Z06 Transmission rebuild saga

#41

I had a guy rebuild my M6 about 2 months ago and he screwed it up twice.. He left the inner hub to the 5th gear synchro out and didnt know it. Didnt catch it the 2nd time either.

I now have the works, Carbon fiber blockers, billet keys, steel 3/4 fork, Bronze slider pads etc.

I wound up tearing into it myself Its not too scary But be careful guys with that cluster gear Numb had trouble pulling out. Its 200 bucks!

I now have the works, Carbon fiber blockers, billet keys, steel 3/4 fork, Bronze slider pads etc.

I wound up tearing into it myself Its not too scary But be careful guys with that cluster gear Numb had trouble pulling out. Its 200 bucks!

#42

Pro

Member Since: Aug 2004

Location: Orlando, FL (UCF)

Posts: 743

Likes: 0

Received 4 Likes

on

4 Posts

2017 C6 of the Year Finalist

Cruise-In VI Veteran

The mainshaft assembly comes apart like any other transmission... you press the gears off with a shop press. The only potential snag I can think of is, since the mainshaft is so long, you might not be able to use one of those smaller bench-top presses. A full size floor-standing press works fine.

The T56 service manual has good instructions on taking it apart:

http://www.ttcautomotive.com/English...ice_Manual.pdf

The T56 service manual has good instructions on taking it apart:

http://www.ttcautomotive.com/English...ice_Manual.pdf

#43

Instructor

Thread Starter

Member Since: Nov 2005

Location: Austin Texas

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

The latest installment:

While I'm waiting on tranny parts to arrive, I decided to take apart the torque tube to check the condition of the couplers. Before the tranny died, I had been getting a slight vibration in the drivetrain at anything above 2000 rpm. I have been operating under the assumption that it was the flywheel, since I didn't have it balanced with the clutch last time around. One thing I noticed before I took the torque tube apart is when you spin it, there is a noticeable amount of runout on the input shaft. I searched the forums, and apparently that's common, because it's attached to a rubber coupler. Supposedly, the pilot bearing keeps everything lined up, but it still doesn't give me a warm fuzzy fealing.

What everyone says is true... the snap ring is a PITA to take off... made my regular set of Craftsman snap ring pliers cry. Only thing I could find was a 9" set at Harbor Freight... cheap crap, but it did the job.

With the snap ring off, you have to tap the shaft out from the clutch side... I used a block of wood and mini-sledge on the input shaft... popped right out. Inside, I found some black shavings that look to be from the snubber contacting the housing:

You can see where the snubber has rubbed the inside of the tube:

The couplers look to be in suprisingly good shape, although there is some wear on the inside of the housing near the front coupler... the coupler doesn't look like it has been rubbed, but I don't know how else those marks got there. Buying a used car is like marrying a hooker... you just don't know what she's been up to.

Front coupler:

Rear coupler:

Inside the tube, front side:

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

While I'm waiting on tranny parts to arrive, I decided to take apart the torque tube to check the condition of the couplers. Before the tranny died, I had been getting a slight vibration in the drivetrain at anything above 2000 rpm. I have been operating under the assumption that it was the flywheel, since I didn't have it balanced with the clutch last time around. One thing I noticed before I took the torque tube apart is when you spin it, there is a noticeable amount of runout on the input shaft. I searched the forums, and apparently that's common, because it's attached to a rubber coupler. Supposedly, the pilot bearing keeps everything lined up, but it still doesn't give me a warm fuzzy fealing.

What everyone says is true... the snap ring is a PITA to take off... made my regular set of Craftsman snap ring pliers cry. Only thing I could find was a 9" set at Harbor Freight... cheap crap, but it did the job.

With the snap ring off, you have to tap the shaft out from the clutch side... I used a block of wood and mini-sledge on the input shaft... popped right out. Inside, I found some black shavings that look to be from the snubber contacting the housing:

You can see where the snubber has rubbed the inside of the tube:

The couplers look to be in suprisingly good shape, although there is some wear on the inside of the housing near the front coupler... the coupler doesn't look like it has been rubbed, but I don't know how else those marks got there. Buying a used car is like marrying a hooker... you just don't know what she's been up to.

Front coupler:

Rear coupler:

Inside the tube, front side:

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

#44

Le Mans Master

The latest installment:

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

Great post BTW..

