Ac 101

#42

Pro

Thread Starter

Crispyc21--

You're getting good advice here. Here's another tip.

It looks like you're just a bit shy of a full chg. I know you're close to the chart specs but not every car fits that mold.

Sometimes we need to play with chg level a bit to get the most out of that particular system. Chg level is very touchy with R134.

Go back and look at the pic of the gages hooked to my car and notice low=35 and high=350. At that chg level my center vent temp was 50 deg.

Try adding a bit more and see what happens. You can always take it out if it doesn't help.

There are many things, beyond chg level, that can adversely affect cooling(air in the system, excess oil, dirty coils, etc. etc. etc.)

Play with the chg a bit, it's a good learning experience and provides quality time with your Vette.

You're getting good advice here. Here's another tip.

It looks like you're just a bit shy of a full chg. I know you're close to the chart specs but not every car fits that mold.

Sometimes we need to play with chg level a bit to get the most out of that particular system. Chg level is very touchy with R134.

Go back and look at the pic of the gages hooked to my car and notice low=35 and high=350. At that chg level my center vent temp was 50 deg.

Try adding a bit more and see what happens. You can always take it out if it doesn't help.

There are many things, beyond chg level, that can adversely affect cooling(air in the system, excess oil, dirty coils, etc. etc. etc.)

Play with the chg a bit, it's a good learning experience and provides quality time with your Vette.

#43

Team Owner

Member Since: Jun 1999

Location: San Antonio Texas

Posts: 30,492

Likes: 0

Received 11 Likes

on

6 Posts

Cruise-In IV Veteran

Cruise-In V Veteran

Just wanted to update on my situation from last night. I noticed that when the car is first started the A/C is not as cold as it is in about 5 minutes. So when I got home last night I left the car running, grabbed my thermometer and stuck it in the center vent. At IDLE, max A/C, max fan, no gauges hooked up, the center vent temp was a cold 55 degrees. I figured the outside temp and humidity were similiar to the night before, if not a bit warmer. Based on this temp reading alone I determined it was not necessary to add anymore r134 to the system.

This morning, same behavior, starts out semi-cold, but after a few minutes blows colder. Maybe I'm imagining things but now that I am paying close attention it appears that the temp fluctuates from real cold to just semi-cold from time to time, even though I have the manual A/C and am not adjusting anything. I figure that it normal though, is that right?

But at least I have the tools and plenty of r134 in the event I need some more cold boost!

This morning, same behavior, starts out semi-cold, but after a few minutes blows colder. Maybe I'm imagining things but now that I am paying close attention it appears that the temp fluctuates from real cold to just semi-cold from time to time, even though I have the manual A/C and am not adjusting anything. I figure that it normal though, is that right?

But at least I have the tools and plenty of r134 in the event I need some more cold boost!

#44

Drifting

Thanks for all the info. Itís a great help. I have a quick question about air in the system and getting it out. When I have the low side hooked up and open the valve air will come out. To get all the air out do I just keep that open until something else comes out? When do I stop, when a mist starts coming out?

#45

Pro

Thanks for all the info. It’s a great help. I have a quick question about air in the system and getting it out. When I have the low side hooked up and open the valve air will come out. To get all the air out do I just keep that open until something else comes out? When do I stop, when a mist starts coming out?

Trying to do this through the low side is fruitless as the air is not there when the system is off, and when the system is running the air is mixed with the gas so you would have to bleed the entire charge and then you would allow more air and moisture into the system when the charge was gone, but the compressor would shut off before that happened on low pressure.

I'll attempt to explain the system operation

in layman's terms.

The compressor is basically a pump, it draws the refrigerant,(r134a), in the form of a vapor from the evaporator, then compresses it and sends it to the bottom line of the condenser, it is cooled in the condenser and exits at the top line and goes back to the evaporator in the form of a liquid,(high pressure side). On the way it passes through the orifice tube which is a small tube with tiny holes in it which allow only so much ref at a time to pass through, this action makes the liquid under high pressure coming in, turn to low pressure going out, and because of the properties of the ref134a it vaporizes which makes it extremely cold,(about 30 below zero), so that when it enters the evaporator it will absorb the heat which is being displaced there by the fan blowing through the evaporator. The result of this is the ref absorbs the heat and the air blowing through it comes back to the cabin cooled while the ref134a is drawn back to the compressor to be sent to the condenser to be cooled and start over again. In effect it is a sealed no beginning, no end circle. Of course there are electronic controls, and a accumulator/drier to clean the ref of moisture and such, but this is the basics of the system. The whole process hinges on the fact that the ref is clean and does not contain air, or dirt, or moisture, and that the condenser is clean, and the parts are working as they were designed to do. And the system is designed to work with a specific amount of ref134a. Less or more will change the pressure differentials and the efficiency of the system.

