Did GM gelcoat C3 Corvettes?

#1

Instructor

Thread Starter

The paint shops I'm talking to keep saying they plan to strip my car down to the "gelcoat" to prep it for painting. Were C3 Corvettes gelcoated at the factory? A knowledgeable friend of mine says they weren't gelcoated. He said GM used a process called "matched metal molding", instead.

What is correct? I don't understand why the word "metal" is used concerning a "fiberglass" body. If you know, give me an explanation of "matched metal molding" that I can understand. Thanks!

What is correct? I don't understand why the word "metal" is used concerning a "fiberglass" body. If you know, give me an explanation of "matched metal molding" that I can understand. Thanks!

#3

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,469 Likes

on

1,248 Posts

Cruise-In II Veteran

Find another shop. There was no gelcoat on factory fiberglass.

Matched metal die is the term used to denote how Corvette fiberglass panels were manufactured. In a nutshell, each part had an upper and lower die made of metal machined to the engineering specifications for the part. A preform of the part was placed in the lower die, resin and additional fiberglass were added. The upper die was lowered onto the bottom die. Heat and pressure were applied curing the resin between the two halves of the die.

Matched metal die is the term used to denote how Corvette fiberglass panels were manufactured. In a nutshell, each part had an upper and lower die made of metal machined to the engineering specifications for the part. A preform of the part was placed in the lower die, resin and additional fiberglass were added. The upper die was lowered onto the bottom die. Heat and pressure were applied curing the resin between the two halves of the die.

Last edited by Easy Mike; 04-07-2013 at 10:29 AM.

#4

Race Director

To the best of my knowledge ....GM did not "gelcoat" any body panels. Now from what I have heard through the years is that sometimes when the C1 early "press-molded" fiberglass panels were made...a layer of resin was slightly thicker on the outside surface and allowed sanding and sometimes would crack if too thick. I have see it...but I have also seen this "cracking" issue in later years Corvettes also up until the introduction of the "SMC" style panels...which is an entirely different material.

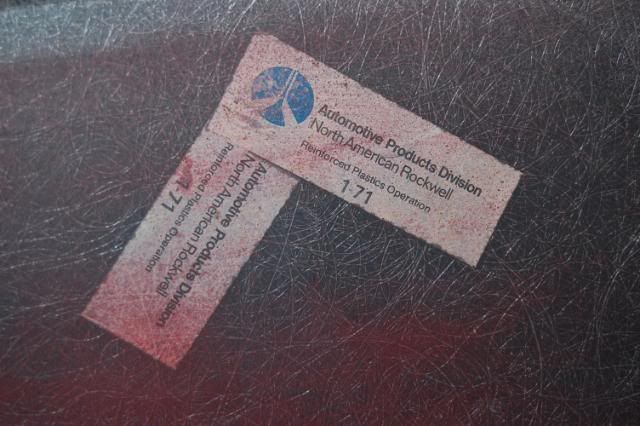

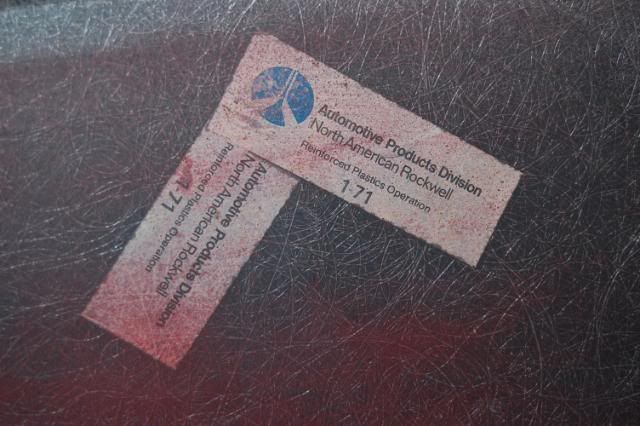

The process to make the fiberglass panels and the SMC panels utilize a press...which are made out of dies that are steel...so I was told by a friend who actually made the top hood surrounds for the 78-82 Corvettes.

