"Shifter Adjustment" Question

#41

Le Mans Master

Member Since: May 2006

Location: DuBois PA

Posts: 5,987

Likes: 0

Received 18 Likes

on

16 Posts

St. Jude Donor '11-'12-'13-'14-'15

Damn Jeff... You coulda wore some better looking shorts at least!

mischiefse7en - I would make sure that someone hadn't shimmed out your detent bolt in the tranny OR installed the actual Anti Venom Bolt, You are running a stock shifter right?

Tim

mischiefse7en - I would make sure that someone hadn't shimmed out your detent bolt in the tranny OR installed the actual Anti Venom Bolt, You are running a stock shifter right?

Tim

Last edited by tstar; 09-06-2009 at 03:29 AM.

#43

NCM Bash 2008-2018

Member Since: Jul 1999

Location: Granby, MA Talladega Super Speedway Vettes 4 Vets Ambassador

Posts: 9,008

Received 75 Likes

on

60 Posts

Middle TN Events Coordinator

Cruise-In 1, 3, 9. 10 & 11 Veteran

Did you try this with the car running or not running? Make sure it is running and the temperature is warmed up. Must have something to do with the fluids being moved around and under pressure in the transmission. Mine won't snap back to center from the right side all the time either if the car is not running. It's probably recommended that the transmission be warmed up as well before you start moving the gearbox around like I demonstrated.

#44

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 16 Likes

on

16 Posts

St. Jude Donor '09-'10-'11

XtremeVette,

Nice shifter ****! I know this is a little off topic, but where does the **** get power? It would be even cooler yet if it would change color while shifting into a different gear!

Nice shifter ****! I know this is a little off topic, but where does the **** get power? It would be even cooler yet if it would change color while shifting into a different gear!

#45

Burning Brakes

Did you try this with the car running or not running? Make sure it is running and the temperature is warmed up. Must have something to do with the fluids being moved around and under pressure in the transmission. Mine won't snap back to center from the right side all the time either if the car is not running. It's probably recommended that the transmission be warmed up as well before you start moving the gearbox around like I demonstrated.

#46

Le Mans Master

Member Since: May 2006

Location: DuBois PA

Posts: 5,987

Likes: 0

Received 18 Likes

on

16 Posts

St. Jude Donor '11-'12-'13-'14-'15

Tim

#47

NCM Bash 2008-2018

Member Since: Jul 1999

Location: Granby, MA Talladega Super Speedway Vettes 4 Vets Ambassador

Posts: 9,008

Received 75 Likes

on

60 Posts

Middle TN Events Coordinator

Cruise-In 1, 3, 9. 10 & 11 Veteran

Eric mine is wired along with 4 other devices to a central switch area that I have created in my ashtray. I'll take a mini movie of that also. I have 5 switches currently all fused and running off the cigarette lighter which itself is also fused.

1. Radar detector power

2. Side Vent lights steady on power

3. Side Vent lights strobe on power (like knight rider)

4. Underdash led power

5. Shift Light power

Jeff

#48

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 16 Likes

on

16 Posts

St. Jude Donor '09-'10-'11

Jeff,

That is too cool. I really like the newer LED's on the market. You might want to start a new thread with your LED videos. I look forward to seeing them!

That is too cool. I really like the newer LED's on the market. You might want to start a new thread with your LED videos. I look forward to seeing them!

#49

Intermediate

Member Since: Mar 2009

Location: San Diego CA

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Perhaps I should make a separate thread, but I am having this problem to an extreme.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

#50

Le Mans Master

Member Since: May 2006

Location: DuBois PA

Posts: 5,987

Likes: 0

Received 18 Likes

on

16 Posts

St. Jude Donor '11-'12-'13-'14-'15

Perhaps I should make a separate thread, but I am having this problem to an extreme.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

Tim

#51

Instructor

Member Since: Jul 2009

Location: chesterfield va

Posts: 175

Likes: 0

Received 0 Likes

on

0 Posts

Did you try this with the car running or not running? Make sure it is running and the temperature is warmed up. Must have something to do with the fluids being moved around and under pressure in the transmission. Mine won't snap back to center from the right side all the time either if the car is not running. It's probably recommended that the transmission be warmed up as well before you start moving the gearbox around like I demonstrated.

#52

Tech Contributor

Member Since: May 2008

Location: Howell Michigan

Posts: 2,844

Likes: 0

Received 16 Likes

on

16 Posts

St. Jude Donor '09-'10-'11

Perhaps I should make a separate thread, but I am having this problem to an extreme.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

I took my car apart to replace the throwout bearing.....and now I can't find reverse at all on the shifter. The shifter clicks over as if to go into reverse, but it is just fifth.

