Head flow Guru's, I have some questions?

#1

Burning Brakes

Thread Starter

I just lightly ported a set of 799's that cam on my truck. Now I didn't have them flowed before I started because I wasn't planning on doing anything to them. But looking at them when I got them off I decided they needed a clean up. On the intake side I took the rocker boss hump out but didn't increase runner cross section, and polished the bowl under the valve guide. No work was done to the guide it's self. I took a sanding roll to knock off the casting bumps in the runner and that is it. No material other than that rocker hump was removed and there was no short side work. On the exhaust side I blended the bowl into the valve seat and polished the runner. I also blended and polished the chamber. I took about 2cc out of the chamber and had them milled .015". The exhaust valves were jacked so I had a three angle valve job done and a 30* back cut put on the valves. Here are the average numbers from other stock 243's vs. my 799's on the same flow bench.

Stock 243's Ported 799's

int

.100 70.8 70.8 +0

.200 138.6 151.9 +13.3

.300 191.7 215.3 +23.6

.400 236.0 253.7 +17.7

.500 265.5 277.3 +11.8

.550 265.5 280.1 +14.6

.600 265.5 262.5 -3

exh.

.100 60.4 62.6 +2.2

.200 107.4 110.6 +3.2

.300 139.0 159.5 +20.5

.400 164.3 183.2 +18.9

.500 176.9 197.5 +20.6

.600 180.1 203.8 +23.7

So now the questions.

1. Why does the stock head even out at .500 lift?

2. Why does my head crash so hard at .550?

3. Is this a good gain for such minimal work?

4. What would I have to do to increas the flow after .500?

5. Is the stock valve the limiting factor?

6. My cam has .604 int lift, is the flow backing up going to hurt my power?

7. Heads were flowed before the milling. Does milling help or hurt flow?

8. Is porting around the valve guide worth it?

9. Should I have polished the short side radius?

10. I know intake runner volume is critical. Does exhaust runner volume mean as much?

I am thinking of starting on a another set of 799's and see what I can get out of them. Any suggestions would be great.

Stock 243's Ported 799's

int

.100 70.8 70.8 +0

.200 138.6 151.9 +13.3

.300 191.7 215.3 +23.6

.400 236.0 253.7 +17.7

.500 265.5 277.3 +11.8

.550 265.5 280.1 +14.6

.600 265.5 262.5 -3

exh.

.100 60.4 62.6 +2.2

.200 107.4 110.6 +3.2

.300 139.0 159.5 +20.5

.400 164.3 183.2 +18.9

.500 176.9 197.5 +20.6

.600 180.1 203.8 +23.7

So now the questions.

1. Why does the stock head even out at .500 lift?

2. Why does my head crash so hard at .550?

3. Is this a good gain for such minimal work?

4. What would I have to do to increas the flow after .500?

5. Is the stock valve the limiting factor?

6. My cam has .604 int lift, is the flow backing up going to hurt my power?

7. Heads were flowed before the milling. Does milling help or hurt flow?

8. Is porting around the valve guide worth it?

9. Should I have polished the short side radius?

10. I know intake runner volume is critical. Does exhaust runner volume mean as much?

I am thinking of starting on a another set of 799's and see what I can get out of them. Any suggestions would be great.

#2

Safety Car

the guys that do this for a living and program the cnc machines spend lots of time figuring all this out. That's why I think it's better to just let them do the work.