#45

Instructor

Thread Starter

Member Since: Nov 2005

Location: Austin Texas

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

I talked to a local drive shaft shop today, and they said they can balance the drive shaft, but just the center portion - they can't do it with the input and output sections attached. Seems like that defeats the purpose. I'd like the reassurance that the shaft is properly balanced, but is it of any value if you can't test the whole thing?

#46

Pro

Member Since: Aug 2004

Location: Orlando, FL (UCF)

Posts: 743

Likes: 0

Received 4 Likes

on

4 Posts

2017 C6 of the Year Finalist

Cruise-In VI Veteran

I talked to a local drive shaft shop today, and they said they can balance the drive shaft, but just the center portion - they can't do it with the input and output sections attached. Seems like that defeats the purpose. I'd like the reassurance that the shaft is properly balanced, but is it of any value if you can't test the whole thing?

I rebuilt my torque tube with new bearings, two LG aluminum couplers, slapped it all back together with blue loctite and proper torque specs. It is solid!!! It took all the abuse that my transmission output shaft couldn't handle. After I took it apart this last time it spins straight as an arrow, like it was brand new, right from down unda. (They are built in Australia).

#47

Safety Car

I wouldn't mind buying a used trans and trying this myself. I am sure that will be the next thing to break in my car. I have done new rad, repl most of sc components, now just breaking in new motor, and already repl clutch. Are there enough how-tos around to DIY? It does seem pretty complicated, but it would be a great learning experience. Can you DIY with no trans experience?

#48

Instructor

Thread Starter

Member Since: Nov 2005

Location: Austin Texas

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

#50

Pro

Member Since: Aug 2004

Location: Orlando, FL (UCF)

Posts: 743

Likes: 0

Received 4 Likes

on

4 Posts

2017 C6 of the Year Finalist

Cruise-In VI Veteran

Here is how my rebuild is going. I took everything apart today to get ready to assemble the new mainshaft. I'm waiting for my new clips and seals in the mail But after today I'm going to need a new tapered bearing (22) and race (11) as I pulled it off wrong.

All in a days work. Check out the old shaft and new.