Also the shifter doesn't have any spring to it.

I did the alignment pin and the adjustment procedure, but still no reverse. Is it possible I could have damaged the linkage while raising or lowering the torque tube? The front of the linkage seems to bend much more easily than before.

#53

NCM Bash 2008-2018

Member Since: Jul 1999

Location: Granby, MA Talladega Super Speedway Vettes 4 Vets Ambassador

Posts: 9,008

Received 75 Likes

on

60 Posts

Middle TN Events Coordinator

Cruise-In 1, 3, 9. 10 & 11 Veteran

#54

Intermediate

Member Since: Mar 2009

Location: San Diego CA

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Thanks

#55

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,738

Received 2,182 Likes

on

1,585 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

This may be a long post but, I'm going to try to explain C5/C6 shifter and how it works and problems that I have seen.

The C5 shifter and for that matter, the C6 shifter does NOT have ANY centering or positioning springs inside the shifter handle or base. If, you remove the shifter handle from the base, the handle will FLOP around to any position that you can move it to. NO gates, no springs no detents, NOTHING. The base is the same way. If you remove the base from the torque tube the yoke inside the box can be moved forward or back and rotated side to side very easily to ANY position!

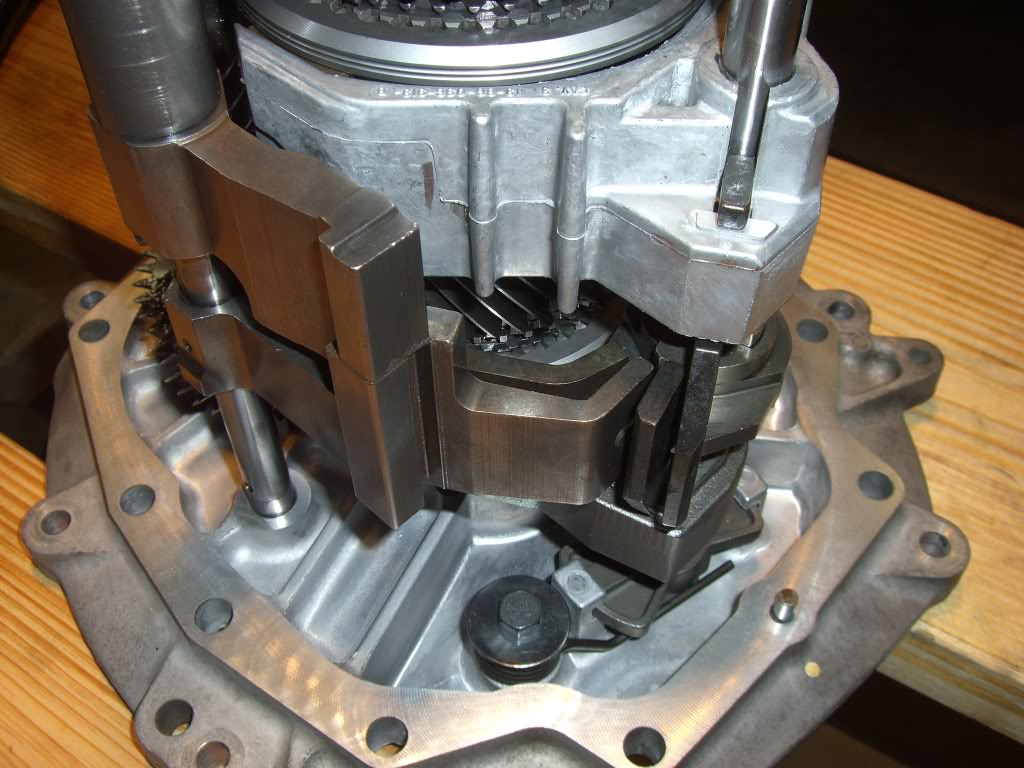

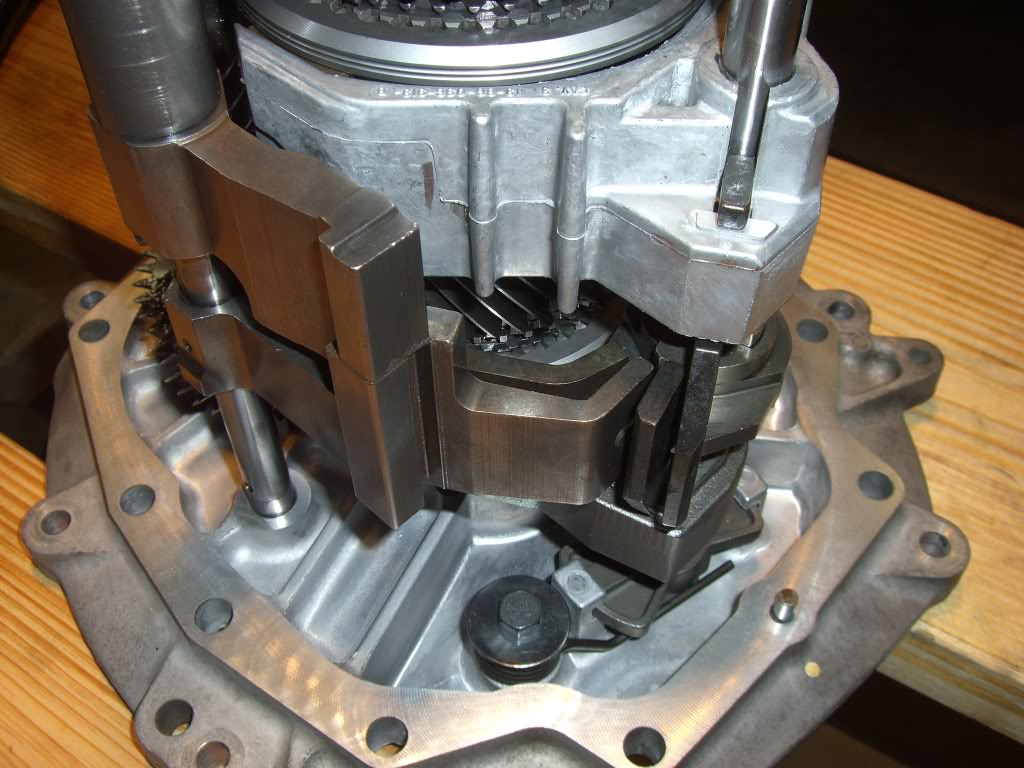

So,, where do we get our gates and return spring force? Its all inside the transmission. The return spring is a wire thats bent into a curly Q loop and the two spring arms force the shifter rod back to the center. Early C5 transmissions had a weaker return spring and the return force from 1st/2nd neutral gate to the 3rd/4th gate was less than desired. Sometimes my 98 coupe would have a tough time returning from the 1st/2nd neutral gate to the 3rd/4th neutral gate. The shifter was perfectly aligned. Later C5's had a better return spring and a more pronounced return pressure. If you shift the trans mission into neutral, you should be able to use two fingers and push the shifter to the left and right. when you release the shifter, it should return to the 3rd/4th gate neutral with out any assistance.

