What clearance Issues When stroking an LT-1 engine

#1

Burning Brakes

Thread Starter

Considering changing the stroke when rebuilding my 71 Lt-1 engine from 3.484 to 3.625 but maybe 3.7. How much grinding on the block if this done---using stroked rods and ARP rod bolts, etc. Make any difference whether I used 5.7 or 6 inch rods for clearance issues. Minimal boring would be done and rest of engine remains stock including solid lifters and an NOS LT-1 cam. Engine retains original look from exterior.

Thanks

Thanks

#2

Safety Car

Depends on which connecting rods you use and how much stroke.

Rod length doesn't make any difference. It all comes down to how the rod is shaped on the big end around the cap and bolts.

There can also be clearance issues with the rod hitting a few lobe noses on the camshaft as the rods approach TDC. The camshaft lobe height, base circle and how the rod is profiled on the shoulder effects rod to cam clearance.

Building a 370 inch SBC back in the 1970's was pretty common using that stroke and milling the quench area's of a 1.560 CH piston's .073 down to 1.487 CH.....

No one makes pistons the right CH today off the shelf for that combo so it'd be a custom piston or having a machine shop mill some 1.560 CH pistons. Custom pistons would be expensive and I don't know how many machine shops would be willing to do that kind of work today.

It's just not a common stroke combination and parts are harder to find for it.

An options would be pistons for a 3.75 stoke and 5.7 rod which is a 1.425 CH but the pistons would be way in the hole with an undecked block (9.025 deck height) and you would need the block decked down to 8.940 deck height to get zero deck.....

Performance wise with you keeping everything else stock 1971 LT1, I don't think increasing the stoke to 3 and 9/16" is going to do much for you except cost a lot more money.

Even if you went a very common 3.75 stoke with 5.7" or 6" rods where parts are very easy to find the stock heads and cam are going to make the performance much less that it could be with a modern heads and cam.

Will

Rod length doesn't make any difference. It all comes down to how the rod is shaped on the big end around the cap and bolts.

There can also be clearance issues with the rod hitting a few lobe noses on the camshaft as the rods approach TDC. The camshaft lobe height, base circle and how the rod is profiled on the shoulder effects rod to cam clearance.

Building a 370 inch SBC back in the 1970's was pretty common using that stroke and milling the quench area's of a 1.560 CH piston's .073 down to 1.487 CH.....

No one makes pistons the right CH today off the shelf for that combo so it'd be a custom piston or having a machine shop mill some 1.560 CH pistons. Custom pistons would be expensive and I don't know how many machine shops would be willing to do that kind of work today.

It's just not a common stroke combination and parts are harder to find for it.

An options would be pistons for a 3.75 stoke and 5.7 rod which is a 1.425 CH but the pistons would be way in the hole with an undecked block (9.025 deck height) and you would need the block decked down to 8.940 deck height to get zero deck.....

Performance wise with you keeping everything else stock 1971 LT1, I don't think increasing the stoke to 3 and 9/16" is going to do much for you except cost a lot more money.

Even if you went a very common 3.75 stoke with 5.7" or 6" rods where parts are very easy to find the stock heads and cam are going to make the performance much less that it could be with a modern heads and cam.

Will

Last edited by rklessdriver; 02-24-2017 at 10:05 AM.

#3

Melting Slicks

those pistons would be only .025 in the hole. Use of a steel shim head gasket of .019 would get you a quench height of .044. Any decking of the block would get you still closer - I'd clean the decks up with a .009 cut and have a quench of .035".

#4

NCM Grand Opening Veteran

Member Since: Sep 2005

Location: South of giving a damn

Posts: 20,899

Received 358 Likes

on

250 Posts

St. Jude Donor '11, '17

I built a 396 and there was a good bit of block grinding even with Eagle H beams, cam clearance was not an issue though. Look, if I was you I'd set that LT-1 aside and do this with another block. Chevy will sell you a bare block that has been factory ground for clearance for a very reasonable price. Course if you have cash there is always Dart.