Hope this clears it up for you a bit.

Below is a more technical explanation of how the ref system works.

++++++++++++++++++++++++++++++++++

A/C Cycle

Refrigerant is the key element in an air conditioning system. R-134a is presently the only EPA approved refrigerant for automotive use. R-134a is a very low temperature gas that can transfer the undesirable heat and moisture from the passenger compartment to the outside air.

The A/C system used on this vehicle is a non-cycling system. Non-cycling A/C systems use a high pressure switch to protect the A/C system from excessive pressure. The high pressure switch will OPEN the electrical signal to the compressor clutch, if the refrigerant pressure becomes excessive. After the high and the low sides of the A/C system pressure equalize, the high pressure switch will CLOSE. This completes the electrical circuit to the compressor clutch. The A/C system is also mechanically protected with the use of a high pressure relief valve. If the high pressure switch were to fail or if the refrigerant system becomes restricted and refrigerant pressure continues to rise, the high pressure relief will pop open and release refrigerant from the system.

The A/C compressor is belt driven and operates when the magnetic clutch is engaged. The compressor builds pressure on the vapor refrigerant. Compressing the refrigerant also adds heat. The refrigerant is discharged from the compressor through the discharge hose, and forced through the condenser and then through the balance of the A/C system.

Compressed refrigerant enters the condenser at a high-temperature, high-pressure vapor state. As the refrigerant flows through the condenser, the heat is transferred to the ambient air passing through the condenser. Cooling causes the refrigerant to condense and change from a vapor to a liquid state.

The condenser is located in front of the radiator for maximum heat transfer. The condenser is made of aluminum tubing and aluminum cooling fins, which allows rapid heat transfer for the refrigerant. The semi-cooled liquid refrigerant exits the condenser and flows through the liquid line to the orifice tube.

The orifice tube is located in the liquid line between the condenser and the evaporator. The orifice tube is the dividing point for the high and the low pressure sides of the A/C system. As the refrigerant passes through the orifice tube, the pressure on the refrigerant is lowered, causing the refrigerant to vaporize at the orifice tube. The orifice tube also measures the amount of liquid refrigerant that can flow into the evaporator.

Refrigerant exiting the orifice tube flows into the evaporator core in a low-pressure, liquid state. Ambient air is drawn through the HVAC module and passes through the evaporator core. Warm and moist air will cause the liquid refrigerant to boil inside the evaporator core. The boiling refrigerant absorbs heat from the ambient air and draws moisture onto the evaporator. The refrigerant exits the evaporator through the suction line and flows back to the compressor in a vapor state, completing the A/C cycle of heat removal. At the compressor, the refrigerant is compressed again and the cycle of heat removal is repeated.

The conditioned air is distributed through the HVAC module for passenger comfort. The heat and moisture removed from the passenger compartment condenses, and discharges from the HVAC module as water.

EDIT-Almost forgot, one trick as to how to tell if there is a lot of air in the system is the guages , they will flutter, they should have a steady rising or dropping action as the pressures change, if they flutter it could mean that there is air in the system, it could also mean the the compressor valves are bad, but it usually means there is air in there.

Last edited by bestvettever; 07-30-2008 at 02:58 PM.

The following users liked this post:

VaughnCo (07-06-2017)

#47

Team Owner

Member Since: Jun 1999

Location: San Antonio Texas

Posts: 30,492

Likes: 0

Received 11 Likes

on

6 Posts

Cruise-In IV Veteran

Cruise-In V Veteran

Just wanted to update on my situation from last night. I noticed that when the car is first started the A/C is not as cold as it is in about 5 minutes. So when I got home last night I left the car running, grabbed my thermometer and stuck it in the center vent. At IDLE, max A/C, max fan, no gauges hooked up, the center vent temp was a cold 55 degrees. I figured the outside temp and humidity were similiar to the night before, if not a bit warmer. Based on this temp reading alone I determined it was not necessary to add anymore r134 to the system.

This morning, same behavior, starts out semi-cold, but after a few minutes blows colder. Maybe I'm imagining things but now that I am paying close attention it appears that the temp fluctuates from real cold to just semi-cold from time to time, even though I have the manual A/C and am not adjusting anything. I figure that it normal though, is that right?

