Motor won't match new mounts

#21

Drifting

Thread Starter

Member Since: Sep 2002

Location: Suwanee,Ga

Posts: 1,642

Likes: 0

Received 0 Likes

on

0 Posts

Please do, I think it's a great idea. I only wish it had occured to me before the install weekend

It is my intention to make up a set using the POS anchor clam shells.

Seems straight forward, but it's always nice to see what you supposed to making , before doing the "making"!

TJM

#22

Drifting

Thread Starter

Member Since: Sep 2002

Location: Suwanee,Ga

Posts: 1,642

Likes: 0

Received 0 Likes

on

0 Posts

Well I'll give these Auto Extra parts a shot tomorrow.

If another fail, then I'm going the Energy Suspension route.

TJM

#23

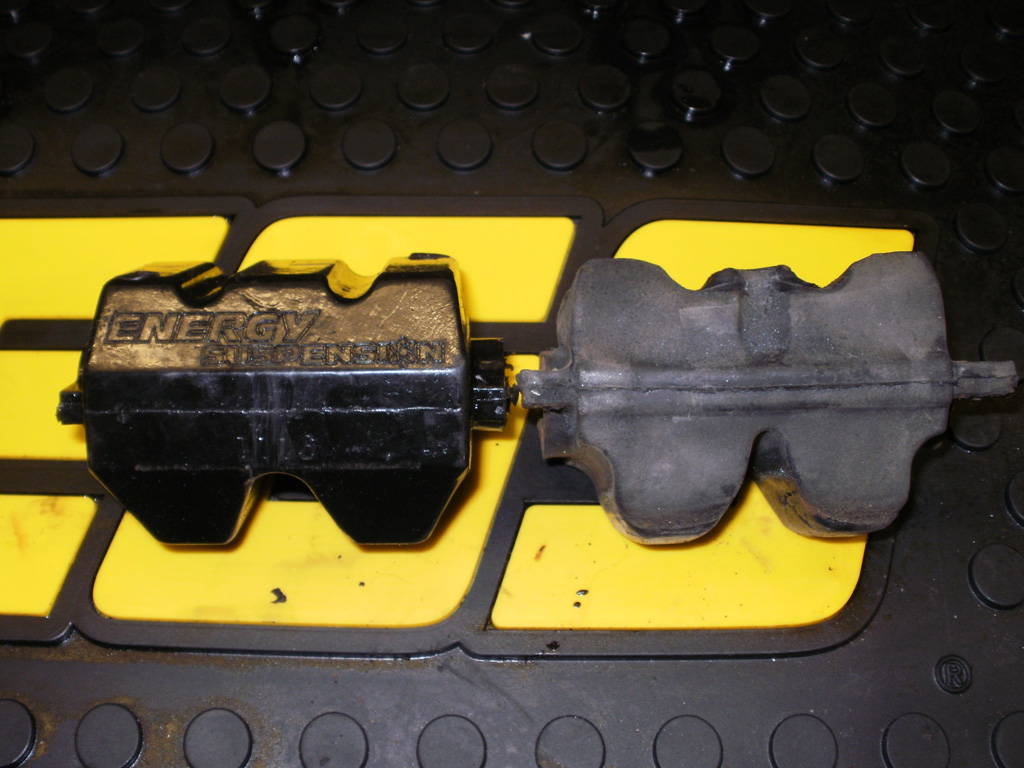

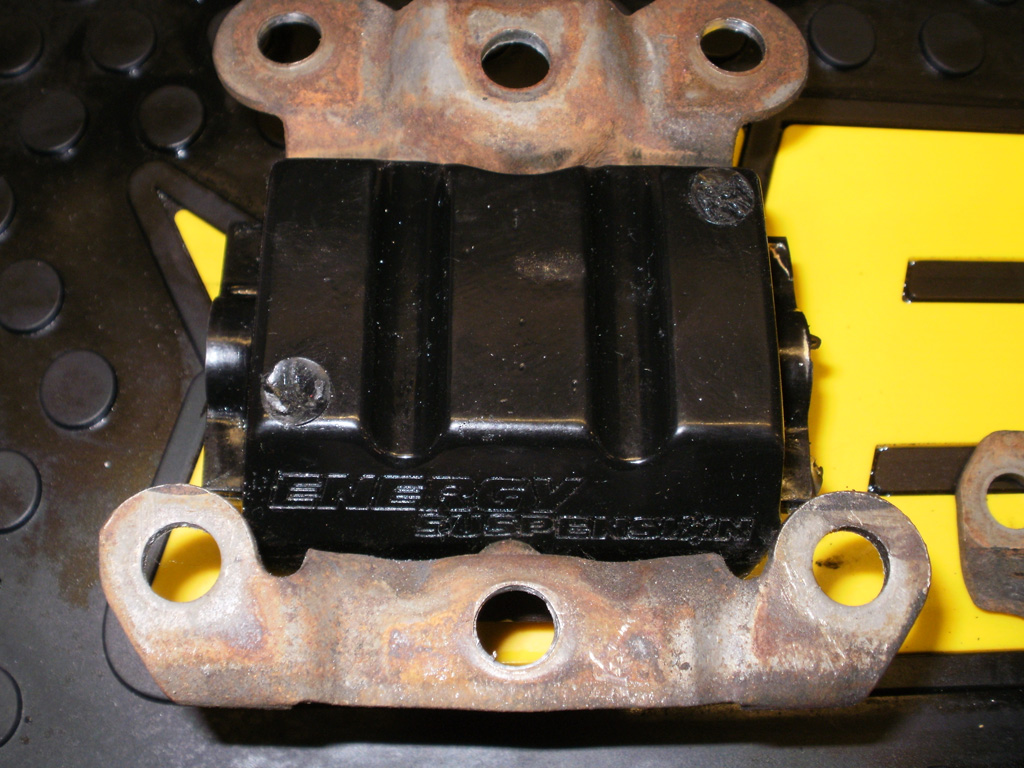

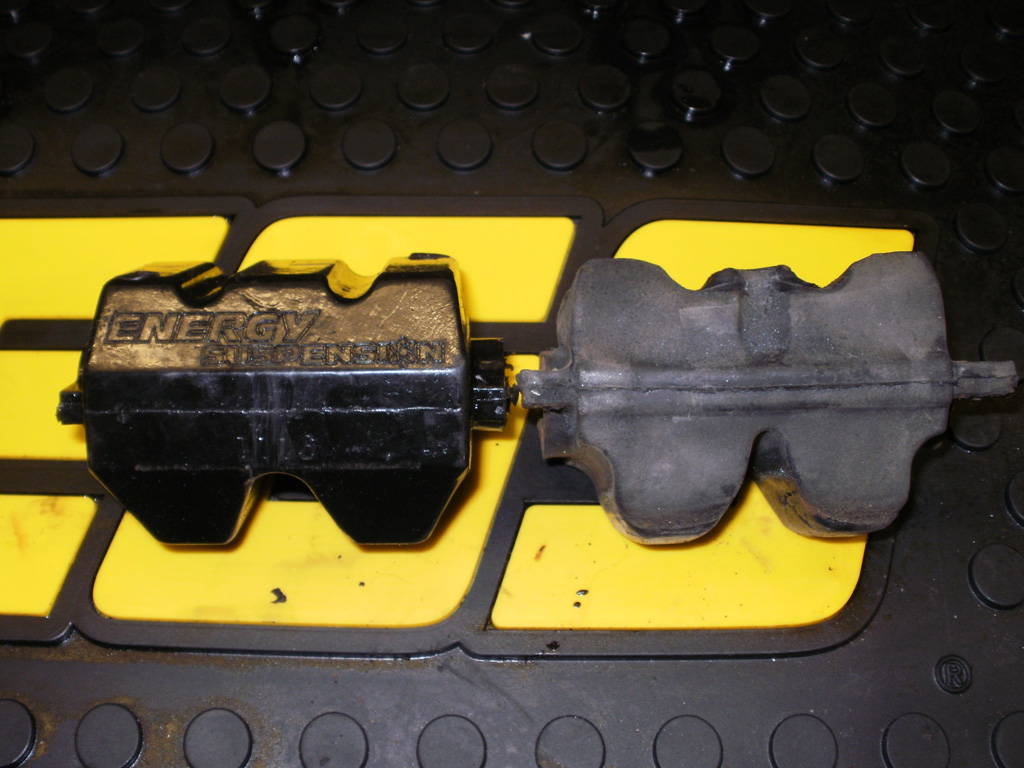

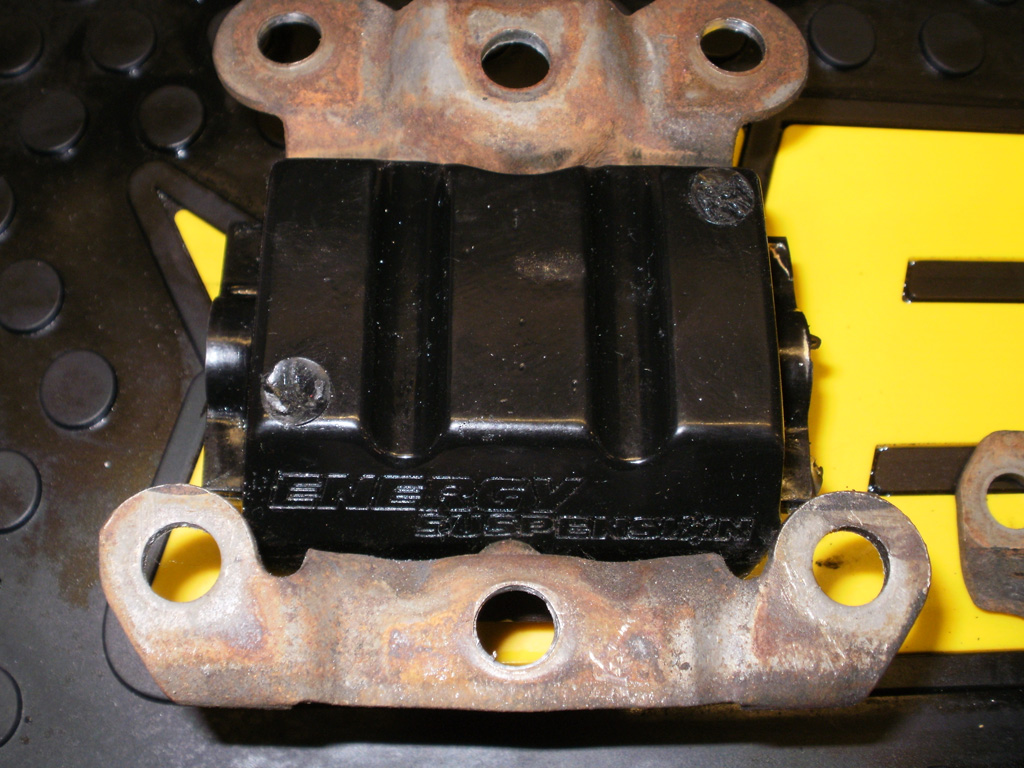

here's mine. anchor 2713 clamshell with Energy Suspension 3.1127G poly-u insert, as installed on drivers's side. can't really see that much.

Last edited by rpoL98; 12-17-2010 at 05:19 PM.

#24

Drifting

Thread Starter

Member Since: Sep 2002

Location: Suwanee,Ga

Posts: 1,642

Likes: 0

Received 0 Likes

on

0 Posts

One of the Anchor parts was just flat wrong.

After getting them "out" and laying them side by side, it was PAINFULLY clear they were at different centers. It wasn't a matter of the rubber being off, the hole dimension to the tabs was dead wrong.

They will get drilled and tossed in a box, because IF ever there is a need for motor mounts they will be Energy Suspension inserts into those clam shells.