#5

Safety Car

The above 3.75 stroke with 5.7 rods and 1.425 CH pistons comes to 9.0";

those pistons would be only .025 in the hole. Use of a steel shim head gasket of .019 would get you a quench height of .044. Any decking of the block would get you still closer - I'd clean the decks up with a .009 cut and have a quench of .035".

those pistons would be only .025 in the hole. Use of a steel shim head gasket of .019 would get you a quench height of .044. Any decking of the block would get you still closer - I'd clean the decks up with a .009 cut and have a quench of .035".

Using 1.425 CH pistons with the 3.625 stroke and 5.7 rod would require the block to be decked to 8.940ish....

Obviously using them on the intended stroke and rod length works out proper.

Will

#6

Le Mans Master

I built a 396 and there was a good bit of block grinding even with Eagle H beams, cam clearance was not an issue though. Look, if I was you I'd set that LT-1 aside and do this with another block. Chevy will sell you a bare block that has been factory ground for clearance for a very reasonable price. Course if you have cash there is always Dart.

#7

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

I definitely would not be stroking an OEM LT-1....get a used 350 block cheap and make it into a 383 if that is what you want to do but the LT-1 has quite the SBC heritage and personally I would not modify the block, whether it can be seen or not, especially for 33 additional cubes....

Build a 406 clone LT-1 and giggle like a school girl......

Jebby

#8

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Considering changing the stroke when rebuilding my 71 Lt-1 engine from 3.484 to 3.625 but maybe 3.7. How much grinding on the block if this done---using stroked rods and ARP rod bolts, etc. Make any difference whether I used 5.7 or 6 inch rods for clearance issues. Minimal boring would be done and rest of engine remains stock including solid lifters and an NOS LT-1 cam. Engine retains original look from exterior.

Thanks

Thanks

I'm not understanding your non-standard stroke lengths. The normal path for offset grinding the crank is to use the smaller journal sbc rods which is 0.010" smaller but adds 0.020" of stroke for a 3.50". Using a 4.030" bore gives you 357 c.i.. But it does save you from decking the block and the smaller journal rods gonna have bigger clearance now than stock.

But this doesn't sound close to what your looking for so please elaborate if you can.

#9

Burning Brakes

Thread Starter

It's hard for me to ask too many questions because I'm not an engine rebuilding expert. I don't want to deck the numbers off the block---can you deck the block and not touch the pad where the numbers are??

My engine builder "thinks" he could stroke stroke it to 3.625 without doing an grinding on the block--would have to see the block, measure it, etc. My thought was why not stroke it if I don't have to grind anything and gain some lowend torque/HP.

I was going to use all new internal parts anyways--forged pistons, forged steel crank, rods, etc. so why not. Wouldn't have to offset grind the crank, and use whatever length rods--since new.

Would have block bored as little as possible to clean up the cylinder walls--maybe--0.005 or 0.010 or 0.020 but not 0.030--I hope.

Does this make sense?

My engine builder "thinks" he could stroke stroke it to 3.625 without doing an grinding on the block--would have to see the block, measure it, etc. My thought was why not stroke it if I don't have to grind anything and gain some lowend torque/HP.

I was going to use all new internal parts anyways--forged pistons, forged steel crank, rods, etc. so why not. Wouldn't have to offset grind the crank, and use whatever length rods--since new.

Would have block bored as little as possible to clean up the cylinder walls--maybe--0.005 or 0.010 or 0.020 but not 0.030--I hope.

Does this make sense?

#11

Race Director

Buy a 383 short block from these guys. It will be cheaper in the long run. You don't have to worry about your numbers being milled off. Just put all your stuff on it and no one will know the difference.

http://www.high-performance-engines....ain-p/sp15.htm

http://www.high-performance-engines....ain-p/sp15.htm

#12

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi W,

"-can you deck the block and not touch the pad where the numbers are??"

Think about it…. the decking procedure removes material from the top surfaces of the block.