But at least I have the tools and plenty of r134 in the event I need some more cold boost!

This morning, same behavior, starts out semi-cold, but after a few minutes blows colder. Maybe I'm imagining things but now that I am paying close attention it appears that the temp fluctuates from real cold to just semi-cold from time to time, even though I have the manual A/C and am not adjusting anything. I figure that it normal though, is that right?

But at least I have the tools and plenty of r134 in the event I need some more cold boost!

Plasticfan,

I need some more advice/expertise based on my situation. I noticed that my A/C started getting warm again so last night I recharged it again and I noticed a couple things.

First, when I went to charge it I noticed again that the Low-side and High-side pressures were low. After adding a fair amount of r134 to the system with the motor running at 2000rpms the high side pressure finally rose over 300psi, but the low side stayed near 22psi......BUT when the rpms dropped back down to idle the low-side pressure jumped to 35psi and held with the high side pressure then dropping down some. Is that normal? Based on humidity/temp conditions how is it possible to get both the low-side and high-side pressures to match the pressure chart as each side seems to depend different on engine speed? BTW, I did get the air-temp out of the vent down to 57 degrees which was cooler then conditions merit based on the chart.

The second thing I noticed was this: If you follow the piping from the High-Side connection point back toward the Low-Side connection point you come to a section of black rubber hose that seems to connect the two metal sections of the system, it starts right in front of the oil filler cap. I noticed at this point that hose didn't seem to be real snug on the metal tubing and I was able to slide the metal tubing another Ĺ - 1 inch further into the hose. There is no clamp to ensure this fits snuggly together. Could this be a point where the system is possibly losing refridgerant? Can anyone else check this spot and tell me how tight or lose their connection is for them.

Thanks!

#48

Pro

Thread Starter

Plasticfan,

I need some more advice/expertise based on my situation. I noticed that my A/C started getting warm again so last night I recharged it again and I noticed a couple things.

First, when I went to charge it I noticed again that the Low-side and High-side pressures were low. We have a leak we need to fix. Use dye or a spray bottle of soapy water on the connections to find it.

After adding a fair amount of r134 to the system with the motor running at 2000rpms the high side pressure finally rose over 300psi, but the low side stayed near 22psi......BUT when the rpms dropped back down to idle the low-side pressure jumped to 35psi and held with the high side pressure then dropping down some. Is that normal? To a degree, yes. The low side will go up and the high side will go down when we return to idle.

Based on humidity/temp conditions how is it possible to get both the low-side and high-side pressures to match the pressure chart as each side seems to depend different on engine speed? It appears you gained 13 psi low side upon return to idle. How much did you lose on the high side?

BTW, I did get the air-temp out of the vent down to 57 degrees which was cooler then conditions merit based on the chart. You're getting close. You may have a partially clogged orifice tube. Be sure to replace that if you open the system to fix the leak.

The second thing I noticed was this: If you follow the piping from the High-Side connection point back toward the Low-Side connection point you come to a section of black rubber hose that seems to connect the two metal sections of the system, it starts right in front of the oil filler cap. I noticed at this point that hose didn't seem to be real snug on the metal tubing and I was able to slide the metal tubing another Ĺ - 1 inch further into the hose. There is no clamp to ensure this fits snuggly together. Could this be a point where the system is possibly losing refridgerant? Can anyone else check this spot and tell me how tight or lose their connection is for them. That black rubber hose is just an insulator to protect the line. It is slipped over the metal line. It does not carry any refrig. Mine does slip a bit.

Thanks!

I need some more advice/expertise based on my situation. I noticed that my A/C started getting warm again so last night I recharged it again and I noticed a couple things.

First, when I went to charge it I noticed again that the Low-side and High-side pressures were low. We have a leak we need to fix. Use dye or a spray bottle of soapy water on the connections to find it.

After adding a fair amount of r134 to the system with the motor running at 2000rpms the high side pressure finally rose over 300psi, but the low side stayed near 22psi......BUT when the rpms dropped back down to idle the low-side pressure jumped to 35psi and held with the high side pressure then dropping down some. Is that normal? To a degree, yes. The low side will go up and the high side will go down when we return to idle.

Based on humidity/temp conditions how is it possible to get both the low-side and high-side pressures to match the pressure chart as each side seems to depend different on engine speed? It appears you gained 13 psi low side upon return to idle. How much did you lose on the high side?

BTW, I did get the air-temp out of the vent down to 57 degrees which was cooler then conditions merit based on the chart. You're getting close. You may have a partially clogged orifice tube. Be sure to replace that if you open the system to fix the leak.