Look familiar....thats how it starts

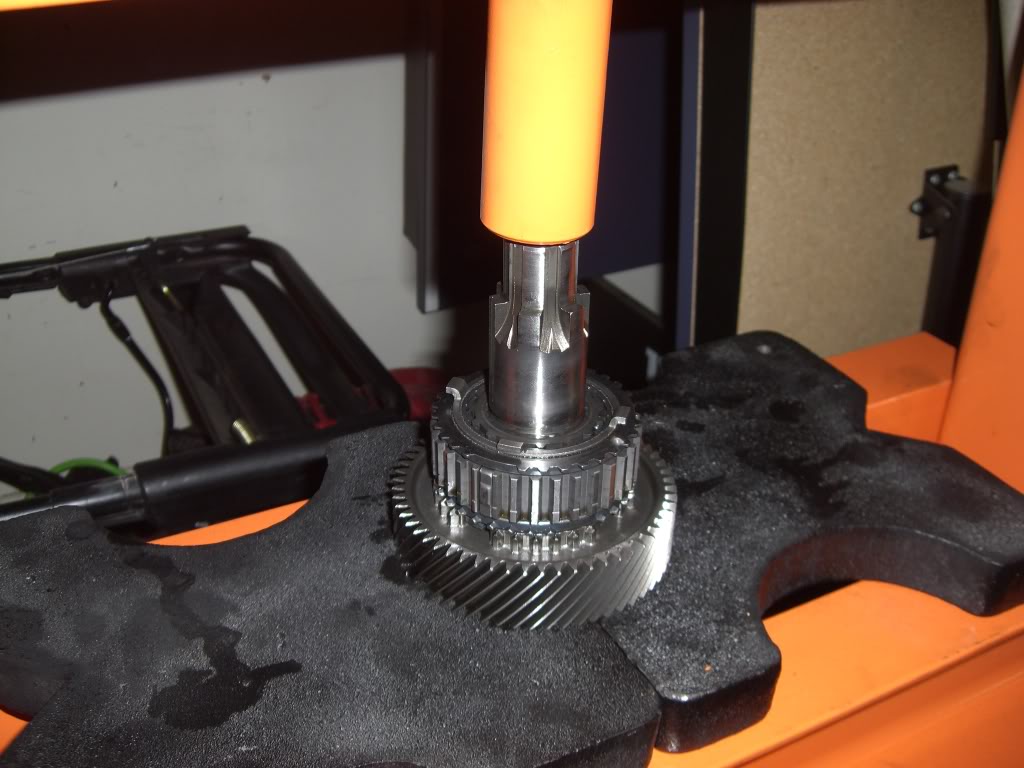

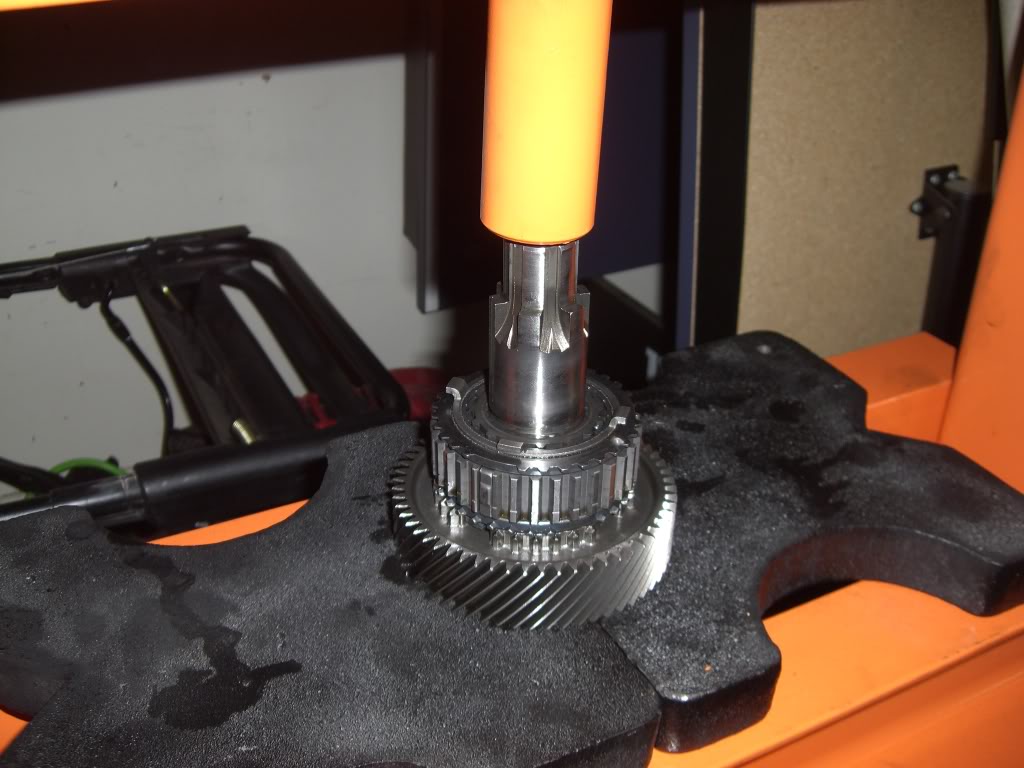

Bearing seperator pressing off 2nd gear and syncro

Pressing off 3rd with syncro

Later,

Max

All in a days work. Check out the old shaft and new.

Look familiar....thats how it starts

Bearing seperator pressing off 2nd gear and syncro

Pressing off 3rd with syncro

Later,

Max

Last edited by Max01GreenMachine; 11-22-2008 at 09:35 PM.

#53

Burning Brakes

Nice work, too bad about the screwing for your last rebuild.

I rebuilt my '02Z tranny three years ago, had no issues getting my 5/6 off, came off easy (just lucky I guess). Did all the same upgrades, steel 3/4 fork, bronze pads on ALL forks, billet keys on ALL sliders, also installed a new 1/2 slider/hub assembly (was having issues going into 1st at rest, fixed the problem temporarily, but now it's back again).

Rebuilding a tranny is no problem if you have some basic mechanical ability and the right tools. The manual helps, too, since there are so many sub-assemblies to keep track of. Always good to see someone doing their own work.

After all the upgrades the tranny felt "tighter", and I felt I got better feedback while shifting (probably due to the bronze fork pads). I had a Hurst shifter at the time, so there was no rubber between me and the tranny. It felt nice, shifted well, I was pleased.

One note: when you're putting the tranny back together, make sure the pin in the shifter shaft goes in and stays in the right place as you lower everything into the front cover... that little pin is what couples the shifter shaft to the centering spring. Without it the shifter won't center properly!

