool steel staps on the main caps is something new to me - thx for pix lars. I can see some huge lightening holes in that cranks counter weight too. Hmmm, never thought of solid motor mounts. I always liked the 1/4-20 bolt trick but that may not be strong enough for this kinda torque. Nice little petcock on the block drain plug too. Thx everyone for sharing here.

Well i just was looking at picking up the block for now and making a street pounder out of it - not a dedicated performance build. Not looking to start a build thread at this time though i appreciate the info. I still have to price things out. Dont know how much i could bore this block yet. But i'm hoping for 0.060" overbore and 413 c.i. - yea get some low end grunt there. And whether i want to use forged ($1800) or cast rotating assembly ($1000) or even use the stock crank. IMHO i dont think stroking a stock 400" block is worth the effort. For a big inch sbc (and a big azz cam) aftermarket block is the way to go. I really like the SCAT rotating assemblies as i can buy them already balanced for little extra money and a lot less headaches.

It's just that i recall the "509" block is the stronger of 400" bunch to use. Or maybe it was the 509 block had only 2 freeze plugs and looked more like a 350" block - i cant recall now. BTW has anyone reduced the coolant hole size on the 400" block deck and re-drilling smaller hole - D. Vizard trick to reduce flow in those areas and keep more coolant under the block deck? I used to see vendor on the shelf plugs for this but no longer know where to find them. And then drilling the steam holes in the heads will be new for me. Something kinda reluctant to do to a brand new aluminum head - unless i find good 'nough used heads. One more item does anyone know where to buy a good crank scraper for a stock 400" block? A ready made on the shelf vendor scraper would be very helpful.

Anyways maybe i'll bring my USB "endoscope"/netbook camera (USB borescope) and take a look inside the cylinder(s) if the owner will let me. Owner has had the block a long time now but keeps saying he "won't give it away". I'd like to pick it up for $300, but i still have to make room for it first. At least i already have a dolly/cradle for it.

Owner has had the block a long time now but keeps saying he "won't give it away". I'd like to pick it up for $300, but i still have to make room for it first. At least i already have a dolly/cradle for it.

Well i just was looking at picking up the block for now and making a street pounder out of it - not a dedicated performance build. Not looking to start a build thread at this time though i appreciate the info. I still have to price things out. Dont know how much i could bore this block yet. But i'm hoping for 0.060" overbore and 413 c.i. - yea get some low end grunt there. And whether i want to use forged ($1800) or cast rotating assembly ($1000) or even use the stock crank. IMHO i dont think stroking a stock 400" block is worth the effort. For a big inch sbc (and a big azz cam) aftermarket block is the way to go. I really like the SCAT rotating assemblies as i can buy them already balanced for little extra money and a lot less headaches.

It's just that i recall the "509" block is the stronger of 400" bunch to use. Or maybe it was the 509 block had only 2 freeze plugs and looked more like a 350" block - i cant recall now. BTW has anyone reduced the coolant hole size on the 400" block deck and re-drilling smaller hole - D. Vizard trick to reduce flow in those areas and keep more coolant under the block deck? I used to see vendor on the shelf plugs for this but no longer know where to find them. And then drilling the steam holes in the heads will be new for me. Something kinda reluctant to do to a brand new aluminum head - unless i find good 'nough used heads. One more item does anyone know where to buy a good crank scraper for a stock 400" block? A ready made on the shelf vendor scraper would be very helpful.

Anyways maybe i'll bring my USB "endoscope"/netbook camera (USB borescope) and take a look inside the cylinder(s) if the owner will let me.

Owner has had the block a long time now but keeps saying he "won't give it away". I'd like to pick it up for $300, but i still have to make room for it first. At least i already have a dolly/cradle for it.

Owner has had the block a long time now but keeps saying he "won't give it away". I'd like to pick it up for $300, but i still have to make room for it first. At least i already have a dolly/cradle for it.

#16

Team Owner

I will give my alternative view point. So many good aftermarket blocks that are stronger and have better oiling. I personally stay away from externally balanced.

SHP block with a 3.875 stroker crank kit and you have 415 ci

SHP block with a 3.875 stroker crank kit and you have 415 ci

#17

Race Director

#18

Melting Slicks

A couple of questions:

I believe I've heard that the 400 block 2 bolt mains caps are far wider and can deal with far more pressure than 350 2 bolt mains motors- can anyone confirm or deny?

Lars mentioned just replacing the bolts with ARP studs; someone else mentioned having a machine shop splay the mains to add extra strength-- if I'm not mistaken, BOTH require work to be done by a machine shop (you need the holes redrilled for studs anyway, right?) I can't see drilling new holes at an angle to support splayed mains caps to cost any more and you'd end up with more strength, right?

-If you have to pay a shop to redrill to put in studs, why wouldn't you just have them splay them and end up with more strength for the same machine shop cost?

Adam

I believe I've heard that the 400 block 2 bolt mains caps are far wider and can deal with far more pressure than 350 2 bolt mains motors- can anyone confirm or deny?

Lars mentioned just replacing the bolts with ARP studs; someone else mentioned having a machine shop splay the mains to add extra strength-- if I'm not mistaken, BOTH require work to be done by a machine shop (you need the holes redrilled for studs anyway, right?) I can't see drilling new holes at an angle to support splayed mains caps to cost any more and you'd end up with more strength, right?

-If you have to pay a shop to redrill to put in studs, why wouldn't you just have them splay them and end up with more strength for the same machine shop cost?

Adam

#19

Drifting

chances are you wont reuse stock crank most people opt for forged, so $500 for a block and parts you will either craigslist, sell at swap meet, give/throw away. What are the limits of stock blocks ?

#20

Le Mans Master

Thread Starter

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Well if you read Smokey Y. (RIP) Power Secrets you will find out want you are trying to achieve is greater clamping force of the main cap. Stronger is kind'a misleading for this objective Newb. Want a stud does is fill the bolt hole much better than the stock bolts do. This helps prevent cap walk as the crank gets hammered and tries to twist. The correct size stud yields less room for the main cap to shift and the greater diameter provides better clamping force also.

The angled/splayed bolts (you have to use bolts on the angle/splayed because thats the only way to get the cap on and off) do a much better job yet at restraining the cap from moving under load. The strength most talk of is clamping force of the cap - the block itself isn't really any stronger for this.

Splayed main caps can be bought for <$50 but the machine work is what becomes expensive. Once added up for comparison all the expensive machine work saves you little compared to an aftermarket block that is cast with thicker sections like the main web and will be stronger in that area - also a four bolt block to begin with. For high hp applications the aftermarket blocks pay for themselves. GM knows this as they offer more than just a few performance BowTie blocks.

Hope this answers your question Newb.

The angled/splayed bolts (you have to use bolts on the angle/splayed because thats the only way to get the cap on and off) do a much better job yet at restraining the cap from moving under load. The strength most talk of is clamping force of the cap - the block itself isn't really any stronger for this.

Splayed main caps can be bought for <$50 but the machine work is what becomes expensive. Once added up for comparison all the expensive machine work saves you little compared to an aftermarket block that is cast with thicker sections like the main web and will be stronger in that area - also a four bolt block to begin with. For high hp applications the aftermarket blocks pay for themselves. GM knows this as they offer more than just a few performance BowTie blocks.

Hope this answers your question Newb.