The second thing I noticed was this: If you follow the piping from the High-Side connection point back toward the Low-Side connection point you come to a section of black rubber hose that seems to connect the two metal sections of the system, it starts right in front of the oil filler cap. I noticed at this point that hose didn't seem to be real snug on the metal tubing and I was able to slide the metal tubing another Ĺ - 1 inch further into the hose. There is no clamp to ensure this fits snuggly together. Could this be a point where the system is possibly losing refridgerant? Can anyone else check this spot and tell me how tight or lose their connection is for them. That black rubber hose is just an insulator to protect the line. It is slipped over the metal line. It does not carry any refrig. Mine does slip a bit.

Thanks!

Try and find that leak and let's see what happens.

Try and find that leak and let's see what happens.

#50

Team Owner

Member Since: Jun 1999

Location: San Antonio Texas

Posts: 30,492

Likes: 0

Received 11 Likes

on

6 Posts

Cruise-In IV Veteran

Cruise-In V Veteran

Thanks!

#52

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

A little extra information for Dons SUPERB thread:

For those that are wanting to know just why your AC System doesn't blow Arctic cold air when something is wrong; heres a bit of information on the INs and OUTs of basic AC Theory and Operation.

Your AC Compressor pumps R-134 GAS ONLY. The LOW or "Suction Side" of your AC compressor contains GAS (R-134) and connects to the suction side of the compressor. The piping on the SUCTION SIDE of the compressor is normally larger than the piping on the High Pressure side.

The compressor pumps that low pressure gas through the compressor up to the HIGH Side or compressor output side of the system.

The high pressure R-134 Gas is VERY HOT and needs to be cooled off. It enters the CONDENSER COIL which is up front in the front area of the radiator and gives up HEAT to the atmosphere to allow that high pressure GAS to cool into a high pressure liquid form of R-134.

The high pressure R-134 liquid, if allowed to escape into the atmosphere, will QUICKLY BOIL OFF and evaporate into a GAS. This change of state, causes the R-134 to get EXTREMELY COLD! It can and will cause FROST BITE and burn human Skin immediately on contact!