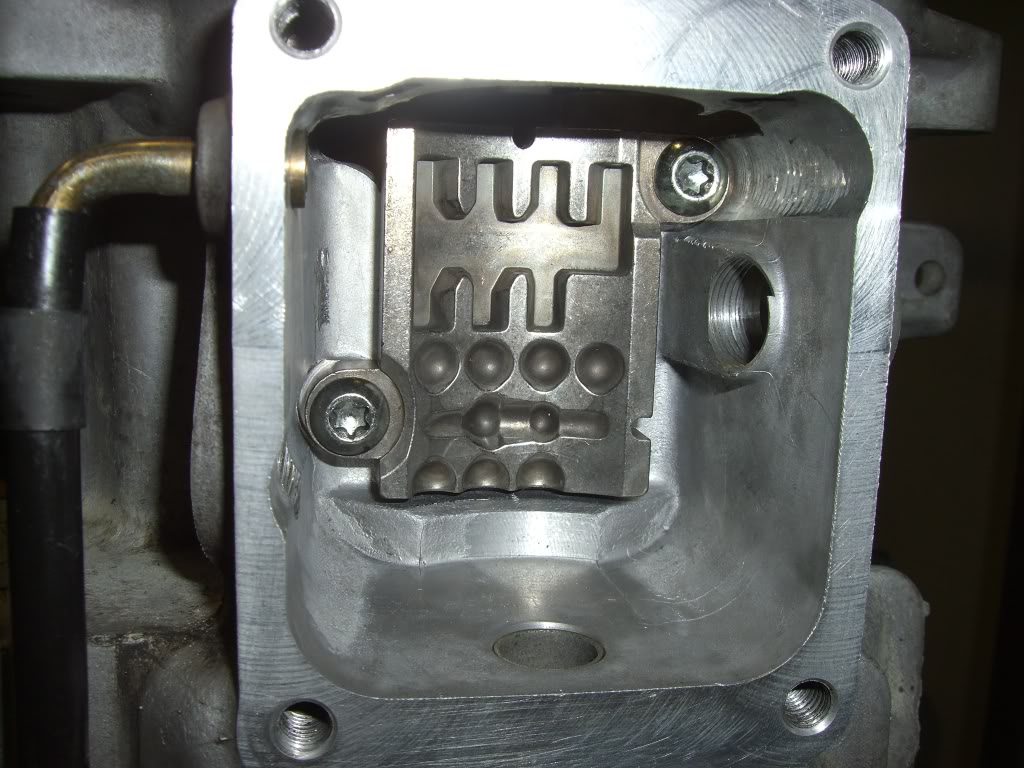

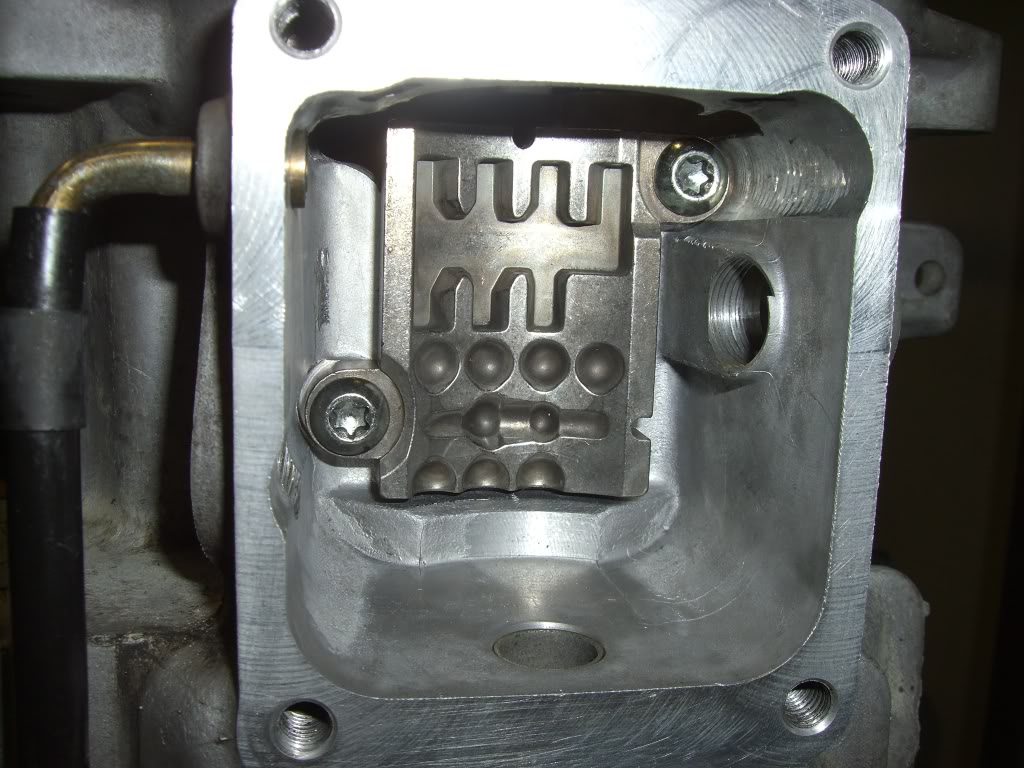

The shift gates come from a steel plate inside the transmission that actually has little gates machined into the plate and a pin follows those gates.

There is a ball detent on that plate that the shift detent ball bearing fits into that provides us the IN GEAR feel. Adding the ANTI VENOM mod, just shims out that detent plug and puts less ball pressure on that detent plate and lessens the in gear feel and some force that is required to shift to that gate. I personally do NOT like anti venom mod feel.

Shift feel also comes from how efficiently your synchros work and there are also some aluminum slider dogs that keep the gear slider ring locked on to the gear that you select. The slider actually slides over the actual gear and locks the gear and the main shaft together. The little dog keeps it from sliding off. Most of the notchey feeling that people complain about, comes from that sliding action and the force it takes to lift that little slider dog. The new T60/60 transmission redesigned the synchros and that slider dog and the sliding action of that device is significantly reduced!

If your transmission fluid (Its actually Mobile 1 ATF Fluid) is dirty, it can effect shift feel and shift efficiency. Early C5 transmissions use paper style synchro blocker rings and may be adversely effected from using synthetic fluid as a refill. AMSOIL has a synthetic ATF that they say is compatible. Later C5 transmissions use a carbon back up ring and the synthetic ATF can be used as an up grade and works very well. It improved the shift feel of my 02 ZO6 MN12 trans some.

Aftermarket shifters: There are TWO styles of aftermarket shifters. OEM style with NO, NADA, ZERO return springs inside the shifter handle & aftermarket types WITH return springs in the handle. There are some shifters that incorporate shift stops (see pictures below)

That being said, aftermarket shifter come in too many to count combinations of design differences. Most have shorter than stock shifter handles which effect shift throw and the force required to move the shift handle. Some move the fulcrum point and shift lever length. Each design will add some additional force that is required to shift the transmission into gear. If you have a 2" long shifter handle, you better be eating your spinach to shift properly. The force require to move the shift handle will be great!