TJM

#25

- 1986 Original Owner -

Guys, I really have to apologize. I must have been drunk (a not so unusual occurrence!) when I last looked at these and thought they were wrong. As Mick said, the Energy Suspension 31127g fit perfectly in the stock clam shells.

I'll clean up and paint these and use them when I put my motor back in.

Sorry for the confusion.

I'll clean up and paint these and use them when I put my motor back in.

Sorry for the confusion.

#26

AFTER you assemble the two clamshell halves, be sure to run a 7/16" drill through the 3 holes for the bolts that go to the block. that made all the world of difference for me.

#28

Snap On Torque Wrenches are the best. Guaranteed Accuracy and top quality construction.

Used by the Top Mechanics everywhere.

Including Aviation and Military Aircraft mechanics.

And Top Race engine Builders around the world.

I would not use any other brand Torque wrench if you gave it to me free.

I would give that other brand Torque Wrench back to You. Or toss it into the garbage dumpster.

I have been a mechanic since 1983.

Started turning wrenches with my dad when I was 4 years old.

1974 year to be exact.

Leaded Gasoline and High Octane gas still at local gas stations back then.

And factory Musclecars Racing on the Streets nightly. Including Big Block C3 Corvettes from my memory.

I Have Built-assembled many race engines with my Snap On Torque Wrenches.

For myself and others.

And have repaired likely well over 10,000 vehicles with my other Snap On Tools by now.

They never let me down.

Thats Why Snap-On.

Use what tools you want.

Try Snap On tools once.

You wont go back to the other brands ever likey.

Used by the Top Mechanics everywhere.

Including Aviation and Military Aircraft mechanics.

And Top Race engine Builders around the world.

I would not use any other brand Torque wrench if you gave it to me free.

I would give that other brand Torque Wrench back to You. Or toss it into the garbage dumpster.

I have been a mechanic since 1983.

Started turning wrenches with my dad when I was 4 years old.

1974 year to be exact.

Leaded Gasoline and High Octane gas still at local gas stations back then.

And factory Musclecars Racing on the Streets nightly. Including Big Block C3 Corvettes from my memory.

I Have Built-assembled many race engines with my Snap On Torque Wrenches.

For myself and others.

And have repaired likely well over 10,000 vehicles with my other Snap On Tools by now.

They never let me down.

Thats Why Snap-On.

Use what tools you want.

Try Snap On tools once.

You wont go back to the other brands ever likey.

#29

Snap On Torque Wrenches are the best. Guaranteed Accuracy and top quality construction.

Used by the Top Mechanics everywhere.

Including Aviation and Military Aircraft mechanics.

And Top Race engine Builders around the world.

I would not use any other brand Torque wrench if you gave it to me free.

I would give that other brand Torque Wrench back to You. Or toss it into the garbage dumpster.

I have been a mechanic since 1983.

Started turning wrenches with my dad when I was 4 years old.

1974 year to be exact.

Leaded Gasoline and High Octane gas still at local gas stations back then.

And factory Musclecars Racing on the Streets nightly. Including Big Block C3 Corvettes from my memory.

I Have Built-assembled many race engines with my Snap On Torque Wrenches.

For myself and others.

And have repaired likely well over 10,000 vehicles with my other Snap On Tools by now.

They never let me down.

Thats Why Snap-On.

Use what tools you want.

Try Snap On tools once.

You wont go back to the other brands ever likey.

Used by the Top Mechanics everywhere.

Including Aviation and Military Aircraft mechanics.

And Top Race engine Builders around the world.

I would not use any other brand Torque wrench if you gave it to me free.

I would give that other brand Torque Wrench back to You. Or toss it into the garbage dumpster.

I have been a mechanic since 1983.

Started turning wrenches with my dad when I was 4 years old.

1974 year to be exact.

Leaded Gasoline and High Octane gas still at local gas stations back then.

And factory Musclecars Racing on the Streets nightly. Including Big Block C3 Corvettes from my memory.

I Have Built-assembled many race engines with my Snap On Torque Wrenches.

For myself and others.