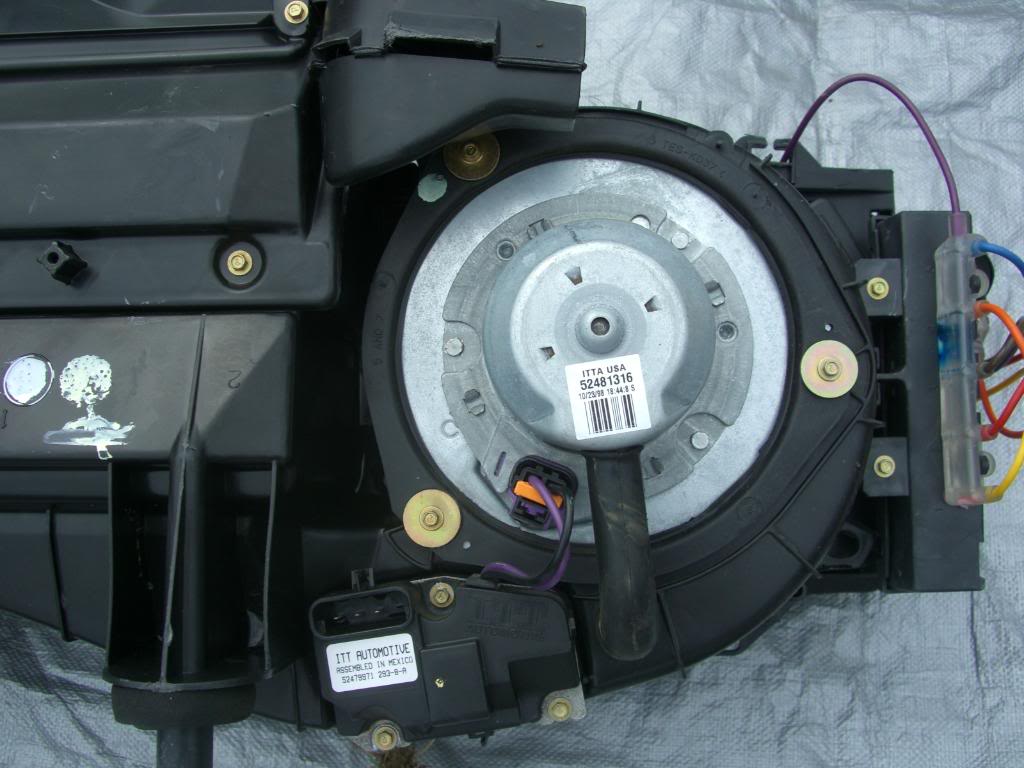

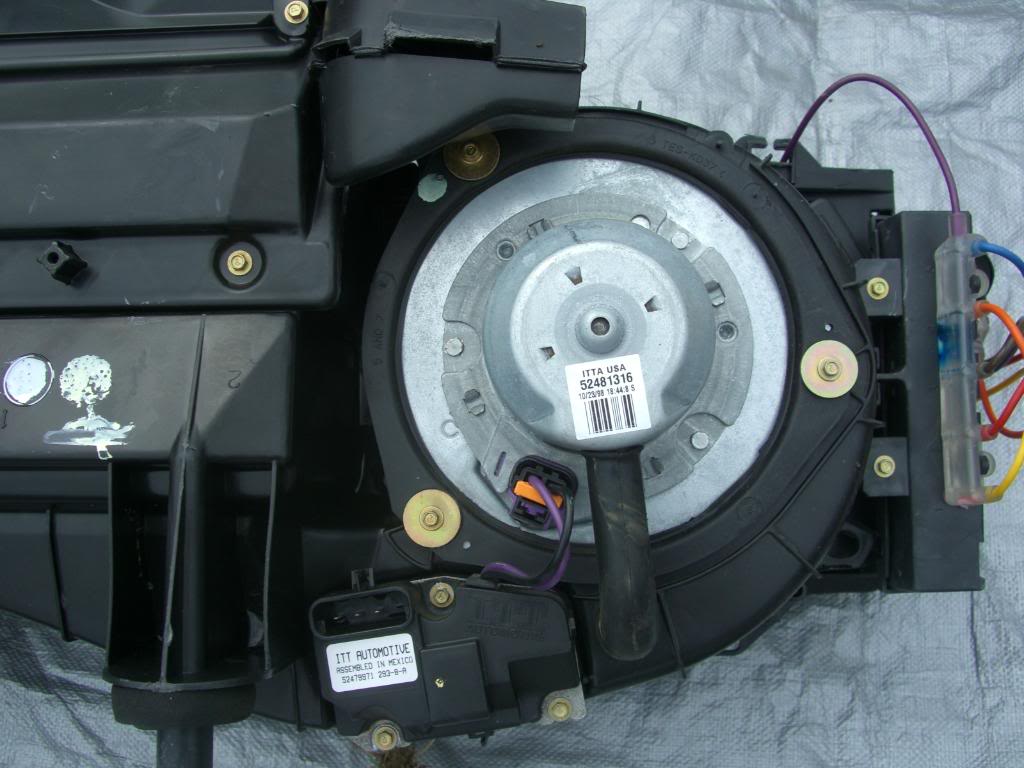

The C5 AC System is a self contained loop and the LIQUID flows through a small tube with a screen and a orifice (Orifice Tube). The small orifice allows an exact amount of LIQUID R-134 to shoot into the EVAPORATOR which is located in the dash HVAC AIR BOX:

The EVAPORATOR allows that Liquid R-134 to evaporate into a low pres sue gas which when the Liquid changes state or boils off into a gas, "changes state" and removes HEAT from the evaporator coils and it gets VERY COLD! So cold in fact that, if there is no air flow over the evaporator, it can freeze into a solid block of ICE!

The engineered pressure in the system, the size of the evaporator and size of the Orifice Tube allow that high pressure injected liquid R-134 from the orifice tube to flow from one end of the evaporator tube to the other end of the evaporator and still remove the heat thru-out the entire length of the evaporator.

IF,,,,,,,,,,the pressure is too low, the shot of R-134 in the evaporator will NOT be enough to cool the entire length of the evaporator. (THAT IS WHY SOMETIMES THE PASSENGERS SIDE IS COLD AND DRIVERS SIDE IS HOT!!)

If there is too much pressure in the LOW side, the liquid is too much in the evaporator and again, it may operate the OPPOSITE of what is listed directly above. NOTE!! This is NOT the only reason for zone differences in tempreature but one of many.

Once the liquid R-134 does its job and evaporates into a gas in the evaporator coil, it exits the evaporator and heads to the SUCTION side of the compressor thru the accumulator and the process starts all over again.

This a very simplified explanation of what happens and not meant to cover all of the things that one need to know to understand what is happening inside the system.