Here is an example of an aftermarket shifter that has built in return springs inside the shifter body. Its a KIRBAN Ripper Shifter. It also has shift stops (Not needed for the T56 tranny but, I use them):

KIRBAN compared to the stock C5 shifter:

Shifter removed from the lower box:

Actual alignment pin inserted into the shift rod:

Alignment of the shifter to the precise neutral position when the transmission is in neutral is critical for proper shifting.

There are TWO basic C5 OEM shifter designs. ZO6 & NON ZO6.

The ONLY difference between the two shifters is the type of bushing that is mounted between the shift box an the torque tube. In this picture is a ZO6 shifter with solid aluminum bushings. Sorry, I don't have a NON ZO6 bushing picture.

The NON ZO6 rubber bushings can deteriorate and cause poor shifting. The box can actually move around and make shifting very vague and difficult. You can replace the old bushings or make some solid nylon or aluminum bushings like the ZO6 style. I do not know if you can get replacement bushings from the dealer. I have been told that they are NOT SOLD Separately! There was a post in the C6 section where someone made their own new bushings and was selling them. Another problem that I have encountered is loose bolts that secure the shifter handle to the shifter base. I have had all four bolts work loose and I had that vague shift feel and difficulty keeping the transmission in gear.

There was a post in the C6 section where someone made their own new bushings and was selling them. Another problem that I have encountered is loose bolts that secure the shifter handle to the shifter base. I have had all four bolts work loose and I had that vague shift feel and difficulty keeping the transmission in gear.

Make sure that there the correct length (when using an aftermarket shifter ) and properly tightened.

If the black plastic shifter foot is worn or damaged it too cam have an adverse effect on shifting. Unfortunately that plastic foot is NOT available from the dealer as a separate part. You have to purchase a complete new shifter.

Make sure that the shifter box to torque tube bolts and the coupler bolt have the proper torque on the bolts.

I hope this helps someone.

Bill

The C5 shifter and for that matter, the C6 shifter does NOT have ANY centering or positioning springs inside the shifter handle or base. If, you remove the shifter handle from the base, the handle will FLOP around to any position that you can move it to. NO gates, no springs no detents, NOTHING. The base is the same way. If you remove the base from the torque tube the yoke inside the box can be moved forward or back and rotated side to side very easily to ANY position!

So,, where do we get our gates and return spring force? Its all inside the transmission. The return spring is a wire thats bent into a curly Q loop and the two spring arms force the shifter rod back to the center. Early C5 transmissions had a weaker return spring and the return force from 1st/2nd neutral gate to the 3rd/4th gate was less than desired. Sometimes my 98 coupe would have a tough time returning from the 1st/2nd neutral gate to the 3rd/4th neutral gate. The shifter was perfectly aligned. Later C5's had a better return spring and a more pronounced return pressure. If you shift the trans mission into neutral, you should be able to use two fingers and push the shifter to the left and right. when you release the shifter, it should return to the 3rd/4th gate neutral with out any assistance.

The shift gates come from a steel plate inside the transmission that actually has little gates machined into the plate and a pin follows those gates.

There is a ball detent on that plate that the shift detent ball bearing fits into that provides us the IN GEAR feel. Adding the ANTI VENOM mod, just shims out that detent plug and puts less ball pressure on that detent plate and lessens the in gear feel and some force that is required to shift to that gate. I personally do NOT like anti venom mod feel.

Shift feel also comes from how efficiently your synchros work and there are also some aluminum slider dogs that keep the gear slider ring locked on to the gear that you select. The slider actually slides over the actual gear and locks the gear and the main shaft together. The little dog keeps it from sliding off. Most of the notchey feeling that people complain about, comes from that sliding action and the force it takes to lift that little slider dog. The new T60/60 transmission redesigned the synchros and that slider dog and the sliding action of that device is significantly reduced!

If your transmission fluid (Its actually Mobile 1 ATF Fluid) is dirty, it can effect shift feel and shift efficiency. Early C5 transmissions use paper style synchro blocker rings and may be adversely effected from using synthetic fluid as a refill. AMSOIL has a synthetic ATF that they say is compatible. Later C5 transmissions use a carbon back up ring and the synthetic ATF can be used as an up grade and works very well. It improved the shift feel of my 02 ZO6 MN12 trans some.