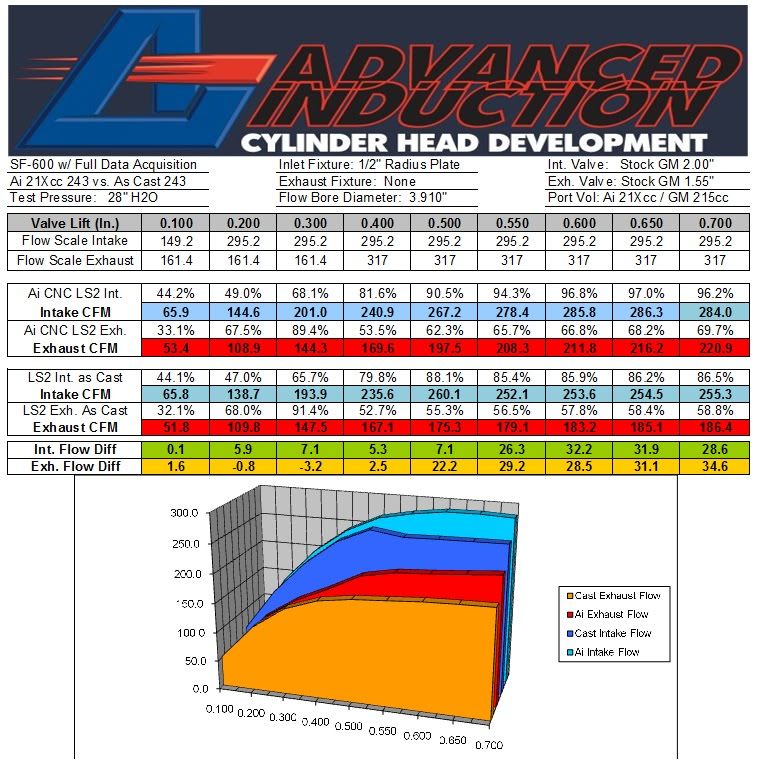

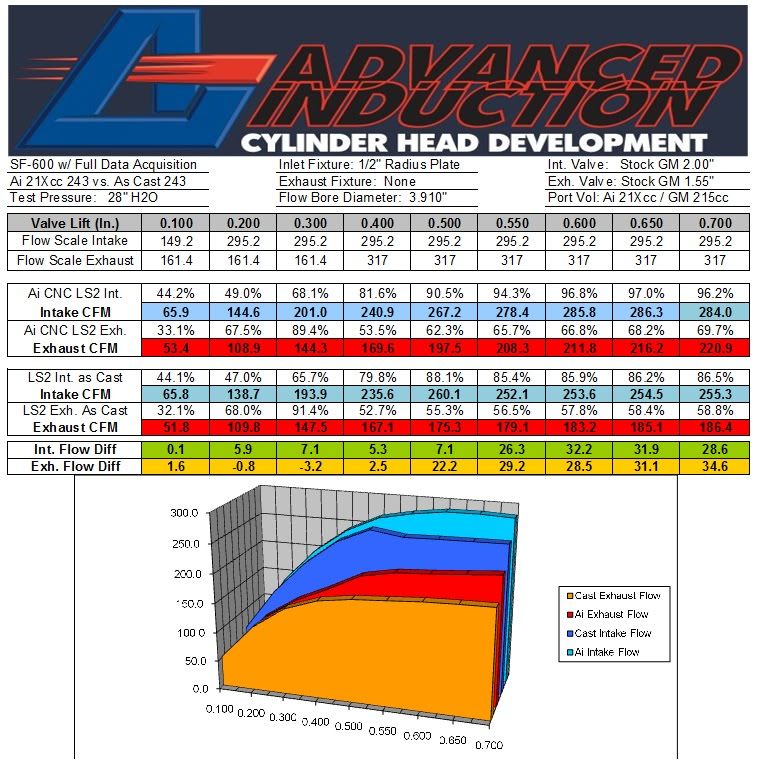

I had AI do my heads but I didn't want any cutting on the intake ports. They did a full cnc port on the exhaust, bowl work on both int and ext plus a 5 angle valve job.

here are the results they sent me from the flow bench

I had AI do my heads but I didn't want any cutting on the intake ports. They did a full cnc port on the exhaust, bowl work on both int and ext plus a 5 angle valve job.

here are the results they sent me from the flow bench

#4

Safety Car

yes, this was part of a head/cam change I did. I didn't want the intake ports cut because I wanted to keep as much low end torque as possable and making power under the curve.

#6

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

#7

Burning Brakes

Thread Starter

I guess first off I didn't want to pay $1,500 for porting. Plust my numbers are actually better up to .550 on the intake and .500 on the exhaust. I know AI is one of the best out there but I think I did alright considering. All I paid for was the valve job. I would love to eventually get a set of their heads. I am curious to know how they kept the intake numbers going with absolutly no intake work. So you still have the rocker boss sticking into the intake runner? I am sure that the boss is only worth a couple CC's at most. That was the only part of the intake that I touched as far as removing material or reshaping. How much did you pick up with your heads?

#8

Safety Car

I guess first off I didn't want to pay $1,500 for porting. Plust my numbers are actually better up to .550 on the intake and .500 on the exhaust. I know AI is one of the best out there but I think I did alright considering. All I paid for was the valve job. I would love to eventually get a set of their heads. I am curious to know how they kept the intake numbers going with absolutly no intake work. So you still have the rocker boss sticking into the intake runner? I am sure that the boss is only worth a couple CC's at most. That was the only part of the intake that I touched as far as removing material or reshaping. How much did you pick up with your heads?

http://advancedinduction.com/LSX/AiL...cGMLS2Head.php

There full CNC with everything is less than a grand.

Last edited by printmanjackson; 02-23-2012 at 02:57 PM.

#9

Le Mans Master

Member Since: Aug 2005

Location: CA.