Here are a few more points that you need to know:

The system contains a SPECIAL AC System OIL. It needs an EXACT amount of oil to lubricate the compressor. When you loose Freon, you normally loose small quantiles of oil. If you loose enough, you will eventually destroy the compressor. How do you know if you need oil?? You don't! If your loosing lots of R-134, you probably need some oil. I always add Freon that contains Refrigerant Oil

How do you know if you need oil?? You don't! If your loosing lots of R-134, you probably need some oil. I always add Freon that contains Refrigerant Oil

You also have something called an accumulator.

It is a multi purposed canister and very important. It insures that ONLY R-134 gas gets back to the pump. It also holds any EXTRA OIL that the system has and doesn't need. It also has a desiccant filter bag in it that removes very fine particles of dirt and removes and holds any residual moisture that is in the system or enters the system after it was evacuated when it was serviced at the factory or at a shop. If the moisture in the system is MORE than the desiccant bag can handle, the moisture will interact with the R-134 and form an acid. The acid will interact with the aluminum AC piping and condenser and evaporator and etch tiny holes into the aluminum from the inside out. Read that as massive $$$$$$$$$$$$$$$ out of wallet.

It also has a desiccant filter bag in it that removes very fine particles of dirt and removes and holds any residual moisture that is in the system or enters the system after it was evacuated when it was serviced at the factory or at a shop. If the moisture in the system is MORE than the desiccant bag can handle, the moisture will interact with the R-134 and form an acid. The acid will interact with the aluminum AC piping and condenser and evaporator and etch tiny holes into the aluminum from the inside out. Read that as massive $$$$$$$$$$$$$$$ out of wallet.

When you OPEN the sealed HVAC system to replace something, you introduce AIR, MOISTURE and DIRT into that perfectly clean system (no mater how careful your are) These are called "NON CONDENSIBLE" and detract to from the systems efficiency.

If you replace a part (Say a Compressor) you have to:

-Install the new compressor

- Add the correct amount of OIL back into the system for the Compressor and new Accumulator!!!!

- Replace the O rings

- Replace the ACCUMULATOR

- EVACUATE the system with a high capacity vacuum pump

- ADD THE EXACT AMOUNT OF R-134

NOTE!!! Any time the system is opened for what ever reason, you should at a MINIMUM replace the orifice Tube and add a small amount of oil and vacuum out "EVACUATE" the system!

You do NOT need a $1000 vacuum pump to evacuate the system. You can get a shop air powered vacuum pump for approx $50. Some people have improvised and removed the AC Compressor from a discarded Refrigerator or Dehumidifier and rigged that up to connect to the LOW side and draw a vacuum on the system.

A by-product of cooling hot humid air is CONDENSATION. Condensation forms on the EVAPORATOR COIL as it cools the humid air. That water collects in the HVAC Air box. It needs to escape or it will drip into the cabin and get the interior wet. Our C5 has a HVAC Condensate Drain in the Air Box that goes thru the fire wall and lets the water drip onto the ground.

Here is the drain tube up close and personal:

Rubber 90 degree rubber boot attached to the HVAC drain tube on the passengers fire wall:

Note!! There are TWO rubber tubes in this picture. The one on the right supplies FRESH COOL AIR to the HVAC fan motor and DOES NOT serve as a drain hose. It will infact get water in it if the HVAC Air Box back floods with condensate water because of a clogged air box drain.

This is a QUICK and very simple overview of your C5 AC system and how it works. Hope it helps!

Bill C

For those that are wanting to know just why your AC System doesn't blow Arctic cold air when something is wrong; heres a bit of information on the INs and OUTs of basic AC Theory and Operation.

Your AC Compressor pumps R-134 GAS ONLY. The LOW or "Suction Side" of your AC compressor contains GAS (R-134) and connects to the suction side of the compressor. The piping on the SUCTION SIDE of the compressor is normally larger than the piping on the High Pressure side.

The compressor pumps that low pressure gas through the compressor up to the HIGH Side or compressor output side of the system.

The high pressure R-134 Gas is VERY HOT and needs to be cooled off. It enters the CONDENSER COIL which is up front in the front area of the radiator and gives up HEAT to the atmosphere to allow that high pressure GAS to cool into a high pressure liquid form of R-134.

The high pressure R-134 liquid, if allowed to escape into the atmosphere, will QUICKLY BOIL OFF and evaporate into a GAS. This change of state, causes the R-134 to get EXTREMELY COLD! It can and will cause FROST BITE and burn human Skin immediately on contact!