Aftermarket shifters: There are TWO styles of aftermarket shifters. OEM style with NO, NADA, ZERO return springs inside the shifter handle & aftermarket types WITH return springs in the handle. There are some shifters that incorporate shift stops (see pictures below)

That being said, aftermarket shifter come in too many to count combinations of design differences. Most have shorter than stock shifter handles which effect shift throw and the force required to move the shift handle. Some move the fulcrum point and shift lever length. Each design will add some additional force that is required to shift the transmission into gear. If you have a 2" long shifter handle, you better be eating your spinach to shift properly. The force require to move the shift handle will be great!

Here is an example of an aftermarket shifter that has built in return springs inside the shifter body. Its a KIRBAN Ripper Shifter. It also has shift stops (Not needed for the T56 tranny but, I use them):

KIRBAN compared to the stock C5 shifter:

Shifter removed from the lower box:

Actual alignment pin inserted into the shift rod:

Alignment of the shifter to the precise neutral position when the transmission is in neutral is critical for proper shifting.

There are TWO basic C5 OEM shifter designs. ZO6 & NON ZO6.

The ONLY difference between the two shifters is the type of bushing that is mounted between the shift box an the torque tube. In this picture is a ZO6 shifter with solid aluminum bushings. Sorry, I don't have a NON ZO6 bushing picture.

The NON ZO6 rubber bushings can deteriorate and cause poor shifting. The box can actually move around and make shifting very vague and difficult. You can replace the old bushings or make some solid nylon or aluminum bushings like the ZO6 style. I do not know if you can get replacement bushings from the dealer. I have been told that they are NOT SOLD Separately!

There was a post in the C6 section where someone made their own new bushings and was selling them. Another problem that I have encountered is loose bolts that secure the shifter handle to the shifter base. I have had all four bolts work loose and I had that vague shift feel and difficulty keeping the transmission in gear.

There was a post in the C6 section where someone made their own new bushings and was selling them. Another problem that I have encountered is loose bolts that secure the shifter handle to the shifter base. I have had all four bolts work loose and I had that vague shift feel and difficulty keeping the transmission in gear.Make sure that there the correct length (when using an aftermarket shifter ) and properly tightened.

If the black plastic shifter foot is worn or damaged it too cam have an adverse effect on shifting. Unfortunately that plastic foot is NOT available from the dealer as a separate part. You have to purchase a complete new shifter.

Make sure that the shifter box to torque tube bolts and the coupler bolt have the proper torque on the bolts.

I hope this helps someone.

Bill

#56

Racer

Regarding spring back to center neutral: 99 coupe 122,000 miles, original owner. I had my tranny " refreshed "at R.P.M. at 113,000 miles due to shifter jumping out of 1st upon starting up. During the refresh the tech strengthed the internal spring ( that resembles a wish bone from a turkey ). he did this by bending it to gain a stronger feel. This action changed the entire feel of the tranny in shifting. It snaps back to the center on it's own.The strong positive feeling never was as great as it is now. I find absolutely no reason to change out the shifter to an after market.

That's my 2 cts !

That's my 2 cts !

#57

Racer

Here man...this should help you out. I got this from a good friend of mine on here (Tim: TSTAR) when I was having the same problems as you. Pay special attention to the 2nd part mostly since you have already done the adjustment. Very small movements make a huge difference. The aligning of the holes is very critical. If you go one way just a hair (I mean really a hair thickness too) then your 1st will be off and be hard to get into. If your off a hair the other way your 4th or other gears will be off. Also pay attention to the re-centering. If aligned properly the shifter will "snap" back to center when pushed from the left of neutral or the right of neutral. If your off a bit. It will hang up for a half a second then move.

Once you remove the trim bezel and the shifter's rubber isolation boot, you will see this.

Simply put the transmission in neutral with the Ebrake on, loosen the 3 Torx fasteners, 2 on the torque tube and one on the pinch bolt for the shifter rod.

Drop the pin into the slot and retorque the fasteners, all 3 to 30 N.M or 22 ft lbs. The 2 torque tube fasteners first, then the pinch bolt. Pull the pin back up, that’s it.

Use an allen wrench or drill bit if your pin is missing…

One step further! I copied this

This made a big improvement, but I occasionally would still get hung up getting into first. I took apart the console again and noticed that even with the alignment pin "in'and all 3 torx bolts loose the shifter "box" still had about 2 millimeters play forward and back. In other words you can tighten the shifter box after you push the shifter box to the front part of this play or to the back part of this play. I decided to try pushing the shifter box all the way forward, tighten everything and drive the car. This made my first gear selection problem COMPLETELY disappear BUT now second felt a bit "crunchy" going in and 3rd and 4th gear were not as easy as before. So I tried moving the shifter box to the back of the possible play and drive the car. My first gear problem came back worse than ever, but the rest of the gears were relatively smoother but not perfect.