Good luck, and GREAT work!

I rebuilt my '02Z tranny three years ago, had no issues getting my 5/6 off, came off easy (just lucky I guess). Did all the same upgrades, steel 3/4 fork, bronze pads on ALL forks, billet keys on ALL sliders, also installed a new 1/2 slider/hub assembly (was having issues going into 1st at rest, fixed the problem temporarily, but now it's back again).

Rebuilding a tranny is no problem if you have some basic mechanical ability and the right tools. The manual helps, too, since there are so many sub-assemblies to keep track of. Always good to see someone doing their own work.

After all the upgrades the tranny felt "tighter", and I felt I got better feedback while shifting (probably due to the bronze fork pads). I had a Hurst shifter at the time, so there was no rubber between me and the tranny. It felt nice, shifted well, I was pleased.

One note: when you're putting the tranny back together, make sure the pin in the shifter shaft goes in and stays in the right place as you lower everything into the front cover... that little pin is what couples the shifter shaft to the centering spring. Without it the shifter won't center properly!

Good luck, and GREAT work!

#54

Race Director

I would check the bearing on the TT as that is what keeps it all lined up.

I'm not sure what kind of power you're making, but the TT's are known for flexing (Whipping) under certain conditions.

Nice work and pictures.

I'm not sure what kind of power you're making, but the TT's are known for flexing (Whipping) under certain conditions.

Nice work and pictures.

#55

Tech Contributor

The latest installment:

While I'm waiting on tranny parts to arrive, I decided to take apart the torque tube to check the condition of the couplers. Before the tranny died, I had been getting a slight vibration in the drivetrain at anything above 2000 rpm. I have been operating under the assumption that it was the flywheel, since I didn't have it balanced with the clutch last time around. One thing I noticed before I took the torque tube apart is when you spin it, there is a noticeable amount of runout on the input shaft. I searched the forums, and apparently that's common, because it's attached to a rubber coupler. Supposedly, the pilot bearing keeps everything lined up, but it still doesn't give me a warm fuzzy fealing.

What everyone says is true... the snap ring is a PITA to take off... made my regular set of Craftsman snap ring pliers cry. Only thing I could find was a 9" set at Harbor Freight... cheap crap, but it did the job.

With the snap ring off, you have to tap the shaft out from the clutch side... I used a block of wood and mini-sledge on the input shaft... popped right out. Inside, I found some black shavings that look to be from the snubber contacting the housing:

You can see where the snubber has rubbed the inside of the tube:

The couplers look to be in suprisingly good shape, although there is some wear on the inside of the housing near the front coupler... the coupler doesn't look like it has been rubbed, but I don't know how else those marks got there. Buying a used car is like marrying a hooker... you just don't know what she's been up to.

Front coupler:

Rear coupler:

Inside the tube, front side:

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

While I'm waiting on tranny parts to arrive, I decided to take apart the torque tube to check the condition of the couplers. Before the tranny died, I had been getting a slight vibration in the drivetrain at anything above 2000 rpm. I have been operating under the assumption that it was the flywheel, since I didn't have it balanced with the clutch last time around. One thing I noticed before I took the torque tube apart is when you spin it, there is a noticeable amount of runout on the input shaft. I searched the forums, and apparently that's common, because it's attached to a rubber coupler. Supposedly, the pilot bearing keeps everything lined up, but it still doesn't give me a warm fuzzy fealing.

What everyone says is true... the snap ring is a PITA to take off... made my regular set of Craftsman snap ring pliers cry. Only thing I could find was a 9" set at Harbor Freight... cheap crap, but it did the job.

With the snap ring off, you have to tap the shaft out from the clutch side... I used a block of wood and mini-sledge on the input shaft... popped right out. Inside, I found some black shavings that look to be from the snubber contacting the housing:

You can see where the snubber has rubbed the inside of the tube:

The couplers look to be in suprisingly good shape, although there is some wear on the inside of the housing near the front coupler... the coupler doesn't look like it has been rubbed, but I don't know how else those marks got there. Buying a used car is like marrying a hooker... you just don't know what she's been up to.