The C5 AC System is a self contained loop and the LIQUID flows through a small tube with a screen and a orifice (Orifice Tube). The small orifice allows an exact amount of LIQUID R-134 to shoot into the EVAPORATOR which is located in the dash HVAC AIR BOX:

The EVAPORATOR allows that Liquid R-134 to evaporate into a low pres sue gas which when the Liquid changes state or boils off into a gas, "changes state" and removes HEAT from the evaporator coils and it gets VERY COLD! So cold in fact that, if there is no air flow over the evaporator, it can freeze into a solid block of ICE!

The engineered pressure in the system, the size of the evaporator and size of the Orifice Tube allow that high pressure injected liquid R-134 from the orifice tube to flow from one end of the evaporator tube to the other end of the evaporator and still remove the heat thru-out the entire length of the evaporator.

IF,,,,,,,,,,the pressure is too low, the shot of R-134 in the evaporator will NOT be enough to cool the entire length of the evaporator. (THAT IS WHY SOMETIMES THE PASSENGERS SIDE IS COLD AND DRIVERS SIDE IS HOT!!)

If there is too much pressure in the LOW side, the liquid is too much in the evaporator and again, it may operate the OPPOSITE of what is listed directly above. NOTE!! This is NOT the only reason for zone differences in tempreature but one of many.

Once the liquid R-134 does its job and evaporates into a gas in the evaporator coil, it exits the evaporator and heads to the SUCTION side of the compressor thru the accumulator and the process starts all over again.

This a very simplified explanation of what happens and not meant to cover all of the things that one need to know to understand what is happening inside the system.

Here are a few more points that you need to know:

The system contains a SPECIAL AC System OIL. It needs an EXACT amount of oil to lubricate the compressor. When you loose Freon, you normally loose small quantiles of oil. If you loose enough, you will eventually destroy the compressor.

How do you know if you need oil?? You don't! If your loosing lots of R-134, you probably need some oil. I always add Freon that contains Refrigerant Oil

How do you know if you need oil?? You don't! If your loosing lots of R-134, you probably need some oil. I always add Freon that contains Refrigerant Oil

You also have something called an accumulator.

It is a multi purposed canister and very important. It insures that ONLY R-134 gas gets back to the pump. It also holds any EXTRA OIL that the system has and doesn't need.

It also has a desiccant filter bag in it that removes very fine particles of dirt and removes and holds any residual moisture that is in the system or enters the system after it was evacuated when it was serviced at the factory or at a shop. If the moisture in the system is MORE than the desiccant bag can handle, the moisture will interact with the R-134 and form an acid. The acid will interact with the aluminum AC piping and condenser and evaporator and etch tiny holes into the aluminum from the inside out. Read that as massive $$$$$$$$$$$$$$$ out of wallet.

It also has a desiccant filter bag in it that removes very fine particles of dirt and removes and holds any residual moisture that is in the system or enters the system after it was evacuated when it was serviced at the factory or at a shop. If the moisture in the system is MORE than the desiccant bag can handle, the moisture will interact with the R-134 and form an acid. The acid will interact with the aluminum AC piping and condenser and evaporator and etch tiny holes into the aluminum from the inside out. Read that as massive $$$$$$$$$$$$$$$ out of wallet.When you OPEN the sealed HVAC system to replace something, you introduce AIR, MOISTURE and DIRT into that perfectly clean system (no mater how careful your are) These are called "NON CONDENSIBLE" and detract to from the systems efficiency.

If you replace a part (Say a Compressor) you have to:

-Install the new compressor

- Add the correct amount of OIL back into the system for the Compressor and new Accumulator!!!!

- Replace the O rings

- Replace the ACCUMULATOR

- EVACUATE the system with a high capacity vacuum pump

- ADD THE EXACT AMOUNT OF R-134

NOTE!!! Any time the system is opened for what ever reason, you should at a MINIMUM replace the orifice Tube and add a small amount of oil and vacuum out "EVACUATE" the system!

You do NOT need a $1000 vacuum pump to evacuate the system. You can get a shop air powered vacuum pump for approx $50. Some people have improvised and removed the AC Compressor from a discarded Refrigerator or Dehumidifier and rigged that up to connect to the LOW side and draw a vacuum on the system.

A by-product of cooling hot humid air is CONDENSATION. Condensation forms on the EVAPORATOR COIL as it cools the humid air. That water collects in the HVAC Air box. It needs to escape or it will drip into the cabin and get the interior wet. Our C5 has a HVAC Condensate Drain in the Air Box that goes thru the fire wall and lets the water drip onto the ground.