And have repaired likely well over 10,000 vehicles with my other Snap On Tools by now.

They never let me down.

Thats Why Snap-On.

Use what tools you want.

Try Snap On tools once.

You wont go back to the other brands ever likey.

#31

They can Break too.

Build enough engines, repair enough cars and trucks daily.

You will find out the same as I did.

Snap On is best, no subsitute.

Make incorrect Torque bolt tightning torque settings.

You may have a failure. sudenly or down the road.

You did a bad repair or build job.

Its YOUR FAULT BEACAUSE YOU TRUSTED THAT CHEAP OFF BRAND TORQUE WRENCH TO BE ACCURATE.

NO ONE ELSE TO BLAME BUT YOURSELF

YES FOR ME SNAP ON ONLY. ESPECIALLY THEIR TORQUE WRENCHES.

I TRUST NOTHING ELSE.

AVIATION MECHANICS WILL AGREE TOO.

HAVE A FAILURE IN AN AIRPLANE ENGINE FASTNER BECAUSE OF AN INACURATE TORQUE WRENCH THAT DIDNT TORQUE DOWN A FASTNER TO FACTORY RECOMENDED SPECS........... THAT AIRPLANE WILL GO DOWN.

PILOT, PASSENGERS, AND OTHERS ON THE GROUND WILL LIKELY DIE.

USE WHAT YOU WANT FOR TOOLS.

BEST MECHANICS DONT USE CHEAP TOOLS.

BR

#32

Cheap off Brand Torque wrenches are not always accurate.

They can Break too.

Build enough engines, repair enough cars and trucks daily.

You will find out the same as I did.

Snap On is best, no subsitute.

Make incorrect Torque bolt tightning torque settings.

You may have a failure. sudenly or down the road.

You did a bad repair or build job.

Its YOUR FAULT BEACAUSE YOU TRUSTED THAT CHEAP OFF BRAND TORQUE WRENCH TO BE ACCURATE.

NO ONE ELSE TO BLAME BUT YOURSELF

YES FOR ME SNAP ON ONLY. ESPECIALLY THEIR TORQUE WRENCHES.

I TRUST NOTHING ELSE.

AVIATION MECHANICS WILL AGREE TOO.

HAVE A FAILURE IN AN AIRPLANE ENGINE FASTNER BECAUSE OF AN INACURATE TORQUE WRENCH THAT DIDNT TORQUE DOWN A FASTNER TO FACTORY RECOMENDED SPECS........... THAT AIRPLANE WILL GO DOWN.

PILOT, PASSENGERS, AND OTHERS ON THE GROUND WILL LIKELY DIE.

USE WHAT YOU WANT FOR TOOLS.

BEST MECHANICS DONT USE CHEAP TOOLS.

BR

They can Break too.

Build enough engines, repair enough cars and trucks daily.

You will find out the same as I did.

Snap On is best, no subsitute.

Make incorrect Torque bolt tightning torque settings.

You may have a failure. sudenly or down the road.

You did a bad repair or build job.

Its YOUR FAULT BEACAUSE YOU TRUSTED THAT CHEAP OFF BRAND TORQUE WRENCH TO BE ACCURATE.

NO ONE ELSE TO BLAME BUT YOURSELF

YES FOR ME SNAP ON ONLY. ESPECIALLY THEIR TORQUE WRENCHES.

I TRUST NOTHING ELSE.

AVIATION MECHANICS WILL AGREE TOO.

HAVE A FAILURE IN AN AIRPLANE ENGINE FASTNER BECAUSE OF AN INACURATE TORQUE WRENCH THAT DIDNT TORQUE DOWN A FASTNER TO FACTORY RECOMENDED SPECS........... THAT AIRPLANE WILL GO DOWN.

PILOT, PASSENGERS, AND OTHERS ON THE GROUND WILL LIKELY DIE.

USE WHAT YOU WANT FOR TOOLS.

BEST MECHANICS DONT USE CHEAP TOOLS.

BR

#33

- 1986 Original Owner -