The decking procedure must continue just beyond the mating surface for the head, but end before the stamp pad.

There will be a 'ledge' between the two; the height of which will depend on the amount the block is decked. (I remember seeing one that would have required rappelling gear to get down.)

Bearing in mind what I think are the constraints you're under with the REST of this rebuild do you think there will be a 10% increase in hp/torque? Do you think you'll be able to tell the difference.

Don't screw with a nice old car… if you want to go quick and be fast, buy something with 400+ hp, (they're everywhere), and have at it!

Regards,

Alan

"-can you deck the block and not touch the pad where the numbers are??"

Think about it…. the decking procedure removes material from the top surfaces of the block.

The decking procedure must continue just beyond the mating surface for the head, but end before the stamp pad.

There will be a 'ledge' between the two; the height of which will depend on the amount the block is decked. (I remember seeing one that would have required rappelling gear to get down.)

Bearing in mind what I think are the constraints you're under with the REST of this rebuild do you think there will be a 10% increase in hp/torque? Do you think you'll be able to tell the difference.

Don't screw with a nice old car… if you want to go quick and be fast, buy something with 400+ hp, (they're everywhere), and have at it!

Regards,

Alan

#13

Le Mans Master

Hi W,

"-can you deck the block and not touch the pad where the numbers are??"

Think about it…. the decking procedure removes material from the top surfaces of the block.

The decking procedure must continue just beyond the mating surface for the head, but end before the stamp pad.

There will be a 'ledge' between the two; the height of which will depend on the amount the block is decked. (I remember seeing one that would have required rappelling gear to get down.)

Bearing in mind what I think are the constraints you're under with the REST of this rebuild do you think there will be a 10% increase in hp/torque? Do you think you'll be able to tell the difference.

Don't screw with a nice old car… if you want to go quick and be fast, buy something with 400+ hp, (they're everywhere), and have at it!

Regards,

Alan

"-can you deck the block and not touch the pad where the numbers are??"

Think about it…. the decking procedure removes material from the top surfaces of the block.

The decking procedure must continue just beyond the mating surface for the head, but end before the stamp pad.

There will be a 'ledge' between the two; the height of which will depend on the amount the block is decked. (I remember seeing one that would have required rappelling gear to get down.)

Bearing in mind what I think are the constraints you're under with the REST of this rebuild do you think there will be a 10% increase in hp/torque? Do you think you'll be able to tell the difference.

Don't screw with a nice old car… if you want to go quick and be fast, buy something with 400+ hp, (they're everywhere), and have at it!

Regards,

Alan

With everything else stock on the LT-1 but the rotating assembly change, you would be lucky for a 7-8% increase in power, more likely about 5% without optimizing/changing other components like compression, cylinder heads, and cam....would barely be noticeable versus a freshly built OEM LT-1. You could easily get the same increase with a freshly built LT-1 OEM with a good set of LT Headers, 2.5 duals, X pipe crossover and free flowing mufflers...prbs more of an increase.

#14

Le Mans Master

#15

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,926 Likes

on

1,931 Posts

Considering changing the stroke when rebuilding my 71 Lt-1 engine from 3.484 to 3.625 but maybe 3.7. How much grinding on the block if this done---using stroked rods and ARP rod bolts, etc. Make any difference whether I used 5.7 or 6 inch rods for clearance issues. Minimal boring would be done and rest of engine remains stock including solid lifters and an NOS LT-1 cam. Engine retains original look from exterior.