It all depends on what year of C3 you are talking about... because this is the era where the material of the body changed. Repair procedures change due to the body material.

DUB

The process to make the fiberglass panels and the SMC panels utilize a press...which are made out of dies that are steel...so I was told by a friend who actually made the top hood surrounds for the 78-82 Corvettes.

It all depends on what year of C3 you are talking about... because this is the era where the material of the body changed. Repair procedures change due to the body material.

DUB

#5

Race Director

In 1970 the Corvette body was made by a process called "Press Molding", or PM for short. Basically two big heavy steel molds with fiberglass in between. By pressing the molds together the resulting panel was much denser than hand laid 'glass.

And no, gelcoat was not used.

Edit: Dub: I thought C1s were hand laid?

And no, gelcoat was not used.

Edit: Dub: I thought C1s were hand laid?

#6

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,469 Likes

on

1,248 Posts

Cruise-In II Veteran

Most of the 53s used hand laid parts but they were moving toward the bag method and moving from that to matched metal dies. The final part to be converted to matched metal die was the 54 underbody. If I recall my Corvette history correctly, everything from 55 on has been matched metal die.

Press molding requires two matched dies.

Press molding requires two matched dies.

#7

Race Director

Almost all production Corvettes were press molded, technically still are, save for some early parts.

SMC just refers to the material used in the press molding process and it changed almost yearly in composition to aid in faster and less costly production.

No gelcoat was used or could be easily used in the process.

A lot of body shops have run into aftermarket hand laid parts that do have gelcoat.

They probably just want to strip all the paint off.

I wouldn't judge them on using incorrect lingo, might be the best shop ever.

SMC just refers to the material used in the press molding process and it changed almost yearly in composition to aid in faster and less costly production.

No gelcoat was used or could be easily used in the process.

A lot of body shops have run into aftermarket hand laid parts that do have gelcoat.

They probably just want to strip all the paint off.

I wouldn't judge them on using incorrect lingo, might be the best shop ever.

#8

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi G70,

The front fenders and hood surround are a good example of match molded parts. The inner surface is almost as smooth as the outer surface, and is the same in appearance. It's not rough like an old 'chopper-gun' part, or varied in texture like 'hand-laid' parts.

The fiberglass supplier worked continuously to control the amount of resin in the part and to improve their ability have the resin evenly distributed throughout the glass.

No gel coat was used....gelcoat was used on boat hulls and porta-potties, on which no paint was to be applied; the gel coat was the finished surface. On Corvettes the paint is the finished surface.

From the 1970 Corvette News.... "low profile resin .... is a term used to describe the surface finish of the fiberglass pieces... it's nearly as smooth as a steel component could be.... all we have to do is scuff sand and solvent wipe to prepare them for painting".

It really is amazing that this material can still be used as a basis for beautiful paint jobs 45 years later.

Regards,

Alan

The front fenders and hood surround are a good example of match molded parts. The inner surface is almost as smooth as the outer surface, and is the same in appearance. It's not rough like an old 'chopper-gun' part, or varied in texture like 'hand-laid' parts.

The fiberglass supplier worked continuously to control the amount of resin in the part and to improve their ability have the resin evenly distributed throughout the glass.

No gel coat was used....gelcoat was used on boat hulls and porta-potties, on which no paint was to be applied; the gel coat was the finished surface. On Corvettes the paint is the finished surface.

From the 1970 Corvette News.... "low profile resin .... is a term used to describe the surface finish of the fiberglass pieces... it's nearly as smooth as a steel component could be.... all we have to do is scuff sand and solvent wipe to prepare them for painting".

It really is amazing that this material can still be used as a basis for beautiful paint jobs 45 years later.

Regards,

Alan

Last edited by Alan 71; 04-07-2013 at 10:49 AM.

#9

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,469 Likes

on

1,248 Posts

Cruise-In II Veteran

Incorrect lingo or ignorance? Here's my take: if I am looking at potentially five figures for prep and paint and the individual who is asking me for those five figures mentions gelcoat, I begin to wonder whether I want to spend my five figures at that location.

#10

Race Director

When people have a hard time looking for "interior vinyl dye", I had repeatedly posted pics and copies of correspondence from manufacturers documenting that there is no such aftermarket thing, it is all paint, special paint of course. People have used the "paint" with great success.

People still consistently refer to it as "dye"

I would like to think, they are not ignorant, just stuck on a widely used "term".

#11

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,469 Likes

on

1,248 Posts

Cruise-In II Veteran

#13

Instructor

Thread Starter

I've only been a member of CF for a couple of months, but I can't get over how much knowledge is out there. Thanks to all the CF members who are willing to share their expertise.

I've never been "hands on", but it doesn't lessen my love for classic cars and especially Corvettes. Now in retirement, I finally am able to enjoy my dream of having one. Even though I have to have a shop do the work, I still want to learn and understand as much as possible. Thanks for your willingness to share what all of you Senior CF Members have learned over your years in the Corvette hobby!

I've never been "hands on", but it doesn't lessen my love for classic cars and especially Corvettes. Now in retirement, I finally am able to enjoy my dream of having one. Even though I have to have a shop do the work, I still want to learn and understand as much as possible. Thanks for your willingness to share what all of you Senior CF Members have learned over your years in the Corvette hobby!

#14

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,469 Likes

on

1,248 Posts

Cruise-In II Veteran

Talk to the folks at the paint shop. You want to ensure they know there is no factory gelcoat. As Noonie suggested, if the misunderstanding is simply terminology, you might be okay.

#15

Melting Slicks

My .02 on this gelcoat business (FWIW). While GM didn't gelcoat panels, oem panels have a tendency to absorb (wick) oils and other contaminents. This is especially true on the upside and side of the drivers side - it has to do with the channeling of air in the engine compartment - it has happened on both my '69 and '67. It shows up by bubbling on the top side of the panel like a bad case of acne. The "pimples" seem to ooze oil Gelcoat provides (FWIU) the best barrier to seal the panels. If you have this oozing problem, wipe over the panel with acetone (over and over again till it almost stops - it will never stop) then apply gelcoat. Don't seal the bottom of the fender because the panel still needs to breathe out the bottom. Newer replacment PM panels aren't made with the same force (pressure from the molds) that oem panels were and especially with the top surround, gelcoat provides a very good barrier to stop this absorbion. I intend to gelcoat my new front end. I've probably said too much already

Gelcoat provides (FWIU) the best barrier to seal the panels. If you have this oozing problem, wipe over the panel with acetone (over and over again till it almost stops - it will never stop) then apply gelcoat. Don't seal the bottom of the fender because the panel still needs to breathe out the bottom. Newer replacment PM panels aren't made with the same force (pressure from the molds) that oem panels were and especially with the top surround, gelcoat provides a very good barrier to stop this absorbion. I intend to gelcoat my new front end. I've probably said too much already .

.

Gelcoat provides (FWIU) the best barrier to seal the panels. If you have this oozing problem, wipe over the panel with acetone (over and over again till it almost stops - it will never stop) then apply gelcoat. Don't seal the bottom of the fender because the panel still needs to breathe out the bottom. Newer replacment PM panels aren't made with the same force (pressure from the molds) that oem panels were and especially with the top surround, gelcoat provides a very good barrier to stop this absorbion. I intend to gelcoat my new front end. I've probably said too much already

Gelcoat provides (FWIU) the best barrier to seal the panels. If you have this oozing problem, wipe over the panel with acetone (over and over again till it almost stops - it will never stop) then apply gelcoat. Don't seal the bottom of the fender because the panel still needs to breathe out the bottom. Newer replacment PM panels aren't made with the same force (pressure from the molds) that oem panels were and especially with the top surround, gelcoat provides a very good barrier to stop this absorbion. I intend to gelcoat my new front end. I've probably said too much already .

.

#16

Burning Brakes

I used to work at a place with a SMC operation. Was always trying to get them to get into the corvette restoration parts business but no luck...interesting process. Today's SMC compounds are very different chemically than what was available even 20 yrs. ago. And you can't use old stock as it expires within months...good epoxy primer is your friend.