Here is the drain tube up close and personal:

Rubber 90 degree rubber boot attached to the HVAC drain tube on the passengers fire wall:

Note!! There are TWO rubber tubes in this picture. The one on the right supplies FRESH COOL AIR to the HVAC fan motor and DOES NOT serve as a drain hose. It will infact get water in it if the HVAC Air Box back floods with condensate water because of a clogged air box drain.

This is a QUICK and very simple overview of your C5 AC system and how it works. Hope it helps!

Bill C

Last edited by Bill Curlee; 07-07-2009 at 11:39 PM.

#53

Burning Brakes

Member Since: May 2007

Location: Denver, North Carolina

Posts: 1,078

Likes: 0

Received 5 Likes

on

2 Posts

Any of you A/C gurus care to take a guess as to why my C5 would blow 45 degree air at the vents while the car is sitting still at idle, but go up to 60+ degrees while going down the road?

#54

Melting Slicks

Member Since: Apr 2009

Location: Gastonia NC

Posts: 2,772

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '10

Wow that is a ton of great information. Thanks so much guys for the time and energy for the write ups. Subscribing as this was something I had wanted to check. Thanks again.

#55

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

#56

Racer

Member Since: Aug 2007

Location: Moline Illinois

Posts: 485

Likes: 0

Received 0 Likes

on

0 Posts

Walmart has a nice little recharge kit with the hose and gauge for less than 20 bucks, gauge and hose is reusable. Comes with oil and leak stop in the can.

Just used it today, put in half a can and it lowered the temp considerably!

Great info from all!

Bill, I read the other forum post, I know my low side pressure is to high, atleast at idle (will check at RPM Wed.) but the air is super cool.

Chris

Just used it today, put in half a can and it lowered the temp considerably!

Great info from all!

Bill, I read the other forum post, I know my low side pressure is to high, atleast at idle (will check at RPM Wed.) but the air is super cool.

Chris

#57

Racer

I've been reading all the posts I can find but haven't found anything related to my problem.

Shortly after a recent "spirited run" with the A/C running, the A/C started blowing warm air. This was a couple of weeks ago and the problem persists. Today, I hooked up a set of gauges but without even turning on the system the low side gauge needle immediately moved to the maximum on the gauge (350 psi). The compressor seems to be working fine in that it turns on immediately when the A/C button is pressed and turns off the button is pressed again. The cooling fans also seem to be working. Anyone care to guess what is causing my problem?

Thanks.

Shortly after a recent "spirited run" with the A/C running, the A/C started blowing warm air. This was a couple of weeks ago and the problem persists. Today, I hooked up a set of gauges but without even turning on the system the low side gauge needle immediately moved to the maximum on the gauge (350 psi). The compressor seems to be working fine in that it turns on immediately when the A/C button is pressed and turns off the button is pressed again. The cooling fans also seem to be working. Anyone care to guess what is causing my problem?

Thanks.

#58

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

Holy Crap!!! The orifice tube would have to be completely clogged (sealed) to get and maintain that pressure. DO NOT run the system until you can suction down the system and inspect the orifice tube.

BC

BC

#59

Racer

Bill, Thanks for the response. Excuse my ignorance, but do you mean to drain/vacuum the system completely? Also, what do you think would cause it to clog? Until, about a week ago, the a/c operated as it should and without any hint of problems.

Thanks

Dan

P.S. I checked the DIC and it is not showing any codes.

Thanks

Dan

P.S. I checked the DIC and it is not showing any codes.

#60

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

YES! Pump down the system (thats the correct way) and remove all the charge. I made a misquote, For the LOW side to be that high, the return to the pump would have to be clogged. That would be the check valves on the back of the pump stuck shut. If the orfice tube was clogged, the high side would be very high and you would have very low suction pressure.

When the system shuts down, the high pressure side should EQUALIZE with the low pressure side and the highest pressure that you should see is around 90-110 PSI on the HIGH and LOW side. During operation the suction side (LOW SIDE) should be around 27-35 PSI and high side should be 150-330.

Are you SURE that you had the gages connected properly? Ive NEVER seen this issue before

Very strange.

When the system shuts down, the high pressure side should EQUALIZE with the low pressure side and the highest pressure that you should see is around 90-110 PSI on the HIGH and LOW side. During operation the suction side (LOW SIDE) should be around 27-35 PSI and high side should be 150-330.

Are you SURE that you had the gages connected properly? Ive NEVER seen this issue before

Very strange.