Thanks

Thanks

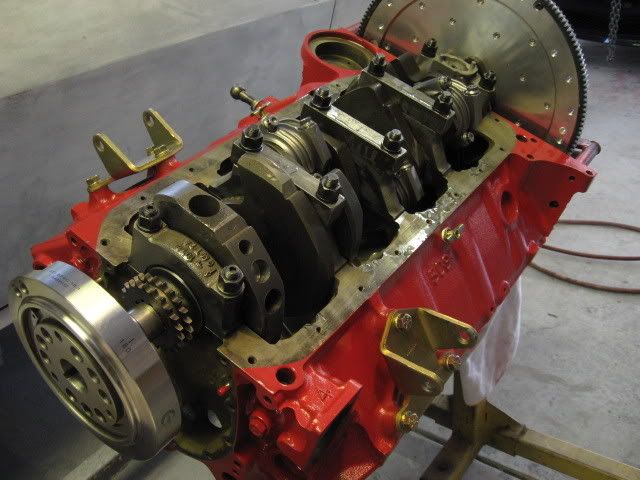

Whether or not you have to notch the block depends mostly on the rods you use. Here is a 3.75" stroke crank I installed in a 350, and there is no block notching needed:

Here is the same 3.75" stroke crank installed in a bored 400 block with some heavy duty H-beam rods, and you can see the little notches I had to put in the oil pan rails in order to get the rod bolts to clear:

These mods are easy to do with a standard-stroke crank - not sure where you're going to find cranks with the strokes you're looking for - sounds expensive to custom grind one with the 3.625 or 3.7" with all the custom parts you'll have to have made just to get an odd-ball 364-inch motor or a 372 (with minimal gains in power). You also need to consider the additional swept volume when considering compression ratio and get pistons with enough of a dish to allow use of the stock LT-1 heads. Either way, I agree with the above posts: Don't do it to an original LT-1. Find a cheap junkyard 350 and build the stroker from that. ...And in answer to your question in post #9 about the 3.625 stroker making sense, the answer is "no."

Lars

Last edited by lars; 02-26-2017 at 04:37 PM.

#16

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Scat and Crower make I beams that fit easily

Hard to find a machinist to try decking like that

Where does one buy new Gen 1 blocks havent seen them in many yrs

3.6 stroke not worth it go 3.75 get some good heads paint em up mill the emblems etc get a better solid flat tappet and a modern hp type carb headers.can still dress it up to look stockish I dont think anyone pays attention to headers if they do who cares? As Will said stroking with stock heads cam esp manifolds dont waste your money. It will have a little more grunt but for the money you spend youll be disappointed. Swain does a nice white jet coating hows that for period? If you got a few bux get a dart block and go 421 sbc now youre talking

If you got a few bux get a dart block and go 421 sbc now youre talking

Believe me power difference is nuts dont be afraid of a little compresion if you have a modern head. There is no way in hell my old solid roller 350 would hold a candle to the 383. Its that big a difference like the smaller motor with 6 lbs of boost better. Just leave the LT1 in a corner of your garage one drive with the bigger motor done right youll forget all about that nostalgia let the next guy fuss over it. Stroker kits are so cheap these days just dont cheap out on heads/valvetrain

This is about having fun. LT-1s by todays standards are super slow even with head work cam tuning etc. btdt

Hard to find a machinist to try decking like that

Where does one buy new Gen 1 blocks havent seen them in many yrs

3.6 stroke not worth it go 3.75 get some good heads paint em up mill the emblems etc get a better solid flat tappet and a modern hp type carb headers.can still dress it up to look stockish I dont think anyone pays attention to headers if they do who cares? As Will said stroking with stock heads cam esp manifolds dont waste your money. It will have a little more grunt but for the money you spend youll be disappointed. Swain does a nice white jet coating hows that for period?

If you got a few bux get a dart block and go 421 sbc now youre talking

If you got a few bux get a dart block and go 421 sbc now youre talkingBelieve me power difference is nuts dont be afraid of a little compresion if you have a modern head. There is no way in hell my old solid roller 350 would hold a candle to the 383. Its that big a difference like the smaller motor with 6 lbs of boost better. Just leave the LT1 in a corner of your garage one drive with the bigger motor done right youll forget all about that nostalgia let the next guy fuss over it. Stroker kits are so cheap these days just dont cheap out on heads/valvetrain

This is about having fun. LT-1s by todays standards are super slow even with head work cam tuning etc. btdt

Last edited by cv67; 02-26-2017 at 06:59 PM.