I was back to square one... So I took a break, and when I came back i decided to totally remove the shifter box and analyze this problem. Once I removed the shifter I noticed that there is a half moon shaped cut out on the shift shaft that the 3rd torx bolt goes through. This cut out prevents the shift shaft from completely coming out of the clamp if the bolt got loose, and is obviously, exactly where the bolt is designed to go through the clamp.

What I did was I installed the shifter box back with only the 2 torx that hold it to the tunnel finger tight and left out the 3rd torx completely. I took a flash light and shined it down the hole, where the bolt goes in the clamp. It turns out that the cut out on the shift shaft can be a millimeter forward of the clamp or a millimeter aft of the clamp and the bolt will still go into the clamp fine and you can tighten it in any of these positions. Thus the 2 millimeters of play.

I made an educated guess that the cut out on the shaft should be EXACTLY aligned with the hole in the clamp (not a bit forward or back even though the bolt will still fit)so I aligned the cut out on the shaft so perfectly that when you shined a light down the hole the cut out on the shaft was not even noticeable. You could just see a perfectly round hole. I then tightened the 2 torx on the torque tube to spec and checked to see if anything moved. Nothing moved and the shaft cut out was still perfectly aligned with the hole in the clamp that holds the 3rd torx. I carefully placed the 3rd torx in the clamp and since the it was so well lined up it I could tighten it with my fingers (up to a point of course) then I carefully tightened it to spec (22 ft pounds) trying not to place any down pressure on the bolt, just rotational pressure enough to get to spec. Buttoned it all back up and WOW. All gears went in perfectly. First smooth as silk, second smooth with no crunch, third and fourth with one finger, fifth and sixth smooth.

All that and synthetic tranny fluid and it should feel awesome!!!!!

Once you remove the trim bezel and the shifter's rubber isolation boot, you will see this.

Simply put the transmission in neutral with the Ebrake on, loosen the 3 Torx fasteners, 2 on the torque tube and one on the pinch bolt for the shifter rod.

Drop the pin into the slot and retorque the fasteners, all 3 to 30 N.M or 22 ft lbs. The 2 torque tube fasteners first, then the pinch bolt. Pull the pin back up, that’s it.

Use an allen wrench or drill bit if your pin is missing…

One step further! I copied this

This made a big improvement, but I occasionally would still get hung up getting into first. I took apart the console again and noticed that even with the alignment pin "in'and all 3 torx bolts loose the shifter "box" still had about 2 millimeters play forward and back. In other words you can tighten the shifter box after you push the shifter box to the front part of this play or to the back part of this play. I decided to try pushing the shifter box all the way forward, tighten everything and drive the car. This made my first gear selection problem COMPLETELY disappear BUT now second felt a bit "crunchy" going in and 3rd and 4th gear were not as easy as before. So I tried moving the shifter box to the back of the possible play and drive the car. My first gear problem came back worse than ever, but the rest of the gears were relatively smoother but not perfect.

I was back to square one... So I took a break, and when I came back i decided to totally remove the shifter box and analyze this problem. Once I removed the shifter I noticed that there is a half moon shaped cut out on the shift shaft that the 3rd torx bolt goes through. This cut out prevents the shift shaft from completely coming out of the clamp if the bolt got loose, and is obviously, exactly where the bolt is designed to go through the clamp.

What I did was I installed the shifter box back with only the 2 torx that hold it to the tunnel finger tight and left out the 3rd torx completely. I took a flash light and shined it down the hole, where the bolt goes in the clamp. It turns out that the cut out on the shift shaft can be a millimeter forward of the clamp or a millimeter aft of the clamp and the bolt will still go into the clamp fine and you can tighten it in any of these positions. Thus the 2 millimeters of play.

I made an educated guess that the cut out on the shaft should be EXACTLY aligned with the hole in the clamp (not a bit forward or back even though the bolt will still fit)so I aligned the cut out on the shaft so perfectly that when you shined a light down the hole the cut out on the shaft was not even noticeable. You could just see a perfectly round hole. I then tightened the 2 torx on the torque tube to spec and checked to see if anything moved. Nothing moved and the shaft cut out was still perfectly aligned with the hole in the clamp that holds the 3rd torx. I carefully placed the 3rd torx in the clamp and since the it was so well lined up it I could tighten it with my fingers (up to a point of course) then I carefully tightened it to spec (22 ft pounds) trying not to place any down pressure on the bolt, just rotational pressure enough to get to spec. Buttoned it all back up and WOW. All gears went in perfectly. First smooth as silk, second smooth with no crunch, third and fourth with one finger, fifth and sixth smooth.

All that and synthetic tranny fluid and it should feel awesome!!!!!