Front coupler:

Rear coupler:

Inside the tube, front side:

So now I'm not sure what to think. Maybe the snubber is rubbing because the couplers are getting old and flexing too much? Maybe the car was over-revved by a past owner? Maybe the vibration problem is due to an unbalanced drive shaft? I'm thinking I need to check the balance of both the clutch/flywheel assembly and the driveshaft. The first one is easy, but there aren't many places that are setup to balance these driveshafts.

#56

Instructor

Thread Starter

Member Since: Nov 2005

Location: Austin Texas

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

Well, a lot of time has past, and I have gradually accumulated all the parts I need to put the tranny back together.

Last weekend, I pressed apart the main shaft and replaced the worn 3-4 synchro. While I was in there, I also swapped in the billet synchro keys on 3-4. I learned something new, and that is the Corvette 1-2 synchro comes with billet keys from the factory. Camera was dead... didn't get any pics of this step.

I fragged the bearing on the mainshaft while pressing off the 3-4 synchro... I don't think there is any way to save it. Here is the new bearing:

And pressed back on:

Closeup of how the 4th gear input shaft mates up to the main shaft:

Since I had to order the new bearing anyway, I went ahead and picked up billet synchro keys for 5-6, as well as bronze pads for 5-6 and reverse. I want the tranny to stay together this time!

Pressing the countershaft extension apart to get to the 5-6 synchro:

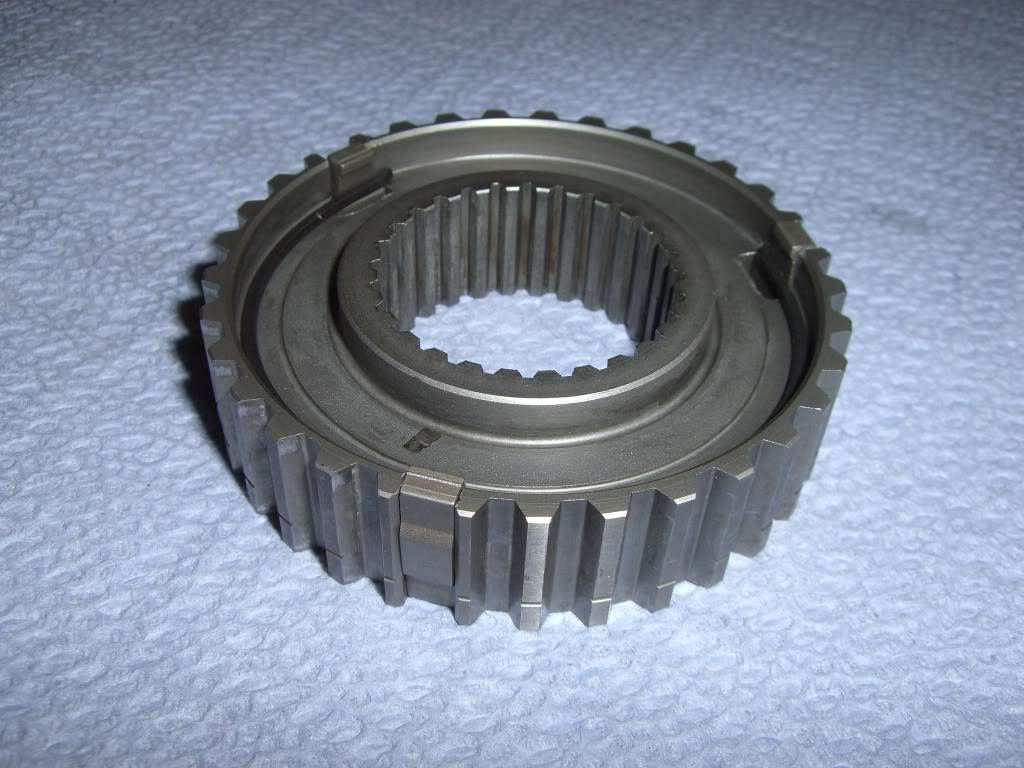

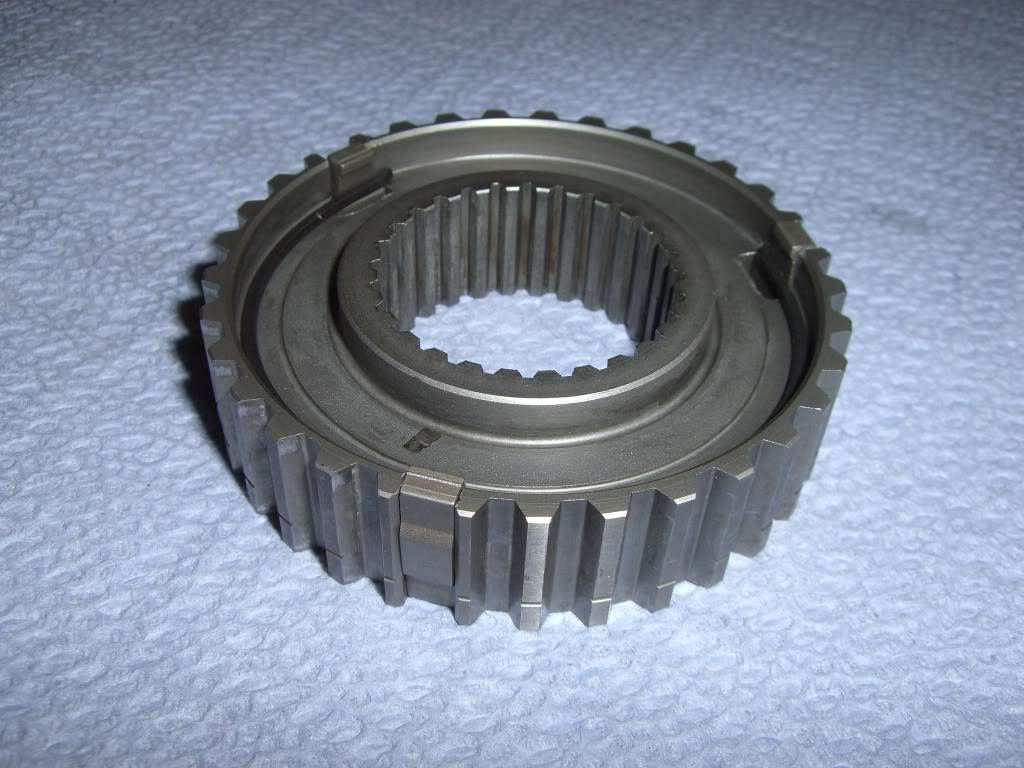

Countershaft extension disassembled:

Billet 5-6 keys installed:

Bronze pads installed on (left to right): reverse, 5-6, 3-4, 1-2 forks:

Comparison between the steel 3-4 fork and the stock aluminum 3-4 fork:

That's it for tonight. All the shafts are assembed, and the next step is to clean up the cases and put things back together. Planning on knocking that out this weekend.

Last weekend, I pressed apart the main shaft and replaced the worn 3-4 synchro. While I was in there, I also swapped in the billet synchro keys on 3-4. I learned something new, and that is the Corvette 1-2 synchro comes with billet keys from the factory. Camera was dead... didn't get any pics of this step.

I fragged the bearing on the mainshaft while pressing off the 3-4 synchro... I don't think there is any way to save it. Here is the new bearing:

And pressed back on:

Closeup of how the 4th gear input shaft mates up to the main shaft:

Since I had to order the new bearing anyway, I went ahead and picked up billet synchro keys for 5-6, as well as bronze pads for 5-6 and reverse. I want the tranny to stay together this time!

Pressing the countershaft extension apart to get to the 5-6 synchro:

Countershaft extension disassembled:

Billet 5-6 keys installed:

Bronze pads installed on (left to right): reverse, 5-6, 3-4, 1-2 forks:

Comparison between the steel 3-4 fork and the stock aluminum 3-4 fork:

That's it for tonight. All the shafts are assembed, and the next step is to clean up the cases and put things back together. Planning on knocking that out this weekend.

#59

Pro

Member Since: Apr 2007

Location: Mc Farland Wisconsin

Posts: 635

Likes: 0

Received 0 Likes

on

0 Posts

I actually talked to Kevin at the gearbox today and he let me know the corvette 1-2 keys werent billet, even though they are solid and may look like billet they are powdered metal, i ordered billet 1-2 keys and i thought they looked very similar but are a bit different.

Last edited by Nver2loud; 12-19-2008 at 07:38 PM. Reason: .

#60

Instructor

Thread Starter

Member Since: Nov 2005

Location: Austin Texas

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

I actually talked to Kevin at the gearbox today and he let me know the corvette 1-2 keys werent billet, even though they are solid and may look like billet they are powdered metal, i ordered billet 1-2 keys and i thought they looked very similar but are a bit different.