Posts: 5,255

Likes: 0

Received 281 Likes

on

258 Posts

St. Jude Donor '13-'14-'15

Old school knowledge dictates that increasing the flow is not always a HP booster---Remember that when you increase the port size you lose port velocity--which results in hurting your bottom end HP and most importantly your TQ--almost everywhere--more velocity = more TQ--- But its all relative--depends on your goals and car's use-

Typically on a DD weekend drag racer application TQ is more important than top end HP--

Huge flow #'s above .550 or .600 by my way of thinking is not that important--as it ONLY increases top end HP and does so only if yur engine is large enough to use the flow

ALSO-- Our engine builder always looks at flow #'s at .450 as a comparison

.450 is the lift area position where the valve is at the most--Its only (in your case )at

.604 a very brief time---

Example :if you put a set of AFR 220 heads on a stock cammed enigne --it would kill off tons of TQ and most likely make your car slowr--Here a set of the smaller 210's would flow about the same but the increased port velocity would really help the TQ and make the car quicker---

PS: What is the compressio ratio of your new heads ?? The 243's have a higher CR that most other LSAheads I belive the 243's are at 10.75--most others are 10.50--Its only a .25--but 10.75 would give you more HP/TQ--everywhere

Typically on a DD weekend drag racer application TQ is more important than top end HP--

Huge flow #'s above .550 or .600 by my way of thinking is not that important--as it ONLY increases top end HP and does so only if yur engine is large enough to use the flow

ALSO-- Our engine builder always looks at flow #'s at .450 as a comparison

.450 is the lift area position where the valve is at the most--Its only (in your case )at

.604 a very brief time---

Example :if you put a set of AFR 220 heads on a stock cammed enigne --it would kill off tons of TQ and most likely make your car slowr--Here a set of the smaller 210's would flow about the same but the increased port velocity would really help the TQ and make the car quicker---

PS: What is the compressio ratio of your new heads ?? The 243's have a higher CR that most other LSAheads I belive the 243's are at 10.75--most others are 10.50--Its only a .25--but 10.75 would give you more HP/TQ--everywhere

#10

Burning Brakes

Thread Starter

Tbu92. You are correct but in this case I didn't increas port volume but a couple CC's. And I gained 19 and 18 cfm at .400 respectively. I also had the head milled back to 64cc's but I am now running a .040 gasket so my compression is at 10.4-5 and my DCR is between 8.6 and 8.7 which is exactly where I wanted it. DCR is what gets your tq back. The truck is a ton stronger just driving around. I will get it on the dyno soon to see what I actually gained. I am not really concerned about .600 lift numbers. What concernes me is the port crashing. I would like it to flow up to the max lift of my cam. But not at the expense of my low end for sure. I am messing with pushrod length and lifter preload right now. Once I get that corrected I will get some numbers.

Printman. That is cool and a good price for someone that doesn't want to tackle the project for them selves. I didn't touch the intake bowl so I am sure I left some flow on the table. Did they do anything with your valve guide area? Or was the work all under the valve guide. I guess my point is that for someone not wanting to do a max effort head you can match or surpass the best company's in the important low to mid lift areas for a tiny investment of cash and some time. I think all the skill comes in when you get highlift numbers that are great and maintain the low lift numbers as well. By the numbers our heads are very comparable with mine ahead a little up to .500-.550 or so. To me with this perticular application the low and mid lift ranges were all that I cared about. These heads are on 5.3L in my 5,000lb truck. This thing will probably never see a track or go over 6,000rpm. Thanks a lot for the comparison data though. AI is a great company and has some bad azz heads for sure.

Printman. That is cool and a good price for someone that doesn't want to tackle the project for them selves. I didn't touch the intake bowl so I am sure I left some flow on the table. Did they do anything with your valve guide area? Or was the work all under the valve guide. I guess my point is that for someone not wanting to do a max effort head you can match or surpass the best company's in the important low to mid lift areas for a tiny investment of cash and some time. I think all the skill comes in when you get highlift numbers that are great and maintain the low lift numbers as well. By the numbers our heads are very comparable with mine ahead a little up to .500-.550 or so. To me with this perticular application the low and mid lift ranges were all that I cared about. These heads are on 5.3L in my 5,000lb truck. This thing will probably never see a track or go over 6,000rpm. Thanks a lot for the comparison data though. AI is a great company and has some bad azz heads for sure.

#11

Safety Car

I didn't see any valve guide area milling, only bowl work. I think the trick is in the valve angles they cut and the blending that was done in the bowl to that. Hope that makes since.

#12

Burning Brakes

Thread Starter

Makes perfect sense. To me the bowl starts under the valve guide. To others the bowl starts at the end of the intake port. I only had a 3 angle done on mine. There was more I could have done to the chamber but I am no professional. I pretty much stayed with the shape that was there and polished it up. The only part I touched was infront of the exhaust valve. It was convex and I made it concave. I wish I had a flow bench and some junk heads. Did they back cut your valves? I went with a 30* but my machinist said they use from 36* to 30* depending on his final port. Just depends on where they want the flow.

#14

Burning Brakes

Thread Starter

What's amazing about their stuff is the quality of air flow and machining behind their stuff. The raw flow data isn't all that impressive but the heads make power and run the number. How many angles are on your valves? I understand they put a 5 angle on the valve seat.

#15

Safety Car

You know they are in North Carolina where all the NASCAR shops are.

#17

Melting Slicks

Here is link that will help with some of your questions, you have to dig a little but there is some good information.

http://speedtalk.com/forum/index.php

http://speedtalk.com/forum/index.php