For the last month shift from 1st to 2nd on mine was not smooth, and 2nd would "pop" out of gear frequently and grind on shifting. I followed the RPM Transmissions adjustment (http://rpmtransmissions.com/files/c5...adjustment.pdf) and it helped, but it wasn't exactly right.

I found that with the 2 assembly bolts and the shaft bolts loose, per the instructions, there was still 2-3 mm of play on the shifting assembly even with the neutral lock on. With mine, only when I would shift hard, would it go into 2nd. Otherwise, it would grind and not go in. That got me thinking that the reason it couldn't go into second without forcing, was there wasn't enough shaft or pressure pushing toward the rear when I put it in second gear. Maybe the reason it would grind was because it wasn't fully being put in 2nd. With the assembly having 2-3mm of play, I pushed the whole assembly toward the front of the car and tightened the 2 assembly bolts down. I the did like Extreme did and took the shaft clamp bolt completely out, and lined up the shaft's notched section with the bolt hole, then tightened it down. Now, 2nd has not popped out nor ground since.

I wanted to mention this to others to try this before springing for expensive transmission work. Thanks to all the advice I've read in this thread, as it has proved invaluable.

#58

NCM Bash 2008-2018

Member Since: Jul 1999

Location: Granby, MA Talladega Super Speedway Vettes 4 Vets Ambassador

Posts: 9,008

Received 75 Likes

on

60 Posts

Middle TN Events Coordinator

Cruise-In 1, 3, 9. 10 & 11 Veteran

Sorry for the bump on a really old thread, but wanted it be known that this recently help me out big time. I thought my 1-2 syncro was shot. Even had a mechanic buddy to start pricing out parts to replace. Thought I would give this a shot and see if it would help.

For the last month shift from 1st to 2nd on mine was not smooth, and 2nd would "pop" out of gear frequently and grind on shifting. I followed the RPM Transmissions adjustment (http://rpmtransmissions.com/files/c5...adjustment.pdf) and it helped, but it wasn't exactly right.

I found that with the 2 assembly bolts and the shaft bolts loose, per the instructions, there was still 2-3 mm of play on the shifting assembly even with the neutral lock on. With mine, only when I would shift hard, would it go into 2nd. Otherwise, it would grind and not go in. That got me thinking that the reason it couldn't go into second without forcing, was there wasn't enough shaft or pressure pushing toward the rear when I put it in second gear. Maybe the reason it would grind was because it wasn't fully being put in 2nd. With the assembly having 2-3mm of play, I pushed the whole assembly toward the front of the car and tightened the 2 assembly bolts down. I the did like Extreme did and took the shaft clamp bolt completely out, and lined up the shaft's notched section with the bolt hole, then tightened it down. Now, 2nd has not popped out nor ground since.

I wanted to mention this to others to try this before springing for expensive transmission work. Thanks to all the advice I've read in this thread, as it has proved invaluable.

For the last month shift from 1st to 2nd on mine was not smooth, and 2nd would "pop" out of gear frequently and grind on shifting. I followed the RPM Transmissions adjustment (http://rpmtransmissions.com/files/c5...adjustment.pdf) and it helped, but it wasn't exactly right.

I found that with the 2 assembly bolts and the shaft bolts loose, per the instructions, there was still 2-3 mm of play on the shifting assembly even with the neutral lock on. With mine, only when I would shift hard, would it go into 2nd. Otherwise, it would grind and not go in. That got me thinking that the reason it couldn't go into second without forcing, was there wasn't enough shaft or pressure pushing toward the rear when I put it in second gear. Maybe the reason it would grind was because it wasn't fully being put in 2nd. With the assembly having 2-3mm of play, I pushed the whole assembly toward the front of the car and tightened the 2 assembly bolts down. I the did like Extreme did and took the shaft clamp bolt completely out, and lined up the shaft's notched section with the bolt hole, then tightened it down. Now, 2nd has not popped out nor ground since.

I wanted to mention this to others to try this before springing for expensive transmission work. Thanks to all the advice I've read in this thread, as it has proved invaluable.

#59

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,738

Received 2,182 Likes

on

1,585 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

I LOVE up-dating this post..  Here is a picture of the SPRING inside the transmission that provides the force that pushes the shifter handle to the center position:

Here is a picture of the SPRING inside the transmission that provides the force that pushes the shifter handle to the center position:

Bottom center in the picture:

Next picture is the plate that controld the shift gates and SHIFTER DETENTS:

Here is a picture of the SPRING inside the transmission that provides the force that pushes the shifter handle to the center position:

Here is a picture of the SPRING inside the transmission that provides the force that pushes the shifter handle to the center position:Bottom center in the picture:

Next picture is the plate that controld the shift gates and SHIFTER DETENTS: